diagram INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 74 of 3924

AT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

SECTION AT

A

B

AT

N

O P

CONTENTS

AUTOMATIC TRANSMISSION

SERVICE INFORMATION .. ..........................5

INDEX FOR DTC ............................................ .....5

Alphabetical Index ............................................... ......5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

7

Precaution .................................................................7

Service Notice or Precaution .....................................8

PREPARATION ...................................................9

Special Service Tool ........................................... ......9

Commercial Service Tool ..........................................9

A/T FLUID ...........................................................11

Changing A/T Fluid ............................................. ....11

Checking A/T Fluid ..................................................11

A/T Fluid Cooler Cleaning .......................................13

A/T CONTROL SYSTEM ....................................16

Cross-Sectional View (2WD Models) .................. ....16

Cross-Sectional View (VQ35DE Models for AWD) ....17

Cross-Sectional View (VK45DE Models for AWD) ....18

Shift Mechanism .................................................. ....18

TCM Function ..........................................................29

CAN Communication ...............................................30

Input/Output Signal of TCM .....................................31

Line Pressure Control .............................................31

Shift Control ............................................................33

Lock-up Control .......................................................34

Engine Brake Control ..............................................35

Control Valve ...........................................................36

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......38

Introduction ......................................................... ....38

OBD-II Function for A/T System ..............................38

One or Two Trip Detection Logic of OBD-II ............38

OBD-II Diagnostic Trouble Code (DTC) .............. ....38

Malfunction Indicator Lamp (MIL) ............................40

TROUBLE DIAGNOSIS ....................................41

DTC Inspection Priority Chart ..................................41

Fail-Safe ..................................................................41

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

42

A/T Electrical Parts Location ...................................48

Circuit Diagram ........................................................49

Inspections Before Trouble Diagnosis .....................49

Road Test ................................................................53

Vehicle Speed at Which Gear Shifting Occurs ........58

Vehicle Speed at Which Lock-up Occurs/Releas-

es .............................................................................

58

Symptom Chart ........................................................59

TCM Input/Output Signal Reference Value .............83

CONSULT-III Function (TRANSMISSION) ..............84

Diagnosis Procedure without CONSULT-III ............91

DTC U1000 CAN COMMUNICATION LINE .....94

Description ........................................................... ....94

On Board Diagnosis Logic .......................................94

Possible Cause ........................................................94

DTC Confirmation Procedure ..................................94

Wiring Diagram - AT - CAN .....................................95

Diagnosis Procedure ...............................................96

DTC P0615 START SIGNAL CIRCUIT .............97

Description ...............................................................97

CONSULT-III Reference Value in Data Monitor

Mode ........................................................................

97

On Board Diagnosis Logic .......................................97

Possible Cause ........................................................97

DTC Confirmation Procedure ..................................97

Wiring Diagram - AT - STSIG ..................................98

Diagnosis Procedure ...............................................99

DTC P0700 TCM .............................................101

Description .............................................................101

On Board Diagnosis Logic .....................................101

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 75 of 3924

AT-2

Possible Cause ......................................................101

DTC Confirmation Procedure ................................101

Diagnosis Procedure .............................................101

DTC P0705 PARK/NEUTRAL POSITION

SWITCH ...........................................................

102

Description ........................................................... ..102

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

102

On Board Diagnosis Logic .....................................102

Possible Cause ......................................................102

DTC Confirmation Procedure ................................102

Wiring Diagram - AT - PNP/SW .............................103

Diagnosis Procedure .............................................103

DTC P0717 TURBINE REVOLUTION SEN-

SOR ..................................................................

106

Description ........................................................... ..106

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

106

On Board Diagnosis Logic .....................................106

Possible Cause ......................................................106

DTC Confirmation Procedure ................................106

Diagnosis Procedure .............................................106

DTC P0720 VEHICLE SPEED SENSOR A/T

(REVOLUTION SENSOR) ...............................

108

Description ........................................................... ..108

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

108

On Board Diagnosis Logic .....................................108

Possible Cause ......................................................108

DTC Confirmation Procedure ................................108

Wiring Diagram - AT - VSSA/T ..............................109

Diagnosis Procedure ........................................... ..110

DTC P0725 ENGINE SPEED SIGNAL ............112

Description ........................................................... ..112

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

112

On Board Diagnosis Logic .....................................112

Possible Cause ......................................................112

DTC Confirmation Procedure ................................112

Diagnosis Procedure .............................................112

DTC P0731 A/T 1ST GEAR FUNCTION .........114

Description ........................................................... ..114

On Board Diagnosis Logic .....................................114

Possible Cause ......................................................114

DTC Confirmation Procedure ................................114

Diagnosis Procedure .............................................115

DTC P0732 A/T 2ND GEAR FUNCTION .........116

Description ........................................................... ..116

On Board Diagnosis Logic .....................................116

Possible Cause ......................................................116

DTC Confirmation Procedure ................................116

Diagnosis Procedure .............................................117

DTC P0733 A/T 3RD GEAR FUNCTION .........118

Description ........................................................... .118

On Board Diagnosis Logic ....................................118

Possible Cause .....................................................118

DTC Confirmation Procedure ................................118

Diagnosis Procedure .............................................119

DTC P0734 A/T 4TH GEAR FUNCTION ..........120

Description ........................................................... .120

On Board Diagnosis Logic ....................................120

Possible Cause .....................................................120

DTC Confirmation Procedure ................................120

Diagnosis Procedure .............................................121

DTC P0735 A/T 5TH GEAR FUNCTION ..........122

Description ........................................................... .122

On Board Diagnosis Logic ....................................122

Possible Cause .....................................................122

DTC Confirmation Procedure ................................122

Diagnosis Procedure .............................................123

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE ..........................................

124

Description ........................................................... .124

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

124

On Board Diagnosis Logic ....................................124

Possible Cause .....................................................124

DTC Confirmation Procedure ................................124

Diagnosis Procedure .............................................124

DTC P0744 A/T TCC S/V FUNCTION (LOCK-

UP) ....................................................................

126

Description ........................................................... .126

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

126

On Board Diagnosis Logic ....................................126

Possible Cause .....................................................126

DTC Confirmation Procedure ................................126

Diagnosis Procedure .............................................126

DTC P0745 LINE PRESSURE SOLENOID

VALVE ..............................................................

128

Description ........................................................... .128

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

128

On Board Diagnosis Logic ....................................128

Possible Cause .....................................................128

DTC Confirmation Procedure ................................128

Diagnosis Procedure .............................................128

DTC P1705 THROTTLE POSITION SENSOR ..130

Description ........................................................... .130

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

130

On Board Diagnosis Logic ....................................130

Possible Cause .....................................................130

DTC Confirmation Procedure ................................130

Diagnosis Procedure .............................................130

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 76 of 3924

AT-3

DE

F

G H

I

J

K L

M A

B

AT

N

O

P

N

DTC P1710 A/T FLUID TEMPERATURE SEN-

SOR CIRCUIT .................................................

..

132

Description .......................................................... ..132

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

132

On Board Diagnosis Logic ....................................132

Possible Cause .....................................................132

DTC Confirmation Procedure ................................132

Wiring Diagram - AT - FTS ....................................133

Diagnosis Procedure .............................................133

Component Inspection ..........................................135

DTC P1721 VEHICLE SPEED SENSOR MTR ..137

Description .......................................................... ..137

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

137

On Board Diagnosis Logic ....................................137

Possible Cause .....................................................137

DTC Confirmation Procedure ................................137

Diagnosis Procedure .............................................137

DTC P1730 A/T INTERLOCK ..........................139

Description .......................................................... ..139

On Board Diagnosis Logic ....................................139

Possible Cause .....................................................139

DTC Confirmation Procedure ................................139

Judgement of A/T Interlock ...................................139

Diagnosis Procedure .............................................139

DTC P1731 A/T 1ST ENGINE BRAKING ........141

Description .......................................................... ..141

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

141

On Board Diagnosis Logic ....................................141

Possible Cause .....................................................141

DTC Confirmation Procedure ................................141

Diagnosis Procedure .............................................141

DTC P1752 INPUT CLUTCH SOLENOID

VALVE ..............................................................

143

Description .......................................................... ..143

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

143

On Board Diagnosis Logic ....................................143

Possible Cause .....................................................143

DTC Confirmation Procedure ................................143

Diagnosis Procedure .............................................143

DTC P1757 FRONT BRAKE SOLENOID

VALVE ..............................................................

145

Description .......................................................... ..145

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

145

On Board Diagnosis Logic ....................................145

Possible Cause .....................................................145

DTC Confirmation Procedure ................................145

Diagnosis Procedure .............................................145

DTC P1762 DIRECT CLUTCH SOLENOID

VALVE ..............................................................

147

Description ........................................................... ..147

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

147

On Board Diagnosis Logic .....................................147

Possible Cause ......................................................147

DTC Confirmation Procedure ................................147

Diagnosis Procedure .............................................147

DTC P1767 HIGH AND LOW REVERSE

CLUTCH SOLENOID VALVE .........................

149

Description .............................................................149

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

149

On Board Diagnosis Logic .....................................149

Possible Cause ......................................................149

DTC Confirmation Procedure ................................149

Diagnosis Procedure .............................................149

DTC P1772 LOW COAST BRAKE SOLENOID

VALVE .............................................................

151

Description .............................................................151

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

151

On Board Diagnosis Logic .....................................151

Possible Cause ......................................................151

DTC Confirmation Procedure ................................151

Diagnosis Procedure .............................................151

DTC P1774 LOW COAST BRAKE SOLENOID

VALVE FUNCTION .........................................

153

Description .............................................................153

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

153

On Board Diagnosis Logic .....................................153

Possible Cause ......................................................153

DTC Confirmation Procedure ................................153

Diagnosis Procedure .............................................153

DTC P1815 MANUAL MODE SWITCH ..........155

Description .............................................................155

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

155

On Board Diagnosis Logic .....................................155

Possible Cause ......................................................155

DTC Confirmation Procedure ................................155

Wiring Diagram - AT - MMSW ...............................156

Diagnosis Procedure .............................................158

Component Inspection ...........................................159

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ................................................................

160

Wiring Diagram - AT - MAIN ..................................160

Diagnosis Procedure .............................................161

CLOSED THROTTLE POSITION AND WIDE

OPEN THROTTLE POSITION CIRCUIT .........

164

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

164

Diagnosis Procedure .............................................164

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 77 of 3924

AT-4

BRAKE SIGNAL CIRCUIT ..............................165

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

165

Diagnosis Procedure .............................................165

A/T INDICATOR CIRCUIT ...............................166

Description ........................................................... ..166

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

166

Diagnosis Procedure .............................................166

TROUBLE DIAGNOSIS FOR SYMPTOMS .....167

Wiring Diagram - AT - NONDTC .......................... ..167

A/T Check Indicator Lamp Does Not Come On .....170

Engine Cannot Be Started in "P" or "N" Position ...170

In "P" Position, Vehicle Moves When Pushed .......171

In "N" Position, Vehicle Moves ..............................172

Large Shock ("N" to "D" Position) ..........................173

Vehicle Does Not Creep Backward in "R" Position ..175

Vehicle Does Not Creep Forward in "D" Position ..178

Vehicle Cannot Be Started from D1 .......................180

A/T Does Not Shift: D1→ D2 ................................ ..182

A/T Does Not Shift: D2→ D3 ................................ ..184

A/T Does Not Shift: D3→ D4 ................................ ..186

A/T Does Not Shift: D4→ D5 ................................ ..188

A/T Does Not Lock-up ......................................... ..190

A/T Does Not Hold Lock-up Condition ...................192

Lock-up Is Not Released .......................................194

Engine Speed Does Not Return to Idle .................194

Cannot Be Changed to Manual Mode ...................195

A/T Does Not Shift: 5th Gear → 4th Gear ........... ..196

A/T Does Not Shift: 4th Gear → 3rd Gear ........... ..197

A/T Does Not Shift: 3rd Gear → 2nd Gear .......... ..199

A/T Does Not Shift: 2nd Gear → 1st Gear ........... ..201

Vehicle Does Not Decelerate by Engine Brake ... ..202

SHIFT CONTROL SYSTEM ............................205

Control Device Removal and Installation ............. ..205

Control Rod Removal and Installation ...................206

Adjustment of A/T Position ....................................207

Checking of A/T Position .......................................207

A/T SHIFT LOCK SYSTEM .............................208

Description ........................................................... ..208

Shift Lock System Electrical Parts Location ..........208

Wiring Diagram - AT - SHIFT .................................209

Diagnosis Procedure .............................................209

KEY INTERLOCK CABLE ...............................212

Component .......................................................... ..212

Removal and Installation .......................................212

ON-VEHICLE SERVICE ...................................215

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

215

Parking Component (2WD Models Only) ..............226

Rear Oil Seal .........................................................233

Revolution Sensor Component (2WD Models

Only) .....................................................................

233

AIR BREATHER HOSE ....................................239

Removal and Installation ...................................... .239

TRANSMISSION ASSEMBLY ..........................241

Removal and Installation (2WD Models) .............. .241

Removal and Installation (AWD Models) ..............243

OVERHAUL ......................................................249

Component .......................................................... .249

Oil Channel ...........................................................261

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

264

DISASSEMBLY .............................................. ..267

Disassembly ......................................................... .267

REPAIR FOR COMPONENT PARTS ..............285

Oil Pump .............................................................. .285

Front Sun Gear, 3rd One-Way Clutch ...................287

Front Carrier, Input Clutch, Rear Internal Gear .....289

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

295

High and Low Reverse Clutch ..............................301

Direct Clutch .........................................................303

ASSEMBLY .................................................... ..306

Assembly (1) ........................................................ .306

Adjustment ............................................................320

Assembly (2) .........................................................323

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

330

General Specification ........................................... .330

Vehicle Speed at Which Gear Shifting Occurs .....330

Vehicle Speed at Which Lock-up Occurs/Releas-

es ..........................................................................

331

Stall Speed ............................................................331

Line Pressure ........................................................331

A/T Fluid Temperature Sensor ..............................332

Turbine Revolution Sensor ...................................332

Vehicle Speed Sensor A/T (Revolution Sensor) ...332

Reverse Brake ......................................................332

Total End Play .......................................................332

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 103 of 3924

AT-30

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000001327136

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-43,

"CAN System Specification Chart".

JPDIA0484GB

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 106 of 3924

A/T CONTROL SYSTEMAT-33

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

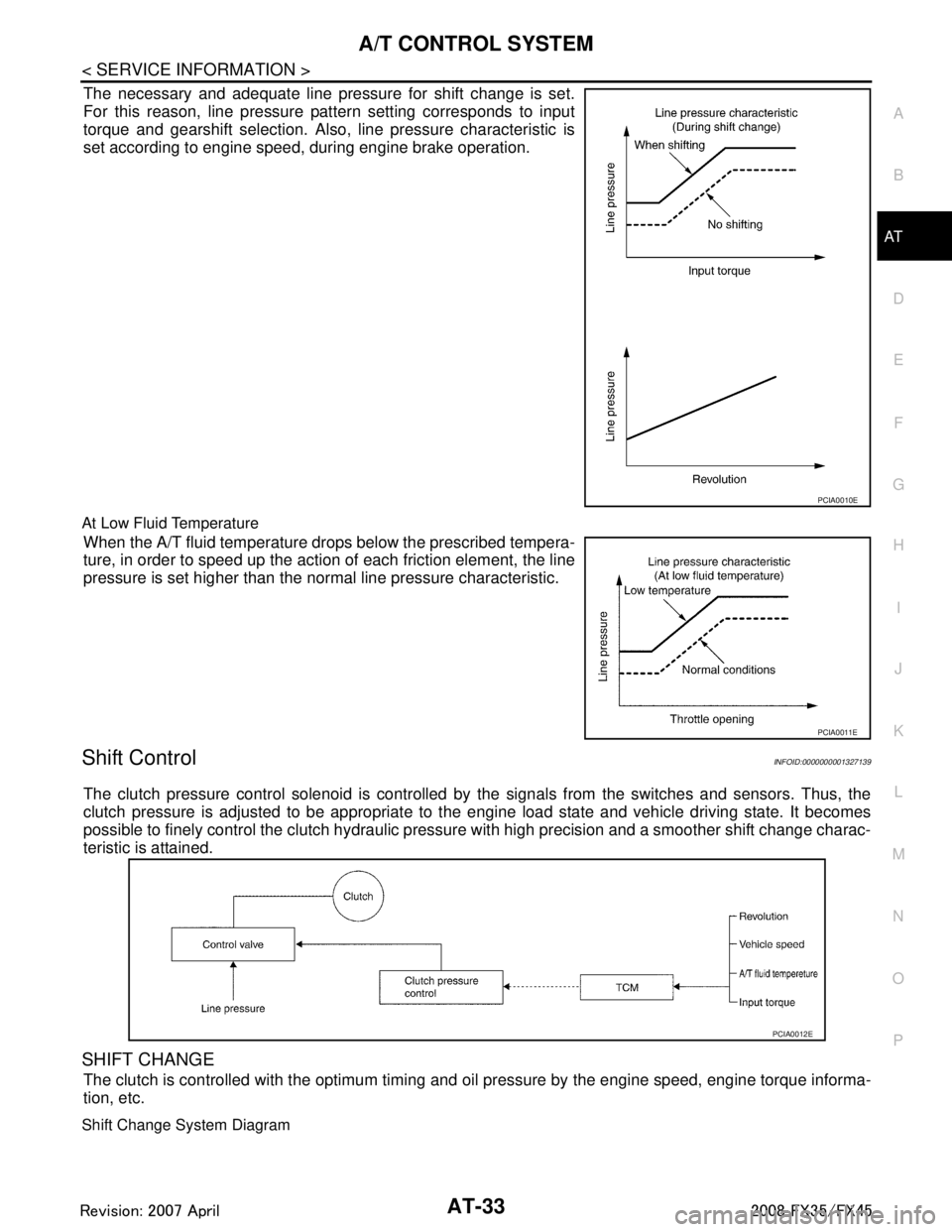

The necessary and adequate line pressure for shift change is set.

For this reason, line pressure pattern setting corresponds to input

torque and gearshift selection. Also, line pressure characteristic is

set according to engine speed, during engine brake operation.

At Low Fluid Temperature

When the A/T fluid temperature drops below the prescribed tempera-

ture, in order to speed up the action of each friction element, the line

pressure is set higher than the normal line pressure characteristic.

Shift ControlINFOID:0000000001327139

The clutch pressure control solenoid is controlled by the signals from the switches and sensors. Thus, the

clutch pressure is adjusted to be appropriate to t he engine load state and vehicle driving state. It becomes

possible to finely control the clutch hydraulic pressu re with high precision and a smoother shift change charac-

teristic is attained.

SHIFT CHANGE

The clutch is controlled with the optimum timing and oil pressure by the engine speed, engine torque informa-

tion, etc.

Shift Change System Diagram

PCIA0010E

PCIA0011E

PCIA0012E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 107 of 3924

AT-34

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

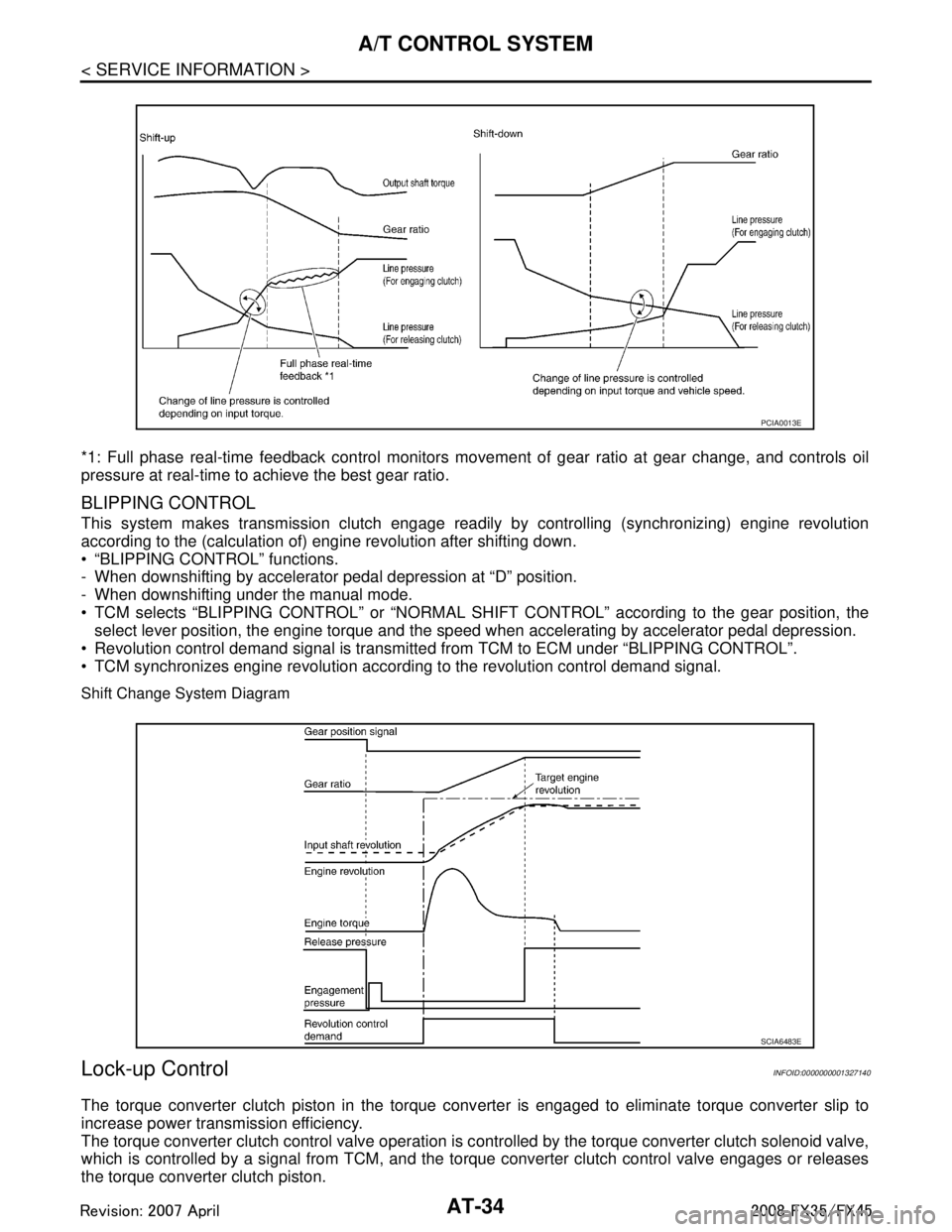

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

pressure at real-time to achieve the best gear ratio.

BLIPPING CONTROL

This system makes transmission clutch engage readily by controlling (synchronizing) engine revolution

according to the (calculation of) engine revolution after shifting down.

“BLIPPING CONTROL” functions.

- When downshifting by accelerator pedal depression at “D” position.

- When downshifting under the manual mode.

TCM selects “BLIPPING CONTROL” or “NORMAL SHIFT CONTROL” according to the gear position, the

select lever position, the engine torque and the speed when accelerating by accelerator pedal depression.

Revolution control demand signal is transmitted from TCM to ECM under “BLIPPING CONTROL”.

TCM synchronizes engine revolution according to the revolution control demand signal.

Shift Change System Diagram

Lock-up ControlINFOID:0000000001327140

The torque converter clutch piston in the torque conv erter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is c ontrolled by the torque converter clutch solenoid valve,

which is controlled by a signal from TCM, and the to rque converter clutch control valve engages or releases

the torque converter clutch piston.

PCIA0013E

SCIA6483E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 108 of 3924

A/T CONTROL SYSTEMAT-35

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Lock-up Operation Condition Table

TORQUE CONVERTER CLUTCH CONTROL VALVE CONTROL

Lock-up Control System Diagram

Lock-up Released

In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied

In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the torque

converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

SMOOTH LOCK-UP CONTROL

When shifting from the lock-up released state to the lock- up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In this way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

The current output from the TCM to the torque converte r clutch solenoid is varied to gradually increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put into

half-clutched status, the torque converter clutch pi ston operating pressure is increased and the coupling is

completed smoothly.

Slip Lock-up Control

In the slip region, the torque converter clutch solenoid cu rrent is controlled with the TCM to put it into the half-

clutched state. This absorbs the engine torque fluctuation and lock-up operates from low speed.

Engine Brake ControlINFOID:0000000001327141

The forward one-way clutch transmits the drive force from the engine to the rear wheels. But the reverse

drive from the rear wheels is not transmitted to the engine because the one-way clutch is idling.

selector lever D position M5 position M4 position M3 position

Gear position 54543

Lock-up ×– ×××

Slip lock-up ××–––

PCIA0014E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 122 of 3924

TROUBLE DIAGNOSISAT-49

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Circuit DiagramINFOID:0000000001327152

Inspections Before Trouble DiagnosisINFOID:0000000001327153

A/T FLUID CHECK

A/T Fluid Leakage and A/T Fluid Level Check

Check for A/T fluid leakage and check the A/T fluid level. Refer to AT- 11 , "Checking A/T Fluid".

TCWM0495E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 168 of 3924

DTC U1000 CAN COMMUNICATION LINEAT-95

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Wiring Diagram - AT - CANINFOID:0000000001327169

TCWM0496E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C