brake sensor INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 38 of 3924

![INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS — GENERAL DESCRIPTIONACS-31

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ENGINE RPM

[rpm] ×× Indicates engine speed read from ICC unit through CAN commu-

nica INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS — GENERAL DESCRIPTIONACS-31

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ENGINE RPM

[rpm] ×× Indicates engine speed read from ICC unit through CAN commu-

nica](/img/42/57017/w960_57017-37.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTIONACS-31

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ENGINE RPM

[rpm] ×× Indicates engine speed read from ICC unit through CAN commu-

nication (ECM transmits engine speed through CAN communica-

tion).

DISTANCE ADJ

[ShortMid/Long] ×××

Indicates set distance memorized in ICC unit.

WIPER SW

[Off/Low/High] ××

Indicates wiper [OFF/LOW/HIGH] status (BCM transmits front

wiper request signal through CAN communication).

MAIN SW

[On/Off] ××× Indicates [On/Off] status as judged from ICC steering switch sig-

nal (ECM transmits ICC steering switch signal through CAN com-

munication).

SET/COAST SW

[On/Off] ××× Indicates [On/Off] status as judged from ICC steering switch sig-

nal (ECM transmits ICC steering switch signal through CAN com-

munication).

CANCEL SW

[On/Off] ××× Indicates [On/Off] status as judged from ICC steering switch sig-

nal (ECM transmits ICC steering switch signal through CAN com-

munication).

RESUME/ACC SW

[On/Off] ××× Indicates [On/Off] status as judged from ICC steering switch sig-

nal (ECM transmits ICC steering switch signal through CAN com-

munication).

CRUISE OPE

[On/Off] ××

Indicates whether controlling or not (On means “controlling”).

BRAKE SW

[On/Off] ××× Indicates [On/Off] status as judged from ICC brake switch signal.

STOP LAMP SW

[On/Off] ××× Indicates [On/Off] status as judged from stop lamp switch signal.

RELEASE SW NO

[On/Off] ×× Indicates [On/Off] status as judged from release switch signal.

ON when brake is depressed.

OFF when brake is not depressed.

RELEASE SW NC

[On/Off] ×× Indicates [On/Off] status as judged from release switch signal.

ON when brake is not depressed.

OFF when brake is depressed.

IDLE SW

[On/Off] ×× Indicates [On/Off] status of idle switch read from ICC unit through

CAN communication (ECM

transmits On/Off status through CAN

communication).

GEAR

[1, 2, 3, 4, 5] ×× Indicates AT gear position read from ICC unit through CAN com-

munication (TCM transmits gear position through CAN commu-

nication).

BUZZER O/P

[On/Off] ×

Indicates [On/Off] status of ICC warning chime output.

ICC WARNING ×NOTE:

This item is displayed, but cannot monitor.

VHCL SPD AT

[km/h] or [mph] ×Indicates vehicle speed calculated from AT vehicle speed sensor

read from ICC unit through CAN communication (TCM transmits

AT vehicle speed sensor signal through CAN communication).

PRESS SENS

[bar] ××× Indicates brake fluid pressure value calculated from signal volt-

age of pressure sensor.

PRESS SENS 2 ×× NOTE:

This item is displayed, but cannot monitor.

D RANGE SW

[On/Off] ×× Indicates [On/Off] status of “D” position read from ICC unit

through CAN communication (TCM transmits On/Off condition of

“D” position through CAN communication).

A/T OD OFF

[On/Off] ×

Indicates [On/Off] status of OD cancel output under control.

Monitored Item [unit]

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM

MENU Description

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 42 of 3924

![INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFO INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFO](/img/42/57017/w960_57017-41.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFOID:0000000001328825

×: Applicable

DTC

No. CONSULT-III

screen terms ICC

system

warning lamp Fail-safe

Malfunctions detected where... Refer-

ence

page

Ve h i c l e -

to-

vehicle

distance control mode Conven-

tional

(fixed

speed) cruise

control mode Brake as-

sist (with

preview

function)

11 CONTROL UNIT ×××× ICC unit internal malfunctionACS-36

20 CAN COMM CIRCUIT ×××× ICC unit detected CAN communi-

cation malfunction. ACS-36

31 POWER SUPPLY CIR

×××× ICC unit power supply voltage is

excessively low (less than 8 V). ACS-37

34 POWER SUPPLY CIR2

×××× ICC unit power supply voltage is

excessively high (more than 19 V). ACS-37

41 VHCL SPEED SE CIRC

×××× Wheel sensor malfunction.

ABS actuator and electric unit

(control unit) malfunction

AT vehicle speed sensor malfunc- tion

TCM malfunction ACS-37

43 ABS/TCS/VDC CIRC

×××× VDC/TCS/ABS system malfunc-

tion ACS-38

45 BRAKE SW/STOP L SW

×××× Brake and stop lamp switch har-

ness is open or shorted.

Brake and stop lamp switch is ON

or stuck to OFF.

Brake and stop lamp switch is stuck to ON. ACS-38

46 OPERATION SW CIRC

××× ICC steering switch harness or spi-

ral cable is open or shorted.

ICC steering switch malfunction ACS-40

61 PRESS SEN CIRCUIT

×× × Brake pressure sensor harness is

open or shorted.

Brake pressure sensor malfunction

Brake pressure sensor input circuit malfunction ACS-41

62

BOOSTER SOL/V

CIRCUIT ×× × Solenoid harness is open or short-

ed.

Solenoid is open.

Solenoid drive circuit malfunction ACS-42

63 RELEASE SW CIRCUIT

×××× Release switch harness is open or

shorted.

Release switch malfunction

Release switch input circuit mal- function ACS-43

65 PRESSURE CONTROL

×× × Booster malfunctionACS-45

74 LASER BEAM OFF CNTR ×× × Laser beam of ICC sensor is off the

aiming point. ACS-45

90 STOP LAMP RLY FIX

×× × Normally open terminal of stop

lamp relay is stuck. ACS-46

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 43 of 3924

![INFINITI FX35 2008 User Guide

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

DTC 11 CONTROL UNIT

INFOID:0000000001328826

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC sy INFINITI FX35 2008 User Guide

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

DTC 11 CONTROL UNIT

INFOID:0000000001328826

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC sy](/img/42/57017/w960_57017-42.png)

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

DTC 11 CONTROL UNIT

INFOID:0000000001328826

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC system.

2. Check if any item other than “DTC 11 CONTRO L UNIT” is indicated on self-diagnosis display.

Is any indicated?

YES >> 1. Repair or replace applicable item. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC unit.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 20 CAN COMM CIRCUITINFOID:0000000001328827

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Turn ignition switch ON and wait for 2 second or more.

2. Check self-diagnosis of ICC system.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to LAN-14, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-35, "

CONSULT-III/GST Data Link Connector (DLC) Circuit".

92 ECM CIRCUIT ×××× ECM malfunction

Accelerator pedal position sensor

malfunction

ICC unit malfunction ACS-50

96 NP RANGE

××× Park/neutral position switch har-

ness is open or shorted.

Park/neutral position switch mal- function.

TCM malfunction ACS-51

97 AT CIRCUIT

××× TCM malfunctionACS-52

98 GEAR POSITION ××× TCM malfunction

AT turbine revolution sensor mal-

function

AT vehicle speed sensor malfunc-

tion ACS-52

102 RADAR STAIN

×× × ICC sensor body window has con-

tamination. ACS-53

103 LASER SENSOR FAIL

×× × ICC sensor internal malfunctionACS-53

104 LASER AIMING INCMP ×× × Laser beam aiming of ICC sensor

is not adjusted. ACS-54

107 LASER COMM FAIL

×× × CAN data received by ICC sensor

is strange (from ICC unit, combina-

tion meter or ECM). ACS-54

109 LASER HIGH TEMP

×× × Temperature around ICC sensor is

excessively high. ACS-54

DTC

No. CONSULT-III

screen terms ICC

system

warning lamp Fail-safe

Malfunctions detected where... Refer-

ence

page

Vehicle-

to-

vehicle

distance control mode Conven-

tional

(fixed

speed) cruise

control mode Brake as-

sist (with

preview

function)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 45 of 3924

![INFINITI FX35 2008 User Guide

ACS-38

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 2.

2.C INFINITI FX35 2008 User Guide

ACS-38

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 2.

2.C](/img/42/57017/w960_57017-44.png)

ACS-38

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 2.

2.CHECK AT VEHICLE SPEED SENSOR

With “Data Monitor” of “ICC”, check “VHCL SPD AT” operates normally.

OK or NG

OK >> 1. Replace ICC unit. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Perform self-diagnosis of TCM. 2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

DTC 43 ABS/TCS/VDC CIRCINFOID:0000000001328830

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC system.

2. Check if “DTC 20 CAN COMM CIRCUIT” other than “D TC 43 ABS/TCS/VDC CIRC” is indicated in self-

diagnosis item in the display.

Is it indicated?

YES >> 1. Repair or replace applicable item. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 2.

2.PERFORM SELF-DIAGNOSIS OF ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

1. Perform self-diagnosis of ABS actuator and electric unit (control unit). Refer to BRC-26, "

Self-Diagnosis".

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC unit. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 45 BRAKE SW/STOP L SWINFOID:0000000001328831

1.CHECK CONNECTOR FOR ICC UNIT

1. Turn ignition switch OFF.

2. Disconnect ICC unit connector, and connect it securely again.

3. Erase DTC and perform ICC system running test. T hen perform self-diagnosis of ICC system again.

Is malfunction indicated?

YES >> GO TO 2.

NO >> Poor connector connection 1. Check connector. (Check connector housing for disconnected, loose, bent, and collapsed ter-minals. If any malfunction is detected, repair applicable part.)

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

2.CHECK STOP LAMP SWITCH AND ICC BRAKE SWITCH

With “Data Monitor” of “ICC”, check if “STO P LAMP SW” and “BRAKE SW” are operated normally.

OK or NG

OK >> 1. Replace ICC unit. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG-1 >> “BRAKE SW” NG: GO TO 3.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 48 of 3924

![INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-41

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

4. Check continuity between spiral cable harness connector and ground.

OK or NG

OK > INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-41

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

4. Check continuity between spiral cable harness connector and ground.

OK or NG

OK >](/img/42/57017/w960_57017-47.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-41

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

4. Check continuity between spiral cable harness connector and ground.

OK or NG

OK >> GO TO 4.

NG >> 1. Repair harness between ECM and spiral cable. 2. Erase DTC and perform I CC system running test.

Then perform self-diagnosis of ICC system again.

4.CHECK SPIRAL CABLE

Check continuity between spiral cable connector terminals.

OK or NG

OK >> 1. Perform self-diagnosis of ECM. 2. After repairing or replacing applicable item, eraseDTC and perform ICC syst em running test. Then

perform self-diagnosis of ICC system again.

NG >> 1. Replace spiral cable. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

DTC 61 PRESS SEN CIRCUITINFOID:0000000001328833

1.CHECK CONNECTOR BRAKE PRES SURE SENSOR AND ICC UNIT

1. Turn ignition switch OFF.

2. Disconnect brake pressure sensor connector and I CC unit connector, and connect them securely again.

3. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system again.

Is malfunction indicated?

YES >> GO TO 2.

NO >> Poor connector connection 1. Check connector. (Check connector housing for disconnected, loose, bent, and collapsed ter-

minals. If any malfunction is detected, repair applicable part.)

2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

2.CHECK HARNESS BETWEEN BRAKE PR ESSURE SENSOR AND ICC UNIT

1. Turn ignition switch OFF.

2. Disconnect ICC unit connector and brake pressure sensor con- nector.

3. Check continuity between brake pressure sensor harness con- nector and ICC unit harness connector.

Spiral cable

connector Te r m i n a l

Ground Continuity

M15 33

No

34

PKIB4165E

Spiral cable

connector Te r m i n a lSpiral cable

connector Terminal Continuity

M15 33

M203 14

Ye s

34 15

PKIB4166E

Brake pressure

sensor connector Te r m i n a lICC unit

connector Terminal Continuity

E142 1

M88 24

Ye s

217

38

SKIA6652E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 49 of 3924

![INFINITI FX35 2008 User Guide

ACS-42

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

4. Check continuity between ICC unit harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> 1. Repair harness bet INFINITI FX35 2008 User Guide

ACS-42

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

4. Check continuity between ICC unit harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> 1. Repair harness bet](/img/42/57017/w960_57017-48.png)

ACS-42

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

4. Check continuity between ICC unit harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> 1. Repair harness between brake pressure sensor and ICC unit.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

3.CHECK POWER SUPPLY CIRCUIT FOR BRAKE PRESSURE SENSOR

1. Connect ICC unit connector.

2. Turn ignition switch ON.

3. Check voltage between ICC unit harness connector terminals.

OK or NG

OK >> 1. Replace brake pressure sensor. Refer to BR-12,

"Removal and Installation".

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Replace ICC unit. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 62 BOOSTER SOL/V CIRCUITINFOID:0000000001328834

1.CHECK SOLENOID/RELEASE SWIT CH AND ICC UNIT CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect brake booster connector and ICC unit connector, and connect them securely again.

3. Erase DTC and perform ICC system running test. T hen perform self-diagnosis of ICC system again.

Is malfunction indicated?

YES >> GO TO 2.

NO >> Poor connector connection 1. Check connector. (Check connector housing for disconnected, loose, bent, and collapsed ter-

minals. If any malfunction is detected, repair applicable part.)

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

2.CHECK HARNESS BETWEEN SOLENO ID/RELEASE SWITCH AND ICC UNIT

ICC unit connector Terminal

GroundContinuity

M88 8

No

17

24

PKIB1444E

ICC unit connector Te r m i n a l

Voltage (Approx.)

(+) ( −)

M88 8 24 5 V

SKIA6653E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 52 of 3924

![INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-45

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DTC 65 PRESSURE CONTROLINFOID:0000000001328836

1.OPERATION CHECK

Check foot brake p INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-45

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DTC 65 PRESSURE CONTROLINFOID:0000000001328836

1.OPERATION CHECK

Check foot brake p](/img/42/57017/w960_57017-51.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-45

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DTC 65 PRESSURE CONTROLINFOID:0000000001328836

1.OPERATION CHECK

Check foot brake pedal operates normally.

OK or NG

OK >> GO TO 2.

NG >> 1. Check brake circuit. 2. After repairing, erase DTC and perform active test (BOOSTER SOL/V3) with CONSULT-III.

Then perform self-diagnosis of ICC system again.

2.CHECK BOOSTER SOLENOID

Check booster solenoid. Refer to ACS-63, "

Booster Solenoid".

OK or NG

OK >> GO TO 3.

NG >> Booster solenoid malfunction 1. Replace brake booster.

2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

3.CHECK HARNESS BETWEEN ICC UNIT AND BRAKE BOOSTER

1. Turn ignition switch OFF.

2. Disconnect ICC unit connector and brake booster connector.

3. Check continuity between ICC unit harness connector (A) and brake booster harness connector (B).

4. Check continuity between ICC unit harness connector and ground.

OK or NG

OK >> 1. Replace ICC unit. 2. Erase DTC and perform I CC system running test.

Then perform self-diagnosis of ICC system again.

NG >> 1. Repair harness between brake booster and ICC unit.

2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

DTC 74 LASER BEAM OFF CNTRINFOID:0000000001328837

1.DIAGNOSTIC CHECK

1. Adjust laser beam aiming. Then erase DT C, and perform ICC system running test.

2. Perform self-diagnosis of ICC system.

3. Check if “DTC 74 LASER BEAM OFF CNTR” is indicated.

Is it indicated?

YES >> 1. Replace ICC sensor, and adjust laser beam aiming.

AB

Continuity

ICC unit

connector Te r m i n a l

Brake booster con-

nector Terminal

M88 10

E54 4

Ye s

12 6

PKIC5179E

ICC unit

connector Te r m i n a l

GroundContinuity

M88 10

No

12

PKIB4148E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 76 of 3924

AT-3

DE

F

G H

I

J

K L

M A

B

AT

N

O

P

N

DTC P1710 A/T FLUID TEMPERATURE SEN-

SOR CIRCUIT .................................................

..

132

Description .......................................................... ..132

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

132

On Board Diagnosis Logic ....................................132

Possible Cause .....................................................132

DTC Confirmation Procedure ................................132

Wiring Diagram - AT - FTS ....................................133

Diagnosis Procedure .............................................133

Component Inspection ..........................................135

DTC P1721 VEHICLE SPEED SENSOR MTR ..137

Description .......................................................... ..137

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

137

On Board Diagnosis Logic ....................................137

Possible Cause .....................................................137

DTC Confirmation Procedure ................................137

Diagnosis Procedure .............................................137

DTC P1730 A/T INTERLOCK ..........................139

Description .......................................................... ..139

On Board Diagnosis Logic ....................................139

Possible Cause .....................................................139

DTC Confirmation Procedure ................................139

Judgement of A/T Interlock ...................................139

Diagnosis Procedure .............................................139

DTC P1731 A/T 1ST ENGINE BRAKING ........141

Description .......................................................... ..141

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

141

On Board Diagnosis Logic ....................................141

Possible Cause .....................................................141

DTC Confirmation Procedure ................................141

Diagnosis Procedure .............................................141

DTC P1752 INPUT CLUTCH SOLENOID

VALVE ..............................................................

143

Description .......................................................... ..143

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

143

On Board Diagnosis Logic ....................................143

Possible Cause .....................................................143

DTC Confirmation Procedure ................................143

Diagnosis Procedure .............................................143

DTC P1757 FRONT BRAKE SOLENOID

VALVE ..............................................................

145

Description .......................................................... ..145

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

145

On Board Diagnosis Logic ....................................145

Possible Cause .....................................................145

DTC Confirmation Procedure ................................145

Diagnosis Procedure .............................................145

DTC P1762 DIRECT CLUTCH SOLENOID

VALVE ..............................................................

147

Description ........................................................... ..147

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

147

On Board Diagnosis Logic .....................................147

Possible Cause ......................................................147

DTC Confirmation Procedure ................................147

Diagnosis Procedure .............................................147

DTC P1767 HIGH AND LOW REVERSE

CLUTCH SOLENOID VALVE .........................

149

Description .............................................................149

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

149

On Board Diagnosis Logic .....................................149

Possible Cause ......................................................149

DTC Confirmation Procedure ................................149

Diagnosis Procedure .............................................149

DTC P1772 LOW COAST BRAKE SOLENOID

VALVE .............................................................

151

Description .............................................................151

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

151

On Board Diagnosis Logic .....................................151

Possible Cause ......................................................151

DTC Confirmation Procedure ................................151

Diagnosis Procedure .............................................151

DTC P1774 LOW COAST BRAKE SOLENOID

VALVE FUNCTION .........................................

153

Description .............................................................153

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

153

On Board Diagnosis Logic .....................................153

Possible Cause ......................................................153

DTC Confirmation Procedure ................................153

Diagnosis Procedure .............................................153

DTC P1815 MANUAL MODE SWITCH ..........155

Description .............................................................155

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

155

On Board Diagnosis Logic .....................................155

Possible Cause ......................................................155

DTC Confirmation Procedure ................................155

Wiring Diagram - AT - MMSW ...............................156

Diagnosis Procedure .............................................158

Component Inspection ...........................................159

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ................................................................

160

Wiring Diagram - AT - MAIN ..................................160

Diagnosis Procedure .............................................161

CLOSED THROTTLE POSITION AND WIDE

OPEN THROTTLE POSITION CIRCUIT .........

164

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

164

Diagnosis Procedure .............................................164

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 77 of 3924

AT-4

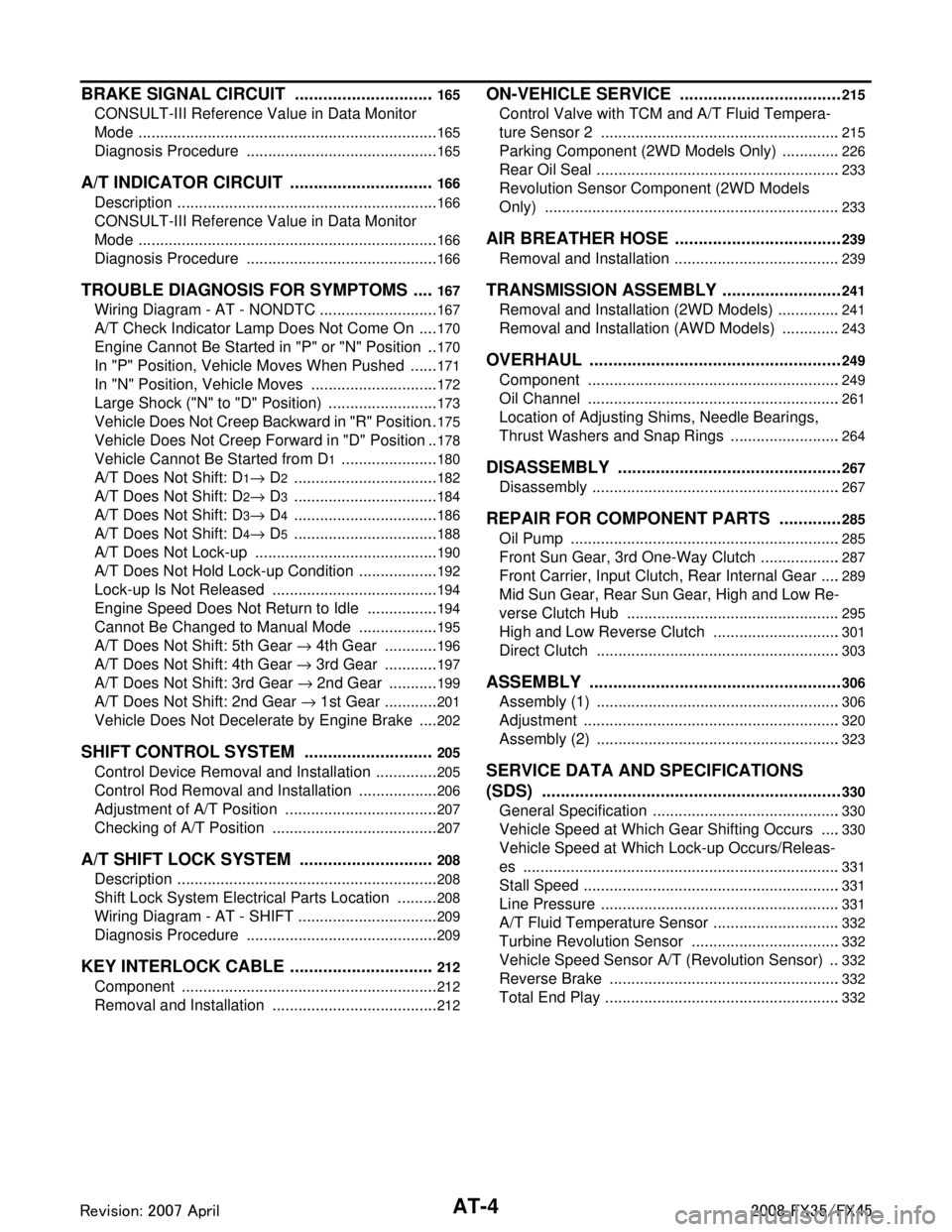

BRAKE SIGNAL CIRCUIT ..............................165

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

165

Diagnosis Procedure .............................................165

A/T INDICATOR CIRCUIT ...............................166

Description ........................................................... ..166

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

166

Diagnosis Procedure .............................................166

TROUBLE DIAGNOSIS FOR SYMPTOMS .....167

Wiring Diagram - AT - NONDTC .......................... ..167

A/T Check Indicator Lamp Does Not Come On .....170

Engine Cannot Be Started in "P" or "N" Position ...170

In "P" Position, Vehicle Moves When Pushed .......171

In "N" Position, Vehicle Moves ..............................172

Large Shock ("N" to "D" Position) ..........................173

Vehicle Does Not Creep Backward in "R" Position ..175

Vehicle Does Not Creep Forward in "D" Position ..178

Vehicle Cannot Be Started from D1 .......................180

A/T Does Not Shift: D1→ D2 ................................ ..182

A/T Does Not Shift: D2→ D3 ................................ ..184

A/T Does Not Shift: D3→ D4 ................................ ..186

A/T Does Not Shift: D4→ D5 ................................ ..188

A/T Does Not Lock-up ......................................... ..190

A/T Does Not Hold Lock-up Condition ...................192

Lock-up Is Not Released .......................................194

Engine Speed Does Not Return to Idle .................194

Cannot Be Changed to Manual Mode ...................195

A/T Does Not Shift: 5th Gear → 4th Gear ........... ..196

A/T Does Not Shift: 4th Gear → 3rd Gear ........... ..197

A/T Does Not Shift: 3rd Gear → 2nd Gear .......... ..199

A/T Does Not Shift: 2nd Gear → 1st Gear ........... ..201

Vehicle Does Not Decelerate by Engine Brake ... ..202

SHIFT CONTROL SYSTEM ............................205

Control Device Removal and Installation ............. ..205

Control Rod Removal and Installation ...................206

Adjustment of A/T Position ....................................207

Checking of A/T Position .......................................207

A/T SHIFT LOCK SYSTEM .............................208

Description ........................................................... ..208

Shift Lock System Electrical Parts Location ..........208

Wiring Diagram - AT - SHIFT .................................209

Diagnosis Procedure .............................................209

KEY INTERLOCK CABLE ...............................212

Component .......................................................... ..212

Removal and Installation .......................................212

ON-VEHICLE SERVICE ...................................215

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

215

Parking Component (2WD Models Only) ..............226

Rear Oil Seal .........................................................233

Revolution Sensor Component (2WD Models

Only) .....................................................................

233

AIR BREATHER HOSE ....................................239

Removal and Installation ...................................... .239

TRANSMISSION ASSEMBLY ..........................241

Removal and Installation (2WD Models) .............. .241

Removal and Installation (AWD Models) ..............243

OVERHAUL ......................................................249

Component .......................................................... .249

Oil Channel ...........................................................261

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

264

DISASSEMBLY .............................................. ..267

Disassembly ......................................................... .267

REPAIR FOR COMPONENT PARTS ..............285

Oil Pump .............................................................. .285

Front Sun Gear, 3rd One-Way Clutch ...................287

Front Carrier, Input Clutch, Rear Internal Gear .....289

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

295

High and Low Reverse Clutch ..............................301

Direct Clutch .........................................................303

ASSEMBLY .................................................... ..306

Assembly (1) ........................................................ .306

Adjustment ............................................................320

Assembly (2) .........................................................323

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

330

General Specification ........................................... .330

Vehicle Speed at Which Gear Shifting Occurs .....330

Vehicle Speed at Which Lock-up Occurs/Releas-

es ..........................................................................

331

Stall Speed ............................................................331

Line Pressure ........................................................331

A/T Fluid Temperature Sensor ..............................332

Turbine Revolution Sensor ...................................332

Vehicle Speed Sensor A/T (Revolution Sensor) ...332

Reverse Brake ......................................................332

Total End Play .......................................................332

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 102 of 3924

A/T CONTROL SYSTEMAT-29

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

TCM FunctionINFOID:0000000001327135

The function of the TCM is to:

Receive input signals sent from various switches and sensors.

Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLINE

The automatic transmission senses vehicle operating condi tions through various sensors or signals. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

1. Front brake 2. Input clutch 3. Direct clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front carrier

19. Mid carrier 20. Rear internal gear 21. Output shaft

22. Parking gear 23. Parking pawl

SCIA1519E

SENSORS (or SIGNALS)

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Manual mode switch signal

Stop lamp switch signal

Turbine revolution sensor

ATF pressure switch Shift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-III co

mmunication

line

Duet-EA control

CAN system Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch sole-

noid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Starter relay

Back-up lamp relay

: