steering wheel INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1 of 3924

ABCDEFGHIJKLQUICK REFERENCE INDEX AGENERAL INFORMATIONGIGeneral InformationBENGINEEMEngine MechanicalLUEngine Lubrication SystemCOEngine Cooling SystemECEngine Control SystemFLFuel SystemEXExhaust SystemACCAccelerator Control SystemCTRANSMISSION/

TRANSAXLEATAutomatic TransmissionDDRIVELINE/AXLETFTransferPRPropeller ShaftFFDFront Final DriveRFDRear Final DriveFAXFront AxleRAXRear AxleESUSPENSIONFSUFront SuspensionRSURear SuspensionWTRoad Wheels & TiresFBRAKESBRBrake SystemPBParking Brake SystemBRCBrake Control SystemGSTEERINGPSPower Steering SystemHRESTRAINTSSBSeat BeltsSRSSupplemental Restraint System

(SRS)IBODYBLBody, Lock & Security SystemGWGlasses, Window System & Mir-

rorsRFRoofEIExterior & InteriorIPInstrument PanelSESeatJAIR CONDITIONERATCAutomatic Air ConditionerKELECTRICALSCStarting & Charging SystemLTLighting SystemDIDriver Information SystemWWWiper, Washer & HornBCSBody Control SystemLANLAN SystemAVAudio Visual, Navigation & Tele-

phone SystemACSAuto Cruise Control SystemPGPower Supply, Ground & Circuit Ele-

mentsLMAINTENANCEMAMaintenanceEdition: April 2007

Revision: April 2007

Page 4 of 3924

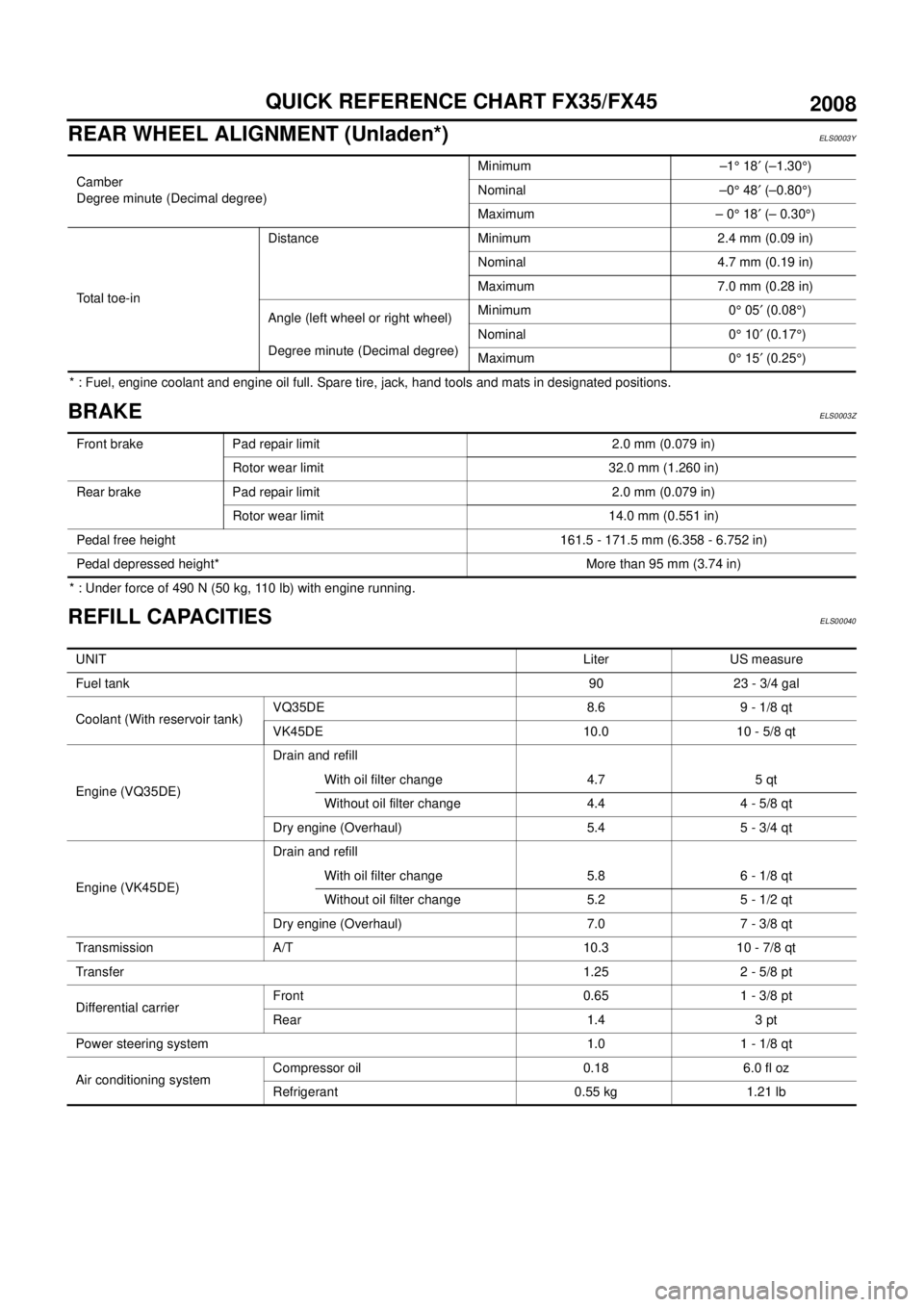

QUICK REFERENCE CHART FX35/FX45

REAR WHEEL ALIGNMENT (Unladen*)

ELS0003Y

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

BRAKEELS0003Z

* : Under force of 490 N (50 kg, 110 lb) with engine running.

REFILL CAPACITIESELS00040

Camber

Degree minute (Decimal degree)Minimum –1° 18′ (–1.30°)

Nominal –0° 48′ (–0.80°)

Maximum – 0° 18′ (– 0.30°)

Total toe-inDistance Minimum 2.4 mm (0.09 in)

Nominal 4.7 mm (0.19 in)

Maximum 7.0 mm (0.28 in)

Angle (left wheel or right wheel)

Degree minute (Decimal degree)Minimum 0° 05′ (0.08°)

Nominal 0° 10′ (0.17°)

Maximum 0° 15′ (0.25°)

Front brake Pad repair limit 2.0 mm (0.079 in)

Rotor wear limit 32.0 mm (1.260 in)

Rear brake Pad repair limit 2.0 mm (0.079 in)

Rotor wear limit 14.0 mm (0.551 in)

Pedal free height 161.5 - 171.5 mm (6.358 - 6.752 in)

Pedal depressed height* More than 95 mm (3.74 in)

UNITLiter US measure

Fuel tank90 23 - 3/4 gal

Coolant (With reservoir tank)VQ35DE 8.6 9 - 1/8 qt

VK45DE 10.0 10 - 5/8 qt

Engine (VQ35DE)Drain and refill

With oil filter change 4.7 5 qt

Without oil filter change 4.4 4 - 5/8 qt

Dry engine (Overhaul) 5.4 5 - 3/4 qt

Engine (VK45DE)Drain and refill

With oil filter change 5.8 6 - 1/8 qt

Without oil filter change 5.2 5 - 1/2 qt

Dry engine (Overhaul) 7.0 7 - 3/8 qt

Transmission A/T 10.3 10 - 7/8 qt

Transfer1.25 2 - 5/8 pt

Differential carrierFront 0.65 1 - 3/8 pt

Rear 1.4 3 pt

Power steering system 1.0 1 - 1/8 qt

Air conditioning systemCompressor oil 0.18 6.0 fl oz

Refrigerant 0.55 kg 1.21 lb

2008

Page 15 of 3924

![INFINITI FX35 2008 Service Manual

ACS-8

< SERVICE INFORMATION >[ICC]

DESCRIPTION

DATA MONITOR INPUT ITEM LIST

DATA MONITOR OUTPUT ITEM LIST

InputData monitored

Item [unit] CAN Description

ECM THRTL OPENING

[%]

×Indicates throttle a INFINITI FX35 2008 Service Manual

ACS-8

< SERVICE INFORMATION >[ICC]

DESCRIPTION

DATA MONITOR INPUT ITEM LIST

DATA MONITOR OUTPUT ITEM LIST

InputData monitored

Item [unit] CAN Description

ECM THRTL OPENING

[%]

×Indicates throttle a](/img/42/57017/w960_57017-14.png)

ACS-8

< SERVICE INFORMATION >[ICC]

DESCRIPTION

DATA MONITOR INPUT ITEM LIST

DATA MONITOR OUTPUT ITEM LIST

InputData monitored

Item [unit] CAN Description

ECM THRTL OPENING

[%]

×Indicates throttle angle read by ICC unit through CAN communication (ECM transmits

throttle angle through CAN communication).

ENGINE RPM

[rpm] ×

Indicates engine speed read by ICC unit through CAN communication (ECM transmits

engine speed through CAN communication).

MAIN SW

[On/Off] ×Indicates [On/Off] status as judged from steering switch signal (ECM transmits steering

switch signal through CAN communication).

SET/COAST SW

[On/Off] ×Indicates [On/Off] status as judged from steering switch signal (ECM transmits steering

switch signal through CAN communication).

CANCEL SW

[On/Off] ×

Indicates [On/Off] status as judged from steering switch signal (ECM transmits steering

switch signal through CAN communication).

RESUME/ACC SW

[On/Off] ×Indicates [On/Off] status as judged from steering switch signal (ECM transmits steering

switch signal through CAN communication).

IDLE SW

[On/Off] ×Indicates [On/Off] status of idle switch read by ICC unit through CAN communication

(ECM transmits ON/OFF status through CAN communication).

TCM VHCL SPD AT

[km/h] or [mph]

×Indicates vehicle speed calculated from AT vehicle speed sensor by ICC unit through

CAN communication (TCM transmits AT vehicle speed sensor signal through CAN com-

munication).

GEAR

[1, 2, 3, 4, 5] ×Indicates AT gear position read by ICC unit through CAN communication (TCM transmits

gear position through CAN communication).

D RANGE SW

[On/Off] ×

Indicates [On/Off] status of “D” position read by ICC unit through CAN communication

(TCM transmits ON/OFF condition of “D” position through CAN communication).

NP RANGE SW

[On/Off] ×Indicates PNP switch signal read by ICC unit through CAN communication (TCM trans-

mits PNP switch signal through CAN communication).

ABS actuator

and electric

unit (control

unit) VHCL SPEED SE

[km/h] or [mph]

×Indicates vehicle speed calculated from wheel sensor by ICC unit through CAN commu-

nication (ABS actuator and electr

ic unit (control unit) transmits wheel speed sensor signal

through CAN communication).

BCM WIPER SW

[Off/Low/High]

×Indicates wiper [Off/Low/High] status (BCM transmits front wiper request signal through

CAN commun

ication).

Brake pres-

sure sensor PRESS SENS

[bar]

Indicates brake fluid pressure value calculated from signal voltage of pressure sensor.

Release

switch RELEASE SW NO

[On/Off]

Indicates [On/Off] status as judged from release switch signal.

ON when brake is depressed.

OFF when brake is not depressed.

RELEASE SW NC

[On/Off] Indicates [On/Off] status as judged from release switch signal.

ON when brake is not depressed.

OFF when brake is depressed.

ICC brake

switch BRAKE SW

[On/Off]

Indicates [On/Off] status as judged from ICC brake switch signal.

Sto p l am p

switchSTOP LAMP SW

[On/Off]

Indicates [On/Off] status as judged from stop lamp switch signal.

Output Data monitored

Item [unit] CAN Description

ICC warning

chime BUZZER O/P

[On/Off]

×

Indicates [On/Off] status of ICC warning chime output.

ICC brake hold

relay STP LMP DRIVE

[On/Off]

Indicates [On/Off] status of brake hold relay drive output.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 16 of 3924

![INFINITI FX35 2008 Service Manual

DESCRIPTIONACS-9

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ACTIVE TEST ITEM LIST

Component DescriptionINFOID:0000000001328807

CAN CommunicationINFOID:0000000001328808

CAN (Contr INFINITI FX35 2008 Service Manual

DESCRIPTIONACS-9

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ACTIVE TEST ITEM LIST

Component DescriptionINFOID:0000000001328807

CAN CommunicationINFOID:0000000001328808

CAN (Contr](/img/42/57017/w960_57017-15.png)

DESCRIPTIONACS-9

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ACTIVE TEST ITEM LIST

Component DescriptionINFOID:0000000001328807

CAN CommunicationINFOID:0000000001328808

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tric control units are equipped onto a vehicle, and eac h control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT

Refer to LAN-43, "CAN System Specification Chart".

Output CONSULT-III ICC

[ACTIVE TEST]

Item CAN Description

Combination

meter ICC BUZZER 1

×Able to start ICC warning chime with a driving signal from ICC unit.

METER LAMP ×Able to turn ICC system display ON with a driving signal from ICC unit.

ICC brake hold

relay STOP LAMP Able to start ICC brake hold relay with a driving signal from ICC unit.

Booster sole-

noid BOOSTER SOL/V

3

Able to start booster solenoid with a driving signal from ICC unit.

ComponentVehicle-to-

vehicle

distance

control mode Conventional

(fixed speed)

cruise

control mode Brake assis

(with preview function) Description

ICC unit ××× Operates electric throttle control actuator and brake

booster based on that sensor signals and CAN commu-

nication data, then controls vehicle distance.

ICC sensor ×× Irradiates laser beam, and receives reflected laser beam

to measure distance from preceding vehicle.

ECM ××× Transmits throttle position signal and ICC steering switch

signal to ICC unit through CAN communication.

ABS actuator and electric

unit (control unit) ××× Transmits wheel speed sensor signal to ICC unit through

CAN communication.

Brake pressure sensor ×× Detects fluid pressure in master cylinder.

Brake booster ×× Adjusts brake fluid pressure, based on command from

ICC unit.

BCM × Transmit front wiper request signal to ICC unit through

CAN communication.

TCM ×× Transmits gear position signal and output shaft revolu-

tion signal to ICC unit through CAN communication.

Unified meter and A/C amp. ××× Receives ICC system display signal, ICC warning lamp

signal and buzzer output signal from ICC unit through

CAN communication.

ICC brake switch, stop lamp

switch ××× Transmit operating signal to ICC unit when touching

brake pedal. ICC unit cancels cruise system at driver's

brake operation.

ICC brake hold relay × Receives stop lamp driving signal from ICC unit, and

turns stop lamp ON.

Parking brake switch ×× The cruise system is cancelled when applied.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 17 of 3924

![INFINITI FX35 2008 Service Manual

ACS-10

< SERVICE INFORMATION >[ICC]

DESCRIPTION

Switch Operation

INFOID:0000000001328809

The system is operated by MAIN switch and four control switches, all mounted on the steering wheel.

ICC Syste INFINITI FX35 2008 Service Manual

ACS-10

< SERVICE INFORMATION >[ICC]

DESCRIPTION

Switch Operation

INFOID:0000000001328809

The system is operated by MAIN switch and four control switches, all mounted on the steering wheel.

ICC Syste](/img/42/57017/w960_57017-16.png)

ACS-10

< SERVICE INFORMATION >[ICC]

DESCRIPTION

Switch Operation

INFOID:0000000001328809

The system is operated by MAIN switch and four control switches, all mounted on the steering wheel.

ICC System DisplayINFOID:0000000001328810

No. Switch name Description

1 RESUME/ACCELERATE switch Resumes set speed or increases speed incrementally.

2 SET/COAST switch Sets desired cruise speed, reduces speed incrementally.

3 CANCEL switch Deactivates system without erasing set speed.

4 MAIN switch Master switch to activate the system

5 DISTANCE switch Changes the following distance from: Long, Middle, Short.

SKIB8558E

SKIA6177E

No. Display items Description

1 Set vehicle speed indicator Indicates the set vehicle speed.

For CANADA models: km/h

For US models: MPH

2 Vehicle ahead detection indicator Indicates whether it detects a vehicle ahead.

3 Set distance indicator Display the selected distance between vehicles set with the DISTANCE switch.

4 Own vehicle indicator Indicates the base vehicle.

5 MAIN switch indicator lamp (Green) Indicates that the MAIN switch is ON.

6 Intelligent cruise control system warning lamp

(Orange) The light comes on if there is a malfunction in the ICC system.

7 SET switch indicator lamp Indicates that the conventional cruise control mode is controlled.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 37 of 3924

![INFINITI FX35 2008 Service Manual

ACS-30

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS —

GENERAL DESCRIPTION

WORK SUPPORT

Cause of Auto-Cancel

Display Item List

NOTE:

Last five cancel (system cancel) causes are displayed.

SELF DI INFINITI FX35 2008 Service Manual

ACS-30

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS —

GENERAL DESCRIPTION

WORK SUPPORT

Cause of Auto-Cancel

Display Item List

NOTE:

Last five cancel (system cancel) causes are displayed.

SELF DI](/img/42/57017/w960_57017-36.png)

ACS-30

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS —

GENERAL DESCRIPTION

WORK SUPPORT

Cause of Auto-Cancel

Display Item List

NOTE:

Last five cancel (system cancel) causes are displayed.

SELF DIAGNOSTIC RESULT

For details, refer to ACS-35, "Diagnostic Trouble Code (DTC) Chart".

DATA MONITOR

×: Applicable

Work Support Monitors aiming direction to facilitate laser beam aiming operation.

Indicates causes of automatic cancellation of the ICC system.

Ecu Identification Displays part number of ICC unit. Test mode Function

Operation Function

CAUSE OF AUTO-CANCEL Indicates causes of automatic cancellation of the ICC system.

LASER BEAM ADJUST Outputs laser beam, calculates dislocation of the beam, and indicates adjustment direction.

For details, refer to

ACS-14

.

Cause of cancellation Description

OPERATING WIPER Windshield wipers were operated at HI or LO speed operation.

OPERATING ABS ABS func tion was operated.

OPERATING TCS TCS function was operated.

OPERATING VDC VDC function was operated.

OPE SW VOLT CIRC Outside the standard control switch input voltage was detected.

ECM CIRCUIT ECM did not permit ICC operation.

LASER SUN BEAM Intense light such as sunlight entered ICC sensor light sensing part.

LASER TEMP Temperature around ICC sensor became low.

OP SW DOUBLE TOUCH ICC steering switches were pressed at the same time.

WHL SPD ELEC NOISE Wheel speed sensor signal caught electromagnetic noise.

VDC/TCS OFF SW VDC OFF switch was pressed.

WHEEL SPD UNMATCH Wheel speed became different from AT vehicle speed.

TIRE SLIP Wheel slipped.

PKB SW ON Parking brake is applied.

IGN LOW VOLT Power supply voltage became low.

SNOW MODE SW Snow mode switch was pressed.

NO RECORD —

Monitored Item [unit] ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM

MENU Description

VHCL SPEED SE

[km/h] or [mph] ××× Indicates vehicle speed calculated from ICC unit through CAN

communication [ABS actuator and

electric unit (control unit)

transmits wheel speed sensor signal through CAN communica-

tion].

SET VHCL SPD

[km/h] or [mph] ××

Indicates set vehicle speed memorized in ICC unit.

THRTL OPENING

[%] ××× Indicates throttle angle read from ICC unit through CAN commu-

nication (ECM transmits throttle angle through CAN communica-

tion).

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 42 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFO INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFO](/img/42/57017/w960_57017-41.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFOID:0000000001328825

×: Applicable

DTC

No. CONSULT-III

screen terms ICC

system

warning lamp Fail-safe

Malfunctions detected where... Refer-

ence

page

Ve h i c l e -

to-

vehicle

distance control mode Conven-

tional

(fixed

speed) cruise

control mode Brake as-

sist (with

preview

function)

11 CONTROL UNIT ×××× ICC unit internal malfunctionACS-36

20 CAN COMM CIRCUIT ×××× ICC unit detected CAN communi-

cation malfunction. ACS-36

31 POWER SUPPLY CIR

×××× ICC unit power supply voltage is

excessively low (less than 8 V). ACS-37

34 POWER SUPPLY CIR2

×××× ICC unit power supply voltage is

excessively high (more than 19 V). ACS-37

41 VHCL SPEED SE CIRC

×××× Wheel sensor malfunction.

ABS actuator and electric unit

(control unit) malfunction

AT vehicle speed sensor malfunc- tion

TCM malfunction ACS-37

43 ABS/TCS/VDC CIRC

×××× VDC/TCS/ABS system malfunc-

tion ACS-38

45 BRAKE SW/STOP L SW

×××× Brake and stop lamp switch har-

ness is open or shorted.

Brake and stop lamp switch is ON

or stuck to OFF.

Brake and stop lamp switch is stuck to ON. ACS-38

46 OPERATION SW CIRC

××× ICC steering switch harness or spi-

ral cable is open or shorted.

ICC steering switch malfunction ACS-40

61 PRESS SEN CIRCUIT

×× × Brake pressure sensor harness is

open or shorted.

Brake pressure sensor malfunction

Brake pressure sensor input circuit malfunction ACS-41

62

BOOSTER SOL/V

CIRCUIT ×× × Solenoid harness is open or short-

ed.

Solenoid is open.

Solenoid drive circuit malfunction ACS-42

63 RELEASE SW CIRCUIT

×××× Release switch harness is open or

shorted.

Release switch malfunction

Release switch input circuit mal- function ACS-43

65 PRESSURE CONTROL

×× × Booster malfunctionACS-45

74 LASER BEAM OFF CNTR ×× × Laser beam of ICC sensor is off the

aiming point. ACS-45

90 STOP LAMP RLY FIX

×× × Normally open terminal of stop

lamp relay is stuck. ACS-46

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 406 of 3924

ATC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION AT C

A

B

AT C

N

O P

CONTENTS

AUTOMATIC AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Working with HFC-134a (R-134a) ......4

General Refrigerant Precaution ................................4

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ......................9

Precaution for Service Equipment .............................9

Precaution for Leak Detection Dye .........................11

PREPARATION ..................................................13

Special Service Tool ........................................... ....13

HFC-134a (R-134a) Service Tool and Equipment ....13

Commercial Service Tool ........................................16

REFRIGERATION SYSTEM ..............................17

Refrigerant Cycle ................................................ ....17

Refrigerant System Protection ................................17

V-6 Variable Displacement Compressor .................17

Component Part Location .......................................21

LUBRICANT ................................................... ....22

Maintenance of Lubricant Quantity in Compressor ....22

AIR CONDITIONER CONTROL .........................24

Description of Air Conditioner LAN Control Sys-

tem ...................................................................... ....

24

System Construction ...............................................24

Description of Control System .................................27

Control Operation ....................................................27

Fail-Safe Function ...................................................28

Discharge Air Flow ..................................................29

System Description .................................................30

CAN Communication System Description ...............30

TROUBLE DIAGNOSIS .....................................32

CONSULT-III Function ........................................ ....32

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

32

Component Parts and Harness Connector Loca-

tion ...........................................................................

34

Schematic ................................................................36

Wiring Diagram - A/C - ............................................37

Auto Amp. Terminal and Reference Value ..............42

Self-Diagnosis Function ...........................................43

Operational Check ...................................................50

Power Supply and Ground Circuit for Auto Amp .....52

LAN System Circuit .................................................54

Mode Door Motor Circuit .........................................57

Air Mix Door Motor Circuit .......................................59

Air Mix Door Motor PBR Circuit ...............................62

Intake Door Motor Circuit .........................................62

Blower Motor Circuit ................................................64

Magnet Clutch Circuit ..............................................69

Insufficient Cooling ..................................................75

Insufficient Heating ..................................................82

Noise .......................................................................83

Self-Diagnosis .........................................................84

Memory Function .....................................................85

Ambient Sensor Circuit ............................................86

In-vehicle Sensor Circuit ..........................................88

Sunload Sensor Circuit ............................................91

Intake Sensor Circuit ...............................................94

CONTROLLER ..................................................97

Removal and Installation of A/C and AV Switch ......97

AUTO AMP ........................................................98

Removal and Installation of Unified Meter and A/C

Amp .........................................................................

98

AMBIENT SENSOR ..........................................99

Removal and Installation .........................................99

IN-VEHICLE SENSOR ....................................100

Removal and Installation .......................................100

SUNLOAD SENSOR .......................................101

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 408 of 3924

PRECAUTIONSATC-3

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612929

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000001612931

NOTE:

This Procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 548 of 3924

AV-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION AV

A

B

AV

N

O P

CONTENTS

AUDIO VISUAL, NAVIGATION & TELEPHONE SYS- TEM

SERVICE INFORMATION ............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

PREPARATION ...................................................4

Commercial Service Tool .................................... ......4

AUDIO .................................................................5

System Description ............................................. ......5

Component Parts Location ........................................6

Schematic - AUDIO - / with Navigation System ........7

Wiring Diagram - AUDIO - / with Navigation Sys-

tem ............................................................................

8

Schematic - AUDIO - without Navigation System ....18

Wiring Diagram - AUDIO - / without Navigation

System ....................................................................

19

Terminal and Reference Value for Audio Unit .........28

Terminal and Reference Value for BOSE Speaker

Amp .........................................................................

30

Terminal and Reference Value for A/C and AV

Switch ......................................................................

32

Terminal and Reference Value for Woofer ..............33

Terminal and Reference Value for Satellite Radio

Tuner ................................................................... ....

34

A/C and AV Switch Self-Diagnosis Function ...........34

Trouble Diagnosis ...................................................35

Power Supply Circuit Inspection .............................36

Audio Steering Wheel Switch Inspection ................37

A/C and AV Switch Inspection ................................39

BOSE Speaker Amp. Inspection .............................39

Vehicle Speed Signal Inspection .............................40

Locking CD Auto-Changer Mechanism ...................41

Removal and Installation of Audio Unit ...................41

Disassembly and Assembly of Audio Unit ...............42

Removal and Installation for A/C and AV Switch ....42

Removal and Installation for Front Door Speaker ....43

Removal and Installation for Rear Door Speaker ....43

Removal and Installation for Instrument Speaker ....43

Removal and Installation for Tweeter .................. ....44

Removal and Installation for Woofer (BOSE Sys-

tem) .........................................................................

44

Removal and Installation for BOSE Speaker Amp ....44

Removal and Installation of Satellite Radio Tuner ....45

Removal and Installation of Satellite Radio Anten-

na ......................................................................... ....

45

ANTENNA .........................................................46

System Description ..................................................46

Wiring Diagram - M/ANT - .......................................47

Terminal and Reference Value for Audio Unit .........48

Antenna Amp. Inspection ........................................48

Location of Antenna .................................................49

Window Antenna Repair ..........................................49

Removal and Installation of Roof Antenna ..............51

Removal and Installation of Satellite Radio Anten-

na ......................................................................... ....

51

INTEGRATED DISPLAY SYSTEM ...................52

System Description ..................................................52

Component Description ...........................................52

CAN Communication Unit ........................................53

Component Parts Location ......................................53

Schematic - INF/D - .................................................54

Wiring Diagram - INF/D - .........................................55

Schematic - COMM - ...............................................61

Wiring Diagram - COMM - .......................................62

Terminal and Reference Value for Display Control

Unit ...................................................................... ....

67

Terminal and Reference Value for Display ..............69

Terminal and Reference Value for A/C and AV

Switch ......................................................................

71

Special Note for Trouble Diagnosis .........................72

On Board Self-Diagnosis Function ..........................72

Self-Diagnosis Mode (DCU) ....................................73

Confirmation/Adjustment Mode ...............................75

CAN Diagnostic Support Monitor .............................77

A/C and AV Switch Self-Diagnosis Function ...........78

CAN Communication Check ....................................79

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C