steering INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 47 of 3924

![INFINITI FX35 2008 User Guide

ACS-40

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

Check continuity between ICC unit harness connector and stop lamp

switch harness connector.

OK or NG

OK >> 1. Replace INFINITI FX35 2008 User Guide

ACS-40

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

Check continuity between ICC unit harness connector and stop lamp

switch harness connector.

OK or NG

OK >> 1. Replace](/img/42/57017/w960_57017-46.png)

ACS-40

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

Check continuity between ICC unit harness connector and stop lamp

switch harness connector.

OK or NG

OK >> 1. Replace ICC unit.

2. Erase DTC and perform ICC system running test.Then perform self-diagnosis of ICC system again.

NG >> 1. Repair harness between ICC unit and stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 46 OPERATION SW CIRCINFOID:0000000001328832

1.CHECK CONNECTOR FOR ECM

1. Turn ignition switch OFF.

2. Disconnect ECM connector, and connect it securely again.

3. Erase DTC and perform ICC system running test. T hen perform self-diagnosis of ICC system again.

Is malfunction indicated?

YES >> GO TO 2.

NO >> Poor connector connection 1. Check connector. (Check connector housing for disconnected, loose, bent, and collapsed ter-minals. If any malfunction is detected, repair applicable part.)

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

2.CHECK ICC STEERING SWITCH

Check ICC steering switch. Refer to ACS-63, "

ICC Steering Switch".

OK or NG

OK >> GO TO 3.

NG >> 1. Replace ICC steering switch. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

3.CHECK ICC STEERING SWITCH SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM connector and spiral cable connector.

3. Check continuity between spiral cable harness connector and ECM harness connector.

ICC unit connector Terminal St op la mp sw i tc h

connector Terminal Continuity

M89 38 E210 2 Yes

PKIB4163E

Spiral cable connector Terminal ECM connector Terminal Continuity

M15 33

M90 82

Ye s

34 99

PKIB4164E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 67 of 3924

![INFINITI FX35 2008 User Guide

ACS-60

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Possible Irregular Condition

1.CHECK FUSES

Check that any of the fuses is blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be INFINITI FX35 2008 User Guide

ACS-60

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Possible Irregular Condition

1.CHECK FUSES

Check that any of the fuses is blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be](/img/42/57017/w960_57017-66.png)

ACS-60

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Possible Irregular Condition

1.CHECK FUSES

Check that any of the fuses is blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK ICC SYSTEM DISPLAY

1. Turn ignition switch ON.

2. Check if all displays illuminate.

Do all displays illuminate?

YES >> GO TO 3.

NO >> GO TO 6.

3.CHECK HARNESS BETWEEN ECM AND ICC STEERING SWITCH

1. Turn ignition switch OFF.

2. Disconnect ECM connector, and check terminals for bend and looseness.

3. Check continuity between ECM harness connector terminals.

Open or short lines Symptoms Malfunction causes

ICC unit power supply malfunction No voltage supply from ignition switch Fuse blown Harness open

Harness shorted

Ground cable not connected Harness open Harness shorted

ICC steering switch malfunction No signal transmitted Harness open Harness shorted

Spiral cable open

Spiral cable shorted

Switch or ECM malfunction

CAN communication system malfunction Signal not transmitted Harness open Harness shorted

CAN communication outside the standard.

Combination meter system malfunction Indication not possible Indicator display malfunction ICC system display segments disappear.

ICC unit malfunction ICC unit internal malfunction.

Unit Power source Fuse No.

ICC unit Ignition switch (ON) 12

Battery 35

ECM connector Terminal Condition Resistance

(Approx.)

M90 82 99 When MAIN switch pressed 0

Ω

When MAIN switch released 5.5 k Ω

PKIB4145E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 68 of 3924

![INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-61

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

4. Check continuity between ECM harness connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO INFINITI FX35 2008 User Guide

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-61

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

4. Check continuity between ECM harness connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO](/img/42/57017/w960_57017-67.png)

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-61

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

4. Check continuity between ECM harness connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK ICC STEERING SWITCH

Check ICC steering switch. Refer to ACS-63, "

ICC Steering Switch".

OK or NG

OK >> 1. Repair or replace harness between ECM and ICC steering switch. 2. Perform self-diagnosis mode for ICC system.

NG >> 1. Replace ICC steering switch. 2. Perform self-diagnosis mode for ICC system.

5.CHECK SELF-DIAGNOSIS

1. Connect ECM connector.

2. Turn ignition switch ON.

3. Perform self-diagnosis mode for ICC system.

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

6.CHECK CONNECTOR FOR ICC UNIT

1. Turn ignition switch OFF.

2. Disconnect ICC unit connector, and c heck terminals for bend and looseness.

3. Connect ICC unit connector.

4. Turn ignition switch ON.

5. Check if all displays illuminate.

Do all displays illuminate?

YES >> Perform self-diagnosis again.

NO >> GO TO 7.

7.CHECK POWER SUPPLY CIRCUIT FOR ICC UNIT

Check voltage between ICC unit harness connector terminals.

OK or NG

OK >> GO TO 8.

NG >> Repair ICC unit power supply harness.

8.CHECK GROUND CIRCUIT FOR ICC UNIT

ECM connector Terminal

GroundContinuity

M90 82

No

99

PKIB4146E

ICC unit connector Te r m i n a l

Voltage (Approx.)

(+) ( −)

M89 33

Ground Battery voltage

42

SKIA1173E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 70 of 3924

![INFINITI FX35 2008 User Guide

ELECTRICAL COMPONENT INSPECTIONACS-63

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ELECTRICAL COMPONENT INSPECTION

ICC Steering SwitchINFOID:0000000001328857

1. Disconnect ICC stee INFINITI FX35 2008 User Guide

ELECTRICAL COMPONENT INSPECTIONACS-63

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ELECTRICAL COMPONENT INSPECTION

ICC Steering SwitchINFOID:0000000001328857

1. Disconnect ICC stee](/img/42/57017/w960_57017-69.png)

ELECTRICAL COMPONENT INSPECTIONACS-63

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ELECTRICAL COMPONENT INSPECTION

ICC Steering SwitchINFOID:0000000001328857

1. Disconnect ICC steering switch.

2. Check resistance between ICC steering switch connector termi- nals by pressing each switch.

Booster SolenoidINFOID:0000000001328858

Disconnect booster solenoid/release switch connector, and measure

resistance between terminals 4 and 6.

Release SwitchINFOID:0000000001328859

Disconnect booster solenoid/release switch connector and check

resistance between the terminals.

NOTE:

If pedal is depressed insufficiently, resistance value may remain unchanged. Terminals Switch Condition Resistance [k

Ω]

14 15 MAIN

Pressed Approx. 0

Released Approx. 5.5

CANCEL Pressed Approx. 0.3

Released Approx. 5.5

DISTANCE Pressed Approx. 0.7

Released Approx. 5.5

SET/COAST Pressed Approx. 1.4

Released Approx. 5.5

RESUME/ACCELERATE Pressed Approx. 2.6

Released Approx. 5.5

PKIB4169E

Terminals Resistance [

Ω]

4 6 Approx. 1.4

PKIC5181E

Condition 1 - 3 1 - 2 2 - 3

Release

the brake pedal. Continuity should

exist. Continuity should

not exist. Continuity should

not exist.

Depress

the brake pedal. Continuity should

not exist. (Note) Continuity should

exist. (Note) Continuity should

not exist.

SKIA1256E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 73 of 3924

![INFINITI FX35 2008 User Guide

ACS-66

< SERVICE INFORMATION >[ICC]

REMOVAL AND INSTALLATION

CAUTION:

Adjust the laser beam aiming every time

the ICC sensor is removed or installed.

ICC Steering SwitchINFOID:0000000001328864

Refer INFINITI FX35 2008 User Guide

ACS-66

< SERVICE INFORMATION >[ICC]

REMOVAL AND INSTALLATION

CAUTION:

Adjust the laser beam aiming every time

the ICC sensor is removed or installed.

ICC Steering SwitchINFOID:0000000001328864

Refer](/img/42/57017/w960_57017-72.png)

ACS-66

< SERVICE INFORMATION >[ICC]

REMOVAL AND INSTALLATION

CAUTION:

Adjust the laser beam aiming every time

the ICC sensor is removed or installed.

ICC Steering SwitchINFOID:0000000001328864

Refer to PS-12, "Removal and Installation".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 406 of 3924

ATC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION AT C

A

B

AT C

N

O P

CONTENTS

AUTOMATIC AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Working with HFC-134a (R-134a) ......4

General Refrigerant Precaution ................................4

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ......................9

Precaution for Service Equipment .............................9

Precaution for Leak Detection Dye .........................11

PREPARATION ..................................................13

Special Service Tool ........................................... ....13

HFC-134a (R-134a) Service Tool and Equipment ....13

Commercial Service Tool ........................................16

REFRIGERATION SYSTEM ..............................17

Refrigerant Cycle ................................................ ....17

Refrigerant System Protection ................................17

V-6 Variable Displacement Compressor .................17

Component Part Location .......................................21

LUBRICANT ................................................... ....22

Maintenance of Lubricant Quantity in Compressor ....22

AIR CONDITIONER CONTROL .........................24

Description of Air Conditioner LAN Control Sys-

tem ...................................................................... ....

24

System Construction ...............................................24

Description of Control System .................................27

Control Operation ....................................................27

Fail-Safe Function ...................................................28

Discharge Air Flow ..................................................29

System Description .................................................30

CAN Communication System Description ...............30

TROUBLE DIAGNOSIS .....................................32

CONSULT-III Function ........................................ ....32

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

32

Component Parts and Harness Connector Loca-

tion ...........................................................................

34

Schematic ................................................................36

Wiring Diagram - A/C - ............................................37

Auto Amp. Terminal and Reference Value ..............42

Self-Diagnosis Function ...........................................43

Operational Check ...................................................50

Power Supply and Ground Circuit for Auto Amp .....52

LAN System Circuit .................................................54

Mode Door Motor Circuit .........................................57

Air Mix Door Motor Circuit .......................................59

Air Mix Door Motor PBR Circuit ...............................62

Intake Door Motor Circuit .........................................62

Blower Motor Circuit ................................................64

Magnet Clutch Circuit ..............................................69

Insufficient Cooling ..................................................75

Insufficient Heating ..................................................82

Noise .......................................................................83

Self-Diagnosis .........................................................84

Memory Function .....................................................85

Ambient Sensor Circuit ............................................86

In-vehicle Sensor Circuit ..........................................88

Sunload Sensor Circuit ............................................91

Intake Sensor Circuit ...............................................94

CONTROLLER ..................................................97

Removal and Installation of A/C and AV Switch ......97

AUTO AMP ........................................................98

Removal and Installation of Unified Meter and A/C

Amp .........................................................................

98

AMBIENT SENSOR ..........................................99

Removal and Installation .........................................99

IN-VEHICLE SENSOR ....................................100

Removal and Installation .......................................100

SUNLOAD SENSOR .......................................101

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 408 of 3924

PRECAUTIONSATC-3

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612929

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000001612931

NOTE:

This Procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 514 of 3924

HEATER & COOLING UNIT ASSEMBLYATC-109

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

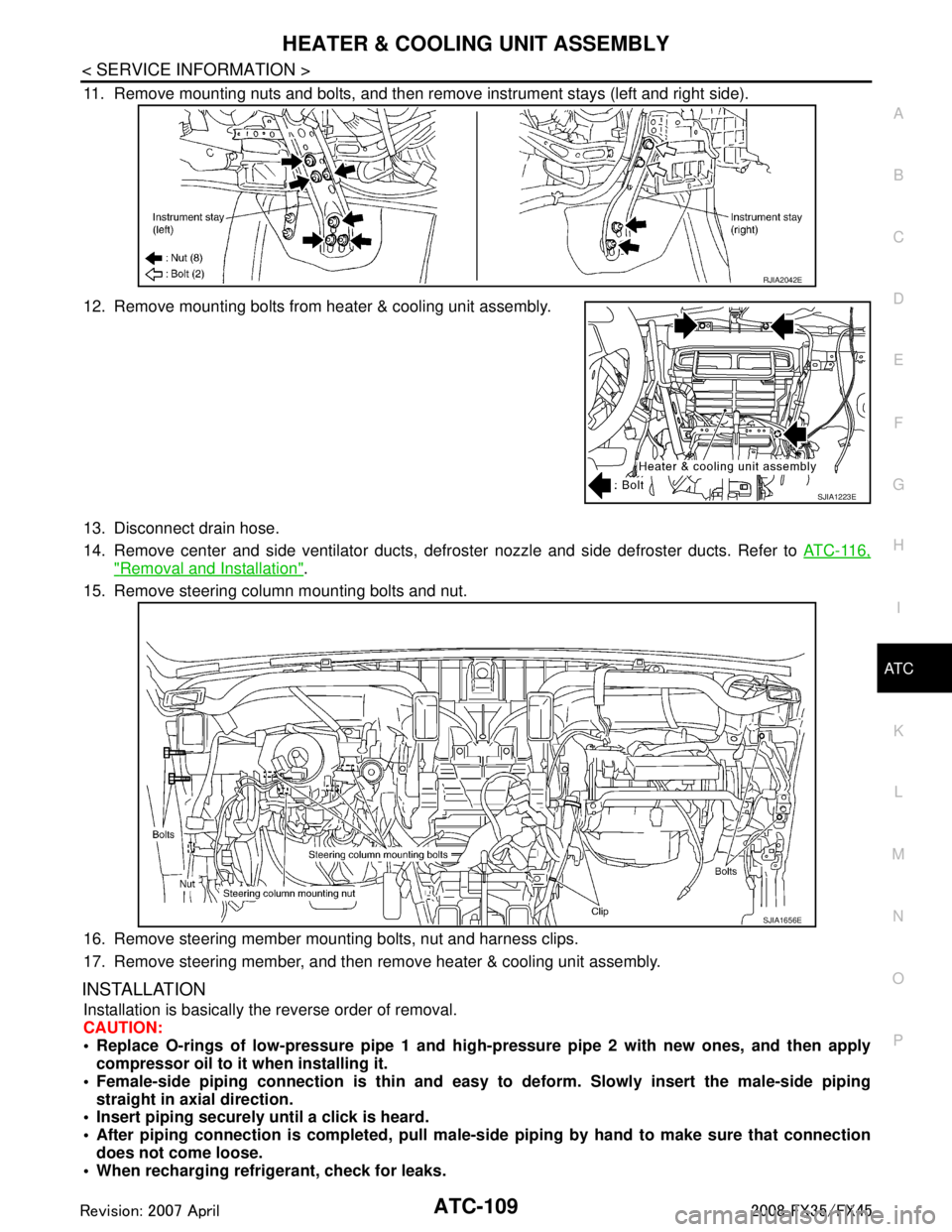

11. Remove mounting nuts and bolts, and then remove instrument stays (left and right side).

12. Remove mounting bolts from heater & cooling unit assembly.

13. Disconnect drain hose.

14. Remove center and side ventilator ducts, defroster nozzle and side defroster ducts. Refer to ATC-116,

"Removal and Installation".

15. Remove steering column mounting bolts and nut.

16. Remove steering member mounting bolts, nut and harness clips.

17. Remove steering member, and then remove heater & cooling unit assembly.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings of low-pressure pipe 1 and high- pressure pipe 2 with new ones, and then apply

compressor oil to it when installing it.

Female-side piping c onnection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is comple ted, pull male-side piping by hand to make sure that connection

does not come loose.

When recharging refrigerant, check for leaks.

RJIA2042E

SJIA1223E

SJIA1656E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 515 of 3924

ATC-110

< SERVICE INFORMATION >

HEATER & COOLING UNIT ASSEMBLY

NOTE:

When filling radiator with coolant, refer to CO-10, "

Changing Engine Coolant" (VQ35DE) or CO-37, "Chang-

ing Engine Coolant" (VK45DE).

Recharge the refrigerant.

Heater & cooling unit assembly mounting bolt: 6.8 N·m (0.69 kg-m, 60 in-lb)

Steering member mounting nut and bolt : 12 N·m (1.2 kg-m, 9 fl-lb)

Steering column mounting nut and bolt : 16.7 N·m (1.7 kg-m, 12 fl-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 540 of 3924

REFRIGERANT LINESATC-135

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

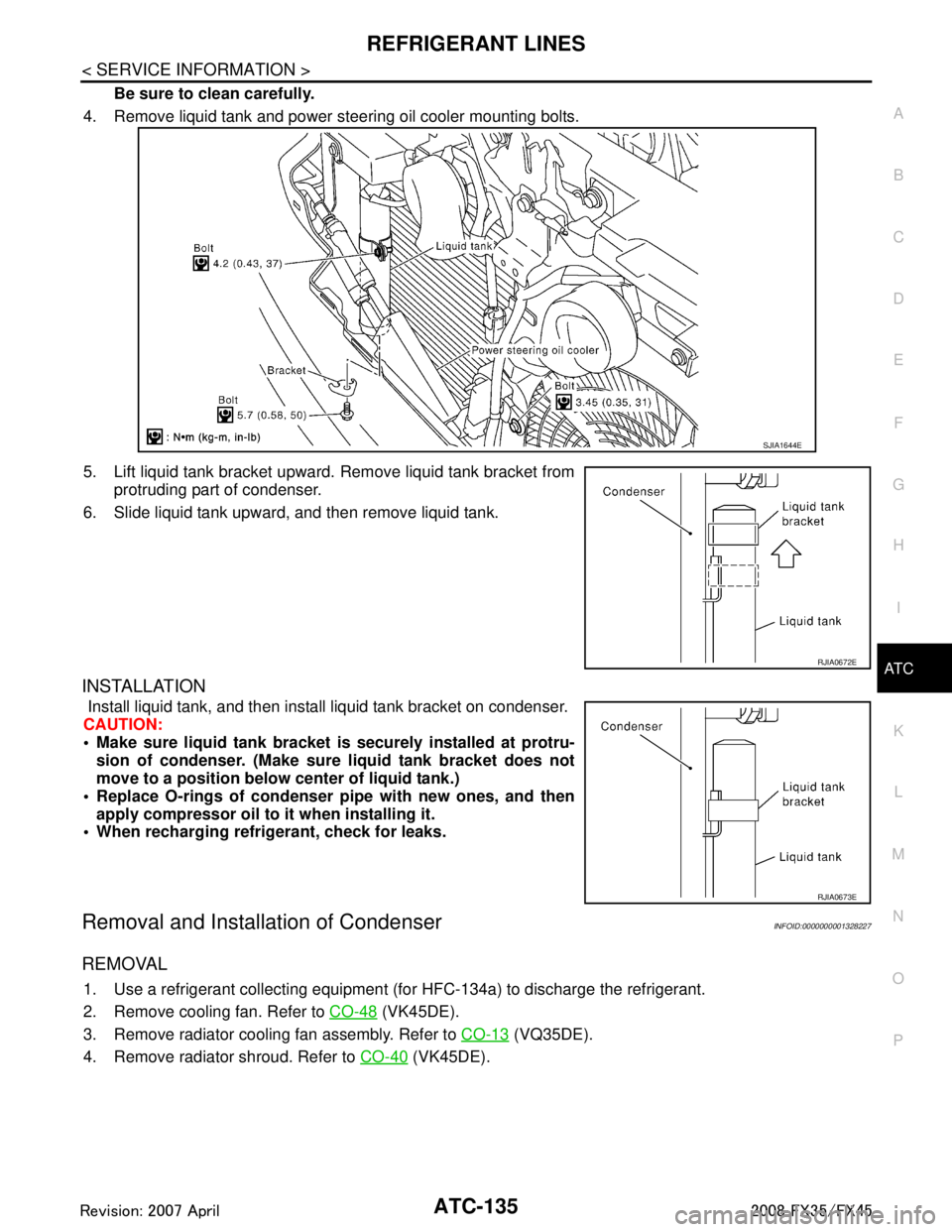

Be sure to clean carefully.

4. Remove liquid tank and power steering oil cooler mounting bolts.

5. Lift liquid tank bracket upward. Remove liquid tank bracket from protruding part of condenser.

6. Slide liquid tank upward, and then remove liquid tank.

INSTALLATION

Install liquid tank, and then install liquid tank bracket on condenser.

CAUTION:

Make sure liquid tank bracket is securely installed at protru- sion of condenser. (Make sure liquid tank bracket does not

move to a position below center of liquid tank.)

Replace O-rings of condenser pipe with new ones, and then

apply compressor oil to it when installing it.

When recharging refrigerant, check for leaks.

Removal and Installation of CondenserINFOID:0000000001328227

REMOVAL

1. Use a refrigerant collecting equipment (f or HFC-134a) to discharge the refrigerant.

2. Remove cooling fan. Refer to CO-48

(VK45DE).

3. Remove radiator cooling fan assembly. Refer to CO-13

(VQ35DE).

4. Remove radiator shroud. Refer to CO-40

(VK45DE).

SJIA1644E

RJIA0672E

RJIA0673E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C