engine coolant INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3336 of 3924

ENGINE MAINTENANCE (VK45DE ENGINE)MA-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

ENGINE MAINTENANCE (VK45DE ENGINE)

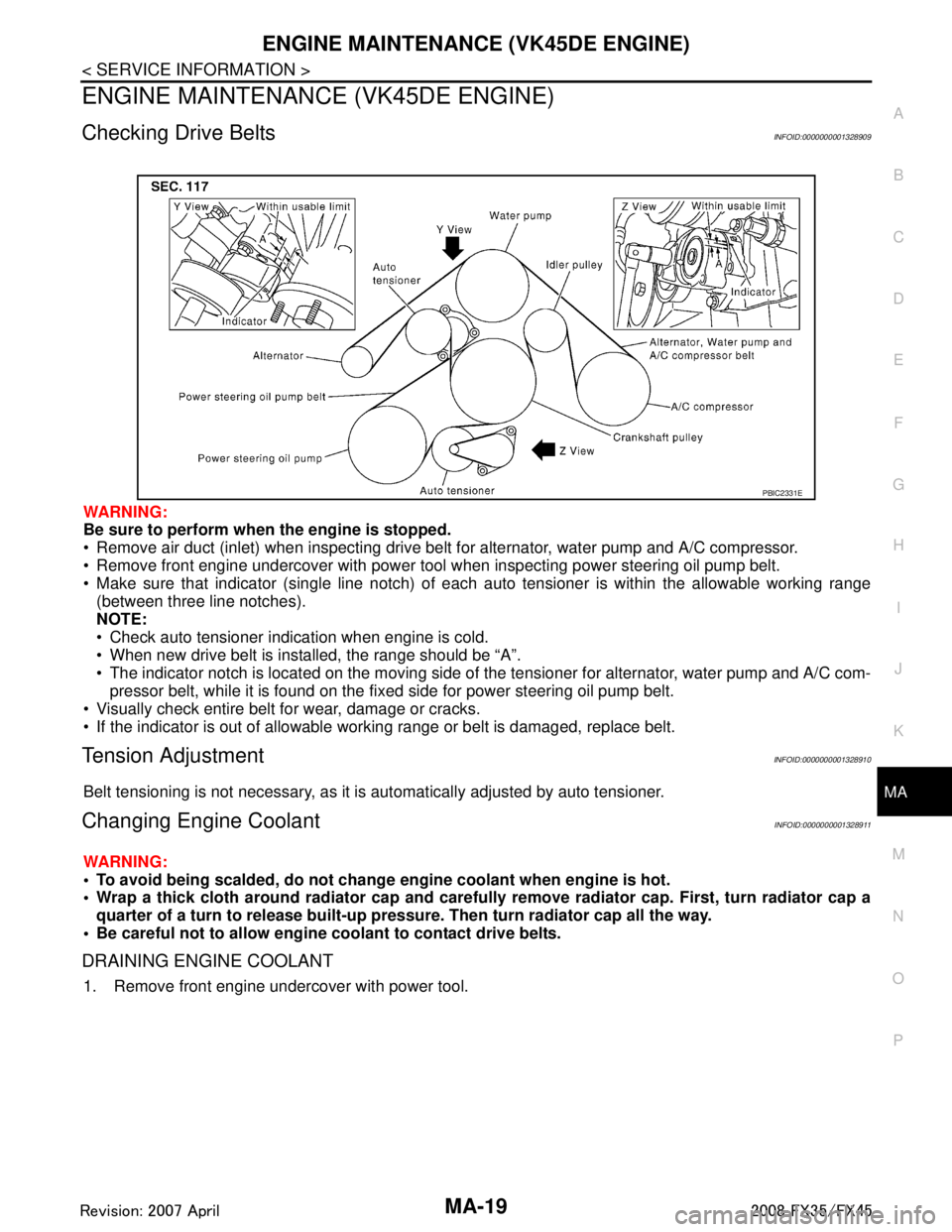

Checking Drive BeltsINFOID:0000000001328909

WARNING:

Be sure to perform when the engine is stopped.

Remove air duct (inlet) when inspecting drive belt for alternator, water pump and A/C compressor.

Remove front engine undercover with power tool when inspecting power steering oil pump belt.

Make sure that indicator (single line notch) of eac h auto tensioner is within the allowable working range

(between three line notches).

NOTE:

Check auto tensioner indication when engine is cold.

When new drive belt is installed, the range should be “A”.

The indicator notch is located on the moving side of the tensioner for alternator, water pump and A/C com-

pressor belt, while it is found on the fi xed side for power steering oil pump belt.

Visually check entire belt for wear, damage or cracks.

If the indicator is out of allowable working range or belt is damaged, replace belt.

Tension AdjustmentINFOID:0000000001328910

Belt tensioning is not necessary, as it is automatically adjusted by auto tensioner.

Changing Engine CoolantINFOID:0000000001328911

WARNING:

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressu re. Then turn radiator cap all the way.

Be careful not to allow engine coolant to contact drive belts.

DRAINING ENGINE COOLANT

1. Remove front engine undercover with power tool.

PBIC2331E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3337 of 3924

MA-20

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VK45DE ENGINE)

2. Open radiator drain plug at the bottom of radiator, and thenremove radiator cap.

When draining all of engine cool ant in the system, open water drai n plugs on cylinder block. Refer

to EM-242, "

Disassembly and Assembly".

3. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system. Refer to "FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, and radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-242, "

Dis-

assembly and Assembly".

2. Make sure that each hose clamp has been firmly tightened.

3. Remove air relief plug on heater hose.

4. Fill thermostat housing and reservoir tank to specified level. Refill engine coolant up to fill er neck of thermostat housing.

Pour engine coolant through engine coolant filler neck slowly of less than 2 (2-1/8 US qt, 1-3/4

Imp qt) a minute to allo w air in system to escape.

Use Genuine NISSAN long Life Antifreeze/Coolant or equivalent mixed with water (distilled or

demineralized). Refer to MA-9

.

SBIA0444E

Radiator drain plug:

: 1.19 N·m (0.12 kg-m, 11 in-lb)

PBIC1530E

Engine coolant capacity

(With reservoir tank at “MAX” level):Approx. 10.0 (10-5/8 US qt, 8-3/4 Imp qt)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3338 of 3924

ENGINE MAINTENANCE (VK45DE ENGINE)MA-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

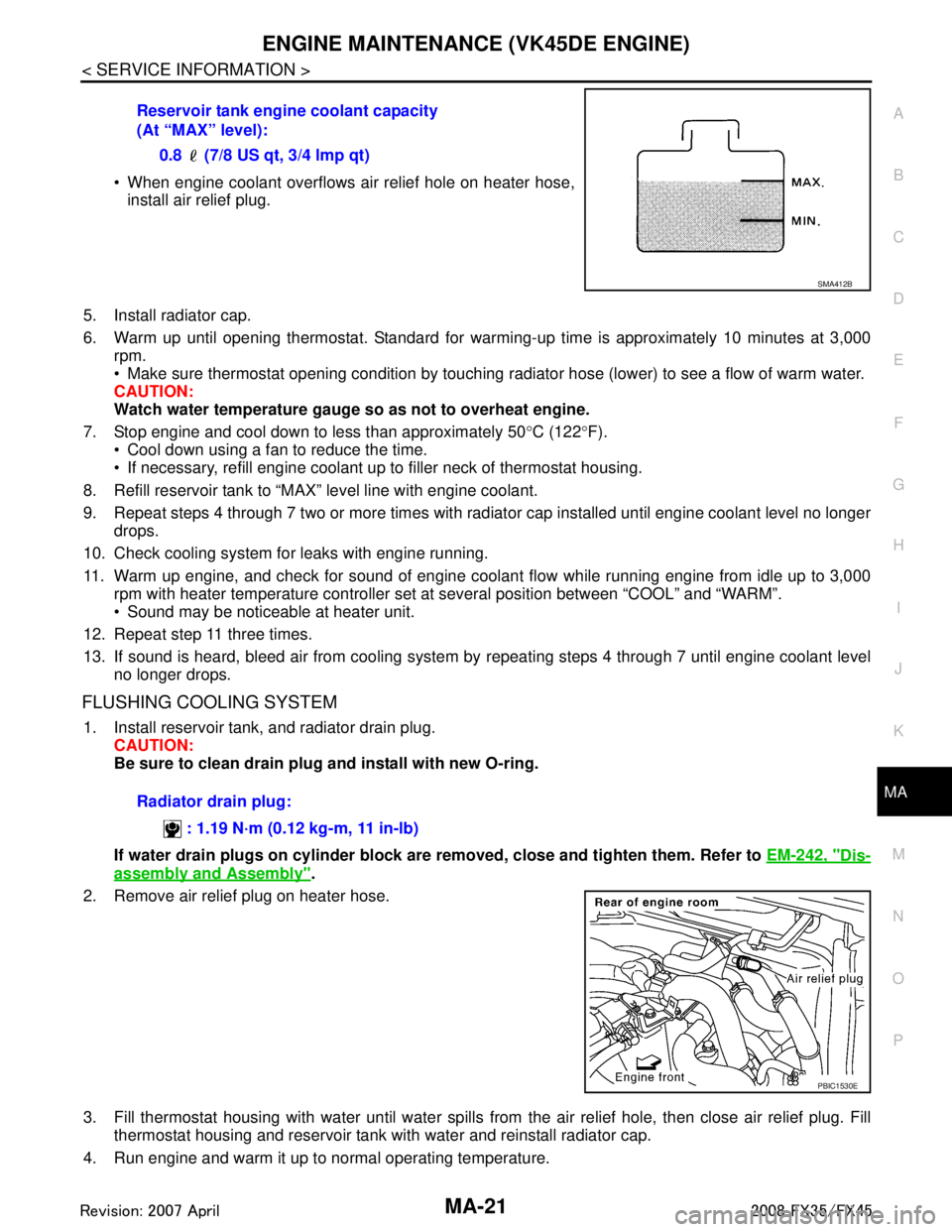

When engine coolant overflows air relief hole on heater hose, install air relief plug.

5. Install radiator cap.

6. Warm up until opening thermostat. Standard for warm ing-up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching r adiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

7. Stop engine and cool down to less than approximately 50 °C (122 °F).

Cool down using a fan to reduce the time.

If necessary, refill engine coolant up to filler neck of thermostat housing.

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap installed until engine coolant level no longer drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating steps 4 through 7 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank, and radiator drain plug. CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-242, "

Dis-

assembly and Assembly".

2. Remove air relief plug on heater hose.

3. Fill thermostat housing with water until water spills from the air relief hole, then close air relief plug. Fill

thermostat housing and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature. Reservoir tank engine coolant capacity

(At “MAX” level):

0.8 (7/8 US qt, 3/4 lmp qt)

SMA412B

Radiator drain plug:

: 1.19 N·m (0.12 kg-m, 11 in-lb)

PBIC1530E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3339 of 3924

MA-22

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VK45DE ENGINE)

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the system. Refer to "DRAINING ENGINE COOLANT".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LineINFOID:0000000001328912

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterINFOID:0000000001328913

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between replacement intervals. Refer to MA-5.

1. Remove air duct (inlet), air cleaner case and mass air flow sensor assembly. Refer to EM-173

.

2. Remove air cleaner filter from air cleaner case.

Changing Engine OilINFOID:0000000001328914

WARNING:

Be careful not to burn yoursel f, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause ski n cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Remove front engine undercover with power tool.

2. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

to LU-23, "

Inspection".

3. Stop engine and wait for 15 minutes.

4. Loosen oil filler cap, and then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. Refer to EM-183

.

CAUTION:

Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Engine oil specification and viscosity:

Refer to MA-9

.

Engine oil capacity (Approximate):

Unit: (US qt, Imp qt)

CAUTION:

SMA803A

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

PBIC0993E

Drain and refill With oil filter change 5.8 (6-1/8, 5-1/8)

Without oil filter change 5.2 (5-1/2, 4-5/8)

Dry engine (engine overhaul) 7.0 (7-3/8, 6-1/8)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3354 of 3924

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-37

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B

MA

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001328938

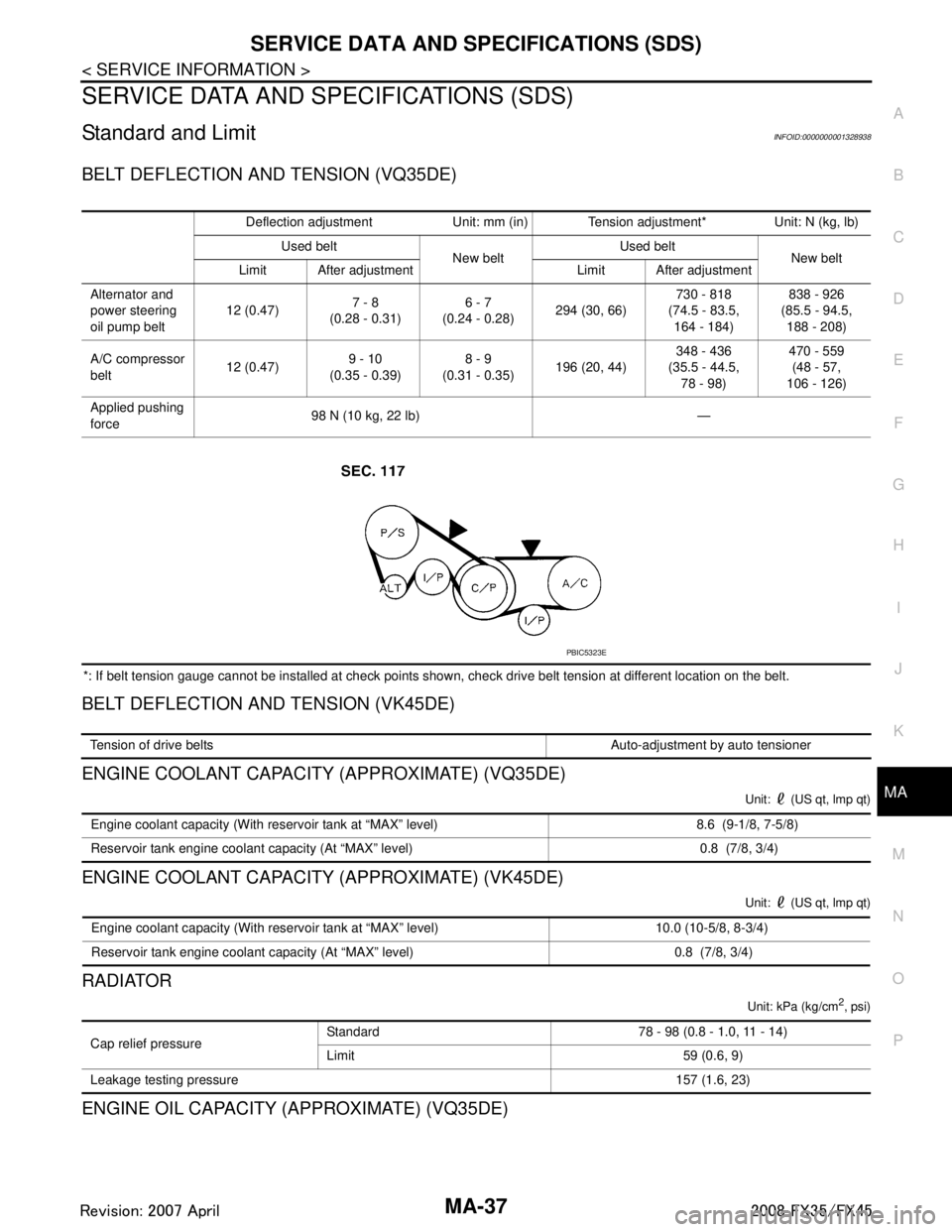

BELT DEFLECTION AND TENSION (VQ35DE)

*: If belt tension gauge cannot be installed at check points shown, check drive belt tension at different location on the belt.

BELT DEFLECTION AND TENSION (VK45DE)

ENGINE COOLANT CAPACITY (APPROXIMATE) (VQ35DE)

Unit: (US qt, lmp qt)

ENGINE COOLANT CAPACITY (APPROXIMATE) (VK45DE)

Unit: (US qt, lmp qt)

RADIATOR

Unit: kPa (kg/cm2, psi)

ENGINE OIL CAPACITY (APPROXIMATE) (VQ35DE)

Deflection adjustment Unit: mm (in) Tension adjustment* Unit: N (kg, lb) Used belt New beltUsed belt

New belt

Limit After adjustment Limit After adjustment

Alternator and

power steering

oil pump belt 12 (0.47)

7 - 8

(0.28 - 0.31) 6 - 7

(0.24 - 0.28) 294 (30, 66) 730 - 818

(74.5 - 83.5, 164 - 184) 838 - 926

(85.5 - 94.5, 188 - 208)

A/C compressor

belt 12 (0.47)

9 - 10

(0.35 - 0.39) 8 - 9

(0.31 - 0.35) 196 (20, 44) 348 - 436

(35.5 - 44.5,

78 - 98) 470 - 559

(48 - 57,

106 - 126)

Applied pushing

force 98 N (10 kg, 22 lb) —

PBIC5323E

Tension of drive belts Auto-adjustment by auto tensioner

Engine coolant capacity (With reservoir tank at “MAX” level) 8.6 (9-1/8, 7-5/8)

Reservoir tank engine coolant capacity (At “MAX” level) 0.8 (7/8, 3/4)

Engine coolant capacity (With reservoir tank at “MAX” level) 10.0 (10-5/8, 8-3/4)

Reservoir tank engine coolant capacity (At “MAX” level) 0.8 (7/8, 3/4)

Cap relief pressure Standard 78 - 98 (0.8 - 1.0, 11 - 14)

Limit 59 (0.6, 9)

Leakage testing pressure 157 (1.6, 23)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3425 of 3924

HARNESSPG-61

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

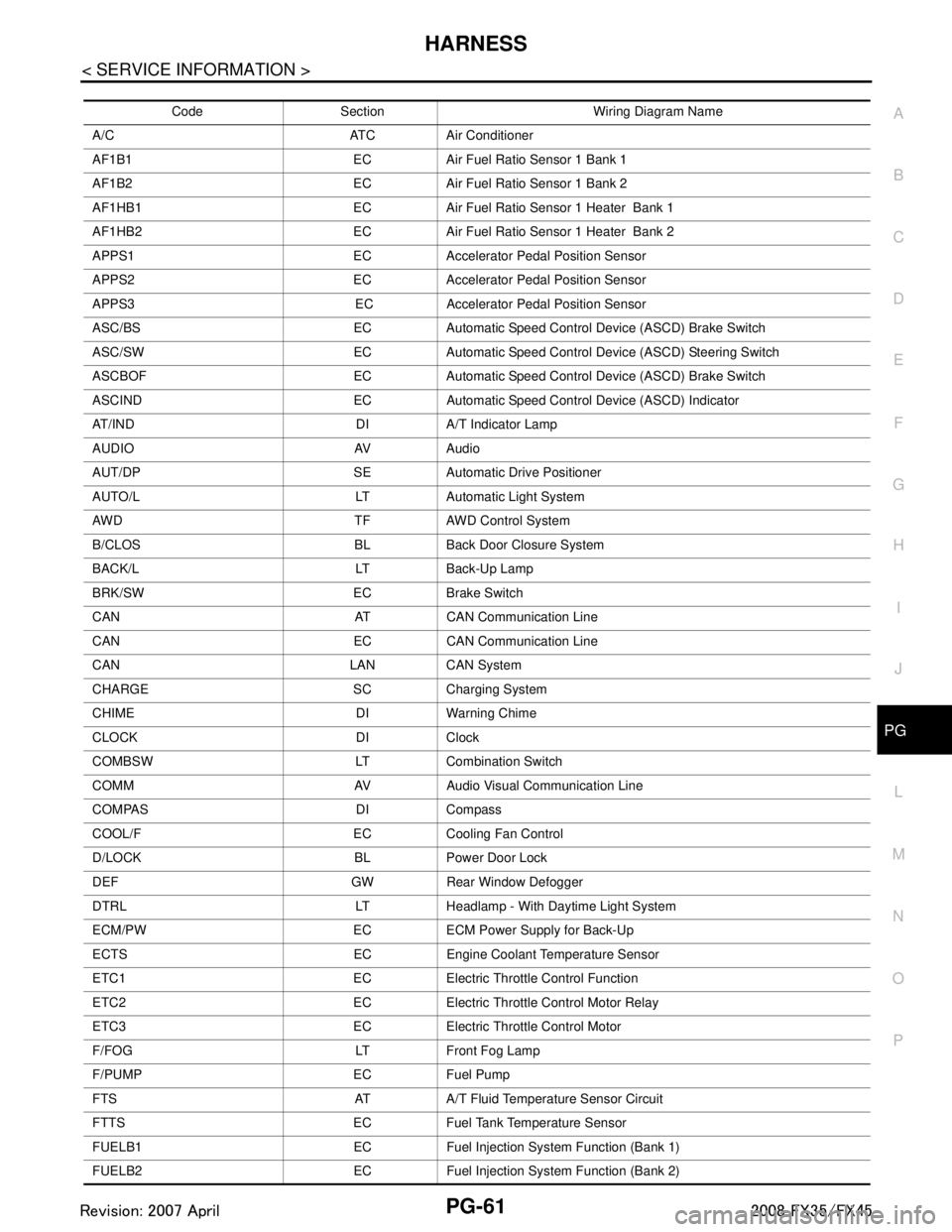

Code Section Wiring Diagram Name

A/C ATC Air Conditioner

AF1B1 EC Air Fuel Ratio Sensor 1 Bank 1

AF1B2 EC Air Fuel Ratio Sensor 1 Bank 2

AF1HB1 EC Air Fuel Ratio Sensor 1 Heater Bank 1

AF1HB2 EC Air Fuel Ratio Sensor 1 Heater Bank 2

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC Automatic Speed Control Device (ASCD) Brake Switch

ASC/SW EC Automatic Speed Control Device (ASCD) Steering Switch

ASCBOF EC Automatic Speed Control Device (ASCD) Brake Switch

ASCIND EC Automatic Speed Contro l Device (ASCD) Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUT/DP SE Automatic Drive Positioner

AUTO/L LT Automatic Light System

AWD TF AWD Control System

B/CLOS BL Back Door Closure System

BACK/L LT Back-Up Lamp

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CLOCK DI Clock

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass

COOL/F EC Cooling Fan Control

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - With Daytime Light System

ECM/PW EC ECM Power Supply for Back-Up

ECTS EC Engine Coolant Temperature Sensor

ETC1 EC Electric Throttle Control Function

ETC2 EC Electric Throttle Control Motor Relay

ETC3 EC Electric Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUELB1 EC Fuel Injection System Function (Bank 1)

FUELB2 EC Fuel Injection System Function (Bank 2)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3583 of 3924

RSU-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

CautionsINFOID:0000000001327548

• When installing rubber bushings, final tightening must be carried out under unladen conditions with tires on

level ground. Oil will shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

Unladen conditions means that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

After servicing suspension parts, be sure to check wheel alignment.

Caulking nuts are not reusable. Always use new ones w hen installing. Since new caulking nuts are pre-oiled,

tighten as they are.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3586 of 3924

REAR SUSPENSION ASSEMBLYRSU-5

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001327552

Make sure the mounting conditions (looseness, ba ck lash) of each component and component status (wear,

damage) are normal.

INSPECTION OF BALL JOINT END PLAY

Measure axial end play by installing and moving up/down with an

iron pry bar or something similar between suspension arm and axle.

CAUTION:

Be careful not to damage ball joint boot.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace if necessary.

Wheel AlignmentInspectionINFOID:0000000001327553

DESCRIPTION

Measure wheel alignment under unladen conditions. “U nladen conditions” means that fuel, engine coolant,

and lubricant are full. Spare tire, jack, hand tools and mats in designated positions.

PRELIMINARY INSPECTION

Check tires for improper air pressure and wear.

Check road wheels for runout.

Check wheel bearing axial end play.

Check ball joint axial end play of suspension arm.

Check shock absorber operation.

Check each mounting point of axle and suspension for looseness and deformation.

Check each link, arm and member for cracks, deformation, and other damage.

Check vehicle posture.

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly ca librated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

THE ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specificati ons listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). DO NOT use this “Rolling Compensation”

method. Standard value

Axial end play : 0 mm (0 in)

SEIA0245J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3599 of 3924

RSU-18

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Alignment (Unladen*)INFOID:0000000001327563

*: Fuel, engine coolant and lubricant are oil full. Spare tire, jack, hand tools and mats are in designated positions.

Ball JointINFOID:0000000001327564

Wheelarch Height (Unladen*)INFOID:0000000001327565

*: Fuel, engine coolant and lubricant are oil full. Spare tire, jack, hand tools and mats are in designated positions.Camber

Degree minute (Decimal degree)

Minimum –1

°18 ′ (–1.30 °)

Nominal –0 °48 ′ (–0.80 °)

Maximum –0 °18 ′ (–0.30 °)

To t a l t o e - i n Distance

Minimum 2.4 mm (0.09 in)

Nominal 4.7 mm (0.19 in)

Maximum 7.0 mm (0.28 in)

Angle (left wheel or right wheel)

Degree minute (Decimal degree) Minimum 0

°05 ′ (0.08 °)

Nominal 0 °10 ′ (0.17 °)

Maximum 0 °15 ′ (0.25 °)

Axial end play 0 mm (0 in)

Swing torque 0.5 − 3.4 N·m (0.06 − 0.34 kg-m, 5 − 30 in-lb)

Measurement on spring balance (cotter pinhole position) 9.7 − 66.0 N (0.98 − 6.7 kg, 2.18 − 14.8 lb)

Rotating torque 0.5 − 3.4 N·m (0.06 − 0.34 kg-m, 5 − 30 in-lb)

Destination USA Canada

Engine VQ35DE VK45DE VQ35DE VK45DE

Axle 2WD AWD AWD

Tire size 265/60R18 265/50R20 265/60R18 265/50R20 265/60R18 265/50R20

Front (Hf) 835 mm

(32.87 in) 834 mm

(32.83 in) 834 mm

(32.83 in) 833 mm

(32.80 in) 832 mm

(32.76 in) 834 mm

(32.83 in) 833 mm

(32.80 in) 832 mm

(32.76 in)

Rear (Hr) 822 mm

(32.36 in) 821 mm

(32.32 in) 829 mm

(32.64 in) 827 mm

(32.56 in) 825 mm

(32.48 in) 827 mm

(32.56 in) 826 mm

(32.52 in) 823 mm

(32.40 in)

SFA818A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3620 of 3924

STARTING SYSTEMSC-11

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

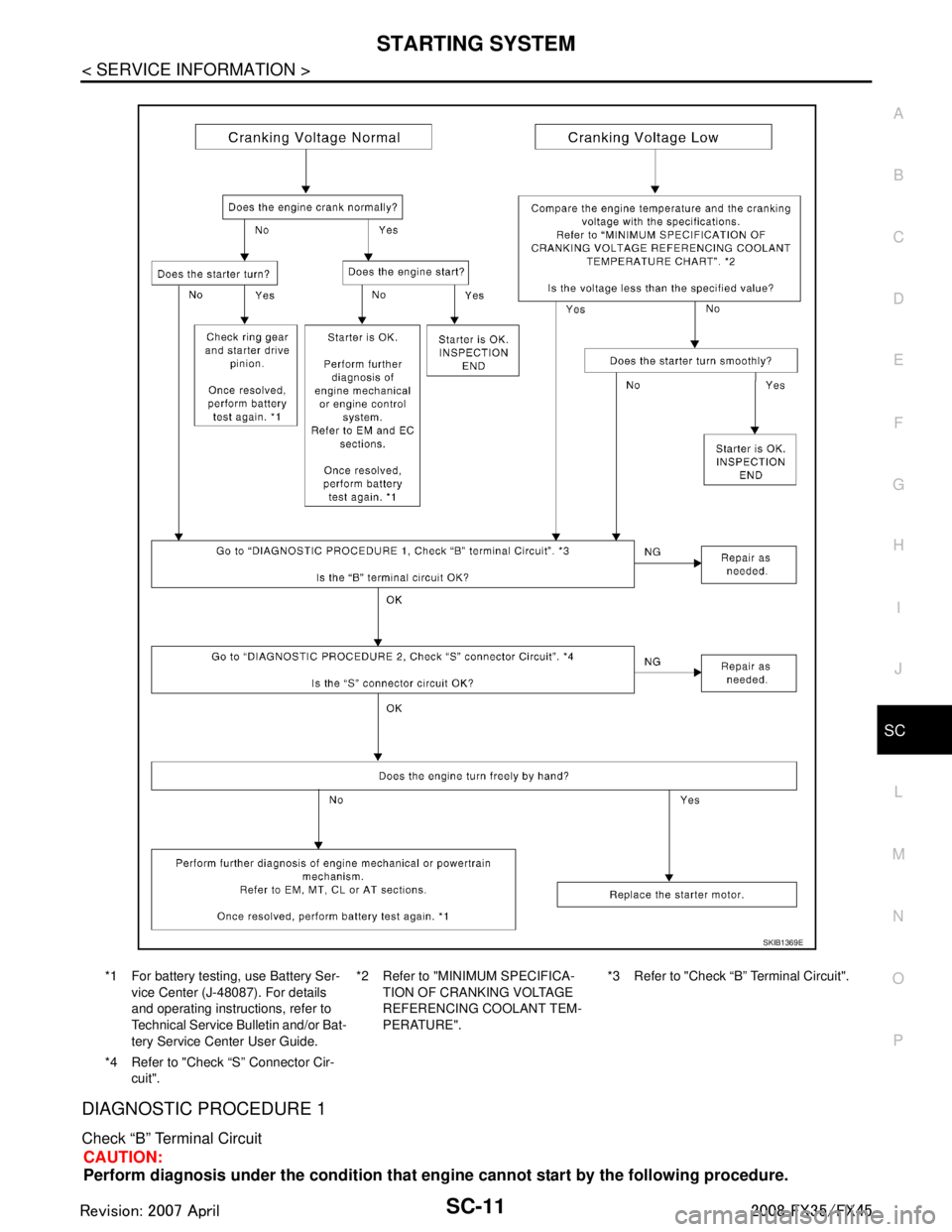

DIAGNOSTIC PROCEDURE 1

Check “B” Terminal Circuit

CAUTION:

Perform diagnosis under the cond ition that engine cannot start by the following procedure.

*1 For battery testing, use Battery Ser-

vice Center (J-480 87). For details

and operating instructions, refer to

Technical Service Bulletin and/or Bat-

tery Service Center User Guide. *2 Refer to "MINIMUM SPECIFICA-

TION OF CRANKING VOLTAGE

REFERENCING COOLANT TEM-

PERATURE". *3 Refer to "Check “B” Terminal Circuit".

*4 Refer to "Check “S” Connector Cir-

cuit".

SKIB1369E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C