steering INFINITI FX35 2008 Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 718 of 3924

TELEPHONEAV-171

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

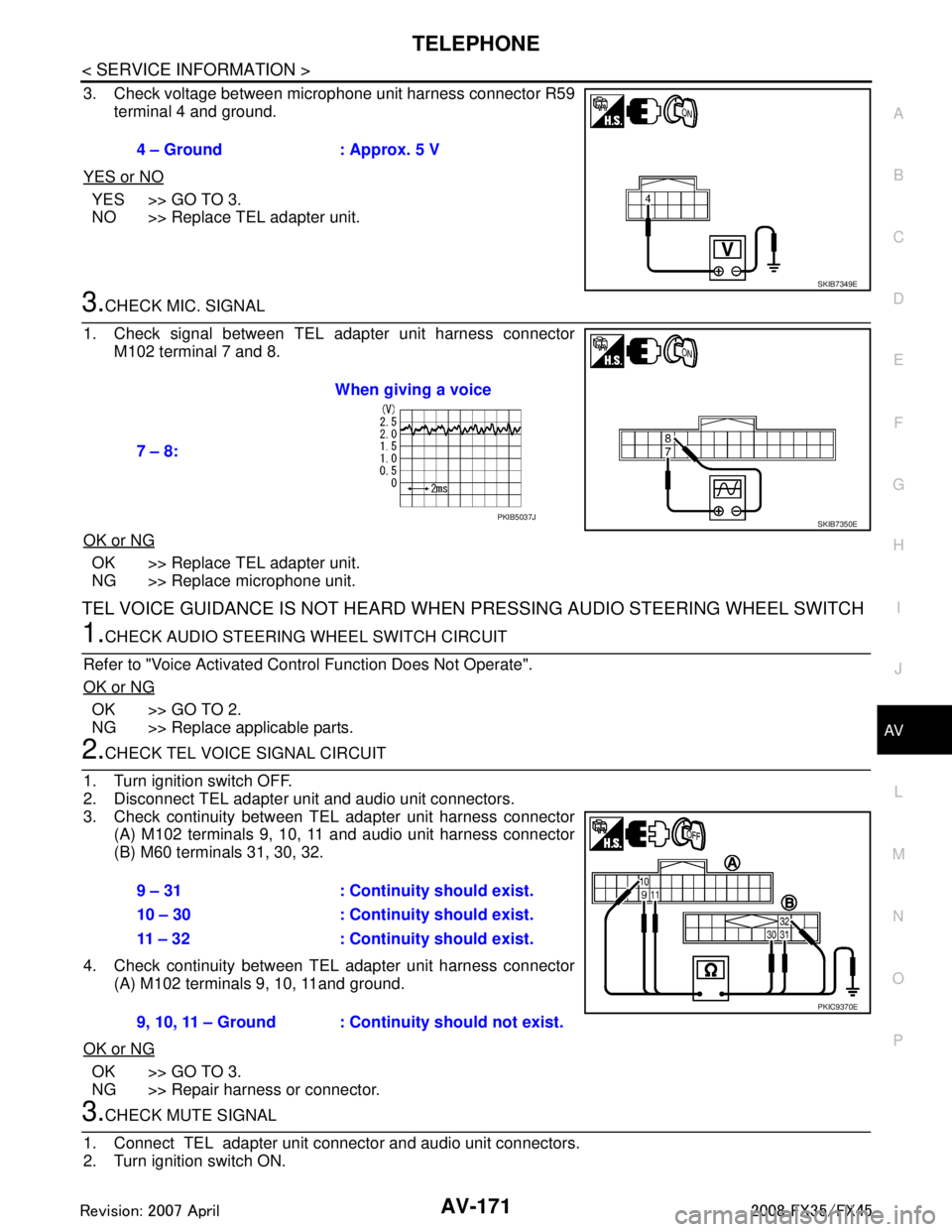

3. Check voltage between microphone unit harness connector R59 terminal 4 and ground.

YES or NO

YES >> GO TO 3.

NO >> Replace TEL adapter unit.

3.CHECK MIC. SIGNAL

1. Check signal between TEL adapter unit harness connector M102 terminal 7 and 8.

OK or NG

OK >> Replace TEL adapter unit.

NG >> Replace microphone unit.

TEL VOICE GUIDANCE IS NOT HEARD WHEN PRESSING AUDIO STEERING WHEEL SWITCH

1.CHECK AUDIO STEERING WHEEL SWITCH CIRCUIT

Refer to "Voice Activated Control Function Does Not Operate".

OK or NG

OK >> GO TO 2.

NG >> Replace applicable parts.

2.CHECK TEL VOICE SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TEL adapter unit and audio unit connectors.

3. Check continuity between TEL adapter unit harness connector (A) M102 terminals 9, 10, 11 and audio unit harness connector

(B) M60 terminals 31, 30, 32.

4. Check continuity between TEL adapter unit harness connector (A) M102 terminals 9, 10, 11and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK MUTE SIGNAL

1. Connect TEL adapter unit connector and audio unit connectors.

2. Turn ignition switch ON. 4 – Ground : Approx. 5 V

SKIB7349E

7 – 8:

When giving a voice

SKIB7350EPKIB5037J

9 – 31 : Continuity should exist.

10 – 30 : Continuity should exist.

11 – 32 : Continuity should exist.

9, 10, 11 – Ground : Continuity should not exist.

PKIC9370E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 735 of 3924

BL-1

BODY

C

DE

F

G H

J

K L

M

SECTION BL

A

B

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

DTC INDEX ..................................................... .....4

INTELLGENT KEY UNIT U1000 ...............................4

INTELLGENT KEY UNIT B2013-B2014 ............. ......4

ECM P1610-P1615 ...................................................4

PRECAUTIONS ...................................................5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

5

Precaution for Work ..................................................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................6

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .......................................................................

7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ............9

Diagnostic Worksheet .............................................11

HOOD .................................................................13

Fitting Adjustment ............................................... ....13

Removal and Installation of Hood Assembly ...........14

Removal and Installation of Hood Lock Control ......15

Hood Lock Control Inspection ............................. ....16

RADIATOR CORE SUPPORT ...........................18

Removal and Installation ..................................... ....18

FRONT FENDER ................................................20

Removal and Installation ..................................... ....20

POWER DOOR LOCK SYSTEM ........................21

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

21

System Description .................................................22

CAN Communication System Description ...............23

CAN Communication Unit .................................... ....23

Schematic/With Intelligent Key ................................24

Wiring Diagram - D/LOCK -/With Intelligent Key .....25

Schematic/Without Intellig ent Key ...........................30

Wiring Diagram - D/LOCK -/Without Intelligent

Key ...................................................................... ....

31

Terminal and Reference Value for BCM ..................35

Terminal and Reference Value for Intelligent Key

Unit (With Intelligent Key System) ...........................

35

Work Flow ................................................................36

CONSULT-III Function (BCM) .................................36

Trouble Diagnosis Chart by Symptom .....................37

Check BCM Power Supply and Ground Circuit .......37

Check Door Switch ..................................................38

Check Key Switch ....................................................42

Check Door Lock and Unlock Switch ......................43

Check Door Lock Actuator (Driver Side) .................45

Check Door Lock Actuator (Passenger Side and

Rear LH/RH) ............................................................

45

Check Fuel Lid Lock Actuator ..................................46

Check Front Door Key Cylinder Switch (Lock) ........47

Check Front Door Key Cylinder Switch (Unlock) .....47

Check Select Unlock Relay Circuit ..........................48

REMOTE KEYLESS ENTRY SYSTEM .............50

Component Parts and Harness Connector Loca-

tion ...........................................................................

50

System Description ..................................................50

CAN Communication System Description ...............53

CAN Communication Unit ........................................53

Schematic ................................................................54

Wiring Diagram - KEYLES - ....................................55

Terminal and Reference Value for BCM ..................58

Terminal and Reference Value for IPDM E/R ..........59

CONSULT-III Function (BCM) .................................60

Work Flow ................................................................62

Trouble Diagnosis Chart by Symptom .....................62

Check Key Fob Battery and Function ......................63

Check ACC Switch ..................................................64

Check Door Switch ..................................................65

Check Key Switch ....................................................68

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 736 of 3924

BL-2

Check Remote Keyless Entry Receiver ..................69

Check IPDM E/R Operation ....................................71

Check Hazard Warning Lamp Function ..................72

Check Horn Function ..............................................72

Check Headlamp Function .....................................72

Check Map Lamp and Ignition Keyhole Illumina-

tion Function ...........................................................

72

ID Code Entry Procedure .......................................73

Removal and Installation of Remote keyless Entry

receiver ................................................................ ...

75

Key Fob Battery Replacement ................................75

INTELLIGENT KEY SYSTEM ............................76

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

76

System Description .................................................78

CAN Communication System Description ..............83

CAN Communication Unit .......................................84

Schematic ...............................................................84

Wiring Diagram - I/KEY - ........................ ................86

Terminal and Reference Value for INTELLIGENT

KEY UNIT ........... ................................. ...................

99

Terminal and Reference Value for Steering Lock

unit ....................................................................... ..

101

Terminal and Reference Value for BCM ................101

Terminal and Reference Value for IPDM E/R ........102

Diagnosis Procedure .............................................103

CONSULT-III Functions (INTELLIGENT KEY) ......103

CONSULT-III Application Item ............................. ..104

List of Operation Related Parts .............................105

Trouble Diagnosis Symptom Chart ........................106

Check CAN Communication System Inspection ....111

Check Intelligent Key Unit Power Supply and

Ground Circuit ..................................................... ..

111

Check Key Switch (Intelligent Key Unit Input) .......112

Check Key Switch (BCM Input) ........................... ..113

Check Ignition Knob Switch ...................................114

Check Door Switch ................................................115

Check Unlock Sensor ............................................117

Check Door Request Switch ..................................119

Check Intelligent Key Warning Buzzer ..................120

Check Outside Key Antenna ............................... ..121

Check Inside Key Antenna ....................................123

Check Steering Lock Unit ......................................124

Check Stop Lamp Switch ......................................126

Check Park Position Switch ...................................126

Check Select Unlock Relay ...................................128

Check Hazard Function .........................................128

Check Horn Function .............................................129

Check Headlamp Function ....................................129

Check IPDM E/R Operation ...................................129

Removal and Installation of Intelligent Key Unit ....130

Intelligent Key Battery Re placement .....................130

DOOR .............................................................. .131

Fitting Adjustment ................................................ ..131

Removal and Installation of Front Door .................132

Removal and Installation of Rear Door ..................133

Removal and Installation of Door Weatherstrip .....134

FRONT DOOR LOCK .......................................135

Removal and Installation ...................................... .135

REAR DOOR LOCK .........................................138

Removal and Installation ...................................... .138

BACK DOOR .................................................. ..141

Fitting Adjustment ................................................ .141

Back Door Assembly .............................................141

Removal and Installation of Back Door Striker .....142

Removal and Installation of Back Door Stay .........143

Removal and Installation of Dave Tail Male & Fe-

male ..................................................................... .

144

Removal and Installation of Back Door Weather-

strip .......................................................................

144

BACK DOOR LOCK ASSEMBLY ....................146

Removal and Installation of Back Door Lock &

Closure Assembly ................................................ .

146

Removal and Installation of Back Door Opener

Switch ...................................................................

146

Disassembly and Assembly ..................................147

BACK DOOR AUTO CLOSURE SYSTEM ......148

Component Parts and Harness Connector Loca-

tion ....................................................................... .

148

System Description ...............................................148

Wiring Diagram - B/CLOS - ...................................150

Terminal and Reference Value for Back Door Clo-

sure Control Unit ...................................................

152

Work Flow .............................................................153

Preliminary Check .................................................153

Trouble Diagnosis Chart by Symptom ..................153

Check Back Door Closure Control Unit Power

Supply and Ground Circuit ....................................

153

Check Half-Latch Switch .......................................154

Check Close Switch ..............................................155

Check Open Switch ..............................................156

Check Back Door Opener Switch (With Intelligent

Key) ...................................................................... .

157

Check Back Door Opener Switch (Without Intelli-

gent Key) ...............................................................

159

Check Unlock Sensor (Without Intelligent Key) ....160

Check Closure Motor ........................................... .161

Removal and Installation of Back Door Closer

Control Unit ...........................................................

162

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ...........................................................

163

Component Parts and Harness Connector Loca-

tion ....................................................................... .

163

System Description ...............................................164

CAN Communication System Description ............166

CAN Communication Unit .....................................166

Schematic .............................................................167

Wiring Diagram - VEHSEC - .................................168

Terminal and Reference Value for BCM ...............173

Terminal and Reference Value for IPDM E/R .......174

CONSULT-III Function ..........................................174

Trouble Diagnosis .................................................176

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 737 of 3924

BL-3

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Preliminary Check ...............................................

..

177

Trouble Diagnosis Symptom Chart .......................177

Diagnosis Procedure 1 ..........................................178

Diagnosis Procedure 2 ..........................................182

Diagnosis Procedure 3 ..........................................183

Diagnosis Procedure 4 ..........................................183

Diagnosis Procedure 5 ..........................................183

Diagnosis Procedure 6 ..........................................184

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) ......................................................

185

Component Parts and Harness Connector Loca-

tion ...................................................................... ..

185

System Description ...............................................185

System Composition .............................................186

ECM Re-Communicating Function ........................187

Wiring Diagram - NATS - ......................................188

Terminal and Reference Value for Steering Lock

Unit/with Intelligent Key System ............................

191

Terminal and Reference Value for Intelligent Key

Unit/with Intelligent Key System ............................

191

Terminal and Reference Value for BCM ............. ..192

CONSULT-III Function ..........................................192

Diagnosis Procedure .............................................194

Trouble Diagnosis Symptom Chart ...................... ..195

Security Indicator Inspection .................................195

Diagnosis Procedure 1 ..........................................195

Diagnosis Procedure 2 ..........................................197

Diagnosis Procedure 3 ..........................................197

Diagnosis Procedure 4 ..........................................197

Diagnosis Procedure 5 ..........................................198

Diagnosis Procedure 6 ..........................................200

Removal and Installation NATS Antenna Amp ......201

INTEGRATED HOMELINK TRANSMITTER ..202

Wiring Diagram - TRNSCV - ..................................202

Trouble Diagnosis ..................................................202

BODY REPAIR ................................................204

Body Exterior Paint Color ......................................204

Body Component Parts .........................................205

Corrosion Protection ..............................................208

Body Sealing .........................................................211

Body Construction .................................................215

Body Alignment .....................................................215

Handling Precaution for Plastics ............................225

Precaution in Repairing High Strength Steel .........228

Replacement Operation .........................................230

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 738 of 3924

BL-4

< SERVICE INFORMATION >

DTC INDEX

SERVICE INFORMATION

DTC INDEX

INTELLGENT KEY UNIT U1000INFOID:0000000001529387

INTELLGENT KEY UNIT B2013-B2014INFOID:0000000001529388

ECM P1610-P1615INFOID:0000000001529389

CONSULT display Descr iption Reference page

U1000: CAN COMM CIRCUIT M alfunction is detected in CA N communication.

BCS-13, "

U1000 CAN

Communication Circuit"

CONSULT display Descr iption Reference page

B2013: STRG COMM 1 .Malfunction is detected in communication of Intelligent

Key unit and steering lock unit BL-124, "

Check Steering

Lock Unit"

B2014: STRG COMM 2

Malfunction is detected in communication of Intelligent Key

unit and steering lock unit. BL-124, "Check Steering

Lock Unit"

CONSULT display Descr

iption Reference page

P1610: LOCK MODE When the starting operation is carried out 5 or more times

consecutively under the following conditions, IVIS(NATS)

will shift the mode to prevent the engine start.

• unregistered ignition key is used (without intelligent key

system)

BCM or ECM malfunctioning BL-198, "

Diagnosis Proce-

dure 5"

P1611: ID DISCORD, IMM-ECM

The result of ID verification between BCM and ECM is NG.

System initialization is required. BL-197, "Diagnosis Proce-

dure 4"

P1612: CHAIN OF ECM-IMMU Communication impossible between ECM and BCM.

BL-197, "Diagnosis Proce-

dure 2"

P1613: ECM INT CIRC-IMMUThe malfunction of ECM internal circuit to BCM communi-

cation line is detected. BL-195, "Diagnosis Proce-

dure 1"

P1614: CHAIN OF IMMU-KEY BCM cannot receive the key ID signal.

BL-200, "Diagnosis Proce-

dure 6"

P1615: DIFFERENCE OF KEY

BCM can receive the key ID signal but the result of ID ver-

ification between key ID and BCM is NG. BL-197, "Diagnosis Proce-

dure 3"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 739 of 3924

PRECAUTIONSBL-5

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612892

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000001612889

NOTE:

This Procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for WorkINFOID:0000000001327777

After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their

operation.

Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 752 of 3924

BL-18

< SERVICE INFORMATION >

RADIATOR CORE SUPPORT

RADIATOR CORE SUPPORT

Removal and InstallationINFOID:0000000001327787

REMOVAL

1. Remove the front fender protector. Refer to EI-24, "Component Parts Location".

2. Remove the front bumper. Refer to EI-14, "

Component Parts Location".

3. Remove the ICC. Refer to ACS-65

.

4. Remove the headlamp. Refer to LT-30, "

Removal and Installation".

5. Remove the washer tank. Refer to WW-28, "

Removal and Installation of Washer Tank".

6. Remove the resonator. Refer to EM-17

or EM-173.

7. Remove the power steering oil cooler. Refer to PS-37

.

8. Remove the ambient sensor. Refer to ATC-99, "

Removal and Installation".

9. Remove the crash zone sensor. Refer to SRS-42, "

Removal and Installation".

10. Remove the horn connector, cooling fan connector and harness clip.

11. Remove the hood lock and disconnect hood lock control cable. Refer to BL-15, "

Removal and Installation

of Hood Lock Control".

12. Remove the reservoir tank. Refer to CO-40, "

Removal and Installation" or CO-13, "Removal and Installa-

tion".

13. Remove mounting blots and remove radiator core support. Remove mounting bolts with power tool.

14. After remove radiator core suppor t, remove the horn, cooling fan.

1. Radiator core support assembly 2. Bolt 3. Bolt

4. Horn (High) 5. Air guide (RH) 6. Cooling fan

7. Air guide (LH) 8. Horn (Low)

PIIA6018E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 814 of 3924

BL-80

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

door switch OFF (when all the doors are closed);

Remote control button of Intelligent Key turns on interior lamp (for 30 seconds) with input of UNLOCK signal

from Intelligent Key.

Panic Alarm Function

When key switch is OFF and ignition knob is not pushed (when mechanical key is not inserted in ignition

knob), BCM turns ON and OFF horn and headlamp intermit tently with input of PANIC ALARM signal from

Intelligent Key. The alarm automatically turns off after 25 seconds or when Intelligent Key unit receives any

signal from Intelligent Key.

Panic alarm operation mode can be changed using “WORK SUPPORT” mode in “PANIC ALARM DELAY”.

Refer to BL-104, "

CONSULT-III Application Item".

Remote Control Power Window Down (Open) Operation

When Intelligent Key unlock switch is turned ON with i gnition switch OFF, and Intelligent Key unlock switch is

detected to be on continuously for 3 seconds, the driver's door and passenger's door power windows are

simultaneously opened.

Power window is operated to open and the operation continues as long as the Intelligent Key unlock switch is

pressed.

Remote control power window down operation mode can be changed using “P/W DOWN DELAY” mode in

“WORK SUPPORT”. Refer to BL-104, "

CONSULT-III Application Item".

Key Reminder Function

As an operation verification function, when doors are lock ed or unlocked using Intelligent Key remote control-

ler button operation, hazard lamps flash and horn sounds.

ENGINE STARTUP FUNCTION

Operation Description

When ignition knob is pressed, Intelligent Key unit sends request signal from inside key antenna, key-ID ver- ification is conducted with Intelligent Key using two-wa y communication, and if verification is successful, an

ignition rotation prohibition latch release signal is sent to steering lock unit. Steering lock unit releases igni-

tion knob rotation prohibition latch. (Ignition knob can now be turned.)

When it becomes possible to rotate the ignition knob, “KEY” warning lamp in combination meter lights up green to notify driver that ignition knob can be turned.

NOTE:

When it becomes impossible to rotate the ignition knob, “KEY” warning lamp in combination meter lights up

red.

When key-ID verification is successful and ignition knob switch is in the ON state, Intelligent Key unit uses CAN communication to send engine start permission signal to BCM.

When BCM receives engine start permission signal, it uses CAN communication to sent starter request sig-

nal to IPDM E/R so that the engine will start when ignition knob is rotated to START position.

Operation Range

Engine can be started when Intelligent Key is in the v ehicle. However, sometimes engine might not start when

Intelligent Key is on instrument panel, rear parcel shelf, or in glove box.

NOTE:

luggage room can enable detection of Intelligent Key by a CONSULT-III function. Refer to BL-104, "

CON-

SULT-III Application Item".

Active Check Function

Confirm whether or not ignition knob can be rotated by checking the color of warning lamp in combination

meter.

WARNING AND ALARM FUNCTION

Vehicle operation Hazard lamp Horn

Door unlocking operation Once —

Door locking operation Twice Once

Condition Operation

Ignition knob rotation possib le “KEY” warning lamp in combin ation meter is lit up green.

Ignition rotation not possibl e “KEY” warning lamp in combin ation meter is lit up red.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 817 of 3924

INTELLIGENT KEY SYSTEMBL-83

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Intelligent Key remote controller button and door reques t switch operations change the engine startup function

settings (startup enabled/disabled) for each Intelligent Key independently.

Settings Change Procedure1. With the ignition switch is in the LOCK positi on (ignition knob not pressed), hold down both the LOCK and

UNLOCK remote control buttons on the Intelligent Key at the same time for at least 10 seconds (The yard-

stick is that the Intelligent Key LED flashes 20 times.)

2. Within 5 seconds of releasing the Intelligent Key remote controller buttons, press the driver door request

switch.

3. The KEY warning lamp in combination meter lights up for 3 seconds (engine starting enabled → starting

disabled: lights up red, engine starting disabled → flashes green). This completes the settings change.

Changing Settings Using CONSULT-III

The settings for the Intelligent Key system func tions can be changed using CONSULT-III (WORK SUPPORT).

Refer to BL-104, "

CONSULT-III Application Item".

NOTE:

Once a function setting is changed, it will remain effective even if the battery is disconnected.

Changing Settings Using Display Unit

The settings of the Intelligent Key system can be changed, using CONSULT-III, display unit, Intelligent Key

and door request switch in the cent er of the instrument panel.

NOTE:

Once a function setting is changed, it will remain effective even if the battery is disconnected.

INTELLIGENT KEY REGISTRATION

Intelligent Key-ID registration is executed using the CONSULT-III. Up to 4 can be registered.

CAUTION:

After a new Intelligent Key-ID is regi stered, be sure to check the function.

When registering an additional Intelligent Key-ID , take any Intelligent Keys already registered and

Intelligent Keys for any other vehicles out of the vehicle before starting.

CONSULT-III can be used to check and delete Intelligent Key-IDs.

For future information, see the CO NSULT-III Operation Manual NATS.

STEERING LOCK UNIT REGISTRATION

Steering Lock Unit ID Registration

CAUTION:

The method for registering a steering lock unit ID depends on the status of the steering lock unit and

Intelligent Key unit (new or old unit).

After registration is completed, press ignition knob with a portable unit in the vehicle so that it can

be rotated, and confirm that it cannot be rotated even when ignition switch is pressed without a por-

table unit in the vehicle.

For further information, see the CONS ULT-III Operation Manual NATS.

CAN Communication System DescriptionINFOID:0000000001327838

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

Setting item Description

Intelligent Key Lock Response-Sound The sound pattern of the Intelligent Key operation can be set as desired. (Setting value:

OFF, Beeper or Horn chirp)

Intelligent Key Unlock Response-Beep

Sound The beep sound when unlocking door with the Intelligent Key operation can be turned ON

or OFF.

Intelligent Key Engine Start Function This function can be performed to ON or OFF.

Intelligent Key Lock/Unlock Function The door handle request switch lock/unlock operation with the Intelligent Key can be can-

celed or activated.

Return All Settings to Default The all settings made by VEHICLE ELECTRONICS will return to default.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 833 of 3924

INTELLIGENT KEY SYSTEMBL-99

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Terminal and Reference Valu e for INTELLIGENT KEY UNITINFOID:0000000001327842

Te r -

minal Wire

color Item Signal

Input/

output Condition

Voltage (V)(Approx.)

Ignition

knob po- sition Operation or conditions

1R/W Steering lock unit power

supply

Output LOCK — 5

2 L CAN-H Input/

Output —— —

3 P CAN-L Input/

Output —— —

4LG Intelligent Key warning

buzzer Output LOCKOperate remote

controller button or door request switch. Buzzer OFF Battery voltage

Sound

buzzer

0

5W/L Door request switch

(driver side) Input —Door request switch operation:

Press (ON).

0

Other than the above (OFF) 5

6 W Ignition switch (ON) Input ON or

START — Battery voltage

7 B/W key switch Input LOCK Insert mechanical key into igni-

tion key cylinder.

Battery voltage

Remove mechanical key from ig-

nition key cylinder. 0

10 LG Ignition switch (ACC) Input ACC or

ON — Battery voltage

11 L/R Power source (Fuse) Input — — Battery voltage

12 B Ground — — — 0

13 P Inside key antenna (+)

(Luggage room) Output

LOCKAny door open

→ all doors shut

(Door switch: ON → OFF)

14 L Inside key antenna (-)

(Luggage room)

Output

15 G Inside key antenna (+)

signal

(Dashboard) Output

LOCKAny door open

→ Close (Door

switch: ON → OFF)

Ignition knob switch: ON (press

ignition knob.)

16 R Inside key

antenna (-)

signal

(Dashboard) Output

17 L Back door antenna (+) Output

LOCKBack door request switch opera-

tion (Switch: ON)

18 W/L Back door antenna (-) Output

SIIA1910J

SIIA1910J

SIIA1910J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C