torque INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3507 of 3924

REAR WHEEL HUB AND KNUCKLERAX-9

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

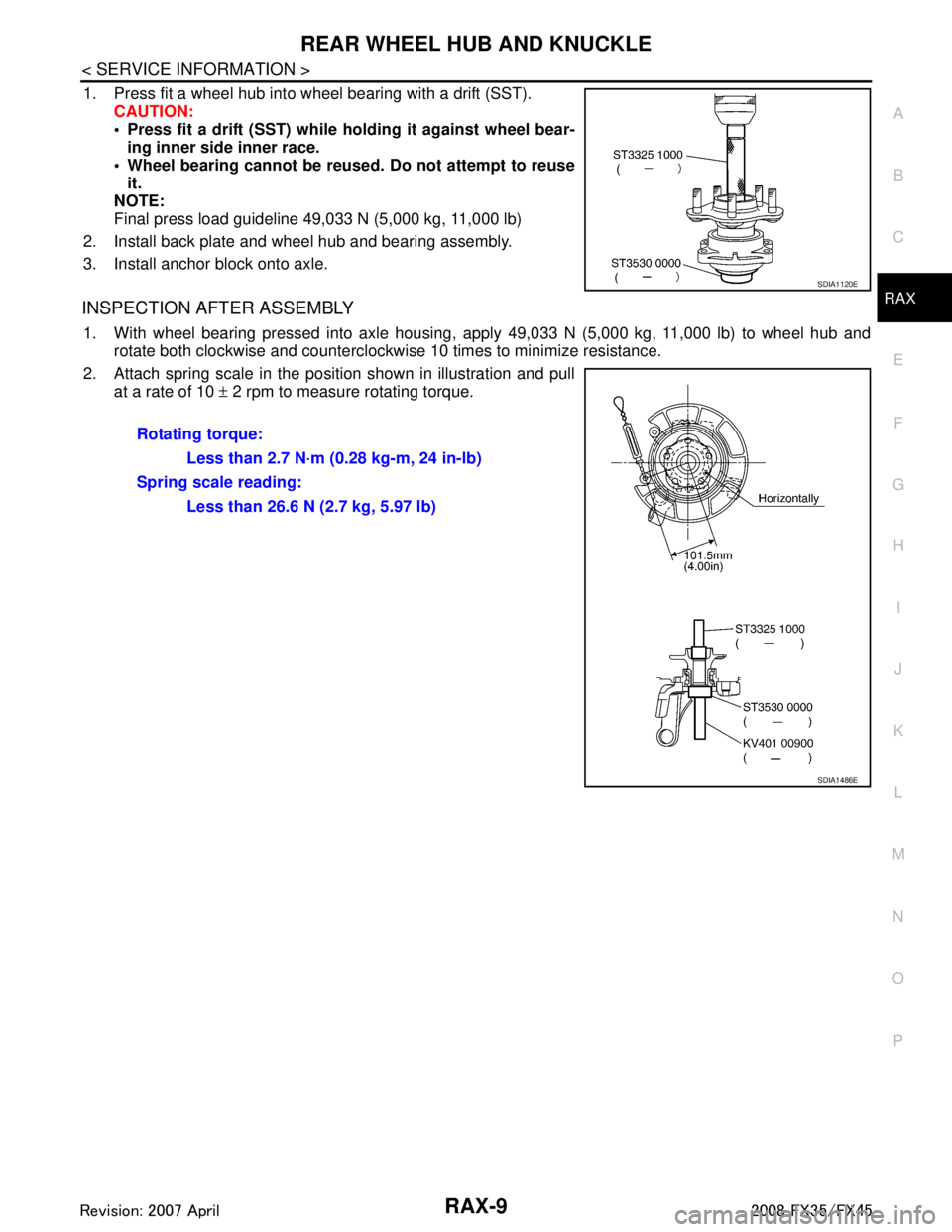

1. Press fit a wheel hub into wheel bearing with a drift (SST). CAUTION:

• Press fit a drift (SST) while ho lding it against wheel bear-

ing inner side inner race.

Wheel bearing cannot be reused. Do not attempt to reuse it.

NOTE:

Final press load guideline 49,033 N (5,000 kg, 11,000 lb)

2. Install back plate and wheel hub and bearing assembly.

3. Install anchor block onto axle.

INSPECTION AFTER ASSEMBLY

1. With wheel bearing pressed into axle housing, apply 49,033 N (5,000 kg, 11,000 lb) to wheel hub and rotate both clockwise and counterclockwise 10 times to minimize resistance.

2. Attach spring scale in the position shown in illustration and pull at a rate of 10 ± 2 rpm to measure rotating torque.

SDIA1120E

Rotating torque:

Less than 2.7 N·m (0.28 kg-m, 24 in-lb)

Spring scale reading: Less than 26.6 N (2.7 kg, 5.97 lb)

SDIA1486E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3508 of 3924

RAX-10

< SERVICE INFORMATION >

REAR DRIVE SHAFT

REAR DRIVE SHAFT

Removal and InstallationINFOID:0000000001327529

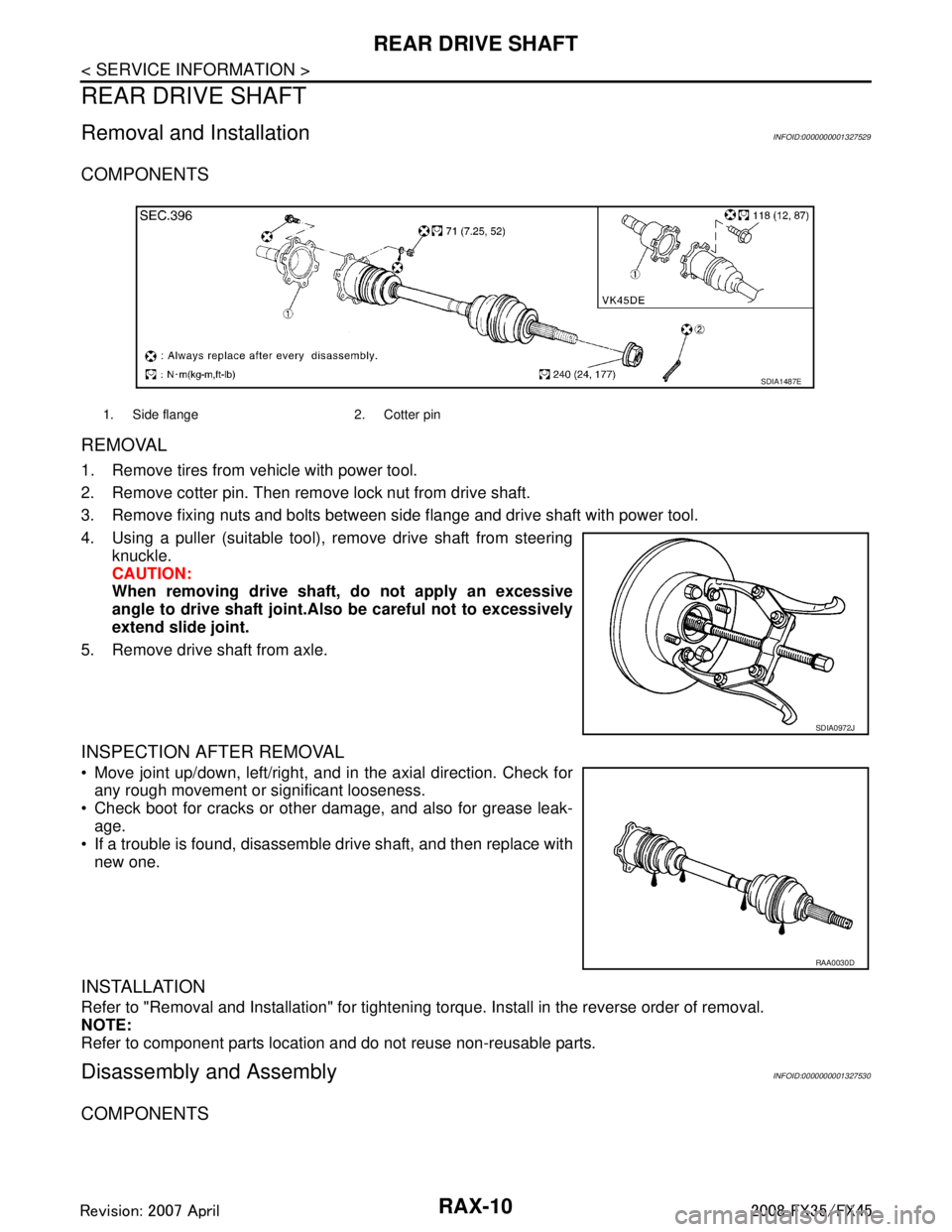

COMPONENTS

REMOVAL

1. Remove tires from vehicle with power tool.

2. Remove cotter pin. Then remove lock nut from drive shaft.

3. Remove fixing nuts and bolts between side flange and drive shaft with power tool.

4. Using a puller (suitable tool), remove drive shaft from steeringknuckle.

CAUTION:

When removing drive shaft, do not apply an excessive

angle to drive shaft joint.Al so be careful not to excessively

extend slide joint.

5. Remove drive shaft from axle.

INSPECTION AFTER REMOVAL

Move joint up/down, left/right, and in the axial direction. Check for any rough movement or significant looseness.

Check boot for cracks or other damage, and also for grease leak- age.

If a trouble is found, disassemble drive shaft, and then replace with

new one.

INSTALLATION

Refer to "Removal and Installation" for tightening torque. Install in the reverse order of removal.

NOTE:

Refer to component parts location and do not reuse non-reusable parts.

Disassembly and AssemblyINFOID:0000000001327530

COMPONENTS

1. Side flange 2. Cotter pin

SDIA1487E

SDIA0972J

RAA0030D

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3515 of 3924

SERVICE DATA AND SPECIFICATIONS (SDS)

RAX-17

< SERVICE INFORMATION >

C EF

G H

I

J

K L

M A

B

RAX

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel BearingINFOID:0000000001327531

Drive ShaftINFOID:0000000001327532

Axial end play 0.05 mm (0.002 in) or less

Rotational torque At a load of 49,033 N (5,000 kg, 11,000 lb)

Less than 2.7 N·m (0.28 kg-m, 24 in-lb)

Measurement of spring scale Less than 26.6 N (2.7 kg, 5.95 lb)

Measuring point (Brake caliper installation points)

SDIA0801E

Joint Wheel side Final drive side

Engine model VQ35DE VK45DE VQ35DE VK45DE

Grease quantity 86

− 96 g

(3.03 − 3.38 oz) 140

− 160 g

(4.93 − 5.64 oz) 124

− 134 g

(4.37 − 4.72 oz) 175

− 195 g

(6.17 − 6.87 oz)

Boots installed length 97 mm (3.82 in) 141.5 mm (5.57 in) 93.9 mm (3.697 in) 147.9 mm (5.82 in)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3517 of 3924

RF-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612895

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PrecautionINFOID:0000000001328027

Disconnect both battery cables in advance.

Do not tamper with or force air bag lid open, as this may adversely affect air bag performance.

Be careful not to scratch pad and other parts.

When removing or disassembling any part, be careful not to damage or deform it. Protect parts, which may get in the way with cloth.

When removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

Keep removed parts protected with cloth.

If a clip is deformed or damaged, replace it.

If an unreusable part is removed, replace it with a new one.

Tighten bolts and nuts firmly to the specified torque.

After re-assembly has been completed, make sure each part functions correctly.

Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

Do not use any organic solvent, such as thinner or benzine.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3546 of 3924

RFD-4

< SERVICE INFORMATION >

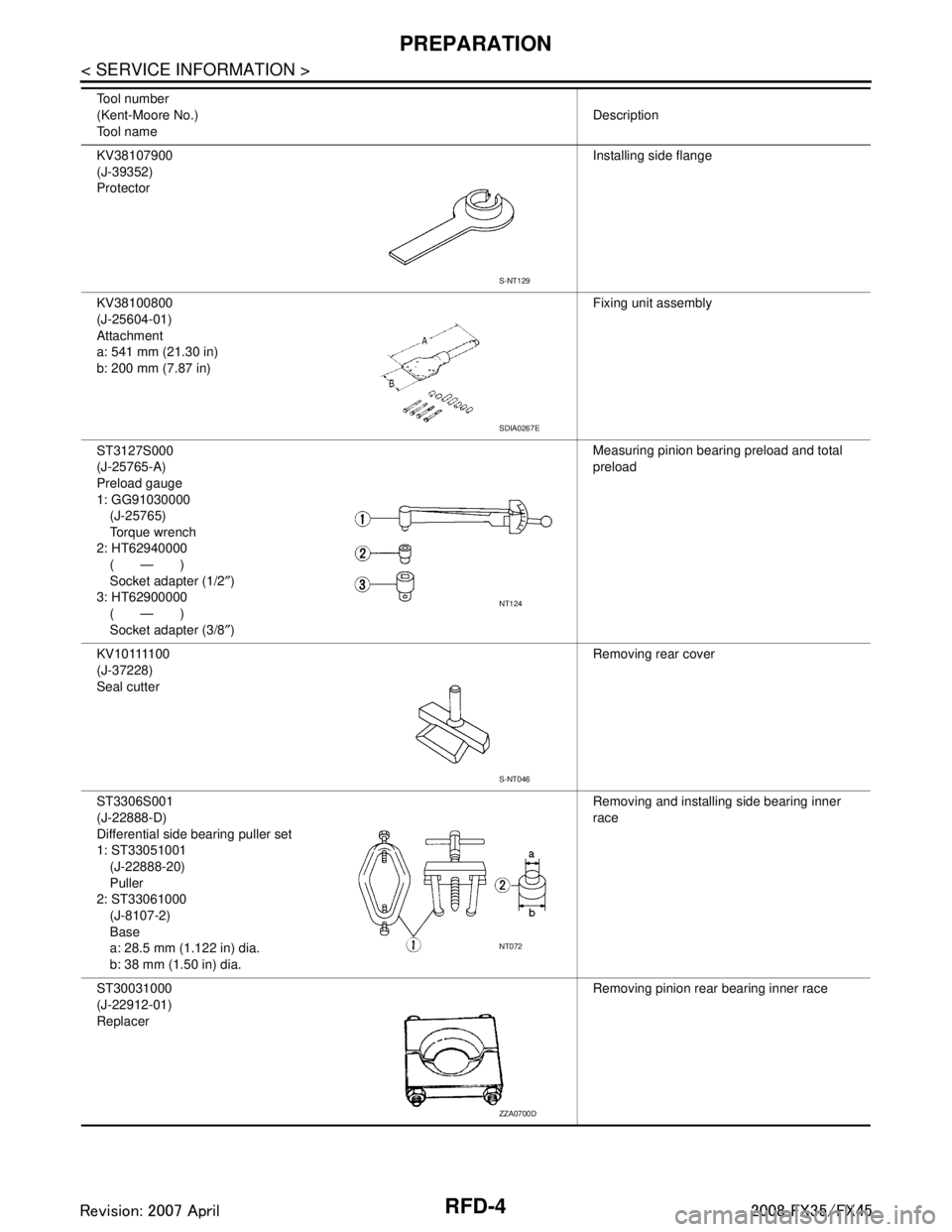

PREPARATION

KV38107900

(J-39352)

ProtectorInstalling side flange

KV38100800

(J-25604-01)

Attachment

a: 541 mm (21.30 in)

b: 200 mm (7.87 in) Fixing unit assembly

ST3127S000

(J-25765-A)

Preload gauge

1: GG91030000 (J-25765)

Torque wrench

2: HT62940000 (—)

Socket adapter (1/2 ″)

3: HT62900000 (—)

Socket adapter (3/8 ″) Measuring pinion bearing preload and total

preload

K V 1 0 1111 0 0

(J-37228)

Seal cutter Removing rear cover

ST3306S001

(J-22888-D)

Differential side bearing puller set

1: ST33051001 (J-22888-20)

Puller

2: ST33061000 (J-8107-2)

Base

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia. Removing and installing side bearing inner

race

ST30031000

(J-22912-01)

Replacer Removing pinion rear bearing inner race

Tool number

(Kent-Moore No.)

Tool name

Description

S-NT129

SDIA0267E

NT124

S-NT046

NT072

ZZA0700D

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3547 of 3924

PREPARATIONRFD-5

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RFD

N

O P

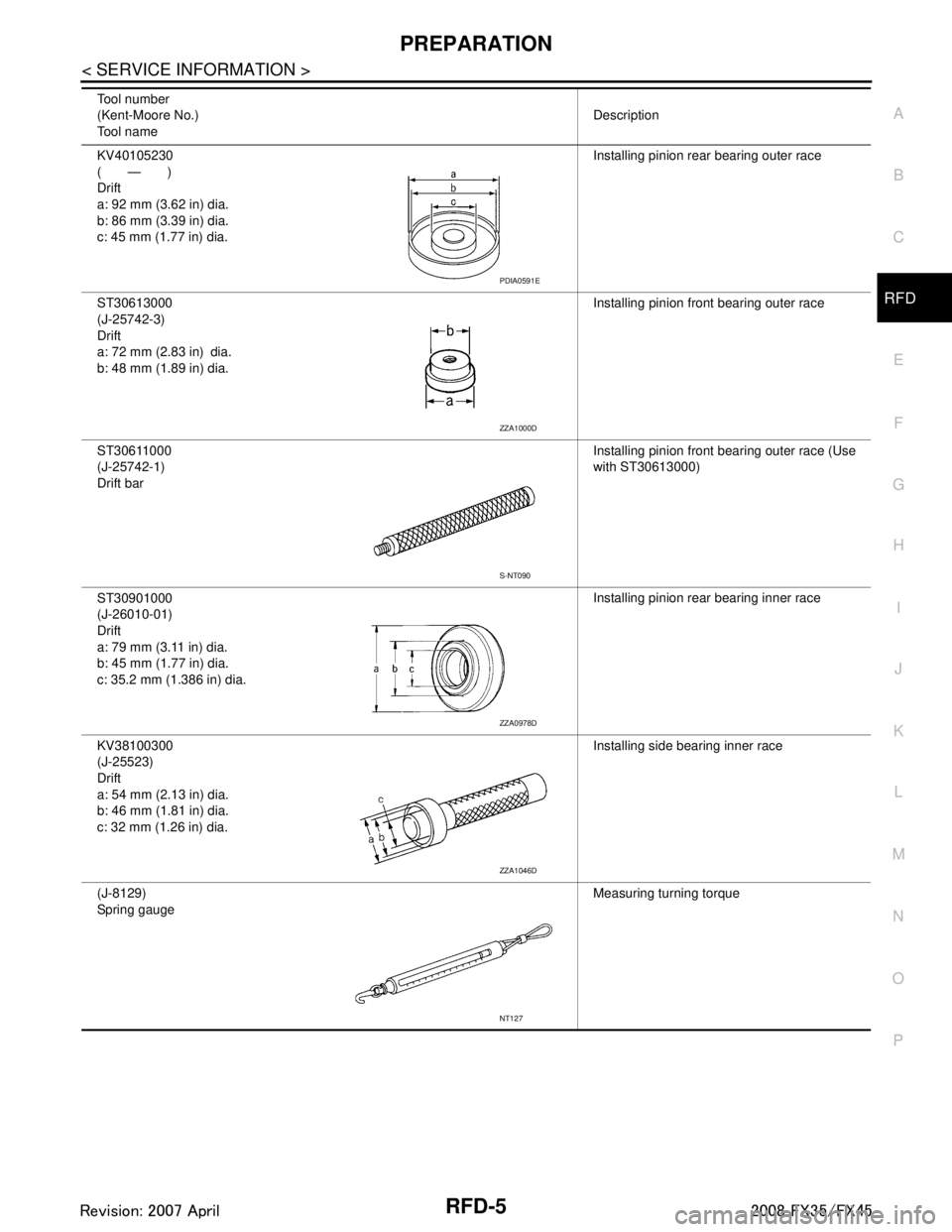

KV40105230

(—)

Drift

a: 92 mm (3.62 in) dia.

b: 86 mm (3.39 in) dia.

c: 45 mm (1.77 in) dia. Installing pinion rear bearing outer race

ST30613000

(J-25742-3)

Drift

a: 72 mm (2.83 in) dia.

b: 48 mm (1.89 in) dia. Installing pinion front bearing outer race

ST30611000

(J-25742-1)

Drift bar Installing pinion front bearing outer race (Use

with ST30613000)

ST30901000

(J-26010-01)

Drift

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35.2 mm (1.386 in) dia. Installing pinion rear bearing inner race

KV38100300

(J-25523)

Drift

a: 54 mm (2.13 in) dia.

b: 46 mm (1.81 in) dia.

c: 32 mm (1.26 in) dia. Installing side bearing inner race

(J-8129)

Spring gauge Measuring turning torque

Tool number

(Kent-Moore No.)

Tool name

Description

PDIA0591E

ZZA1000D

S-NT090

ZZA0978D

ZZA1046D

NT127

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3551 of 3924

DIFFERENTIAL GEAR OILRFD-9

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RFD

N

O P

DIFFERENTIAL GEAR OIL

Changing Differential Gear OilINFOID:0000000001327495

DRAINING

1. Stop engine.

2. Remove drain plug (1) and drain gear oil.

3. Set a gasket on drain plug (1) and install it to final drive assem- bly and tighten to the specified torque. Refer to RFD-17, "

Disas-

sembly and Assembly".

CAUTION:

Never reuse gasket.

FILLING

1. Remove filler plug (1). Fill with new gear oil until oil level reaches the specified level near filler plug mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug (1), then install it to final drive assembly. Refer to RFD-17, "

Disas-

sembly and Assembly".

CAUTION:

Never reuse gasket.

Checking Differential Gear OilINFOID:0000000001327496

OIL LEAKAGE AND OIL LEVEL

Make sure that oil is not leaking from final drive assembly or around it.

Remove filler plug (1) and check oil level from filler plug mounting hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

Set a gasket on filler plug (1) and install it on final drive assembly.

Refer to RFD-17, "

Disassembly and Assembly".

CAUTION:

Never reuse gasket.

PDIA0748J

Oil grade and Viscosity:

Refer to MA-9, "

Fluids and Lubricants".

Oil capacity:

Approx. 1.4 (3 US pt, 2-1/2 Imp pt)

PDIA0749J

PDIA0749J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3555 of 3924

FRONT OIL SEALRFD-13

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RFD

N

O P

5. Tighten to drive pinion lock nut, while adjust total preload torque.

CAUTION:

Adjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

If the preload torque exceeds the specified value, replace

collapsible spacer and tighte n it again to adjust. Never

loosen drive pinion lock nut to adjust the preload torque.

6. Make a stamping for identificati on of front oil seal replacement

frequency. Refer to "IDENTIFICATION STAMP OF REPLACE-

MENT FREQUENCY OF FRONT OIL SEAL".

CAUTION:

Be sure to make a stamping after replacing front oil seal.

7. Install propeller shaft. Refer to PR-9, "

Removal and Installation".

8. Install side flange with the following procedure.

a. Attach the protector to side oil seal.

b. After the side flange is inserted and the serrated part of side gear has engaged the serrated part of flange, remove the pro-

tector.

c. Put a suitable drift on the center of side flange, then drive it until sound changes.

NOTE:

When installation is completed, driving sound of the side flange turns into a sound which seems to affect

the whole final drive.

d. Confirm that the dimension of the side flange installation (Mea- surement A) in the figure comes into the following.

9. Install drive shaft. Refer to RAX-10

.

10. Install rear wheel sensor. Refer to BRC-52

.

11. Install center muffler. Refer to EX-3

.

12. Refill gear oil to the final drive and check oil level. Refer to RFD-

9, "Changing Differential Gear Oil".

13. Check the final drive for oil leakage. Refer to RFD-9, "

Checking

Differential Gear Oil".

Tool number A: ST3127S000 (J-25765-A)

Drive pinion lock nut tightening torque:

147 - 323 N·m (15 - 32 kg-m, 109 - 238 ft-lb)

Total preload torque: Total preload torque should equal the measurement tak-

en during removal plus an ad ditional 0.1 - 0.4 N·m (0.01 -

0.04 kg-m, 1 - 3 in-lb).

Tool number : KV38107900 (J-39352)

PDIA0981E

SDIA0822E

Measurement A: 326 - 328 mm (12.83 - 12.91 in)

SDIA1039E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3559 of 3924

REAR FINAL DRIVE ASSEMBLYRFD-17

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RFD

N

O P

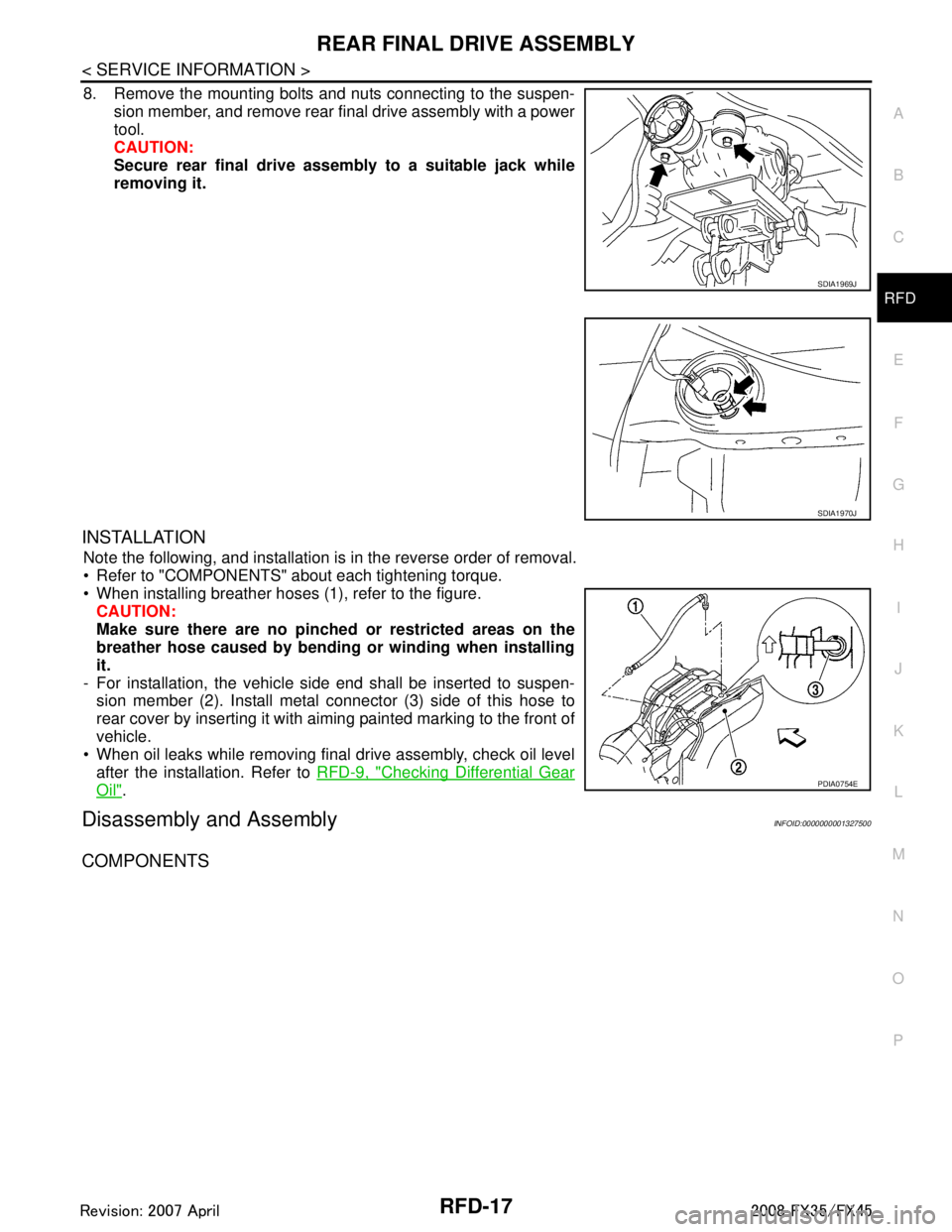

8. Remove the mounting bolts and nuts connecting to the suspen- sion member, and remove rear final drive assembly with a power

tool.

CAUTION:

Secure rear final drive assembly to a suitable jack while

removing it.

INSTALLATION

Note the following, and installation is in the reverse order of removal.

Refer to "COMPONENTS" about each tightening torque.

When installing breather hoses (1), refer to the figure.CAUTION:

Make sure there are no pinched or restricted areas on the

breather hose caused by bending or winding when installing

it.

- For installation, the vehicle side end shall be inserted to suspen- sion member (2). Install metal connector (3) side of this hose to

rear cover by inserting it with aiming painted marking to the front of

vehicle.

When oil leaks while removing final drive assembly, check oil level

after the installation. Refer to RFD-9, "

Checking Differential Gear

Oil".

Disassembly and AssemblyINFOID:0000000001327500

COMPONENTS

SDIA1969J

SDIA1970J

PDIA0754E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3560 of 3924

RFD-18

< SERVICE INFORMATION >

REAR FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

Before inspection and adjustment, drain gear oil.

Total Preload Torque

1. Secure final drive assembly onto an attachment.

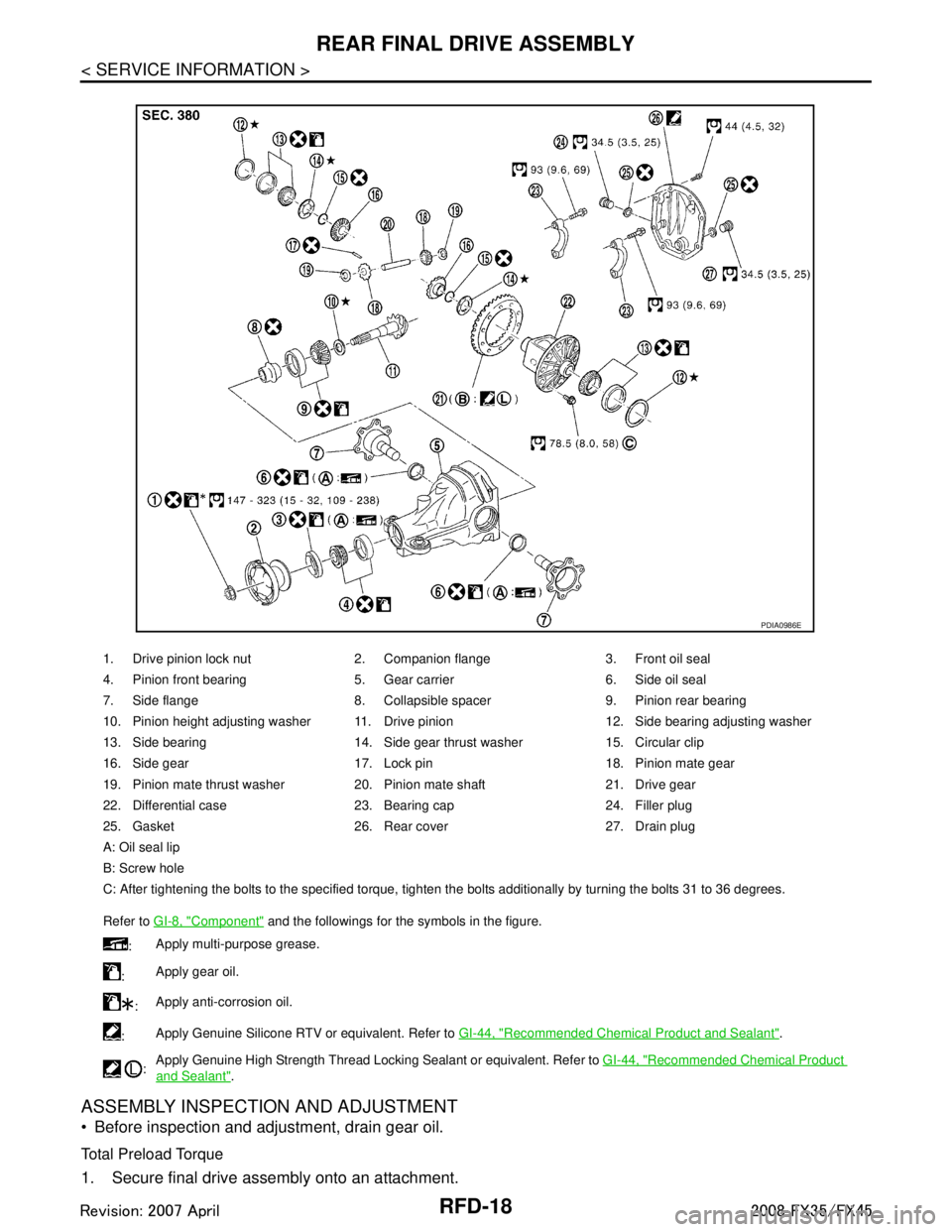

1. Drive pinion lock nut 2. Companion flange 3. Front oil seal

4. Pinion front bearing 5. Gear carrier 6. Side oil seal

7. Side flange 8. Collapsible spacer 9. Pinion rear bearing

10. Pinion height adjusting washer 11. Drive pinion 12. Side bearing adjusting washer

13. Side bearing 14. Side gear thrust washer 15. Circular clip

16. Side gear 17. Lock pin 18. Pinion mate gear

19. Pinion mate thrust washer 20. Pinion mate shaft 21. Drive gear

22. Differential case 23. Bearing cap 24. Filler plug

25. Gasket 26. Rear cover 27. Drain plug

A: Oil seal lip

B: Screw hole

C: After tightening the bolts to the specified torque, tighten the bolts additionally by turning the bolts 31 to 36 degrees.

Refer to GI-8, "

Component" and the followings for the symbols in the figure.

: Apply multi-purpose grease.

: Apply gear oil.

: Apply anti-corrosion oil.

: Apply Genuine Silicone RTV or equivalent. Refer to

GI-44, "

Recommended Chemical Product and Sealant".

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to

GI-44, "

Recommended Chemical Product

and Sealant".

PDIA0986E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C