engine INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1124 of 3924

![INFINITI FX35 2008 Service Manual

THERMOSTAT AND WATER CONTROL VALVECO-53

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Refer to

GI-8, "Component" for symbols in the figure.

Removal and InstallationINFOID:000000 INFINITI FX35 2008 Service Manual

THERMOSTAT AND WATER CONTROL VALVECO-53

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Refer to

GI-8, "Component" for symbols in the figure.

Removal and InstallationINFOID:000000](/img/42/57017/w960_57017-1123.png)

THERMOSTAT AND WATER CONTROL VALVECO-53

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Refer to

GI-8, "Component" for symbols in the figure.

Removal and InstallationINFOID:0000000001325885

REMOVAL

1. Drain engine coolant from drain plugs on radiat or and both side of cylinder block. Refer to CO-37, "Chang-

ing Engine Coolant" and EM-242, "Disassembly and Assembly".

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

2. Remove engine cover with power tool. Refer to EM-169, "

Component".

3. Remove air duct (inlet). Refer to EM-173, "

Component".

4. Disconnect water suction hose from water inlet.

5. Remove water inlet and thermostat. CAUTION:

Do not disassemble thermostat.

6. Remove intake manifolds (upper and lower). Refer to EM-175, "

Component".

7. Disconnect radiator hose (upper) and wa ter hoses from thermostat housing.

8. Disconnect heater hoses from water outlet and heater pipe.

9. Remove thermostat housing, water outlet pipe, water connector, water control valve, water outlet and heater pipe.

CAUTION:

Do not disassemble water control valve.

INSPECTION AFTER REMOVAL

Make sure that valves both in thermostat and water c ontrol valve are completely closing at normal tempera-

ture.

Place a thread so that it is caught in the valves of the thermostat

and water control valve. Immerse fully in a container filled with

water. Heat while stirring. (The example in the figure shows ther-

mostat.)

The valve opening temperature is the temperature at which the valve opens and falls from the thread.

Continue heating. Check the maximum valve lift. NOTE:

The maximum valve lift standard temperature for water control

valve is the reference value.

After checking the maximum valve lift, lower the water tempera-

ture and check the valve closing temperature.

Standard values:

If the malfunctioning condition, when closing valve at nor mal temperature, or measured values are out of the

standard, replace thermostat and/or water control valve.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Be careful not to spill engine coolant over en gine room. Use rag to absorb engine coolant.

Thermostat and Water Control Valve

D. To heater core E. To cylinder head (left bank) F. To cylinder head (right bank)

G. To intake manifold adapter

SLC252B

Thermostat Water control valve

Valve opening temperature 80 - 84 °C (176 - 183 °F) 93.5 - 96.5 °C (200 - 206 °F)

Maximum valve lift More than 10 mm/95

°C

(0.39 in/203 °F) More than 8 mm/108

°C

(0.315 in/226 °F)

Valve closing temperature 77 °C (171 °F) 90 °C (194 °F)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1125 of 3924

![INFINITI FX35 2008 Service Manual

CO-54

< SERVICE INFORMATION >[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Install thermostat and water control valve with the whole circumfer-

ence of each flange part fit securely inside rubber rin INFINITI FX35 2008 Service Manual

CO-54

< SERVICE INFORMATION >[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Install thermostat and water control valve with the whole circumfer-

ence of each flange part fit securely inside rubber rin](/img/42/57017/w960_57017-1124.png)

CO-54

< SERVICE INFORMATION >[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Install thermostat and water control valve with the whole circumfer-

ence of each flange part fit securely inside rubber ring. (The exam-

ple in the figure shows thermostat.)

Install thermostat with jiggle valve facing upwards. (The position deviation may be within the range of ±10 degrees)

Install water control valve with the up-mark facing up and the frame

center part facing upwards. (The position deviation may be within

the range of ±10 degrees)

Water Outlet Pipe and Heater Pipe

First apply a neutral detergent to O-rings, then quickly insert the insertion parts of the water outlet pipe and

heater pipe into the installation holes.

INSPECTION AFTER INSTALLATION

Check for leaks of engine coolant using radiator cap tester adapter (commercial service tool) and radiator

cap tester (commercial service tool). Refer to CO-37, "

Inspection".

Start and warm up engine. Visually check if there is no leaks of engine coolant.

PBIC0157E

PBIC0158E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1126 of 3924

![INFINITI FX35 2008 Service Manual

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-55

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001325886

ENGINE COO INFINITI FX35 2008 Service Manual

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-55

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001325886

ENGINE COO](/img/42/57017/w960_57017-1125.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-55

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001325886

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

RADIATOR

Unit: kPa (kg/cm2, psi)

THERMOSTAT

WATER CONTROL VALVE

Engine coolant capacity [With reservoir tank at (“MAX” level)] 10.0 (10-5/8, 8-3/4)

Reservoir tank engine coolant capacity (at “MAX” level) 0.8 (7/8, 3/4)

Radiator cap relief pressure

Standard 78 - 98 (0.8 - 1.0, 11 - 14)

Limit 59 (0.6, 9)

Leakage testing pressure 157 (1.6, 23)

Valve opening temperature 80 - 84 °C (176 - 183 °F)

Maximum valve lift More than 10 mm/95 °C (0.39 in/203 °F)

Valve closing temperature 77 °C (171 °F)

Valve opening temperature 93.5 - 96.5 °C (200 - 206 °F)

Maximum valve lift More than 8 mm/108 °C (0.315 in/226 °F)

Valve closing temperature 90 °C (194 °F)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1127 of 3924

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................3

DTC INDEX ..................................................... .....3

U1000 - U1010 .................................................... ......3

B2202 - B2205 ..........................................................3

C1B00 - C1B03 .........................................................3

PRECAUTION .....................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

COMBINATION METERS ...................................5

System Description ............................................. ......5

Component Parts and Harness Connector Loca-

tion ............................................................................

8

Arrangement of Combination Meter ..........................9

Circuit Diagram .......................................................10

Wiring Diagram - METER - .....................................11

Terminal and Reference Value for Combination

Meter .......................................................................

13

Terminal and Reference Value for Unified Meter

and A/C Amp ...........................................................

14

Self-Diagnosis Mode of Combination Meter ............14

CONSULT-III Function (METER/M&A) ...................15

Trouble Diagnosis ...................................................15

Symptom Chart .......................................................16

Power Supply and Ground Circuit Inspection .........16

Vehicle Speed Signal Inspection .............................17

Engine Speed Signal Inspection .............................18

Engine Coolant Temperature Signal Inspection ......19

Fuel Level Sensor Signal Inspection .......................19

Fuel Gauge Pointer Fluctuates, Indicator Wrong

Value or Varies ........................................................

21

Fuel Gauge Does Not Move to FULL Position ........21

Odo/Trip Meter and Illumination Control Switch In-

spection ............................................................... ....

21

Electrical Component Inspection .............................21

Removal and Installation of Combination Meter .....22

Disassembly and Assembly of Combination Meter

....

23

Removal and Installation of Odo/Trip Meter and Il-

lumination Control Switch .................................... ....

24

UNIFIED METER AND A/C AMP ......................26

System Description ..................................................26

Schematic ................................................................27

CONSULT-III Function (METER/M&A) ....................27

Power Supply and Ground Circuit Inspection ..........29

DTC [U1000] CAN Communication Circuit ..............30

DTC [B2202] Meter Commun ication Circuit ............30

DTC [B2205] Vehicle Speed Circuit .................... ....32

Removal and Installation of Unified Meter and A/C

Amp .........................................................................

32

WARNING LAMPS ............................................34

System Description .............................................. ....34

Schematic ................................................................35

Wiring Diagram - WARN - .......................................36

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

43

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

45

Component Inspection .............................................46

A/T INDICATOR ................................................47

System Description ..................................................47

Wiring Diagram - AT/IND - .......................................48

A/T Indicator Is Malfunction .....................................49

WARNING CHIME .............................................51

System Description .............................................. ....51

Component Parts and Harness Connector Loca-

tion ...........................................................................

53

Schematic ................................................................54

Wiring Diagram - CHIME - .......................................55

Terminal and Reference Value for BCM ..................57

Terminal and Reference Value for Unified Meter

and A/C Amp. ...................................................... ....

59

Terminal and Reference Value for Combination

Meter .......................................................................

59

CONSULT-III Function (METER/M&A) ....................60

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1131 of 3924

COMBINATION METERSDI-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

COMBINATION METERS

System DescriptionINFOID:0000000001328433

UNIFIED METER CONTROL UNIT

Speedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled by the

unified meter control unit, which is built into the comb ination meter. Unified meter control unit receives sig-

nals from unified meter and A/C amp.

Warning lamp and indicator lamp of combination meter are controlled by signals drawn from the unified meter and A/C amp.

Odo/trip meter, A/T indicator and ICC system disp lay segments can be checked in self-diagnosis mode.

Meters/gauges can be checked in self-diagnosis mode.

UNIFIED METER AND A/C AMP.

Refer to DI-26, "System Description" in “UNIFIED METER AND A/C AMP”.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

through 10A fuse [No. 19, located in the fuse block (J/B)]

to combination meter terminal 8, and

to unified meter and A/C amp. terminal 21.

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 14, located in the fuse block (J/B)]

to combination meter terminal 7,

through 10A fuse [No. 12, located in the fuse block (J/B)]

to unified meter and A/C amp. terminal 22.

With the ignition switch in the ACC or ON position, power is supplied

through 10A fuse [No. 6, located in the fuse block (J/B)]

to combination meter terminal 4,

through 15A fuse [No. 10, located in the fuse block (J/B)], and

through 15A fuse [No. 11, located in the fuse block (J/B)]

to unified meter and A/C amp. terminal 46.

Ground is supplied

to combination meter terminals 5, 6 and 15

through grounds M35, M45 and M85,

to unified meter and A/C amp. terminals 29 and 30

through grounds M35, M45 and M85.

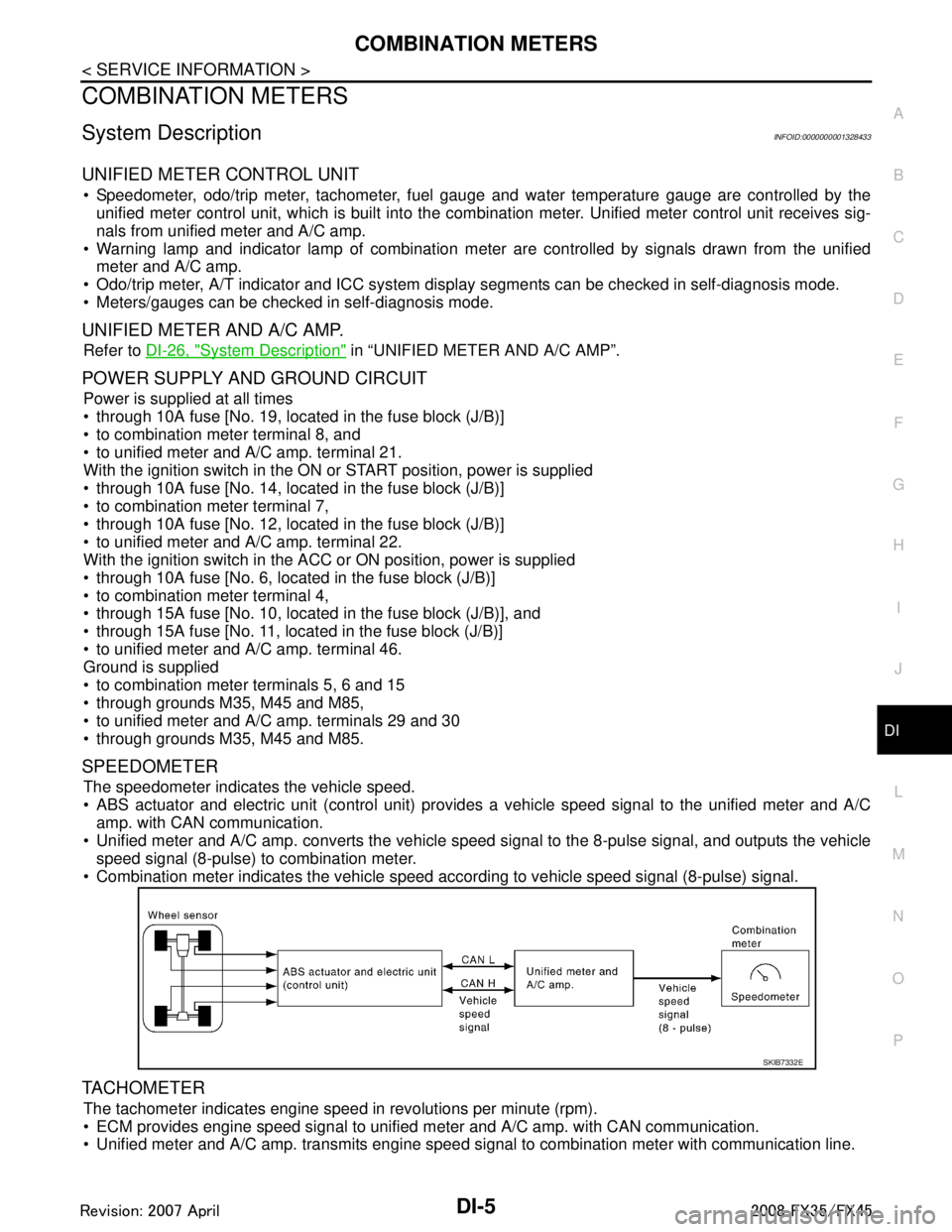

SPEEDOMETER

The speedometer indicates the vehicle speed.

ABS actuator and electric unit (control unit) provides a vehicle speed signal to the unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. converts the vehicle s peed signal to the 8-pulse signal, and outputs the vehicle

speed signal (8-pulse) to combination meter.

Combination meter indicates the vehicle speed according to vehicle speed signal (8-pulse) signal.

TACHOMETER

The tachometer indicates engine speed in revolutions per minute (rpm).

ECM provides engine speed signal to unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. transmits engine speed signal to combination meter with communication line.

SKIB7332E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1132 of 3924

DI-6

< SERVICE INFORMATION >

COMBINATION METERS

Combination meter indicates the engine speed according to engine speed signal.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

ECM provides engine coolant temperature signal to unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. transmits engine coolant temperature signal to combination meter with commu-

nication line.

Combination meter indicates the engine coolant temper ature according to engine coolant temperature sig-

nal.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

Unified meter and A/C amp. reads a resistor signal from fuel level sensor.

Signal is supplied- from unified meter and A/C amp. terminal 36

- through the fuel level sensor unit and fuel pump (main) terminals 5 and 2, and

- through the fuel level sensor unit (sub) terminals 2 and 1

- to unified meter and A/C amp. terminal 28 for the fuel gauge.

Unified meter and A/C amp. provides a fuel level signal to combination meter with communication line.

Combination meter indicates the approximate fuel level according to the fuel level signal.

ODO/TRIP METER

ABS actuator and electric unit (control unit) provi des a vehicle speed signal to the unified meter and A/C

amp. with CAN communication.

Unified meter and A/C amp. converts the vehicle s peed signal to the 8-pulse signal, and outputs the vehicle

speed signal (8-pulse) to combination meter.

Combination meter uses the vehicle speed signal (8- pulse) to calculate the mileage, and displays it.

How to Change The Display For Odo/trip Meter

PKIB7631E

PKIB7632E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1142 of 3924

DI-16

< SERVICE INFORMATION >

COMBINATION METERS

Perform self-diagnosis mode of combination meter. Refer to DI-14, "Self-Diagnosis Mode of Combination

Meter".

Does self-diagnosis function operate?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK UNIFIED METER AND A/C AMP. (CONSULT-III)

Perform self-diagnosis of unified meter and A/C amp. Refer to DI-27, "

CONSULT-III Function (METER/M&A)".

Self-diagnosis results

No malfunction detected >> INSPECTION END

Malfunction detected >> Check applicable parts, and repair or replace corresponding parts.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT OF COMBINATION METER

Check power supply and ground circuit of combination meter. Refer to DI-16, "

Power Supply and Ground Cir-

cuit Inspection".

OK or NG

OK >> Check odo/trip meter switch. Refer to DI-21, "Odo/Trip Meter and Illumination Control Switch

Inspection".

NG >> Repair malfunctioning part.

Symptom ChartINFOID:0000000001328443

Power Supply and Ground Circuit InspectionINFOID:0000000001328444

1.CHECK FUSE

Check for blown combination meter fuses.

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3, "

Schematic".

2.CHECK POWER SUPPLY CIRCUIT

Symptom Possible cause

Speedometer and odo/trip meter indication is malfunctioning. Refer to DI-17, "

Vehicle Speed Signal Inspection".

Tachometer indication is malfunctioning. Refer to DI-18, "

Engine Speed Signal Inspection".

Water temperature gauge indication is malfunctioning. Refer to DI-19, "

Engine Coolant Temperature Signal Inspection".

Fuel gauge indication is malfunctioning. Refer to DI-19, "

Fuel Level Sensor Signal Inspection".

Low-fuel warning lamp indication is irregular.

A/T indicator is malfunctioning. Refer to DI-49, "

A/T Indicator Is Malfunction".

Illumination control does not operate. Refer to

DI-21, "

Odo/Trip Meter and Illumination Control Switch In-

spection".

Power source Fuse No.

Battery power supply 19 ACC power supply 6

Ignition power supply 14

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1143 of 3924

COMBINATION METERSDI-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Check voltage between combination meter harness connector M20

terminals 4, 7, 8 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between combination meter and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter harness connector M20 terminals 5, 6, 15 and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Vehicle Speed Signal InspectionINFOID:0000000001328445

Symptom: Speedometer and odo/trip meter indication is malfunction.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Connect CONSULT-III, and start engine.

2. Select “METER /M&A” on CONSULT-III.

3. Using “SPEED METER” on “Data Moni tor”, compare the value of “Data Monitor” with speedometer pointer

of combination meter.

OK or NG

OK >> Perform self-diagnosis of ABS actuator and electric unit (control unit). Refer to BRC-26, "CON-

SULT-III Functions (ABS)".

NG >> GO TO 2.

2.CHECK UNIFIED METER AND A/ C AMP. OUTPUT SIGNAL

1. Drive vehicle at approximately 40 km/h (25 MPH).

Terminals Ignition switch position

(+) (–) OFF ACC ON

Connector Terminal

M20 4

Ground 0 V

Battery

voltage Battery

voltage

70 V0 V Battery

voltage

8 Battery

voltage Battery

voltage Battery

voltage

SKIB8525E

5 – Ground

: Continuity should exist.

6 – Ground

15 – Ground

SKIB8526E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1144 of 3924

DI-18

< SERVICE INFORMATION >

COMBINATION METERS

2. Check voltage signal between unified meter and A/C amp. har-ness connector M56 terminal 26 and ground.

OK or NG

OK >> GO TO 3.

NG-1 >> If monitor indicates “0 V” constantly, perform the following. 1. Check each unit inputting vehicle speed signal (8 pulse), harness and connector betweeneach unit and unified meter and A/C amp.

2. Repair or replace malfunctioning part.

NG-2 >> If monitor indicates “5 V” or “12 V” constantly, replace unified meter and A/C amp. Refer to DI-32,

"Removal and Installation of Unified Meter and A/C Amp".

3.CHECK CONTINUITY BETWEEN COMBINATION METER AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and unified meter and A/C amp. connector.

3. Check continuity between combination meter harness connector

M20 terminal 1 and unified meter and A/C amp. harness con-

nector M56 terminal 26.

OK or NG

OK >> Replace combination meter.

NG >> Repair harness or connector.

Engine Speed Signal InspectionINFOID:0000000001328446

Symptom: Tachometer indication is malfunction.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Connect CONSULT-III, and start engine.

2. Select “METER/M&A” on CONSULT-III.

3. Using “TACHO METER” on “Data Monitor”, compare the value of “Data Monitor” with tachometer pointer

of combination meter.

OK or NG

OK >> GO TO 2.

NG >> Replace combination meter.

2.CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

Select “Data Monitor” of CONSULT-III to compare values between “ ENG SPEED” of “ENGINE” and “TACHO

METER” of “METER/M&A”.

OK or NG

OK >> Perform self-diagnosis of ECM. Refer to EC-117, "CONSULT-III Function (ENGINE)" (VQ35DE)

or EC-695, "

CONSULT-III Function (ENGINE)" (VK45DE).

NG >> Replace unified meter and A/C amp. Refer to DI-32, "

Removal and Installation of Unified Meter

and A/C Amp".

26 – Ground:

NOTE:

Maximum voltage may be 5 V due to

specifications (connected units).

SKIB0338E

PKIA1935E

1 – 26 : Continuity should exist.

SKIB0343E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1145 of 3924

COMBINATION METERSDI-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Engine Coolant Temperature Signal InspectionINFOID:0000000001328447

Symptom: Water temperature gauge indication is malfunction.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Connect CONSULT-III, and start engine.

2. Select “METER/M&A” on CONSULT-III.

3. Using “W TEMP METER” on “Data Monitor”, compare the value of “Data Monitor” with water temperature

gauge pointer of combination meter.

OK or NG

OK >> GO TO 2.

NG >> Replace combination meter.

2.CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

Select “Data Monitor” of CONSULT-“COOLAN TEMP/S ” of “ENGINE” and “W TEMP METER” of “METER/

M&A”.

OK or NG

OK >> Perform self-diagnosis of ECM. Refer to EC-117, "CONSULT-III Function (ENGINE)" (VQ35DE)

or EC-695, "

CONSULT-III Function (ENGINE)" (VK45DE).

NG >> Replace unified meter and A/C amp. Refer to DI-32, "

Removal and Installation of Unified Meter

and A/C Amp".

Fuel Level Sensor Signal InspectionINFOID:0000000001328448

Symptom:

Fuel gauge indication is malfunctioning.

Low-fuel warning lamp indication is irregular.

NOTE:

The following symptoms are not malfunctions.

Fuel gauge Depending on vehicle posture or driving circumstance, the fuel level in the tank varies, and the pointer may

fluctuate.

If the vehicle is fueled with the ignition switch ON, the pointer will move slowly.

Low-fuel warning lamp

Depending on vehicle posture or driving circumstance, t he fuel in the tank flows and the warning lamp ON

timing may change.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Select “METER A/C AMP” on CONSULT-III.

2. Using “FUEL METER” on “Data Monitor”, compare t he value of “Data Monitor” with fuel gauge pointer of

combination meter.

OK or NG

Water temperature gauge pointer Reference value of data monitor [ °C ( °F)]

Hot Approx. 130 (266)

Middle Approx. 70 - 105 (158 - 221) Cold Approx. 50 (122)

Fuel gauge pointer Reference value of data monitor [lit.] Full Approx. 86

Three quarters Approx. 70 Half Approx. 48

A quarter Approx. 25 Empty Approx. 9

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C