clock INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 661 of 3924

AV-114

< SERVICE INFORMATION >

NAVIGATION SYSTEM

Self-Diagnosis Mode (DCU)

INFOID:0000000001328753

OPERATION PROCEDURE

1. Start the engine.

2. Turn the audio system OFF.

3. While pressing the “4” button, turn the volume control dial clock- wise or counterclockwise for 30 clicks or more. (When the self-

diagnosis mode is started, a short beep will be heard.)

Shifting from current screen to previous screen is performed

by pressing “BACK” button.

Mode Description

Self Diagnosis (DCU) Display control unit diagnosis

Analyzes connection between the display control unit and each unit, and

operation of each unit.

Self Diagnosis (NAVI) NAVI control unit diagnosis (DVD-ROM drive will not be diagnosed when

no DVD-ROM is in it.).

Analyzes connection between the NAVI control unit and the GPS anten-

na.

Confirmation/

Adjustment Display Diagnosis

Color tone and shading of the display control unit-generated image can be

checked by the display of a color bar and a gray scale.

Vehicle Signals Diagnosis of signals that are input to display control unit can be performed

for Vehicle Speed, IGN, Reverse and Light.

Auto Climate Control Refer to AT C - 4 3 , "

Self-Diagnosis Function".

Navigation Display Diagnosis

Color tone and shading of the NAVI control unit-generated image can be

checked by the display of a color bar and a gray scale.

Vehicle Signals Diagnosis of signals that are input to NAVI control unit can be performed for

Vehicle speed, Lights, Ignition and Reverse.

Navigation Steering An-

gle

Adjustment

This mode is used to correct difference between actual turning angle of a

vehicle and turning angle of the vehicle mark on the display.

Speed

Calibration Under ordinary conditions, the navigation system distance measuring func-

tion will automatically compensate for minute decreases in wheel and tire

diameter caused by tire wear or low-pressure. Speed Calibration can im-

mediately restore system accuracy in cases such as when distance calibra-

tion is needed because of the use of tire chains.

Error History Malfunctions that occurred in the past are displayed, along with the number

of times each has occurred. Time and location when/where the errors oc-

curred are also displayed.

Delete Unit Connection Log Erase the connection history of unit and error history.

CAN DIAG SUPPOPT MONITOR The transmitting/recei ving of CAN communication can be monitored.

SKIB8642E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 664 of 3924

NAVIGATION SYSTEMAV-117

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

Self-Diagnosis Mode (NAVI)INFOID:0000000001328754

OPERATION PROCEDURE

1. Start the engine.

2. Turn the audio system OFF.

3. While pressing the “4” button, turn the volume control dial clock- wise or counterclockwise for 30 clicks or more. (When the self-

diagnosis mode is started, a short beep will be heard.)

Shifting from current screen to previous screen is performedby pressing “BACK” button.

4. The initial trouble diagnosis screen will be shown, and items “Self Diagnosis (DCU)”, “Self Diagnosis (NAVI)”, “Confirmation/

Adjustment” and “CAN DIAG SUPPORT MONITOR” will

become selective.

NOTE:

Select “Self Diagnosis (DCU)” when “Self Diagnosis (NAVI)” is

not available. Repair malfunctioning part.

4 NAVI control unit power supply and ground circuit mal-

function is detected.

Malfunction is detected on communication signal be-

tween display control unit and NAVI control unit. 1. Check NAVI control unit power supply and ground cir-

cuit.

2. Check communication circuit between display control unit and NAVI control unit.

3. If the results from the above checkup show no mal- function, replace either display control unit or NAVI

control unit, and then start self-diagnosis.

4. If self-diagnosis results still show any malfunction, re- place the other unit.

5 GPS antenna connection malfunction is detected. 1. Check if GPS antenna feeder line is snapped or

pinched.

2. If the results from the above checkup show no mal- function, replace GPS antenna, and then restart self-

diagnosis.

3. If self-diagnosis results still show any malfunction, re- place NAVI control unit.

6 Satellite radio tuner power supply and ground circuit mal-

function is detected.

Malfunction is detected on communication signal be-

tween audio unit and satellite radio tuner. 1. Check satellite radio tuner power supply and ground

circuit.

2. Check communication circuit between audio unit and satellite radio tuner.

3. Check communication signal between audio unit and

satellite radio tuner.

4. If the results from the above checkup show no mal- function, replace either audio unit or satellite radio tun-

er, and then start self-diagnosis.

5. If self-diagnosis results still show any malfunction, re- place the other unit.

Diagnosis

No. Possible cause Action to take

SKIB8642E

SKIB7874E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 667 of 3924

AV-120

< SERVICE INFORMATION >

NAVIGATION SYSTEM

3. While pressing the “4” button, turn the volume control dial clock-wise or counterclockwise for 30 clicks or more. (When the self-

diagnosis mode is started, a short beep will be heard.)

Shifting from current screen to previous screen is performed

by pressing “BACK” button.

4. The initial trouble diagnosis screen will be shown, and items “Self Diagnosis (DCU)”, “Self Diagnosis (NAVI)”, “Confirmation/

Adjustment” and “CAN DIAG SUPPORT MONITOR” will

become selective.

5. Select “Confirmation/Adjustment”.

6. Each diagnosis is shown by selecting each screen switch on Confirmation/Adjustment screen.

DISPLAY DIAGNOSIS

Color tone and shading of the display control unit-generat ed image can be checked by the display of a color

bar and a gray scale.

If RGB signal is malfunctioning, the tint of the color bar display is as follows.

SKIB8642E

SKIB7874E

SKIA4220E

SKIB7777E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 672 of 3924

NAVIGATION SYSTEMAV-125

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

Erase the connection history of unit and error history that is recorded

in NAVI control unit (clear the connection history of the removed

unit).

CAN Diagnostic Support MonitorINFOID:0000000001328756

OPERATION PROCEDURE

1. Start the engine.

2. Turn the audio system OFF.

3. While pressing the “4” button, turn the volume control dial clock- wise or counterclockwise for 30 clicks or more. (When the self-

diagnosis mode is started, a short beep will be heard.)

Shifting from current screen to previous screen is performedby pressing “BACK” button.

4. The initial trouble diagnosis screen will be shown, and items “Self Diagnosis (DCU)”, “Self Diagnosis (NAVI)”, “Confirmation/

Adjustment” and “CAN DIAG SUPPORT MONITOR” will

become selective.

5. Select “CAN DIAG SUPPORT MONITOR”.

6. The transmitting/receiving of CAN communication can be moni- tored.

SKIB6979E

SKIB8642E

SKIB7874E

Item Content Error counter

(Reference value)

CAN_COMM OK/NG 0 - 50

CAN_CIRC_1 OK/UNKWN 0 - 50

CAN_CIRC_2 OK/UNKWN 0 - 50

CAN_CIRC_3 OK/UNKWN 0 - 50

CAN_CIRC_4 OK/UNKWN 0 - 50

CAN_CIRC_5 OK/UNKWN 0 - 50

CAN_CIRC_6 OK/UNKWN 0 - 50

CAN_CIRC_7 OK/UNKWN 0 - 50

SKIA4288E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 741 of 3924

SQUEAK AND RATTLE TROUBLE DIAGNOSISBL-7

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Work FlowINFOID:0000000001327780

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to BL-11, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 989 of 3924

BRAKE PEDALBR-5

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE PEDAL

Inspection and AdjustmentINFOID:0000000001327607

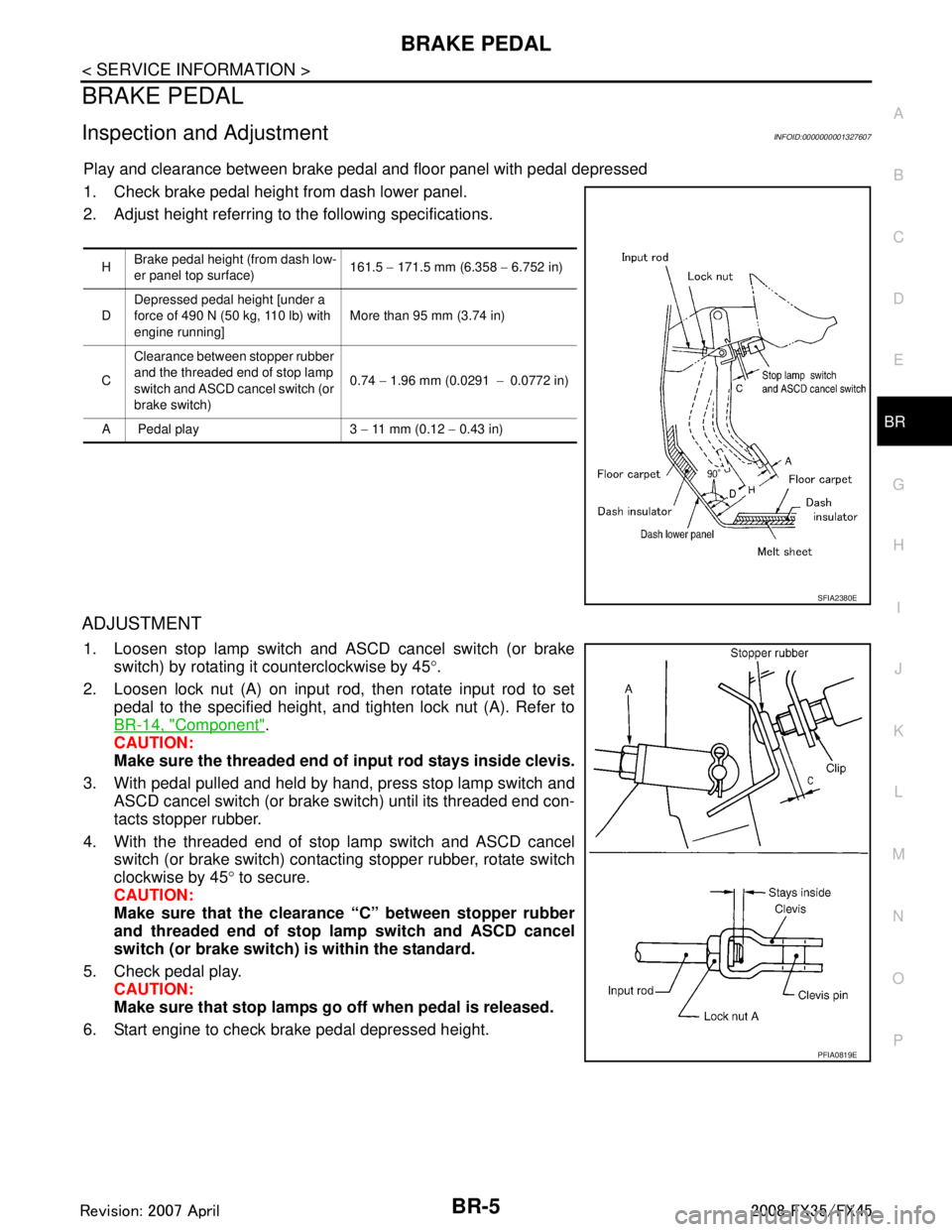

Play and clearance between brake pedal and floor panel with pedal depressed

1. Check brake pedal height from dash lower panel.

2. Adjust height referring to the following specifications.

ADJUSTMENT

1. Loosen stop lamp switch and ASCD cancel switch (or brake switch) by rotating it counterclockwise by 45 °.

2. Loosen lock nut (A) on input rod, then rotate input rod to set pedal to the specified height, and tighten lock nut (A). Refer to

BR-14, "

Component".

CAUTION:

Make sure the threaded end of input rod stays inside clevis.

3. With pedal pulled and held by hand, press stop lamp switch and ASCD cancel switch (or brake switch) until its threaded end con-

tacts stopper rubber.

4. With the threaded end of stop lamp switch and ASCD cancel switch (or brake switch) contacting stopper rubber, rotate switch

clockwise by 45 ° to secure.

CAUTION:

Make sure that the clearance “C” between stopper rubber

and threaded end of stop lamp switch and ASCD cancel

switch (or brake switch) is within the standard.

5. Check pedal play. CAUTION:

Make sure that stop lamps go off when pedal is released.

6. Start engine to check brake pedal depressed height.

H Brake pedal height (from dash low-

er panel top surface) 161.5

− 171.5 mm (6.358 − 6.752 in)

D Depressed pedal height [under a

force of 490 N (50 kg, 110 lb) with

engine running] More than 95 mm (3.74 in)

C Clearance between stopper rubber

and the threaded end of stop lamp

switch and ASCD cancel switch (or

brake switch) 0.74

− 1.96 mm (0.0291 −0.0772 in)

A Pedal play 3 − 11 mm (0.12 − 0.43 in)

SFIA2380E

PFIA0819E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 994 of 3924

BR-10

< SERVICE INFORMATION >

BRAKE TUBE AND HOSE

BRAKE TUBE AND HOSE

Hydraulic CircuitINFOID:0000000001327613

CAUTION:

All brake hoses and tubes must be free from excessive bending, twisting and pulling.

Make sure there is no interference with other part s when turning steering both clockwise and coun-

terclockwise.

The brake tubes and hoses is an important safety pa rt. If a brake fluid leak is detected, always disas-

semble the parts. Replace applicable part with a new one, if necessary.

Be careful not to splash brake fluid on painted areas; it way cause paint damage. If brake fluid is

splashed on painted surfaces of bo dy, immediately wipe it off and them wash it away with water

immediately.

Do not bend or twist brake hose sharply, or strongly pull it.

When removing components, cover br ake line connections so that no dirt, no dust, or other foreign

matter gets in.

Refill with new brake fluid “ DOT 3 ”.

Do not reuse drained brake fluid.

Removal and Installation of Fr ont Brake Tube and Brake HoseINFOID:0000000001327614

REMOVAL

1. Drain brake fluid. Refer to BR-8, "Drain and Refill".

2. Using a flare nut wrench, remove brake tube from brake hose.

3. Remove union bolt and remove brake hose from caliper assembly.

4. Remove lock plate and remove brake hose from vehicle.

INSTALLATION

1. Position brake hose by aligning with the protrusion on caliper assembly, and them tighten union bolt to the specified torque.

CAUTION:

Do not reuse copper washer.

2. Install brake hose to brake tube. Temporarily tighten flare nut by hand as much as possible. Secure them it to bracket with lock

plate.

3. Using a flare nut torque wrench, tighten flare nut to the specified

torque.

4. Refill brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake

System".

PFIA0818E

SFIA1204E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1094 of 3924

![INFINITI FX35 2008 User Guide

WATER PUMPCO-23

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

a. Remove lower mounting bolt.

CAUTION:

Be careful not to drop mounting bolt inside timing chain

case.

b. Loosen upper INFINITI FX35 2008 User Guide

WATER PUMPCO-23

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

a. Remove lower mounting bolt.

CAUTION:

Be careful not to drop mounting bolt inside timing chain

case.

b. Loosen upper](/img/42/57017/w960_57017-1093.png)

WATER PUMPCO-23

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

a. Remove lower mounting bolt.

CAUTION:

Be careful not to drop mounting bolt inside timing chain

case.

b. Loosen upper mounting bolt slowly, and then turn chain ten- sioner (primary) on the mounting bolt so that plunger is fully

expanded.

NOTE:

Even if plunger is fully expanded, it is not dropped from the body

of timing chain tensioner (primary).

c. Turn crankshaft pulley clockwise so that timing chain on the tim- ing chain tensioner (primary) side is loose.

d. Remove upper mounting bolt, and then remove timing chain ten- sioner (primary).

CAUTION:

Be careful not to drop mounting bolt inside timing chain

case.

8. Remove water pump as follows:

a. Remove three water pump mounting bolts. Secure a gap between water pump gear and timing chain, by turning crank-

shaft pulley counterclockwise until timing chain looseness on

water pump sprocket becomes maximum.

PBIC3575E

PBIC4820E

PBIC3576E

PBIC1193E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1096 of 3924

![INFINITI FX35 2008 User Guide

WATER PUMPCO-25

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

a. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose.

b. P INFINITI FX35 2008 User Guide

WATER PUMPCO-25

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

a. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose.

b. P](/img/42/57017/w960_57017-1095.png)

WATER PUMPCO-25

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

a. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose.

b. Pull plunger stopper tab up (or turn lever downward) so as to remove plunger stopper tab from the ratchet of plunger.

NOTE:

Plunger stopper tab and lever are synchronized.

c. Push plunger into the inside of tensioner body.

d. Hold plunger in the fully compressed position by engaging plunger stopper tab with the tip of ratchet.

e. To secure lever, insert stopper pin through hole of lever into ten- sioner body hole.

The lever parts and the tab are synchronized. Therefore, theplunger will be secured under this condition.

NOTE:

Figure shows the example of 1.2 mm (0.047 in) diam eter thin screwdriver being used as the stopper pin.

f. Install timing chain tensioner (primary). Remove dust and foreign material completely from backside of timing chain tensioner (primary) and

from installation area of rear timing chain case.

g. Remove stopper pin.

h. Make sure again that timing chain and water pump sprocket are engaged.

4. Install chain tensioner cover and water pump cover as follows:

a. Before installing, remove all traces of old liquid gasket from mat- ing surface of water pump cover and chain tensioner cover

using a scraper. Also remove traces of old liquid gasket from the

mating surface of front timing chain case.

PBIC4820E

PBIC3568E

PBIC3577E

SLC446B

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1128 of 3924

DI-2

CONSULT-III Function (BCM) ................................60

Trouble Diagnosis ...................................................61

Symptom Chart .......................................................61

Power Supply and Ground Circuit Inspection .........61

Combination Meter Buzzer Circuit Inspection .........62

Front Door Switch (Driver Side) Signal Inspection ...63

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ...

64

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ...

65

Lighting Switch Signal Inspection ...........................66

Seat Belt Buckle Switch (Driver Side) Signal In-

spection ............................................................... ...

66

Component Inspection ............................................67

LANE DEPARTURE WARNING SYSTEM ........69

Precaution for Lane Departure Warning (LDW)

system ................................................................. ...

69

System Description .................................................69

Action Test ..............................................................71

Camera Aiming Adjustment ....................................71

Component Parts and Harness Connector Loca-

tion ..........................................................................

76

Schematic ...............................................................77

Wiring Diagram - LDW - .........................................78

Terminal and Reference Value for LDW Camera

Unit .........................................................................

81

CONSULT-III Function (LDW) ................................81

Trouble Diagnosis ...................................................83

Preliminary Check ..................................................84

Power Supply and Ground Circuit Inspection .........84

DTC [C1B00] CAMERA UNIT MALF ......................85

DTC [C1B01] CAM AIMING INCMP .......................85

DTC [C1B02] VHCL SPD DATA MALF ..................85

DTC [C1B03] ABNRML TEMP DETECT ................86

DTC [U1000] CAN COMM CIRCUIT ......................86

DTC [U1010] CONTROL UNIT (CAN) ....................86

LDW Chime Circuit Inspection ................................86

LDW Switch Circuit Inspection ...............................88

LDW Indicator Lamp Circuit Inspection ..................90

Turn Signal Input Inspection ................................ ...91

Electrical Component Inspection ............................91

Removal and Installation for LDW Camera Unit .....91

Removal and Installation for LDW Chime ............ ...91

Removal and Installation for LDW Switch ...............92

CAN COMMUNICATION ...................................93

System Description .............................................. ...93

CAN Communication Unit .......................................93

COMPASS .........................................................94

Precaution for Compass ...................................... ...94

System Description .................................................94

Troubleshooting ......................................................94

Zone Variation Setting Procedure ...........................95

Calibration Procedure .............................................95

Wiring Diagram - COMPAS - ..................................97

Removal and Installation of Compass ....................97

CLOCK ..............................................................98

Wiring Diagram - CLOCK - .................................. ...98

Removal and Installation of Clock ...........................98

REAR VIEW MONITOR ....................................100

System Description .............................................. .100

Component Parts and Harness Connector Loca-

tion ........................................................................

101

Schematic .............................................................102

Wiring Diagram - R/VIEW - ...................................103

Terminal and Reference Value for Rear View

Camera Control Unit .............................................

106

CONSULT-III Function (REARVIEW CAMERA) ...106

Side Distance Guideline Correction ......................107

Power Supply and Ground Circuit Inspection .......108

Rear View Is Not Displayed with the A/T Selector

Lever in R-Position ................................................

108

The Rear View Image Is Distorted ........................112

Removal and Installation of Rear View Camera

Control Unit .......................................................... .

113

Removal and Installation of Rear View Camera ...113

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C