window INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1 of 3924

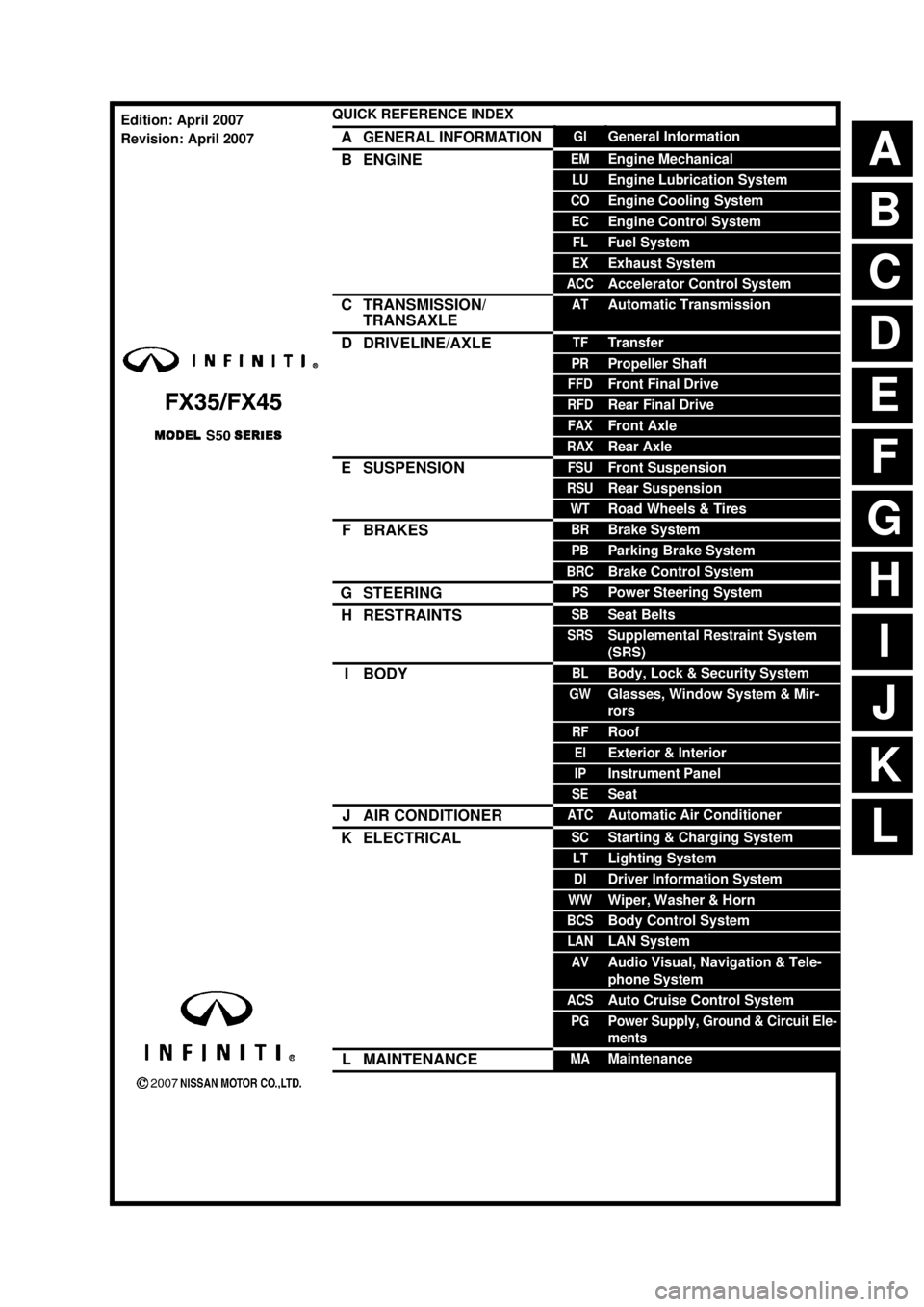

ABCDEFGHIJKLQUICK REFERENCE INDEX AGENERAL INFORMATIONGIGeneral InformationBENGINEEMEngine MechanicalLUEngine Lubrication SystemCOEngine Cooling SystemECEngine Control SystemFLFuel SystemEXExhaust SystemACCAccelerator Control SystemCTRANSMISSION/

TRANSAXLEATAutomatic TransmissionDDRIVELINE/AXLETFTransferPRPropeller ShaftFFDFront Final DriveRFDRear Final DriveFAXFront AxleRAXRear AxleESUSPENSIONFSUFront SuspensionRSURear SuspensionWTRoad Wheels & TiresFBRAKESBRBrake SystemPBParking Brake SystemBRCBrake Control SystemGSTEERINGPSPower Steering SystemHRESTRAINTSSBSeat BeltsSRSSupplemental Restraint System

(SRS)IBODYBLBody, Lock & Security SystemGWGlasses, Window System & Mir-

rorsRFRoofEIExterior & InteriorIPInstrument PanelSESeatJAIR CONDITIONERATCAutomatic Air ConditionerKELECTRICALSCStarting & Charging SystemLTLighting SystemDIDriver Information SystemWWWiper, Washer & HornBCSBody Control SystemLANLAN SystemAVAudio Visual, Navigation & Tele-

phone SystemACSAuto Cruise Control SystemPGPower Supply, Ground & Circuit Ele-

mentsLMAINTENANCEMAMaintenanceEdition: April 2007

Revision: April 2007

Page 21 of 3924

![INFINITI FX35 2008 Service Manual

ACS-14

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

OutlineINFOID:0000000001328812

Adjust the laser beam aiming every time the ICC sensor is removed or insta INFINITI FX35 2008 Service Manual

ACS-14

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

OutlineINFOID:0000000001328812

Adjust the laser beam aiming every time the ICC sensor is removed or insta](/img/42/57017/w960_57017-20.png)

ACS-14

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

OutlineINFOID:0000000001328812

Adjust the laser beam aiming every time the ICC sensor is removed or installed.

CAUTION:

Adjust laser beam aiming at a horizontal place as

far as 12 m (39 ft) forward the vehicle can be seen.

Adjust laser beam aiming 5 seconds after starting engine.

Never view ICC sensor integrated un it body window directly during laser beam aiming adjustment.

Follow the CONSULT-III when adju sting the laser beam aiming (laser beam aiming adjustment can-

not be operated without CONSULT-III).

Never ride on vehicle during l aser beam aiming adjustment.

Idle and turn headlamps OFF duri ng laser beam aiming adjustment.

PreparationINFOID:0000000001328813

Adjust the tire pressure to the specified value.

See that there is no load in the vehicle.

Coolant, engine oil filled up to correct level and full fuel tank.

Shift the gear into “P” position and release the parking brake.

Clean the ICC sensor with a soft cloth.

Outline of Adjustment ProcedureINFOID:0000000001328814

1. Set up the ICC target board [KV99110100 (J-45718)].

2. Adjust the sensor following the procedure on CONSUL T-III. (Turn manually the screw for up-down position

adjustment. ICC sensor automatically adjust the right-left position.)

Setting the ICC Target BoardINFOID:0000000001328815

Accurate ICC target board setting is required for the laser beam aiming adjustment.

CAUTION:

ICC system does not function normally if laser beam aiming is not accurate.

ADJUSTING HEIGHT OF THE TARGET

1. Attach a triangle scale at the center.

SKIA6179E

SKIA5974E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 22 of 3924

![INFINITI FX35 2008 Service Manual

LASER BEAM AIMING ADJUSTMENTACS-15

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

2. Adjust the height of the target board stand so that the point of the triangle aims the cent er of INFINITI FX35 2008 Service Manual

LASER BEAM AIMING ADJUSTMENTACS-15

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

2. Adjust the height of the target board stand so that the point of the triangle aims the cent er of](/img/42/57017/w960_57017-21.png)

LASER BEAM AIMING ADJUSTMENTACS-15

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

2. Adjust the height of the target board stand so that the point of the triangle aims the cent er of the ICC sensor.

ADJUSTING THE RIGHT-LEFT POSITION OF THE TARGET

1. Attach a scale [at least 350 mm (14 in) or longer] or stick as

shown in the figure.

2. Suspend a thread with weight on the tip of the thread to 310 mm (12.2 in) left side of the target board from the center of the target

board on top.

SETTING THE TARGET

1. Suspend a thread with weight on tip to splice the cent er of the front and rear bumpers. Then, mark the

center point on the ground as each weight points.

2. Link the front and rear bumpers center points ma rked on the ground, and mark a point 5 m (16.4 ft) ahead

of the sensor, on the extended line of the previous lin k line of the bumper center points. Then, adjust the

position of the target board so that the weight come on the top of the marked point [5 m (16.4 ft) ahead of

the sensor] and face to the vehicle.

3. Adjust the position of the target board so that the extended line that links the center of the rear window glass (the center of the

rear window defogger pattern) and the center of the windshield

(the setting part of the room mirror) align with the weight sus-

pended from the board.

4. Remove the thread suspended to the left side of board and sus- pend a thread with weight on tip on the center of the target

board. Then mark the point of weight on the ground.

SKIA6180E

SKIA1211E

SKIA5975E

SKIA1213E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 43 of 3924

![INFINITI FX35 2008 Service Manual

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

DTC 11 CONTROL UNIT

INFOID:0000000001328826

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC sy INFINITI FX35 2008 Service Manual

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

DTC 11 CONTROL UNIT

INFOID:0000000001328826

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC sy](/img/42/57017/w960_57017-42.png)

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

DTC 11 CONTROL UNIT

INFOID:0000000001328826

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC system.

2. Check if any item other than “DTC 11 CONTRO L UNIT” is indicated on self-diagnosis display.

Is any indicated?

YES >> 1. Repair or replace applicable item. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC unit.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 20 CAN COMM CIRCUITINFOID:0000000001328827

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Turn ignition switch ON and wait for 2 second or more.

2. Check self-diagnosis of ICC system.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to LAN-14, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-35, "

CONSULT-III/GST Data Link Connector (DLC) Circuit".

92 ECM CIRCUIT ×××× ECM malfunction

Accelerator pedal position sensor

malfunction

ICC unit malfunction ACS-50

96 NP RANGE

××× Park/neutral position switch har-

ness is open or shorted.

Park/neutral position switch mal- function.

TCM malfunction ACS-51

97 AT CIRCUIT

××× TCM malfunctionACS-52

98 GEAR POSITION ××× TCM malfunction

AT turbine revolution sensor mal-

function

AT vehicle speed sensor malfunc-

tion ACS-52

102 RADAR STAIN

×× × ICC sensor body window has con-

tamination. ACS-53

103 LASER SENSOR FAIL

×× × ICC sensor internal malfunctionACS-53

104 LASER AIMING INCMP ×× × Laser beam aiming of ICC sensor

is not adjusted. ACS-54

107 LASER COMM FAIL

×× × CAN data received by ICC sensor

is strange (from ICC unit, combina-

tion meter or ECM). ACS-54

109 LASER HIGH TEMP

×× × Temperature around ICC sensor is

excessively high. ACS-54

DTC

No. CONSULT-III

screen terms ICC

system

warning lamp Fail-safe

Malfunctions detected where... Refer-

ence

page

Vehicle-

to-

vehicle

distance control mode Conven-

tional

(fixed

speed) cruise

control mode Brake as-

sist (with

preview

function)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 60 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-53

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK TCM GEAR POSITION SIGNAL

With “Dat INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-53

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK TCM GEAR POSITION SIGNAL

With “Dat](/img/42/57017/w960_57017-59.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-53

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK TCM GEAR POSITION SIGNAL

With “Data Monitor” of “TCM”, chec k that gear positions are correct.

OK or NG

OK >> 1. Replace ICC unit. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Perform TCM self-diagnosis. 2. After repairing or replacing applicable item , erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

5.CHECK TCM TURBINE ROTATION

With TCM diagnosis, check that turbine rpm is normal. Refer to AT-106, "

Diagnosis Procedure".

OK or NG

OK >> 1. Replace ICC unit. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Perform TCM self-diagnosis. 2. After repairing or replacing applicable item , erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

DTC 102 RADAR STAININFOID:0000000001328843

1.VISUAL INSPECTION 1

Check that there is no contamination and fo reign material on ICC sensor body window.

OK or NG

OK >> GO TO 2.

NG >> 1. If any, remove them. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

2.VISUAL INSPECTION 2

Check ICC sensor body window for cracks.

OK or NG

OK >> GO TO 3.

NG >> 1. Replace ICC sensor, and adjust laser beam aiming. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

3.ASKING COMPLAINTS

1. Ask if there is any trace of contamination or foreign material on ICC sensor.

2. Ask if vehicle was driven in snow or ICC sensor was frosted.

3. Ask if ICC sensor was fogged temporarily. (Fr ont window glass may have also tended to be fogged.)

Is there any symptom?

YES >> Explain difference in displays between cont amination detection result and current indication to

customer, and tell them “This is not malfunction”.

NO >> 1. Replace ICC sensor, and adjust laser beam aiming. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

DTC 103 LASER SENSOR FAILINFOID:0000000001328844

1.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC system.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 65 of 3924

![INFINITI FX35 2008 Service Manual

ACS-58

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Chime does not sound when the system does not det

ect any vehicle ahead. (Diagnose the conditions under

which the system is detect INFINITI FX35 2008 Service Manual

ACS-58

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Chime does not sound when the system does not det

ect any vehicle ahead. (Diagnose the conditions under

which the system is detect](/img/42/57017/w960_57017-64.png)

ACS-58

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Chime does not sound when the system does not det

ect any vehicle ahead. (Diagnose the conditions under

which the system is detecting the vehicle ahead and when the system is malfunctioning. If there is any mal-

function in detecting the vehicle ahead, check the system following the ACS-58, "

Symptom 7 ICC System

Frequently Cannot Detect the Vehicl e Ahead/ Detection Zone Is Short".

1.CHECK ICC WARNING CHIME

With “Active Test” of “ICC”, check t hat ICC warning chime operates normally.

OK or NG

OK >> Determine preceding vehicle detection status when malfunction occurred. If chime should have

sounded: after replacing ICC unit. Perform ICC system running test, and then perform self-diag-

nosis of ICC system again.

NG >> GO TO 2.

2.PERFORM SELF-DIAGNOSIS OF ICC SYSTEM

1. Perform self-diagnosis of ICC system.

2. Check if “DTC 20 CAN COMM CIRCUIT” is indicated.

Is it indicated?

YES >> Refer to ACS-36, "DTC 20 CAN COMM CIRCUIT".

NO >> GO TO 3.

3.PERFORM SELF-DIAGNOSIS OF UNIFIED METER AND A/C AMP.

Perform self-diagnosis of unified meter and A/C amp. Refer to DI-27, "

CONSULT-III Function (METER/M&A)".

OK or NG

OK >> 1. Replace combination meter. 2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Symptom 6 Driving Force Is HuntingINFOID:0000000001328854

1.CHECK SELF-DIAGNOSIS OF ECM

Perform self-diagnosis of ECM.

OK or NG

OK >> Refer to ACS-58, "Symptom 7 ICC System Frequently Cannot Detect the Vehicle Ahead/ Detec-

tion Zone Is Short".

NG >> 1. Repair or replace applicable parts.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Symptom 7 ICC System Frequent ly Cannot Detect the Vehicle Ahead/ Detection Zone

Is Short

INFOID:0000000001328855

The detection function may become unstable in the following cases.

When the reflector of the vehicle ahead is def icient/ not clean enough to reflect the radar.

When driving a road with extremely sharp corners.

When the radar cannot detect the reflector of the vehicle ahead as the vehicle ahead is passing a hill or

passing the peak.

1.VISUAL CHECK

Check ICC sensor body window for contamination and foreign materials.

OK or NG

OK >> If any contamination or foreign materials ar e found, remove them. Then perform ICC system run-

ning test.

NG >> GO TO 2.

2.CHECK FUNCTION

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 66 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-59

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

After adjusting ICC sensor beam aiming, perform ICC system running test. Check that preceding veh INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-59

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

After adjusting ICC sensor beam aiming, perform ICC system running test. Check that preceding veh](/img/42/57017/w960_57017-65.png)

TROUBLE DIAGNOSIS FOR SYMPTOMSACS-59

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

After adjusting ICC sensor beam aiming, perform ICC system running test. Check that preceding vehicle

detection performance has been improved.

OK or NG

OK >> INSPECTION END

NG >> 1. Replace ICC sensor, and perform laser beam aiming adjustment. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

Symptom 8 the System Does Not De tect the Vehicle Ahead at AllINFOID:0000000001328856

1.VISUAL CHECK 1

With ignition switch turned ON (engine not started), che ck that all indicator lamps in ICC system display are

continuously lit. (Check for a missing segm ent in preceding vehicle detection display.)

OK or NG

OK >> GO TO 2.

NG >> Check for combination meter. Refer to DI-15, "

Trouble Diagnosis".

2. VISUAL CHECK 2

Check ICC sensor body window for c ontamination and foreign materials.

OK or NG

OK >> If any contamination or foreign materials are found, remove them. Perform ICC system running

test.

NG >> GO TO 3.

3.VISUAL CHECK 3

Check ICC sensor body window for cracks and scratches.

OK or NG

OK >> GO TO 4.

NG >> 1. Replace ICC sensor, and perform laser beam aiming adjustment. 2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

4.ADJUST ICC SENSOR

After adjusting ICC sensor beam aiming, perform ICC system running test. Check that preceding vehicle

detection performance has been improved.

OK or NG

OK >> INSPECTION END

NG >> 1. Replace ICC sensor, and perform laser beam aiming adjustment.

2. Erase DTC and perform ICC syst em running test. Then perform self-diagnosis of ICC system

again.

SELF-DIAGNOSIS BY ICC SYST EM DISPLAY WILL NOT RUNINFOID:0000000001544638

PKIB4144E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 433 of 3924

ATC-28

< SERVICE INFORMATION >

AIR CONDITIONER CONTROL

When pressing AUTO switch, air inlet, air outlet, fan speed, and discharge air temperature are automatically

controlled.

TEMPERATURE CONTROL SWITCH (POTENTIO TEMPERATURE CONTROL) (DRIVER SIDE)

The set temperature is increased or decreased with this switch.

TEMPERATURE CONTROL SWITCH (POTENTIO TEMPERATURE CONTROL) (PASSENGER

SIDE)

The set temperature is increased or decreased with this switch.

When the temperature switch is pressed, the DUA L switch indicator will automatically illuminate.

INTAKE SWITCH

When intake switch is ON, REC LED turns ON, and air inlet is fixed to REC.

When press intake switch again, FRE LED turns ON, and air inlet is fixed to FRE.

When intake switch is pressed for approximately 1. 5 seconds or longer, FRE and REC LEDs blink twice.

Then, automatic control mode is entered. Inlet status is displayed by LED even during automatic controlled.

When FRE LED is turned ON, shifting mode position to D/ F or DEF, or when compressor is turned from ON

to OFF, intake switch is automatically turned OFF (fixed to FRE mode). REC mode can be re-entered by

pressing intake switch again, and then compressor is turned ON. (Except D/F or DEF position)

DEFROSTER (DEF) SWITCH

Mode doors are set to the defrost position with this switch . Also, intake doors are set to the outside air position,

and compressor turns ON.

REAR WINDOW DEFOGGER SWITCH

When illumination is ON, rear window is defogged.

OFF SWITCH

Compressor and blower are OFF, the intake door s and the mode doors are automatically controlled.

A/C SWITCH

Compressor is ON or OFF with this switch.

(Pressing the A/C switch when the A/C switch is ON will turn OFF the A/C switch and compressor.)

MODE SWITCH

The air discharge outlets is controlled with this switch.

FAN SWITCH

The blower speed is manually controlled with this swit ch. Seven speeds are available for manual control (as

shown on the display screen).

DUAL SWITCH

When the DUAL switch indicator is illuminated, the driver side and passenger side temperature can each be set independently.

When the DUAL switch indicator is not illuminated, t he driver side setting temperature is applied to both

sides.

Fail-Safe FunctionINFOID:0000000001328171

If a communication error exists between the unified meter and A/C amp., and the A/C and AV switch for 30

seconds or longer, air conditioner is controlled under following conditions:

Compressor : ON

Air outlet : AUTO

Air inlet : FRE (Fresh)

Blower fan speed : AUTO

Set temperature : Setting befo re communication error occurs

Display : OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 482 of 3924

TROUBLE DIAGNOSISATC-77

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

PERFORMANCE CHART

Test Condition

Testing must be performed as follows:

*1 ATC-125, "Removal and Installation

of Compressor Clutch"

*2AT C - 6 4 , "Blower Motor Circuit"*3 EM-14, "Checking Drive Belts"

(VQ35DE) or EM-170, "

Checking

Drive Belts" (VK45DE)

SJIA1642E

Vehicle condition Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door windows Open

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 543 of 3924

ATC-138

< SERVICE INFORMATION >

REFRIGERANT LINES

O-rings are different from low-pressure pipe 1 (high-pressure pipe 2) and low-pressure pipe 2 (high-

pressure pipe 3).

Mark the mounting position of intake sensor bracket prior to removal so that the reinstalled sensor

can be located in the same position.

When recharging refrigerant, check for leaks.

Removal and Installation of Expansion ValveINFOID:0000000001328230

REMOVAL

1. Remove evaporator. Refer to ATC-137, "Removal and Installation of Evaporator".

2. Remove mounting bolts, and then remove expansion valve. CAUTION:

Cap or wrap the joint of evaporator with suitable material

such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings of evaporator with new ones, and then apply compressor oil to it when installing it.

O-rings are different from low-pressure pipe 1 (h igh-pressure pipe 2) and low-pressure pipe 2 (high-

pressure pipe 3).

When recharging refrigerant, check for leaks.

Checking of Refrigerant LeaksINFOID:0000000001328231

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage ma y indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electrical leak detector or fluorescent dye leak

detector (SST: J-42220).

If dye is observed, c onfirm the leak with an electrical leak detector. It is possible a prior leak was repaired and

not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electric al leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electrical leak detector probe slower and closer to the suspected leak area will improve the

chances of finding a leak.

Checking System for Leaks Using the Fluore scent Leak DetectorINFOID:0000000001328232

1. Check A/C system for leaks using the UV lamp and safety goggles (SST: J-42220) in a low sunlight area

(area without windows preferable). Illuminate all co mponents, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner (SST: J-43872) to prevent future

misdiagnosis. Low-pressure pipe 1 bracket mounting bolt

: 5.5 N·m (0.56 kg-m, 49 in-lb)

RJIA1864E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C