fuel filter INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2140 of 3924

![INFINITI FX35 2008 User Guide

EC-900

< SERVICE INFORMATION >[VK45DE]

DTC P0300 - P0308 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 8 CYLINDER MIS-

FIRE

Fuel lines (Refer to FL-3, "Checking Fuel Line".)

Fuel filter for clogging

>> Re INFINITI FX35 2008 User Guide

EC-900

< SERVICE INFORMATION >[VK45DE]

DTC P0300 - P0308 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 8 CYLINDER MIS-

FIRE

Fuel lines (Refer to FL-3, "Checking Fuel Line".)

Fuel filter for clogging

>> Re](/img/42/57017/w960_57017-2139.png)

EC-900

< SERVICE INFORMATION >[VK45DE]

DTC P0300 - P0308 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 8 CYLINDER MIS-

FIRE

Fuel lines (Refer to FL-3, "Checking Fuel Line".)

Fuel filter for clogging

>> Repair or replace.

13.CHECK IGNITION TIMING

Check the following items. Refer to EC-658, "

Basic Inspection".

OK or NG

OK >> GO TO 14.

NG >> Follow the Basic Inspection.

14.CHECK AIR FUEL RATIO (A/F) SENSOR 1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect air fuel ratio (A/F) sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals. Refer to Wiring Diagram.

5. Check harness continuity between the following terminals and ground. Refer to Wiring Diagram.

Items Specifications

Target idle speed 650 ± 50 rpm (in P or N position)

Ignition timing 12 ± 5 ° BTDC (in P or N position)

: Vehicle front 1. A/F sensor 1 (Bank 2)

harness connector2. A/F sensor 1 (Bank 1)

harness connector

A/F sensor 1 terminal ECM terminal

Bank 1 116

275

535

656

Bank 2 176

277

557

658

Continuity should exist.

Bank 1 Bank 2

A/F sensor 1 terminal ECM terminal A/F sensor 1 terminal ECM terminal 116176

PBIB3246E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2485 of 3924

EM-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

VQ35DE

SERVICE INFORMATION .. ..........................

4

PRECAUTIONS .............................................. .....4

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Drain Engine Coolant and Engine

Oil ..............................................................................

4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment ..........................................................................

4

Precaution for Assembly and Installation ..................5

Precaution for Angle Tightening ................................5

Precaution for Liquid Gasket .....................................5

PREPARATION ...................................................7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................9

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

12

NVH Troubleshooting - Engine Noise ................. ....12

Use the Chart Below to Help You Find the Cause

of the Symptom .......................................................

12

DRIVE BELTS ....................................................14

Checking Drive Belts ........................................... ....14

Tension Adjustment ................................................14

Removal and Installation .........................................15

AIR CLEANER AND AIR DUCT ........................17

Component .......................................................... ....17

Removal and Installation .........................................17

Changing Air Cleaner Filter .....................................18

INTAKE MANIFOLD COLLECTOR ...................19

Component .......................................................... ....19

Removal and Installation .........................................19

INTAKE MANIFOLD ...........................................24

Component .......................................................... ....24

Removal and Installation .........................................24

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

26

Component ..............................................................26

Removal and Installation .........................................26

OIL PAN AND OIL STRAINER .........................30

Component (2WD Models) ......................................30

Removal and Installation (2WD Models) .................30

Component (AWD Models) ......................................35

Removal and Installation (AWD Models) .................36

IGNITION COIL .................................................42

Component ..............................................................42

Removal and Installation .........................................42

SPARK PLUG (PLATINUM-TIPPED TYPE) .....43

Component ..............................................................43

Removal and Installation .........................................43

FUEL INJECTOR AND FUEL TUBE ................45

Component ..............................................................45

Removal and Installation .........................................45

ROCKER COVER .............................................51

Component ..............................................................51

Removal and Installation .........................................51

FRONT TIMING CHAIN CASE .........................54

Removal and Installation .........................................54

TIMING CHAIN ..................................................64

Component .......................................................... ....64

Removal and Installation .........................................65

CAMSHAFT .......................................................83

Component ..............................................................83

Removal and Installation .........................................84

Valve Clearance ......................................................91

OIL SEAL ..........................................................97

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2486 of 3924

EM-2

Removal and Installation of Valve Oil Seal .............97

Removal and Installation of Front Oil Seal .............97

Removal and Installation of Rear Oil Seal ..............98

CYLINDER HEAD ............................................100

On-Vehicle Service .............................................. ..100

Component ............................................................101

Removal and Installation .......................................101

Disassembly and Assembly ...................................105

Inspection After Disassembly ................................107

ENGINE ASSEMBLY .......................................112

Component (2WD Models) .................................. ..112

Removal and Installation (2WD Models) ...............112

Component (AWD Models) ....................................117

Removal and Installation (AWD Models) ...............117

CYLINDER BLOCK .........................................122

Component .......................................................... ..122

Disassembly and Assembly ...................................123

How to Select Piston and Bearing .........................134

Inspection After Disassembly ................................138

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

149

Standard and Limit .............................................. ..149

VK45DE

SERVICE INFORMATION ..........................

160

PRECAUTIONS .............................................. .160

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

160

Precaution for Drain Engine Coolant and Engine

Oil ..........................................................................

160

Precaution for Disconnecting Fuel Piping ..............160

Precaution for Removal and Disassembly .............160

Precaution for Inspection, Repair and Replace-

ment .......................................................................

160

Precaution for Assembly and Installation ..............161

Parts Requiring Angle Tightening ..........................161

Precaution for Liquid Gasket .................................161

PREPARATION .............................................. .163

Special Service Tool ............................................ ..163

Commercial Service Tool ......................................164

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ..........................

167

NVH Troubleshooting - Engine Noise .................. ..167

Use the Chart Below to Help You Find the Cause

of the Symptom .....................................................

167

ENGINE ROOM COVER ..................................169

Component .......................................................... ..169

Removal and Installation .......................................169

DRIVE BELTS ..................................................170

Component .......................................................... ..170

Checking Drive Belts .............................................170

Tension Adjustment ...............................................170

Removal and Installation ...................................... .170

Component ...........................................................171

Drive Belt Auto Tensioner and Idler Pulley ...........172

AIR CLEANER AND AIR DUCT .......................173

Component .......................................................... .173

Removal and Installation .......................................173

Changing Air Cleaner Filter ...................................174

INTAKE MANIFOLD .........................................175

Component .......................................................... .175

Removal and Installation .......................................176

EXHAUST MANIFOLD AND THREE WAY

CATALYST .......................................................

179

Component .......................................................... .179

Removal and Installation .......................................179

OIL PAN AND OIL STRAINER ........................183

Component .......................................................... .183

Removal and Installation .......................................183

IGNITION COIL .................................................187

Component .......................................................... .187

Removal and Installation .......................................187

SPARK PLUG (PLATINUM-TIPPED TYPE) ....188

Component .......................................................... .188

Removal and Installation .......................................188

FUEL INJECTOR AND FUEL TUBE ................190

Component .......................................................... .190

Removal and Installation .......................................190

ROCKER COVER .............................................196

Component .......................................................... .196

Removal and Installation .......................................196

TIMING CHAIN .................................................199

Component .......................................................... .199

Removal and Installation .......................................200

CAMSHAFT ......................................................211

Component .......................................................... .211

Removal and Installation .......................................211

Valve Clearance ....................................................218

OIL SEAL ..........................................................222

Removal and Installation of Valve Oil Seal ...........222

Removal and Installation of Front Oil Seal ........... .222

Removal and Installation of Rear Oil Seal ............224

CYLINDER HEAD .............................................226

On-Vehicle Service .............................................. .226

Component ...........................................................227

Removal and Installation .......................................227

Disassembly and Assembly ..................................229

Inspection After Disassembly ................................232

ENGINE ASSEMBLY ..................................... ..237

Component .......................................................... .237

Removal and Installation .......................................237

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2833 of 3924

FL-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION FL

A

FL

N

O P

CONTENTS

FUEL SYSTEM

SERVICE INFORMATION .. ..........................2

PREPARATION .............................................. .....2

Commercial Service Tool .................................... ......2

FUEL SYSTEM ....................................................3

Checking Fuel Line ............................................. ......3

General Precaution ...................................................3

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY ..........................

4

Component .......................................................... ......4

Removal and Installation ..................................... .....4

Component ...............................................................8

Disassembly and Assembly ......................................8

FUEL TANK ..................................... .................10

Component .......................................................... ....10

Removal and Installation .........................................10

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

12

Standard and Limit ..................................................12

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2836 of 3924

FL-4

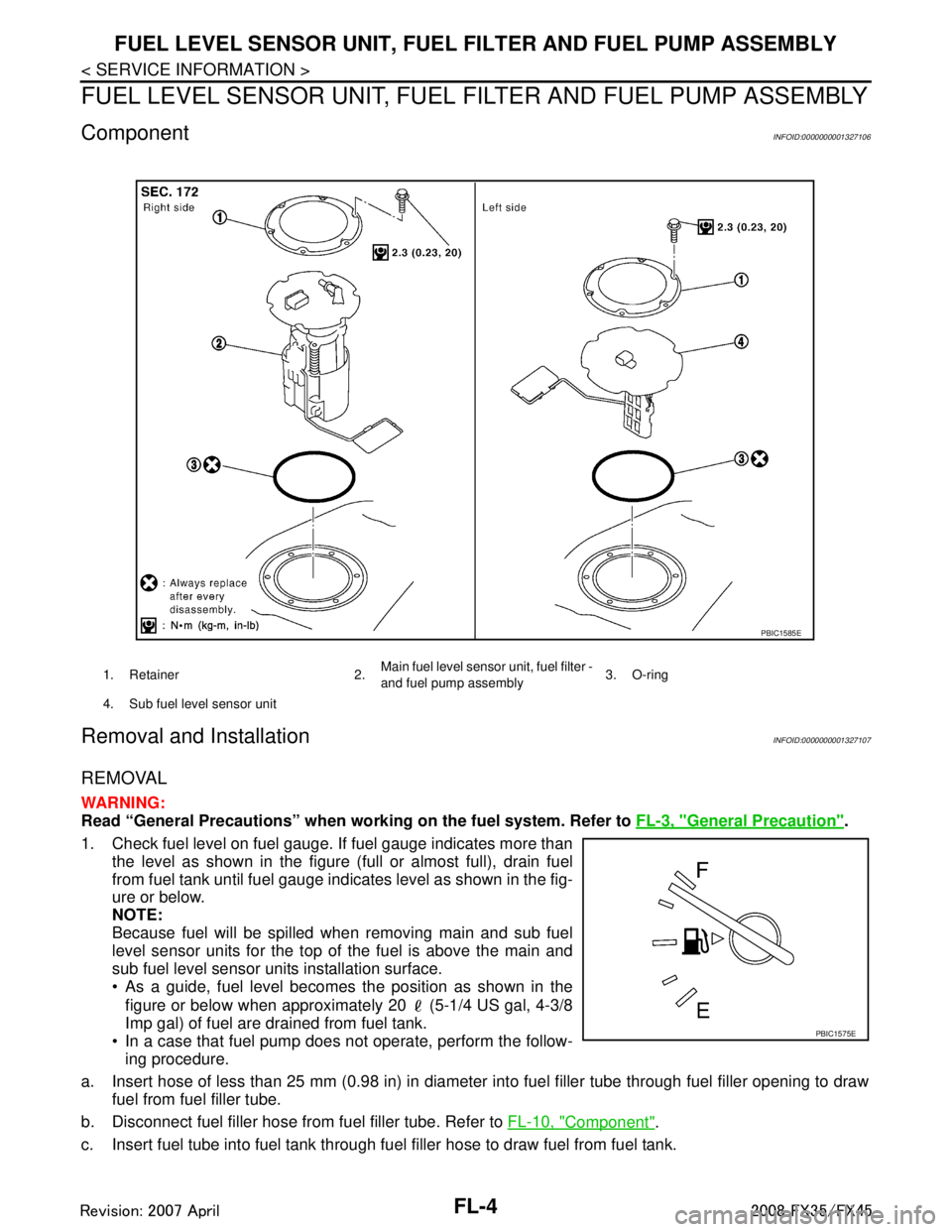

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

ComponentINFOID:0000000001327106

Removal and InstallationINFOID:0000000001327107

REMOVAL

WARNING:

Read “General Precautions” when wo rking on the fuel system. Refer to FL-3, "

General Precaution".

1. Check fuel level on fuel gauge. If fuel gauge indicates more than the level as shown in the figure (full or almost full), drain fuel

from fuel tank until fuel gauge indicates level as shown in the fig-

ure or below.

NOTE:

Because fuel will be spilled when removing main and sub fuel

level sensor units for the top of the fuel is above the main and

sub fuel level sensor units installation surface.

• As a guide, fuel level becomes the position as shown in the

figure or below when approximately 20 (5-1/4 US gal, 4-3/8

Imp gal) of fuel are drained from fuel tank.

In a case that fuel pump does not operate, perform the follow-

ing procedure.

a. Insert hose of less than 25 mm (0.98 in) in diameter into fuel filler tube through fuel filler opening to draw

fuel from fuel filler tube.

b. Disconnect fuel filler hose from fuel filler tube. Refer to FL-10, "

Component".

c. Insert fuel tube into fuel tank through fuel filler hose to draw fuel from fuel tank.

1. Retainer 2. Main fuel level sensor unit, fuel filter -

and fuel pump assembly

3. O-ring

4. Sub fuel level sensor unit

PBIC1585E

PBIC1575E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2837 of 3924

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-5

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K L

M A

FL

NP

O

2. Release the fuel pressure from the fuel lines. Refer to

EC-87, "Fuel Pressure Check" (VQ35DE) or EC-

665, "Fuel Pressure Check" (VK45DE).

3. Open fuel filler lid.

4. Open filler cap and release the pressure inside fuel tank.

5. Remove rear seat cushion. Refer to SE-95, "

Removal and Installation".

6. Peel off floor carpet, then remove inspection hole cover for main and sub fuel level sensor units by turning clips clockwise by 90

degrees.

7. Disconnect harness connector and fuel feed tube.

Disconnect quick connector as follows: Hold the sides of connector, push in tabs and pull out tube.

If quick connector sticks to tube of main fuel level sensor unit, push and pull quick connector several times until they start to

move.Then disconnect them by pulling.

CAUTION:

PBIC1576E

PBIC1577E

SFE562A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2838 of 3924

FL-6

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Quick connector can be disconnected when the tabs are

completely depressed. Do not twist it more than neces-

sary.

Do not use any tools to disconnected quick connector.

Keep resin tube away from heat. Be especially careful when welding near the resin tube.

Prevent acid liquid such as battery electrolyte, etc. from getting on resin tube.

Do not bend or twist resin tube during installation and

disconnection.

Do not remove the remaining retainer on hard tube (or the equivalent) except when resin tube or retainer is

replaced.

When resin tube or hard tube (or the equivalent) is replaced, also replace retainer with new one.

To keep the connecting porti on clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags or something similar.

8. Remove main fuel level sensor unit, fuel filter and fuel pump assembly, and sub fuel level sensor unit as

follows:

CAUTION:

Do not bend float arm during removal.

Avoid impacts such as fallin g when handling components.

a. Removal of main fuel level sensor uni t, fuel filter and fuel pump assembly:

i. Remove retainer.

ii. Raise main fuel level sensor unit, fuel filter and fuel pump assembly, and using snap ring pliers, remove fuel hose connec-

tor.

CAUTION:

Be careful not to damage fu el hose connector by expanding

them excessively.

b. Removal of sub fuel level sensor unit:

i. Remove retainer.

ii. Raise and release sub fuel level sensor unit to remove.

INSTALLATION

Note to the following, and install in the reverse order of removal.

Main and Sub Fuel Level Sensor Unit

Retainer color: White

SBIA0504E

PBIC0163E

PBIC1578E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2839 of 3924

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-7

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K L

M A

FL

NP

O

When installing fuel hose connector insert them fully until a click

sound of full stopper engagement is heard.

Face main and sub fuel level sensor units as shown in the figure, and install them with the knock pin on back aligned with pin hole on

fuel tank.

Install retainer so that its notch becomes parallel with the notch on fuel tank.

Tighten retainer mounting bolts evenly.

Quick Connector

Connect quick connector as follows:

1. Check the connection for damage or any foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click sound is

heard.

3. After connecting, make sure that the connection is secure by following method. Pull the tube and the connector to make sure they are securelyconnected.

Visually confirm that the two retainer tabs are connected to the

connector.

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

PBIC1579E

PBIC1065E

PBIC1652E

PBIC1653E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2840 of 3924

FL-8

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

1. Turn ignition switch “ON” (with engine stopped), then check connections for leaks by applying fuel pres-

sure to fuel piping.

2. Start engine and let it idle and make sure there are no fuel leaks at the fuel system connections.

ComponentINFOID:0000000001327108

Disassembly and AssemblyINFOID:0000000001327109

CAUTION:

Sub fuel level sensor unit cannot be disassembled and should be replaced as a unit.

DISASSEMBLY

Remove fuel level sensor unit as follows.

1. Disconnect harness connector.

Hold connector by fingers and pull it out, because there is no

stopper release tab.

2. Using suitable tool, pull up tabs points as shown in the figure (two points) to release the lock.

CAUTION:

Be careful not to damage it.

1. Fuel level sensor unit 2. Fuel filter and fuel pump assembly

PBIC1081E

PBIC1078E

PBIC1654E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2841 of 3924

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-9

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K L

M A

FL

NP

O

3. After fixing tabs are disengaged, slide fuel level sensor unit out

in direction shown by the arrow.

CAUTION:

Do not disassemble fuel filt er and fuel pump assembly.

ASSEMBLY

1. Check for damage of fuel level sensor unit installa tion position on the side of fuel filter and fuel pump

assembly.

2. Slide fuel level sensor unit until it aligns to installation groove, then insert it until stop. After inserting, apply force in reverse direction (removal direction) to ensure it cannot be pulled out.

3. Connect harness connector. Securely insert harness connector until it stops.

PBIC1080E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C