height adjustment INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3568 of 3924

RFD-26

< SERVICE INFORMATION >

REAR FINAL DRIVE ASSEMBLY

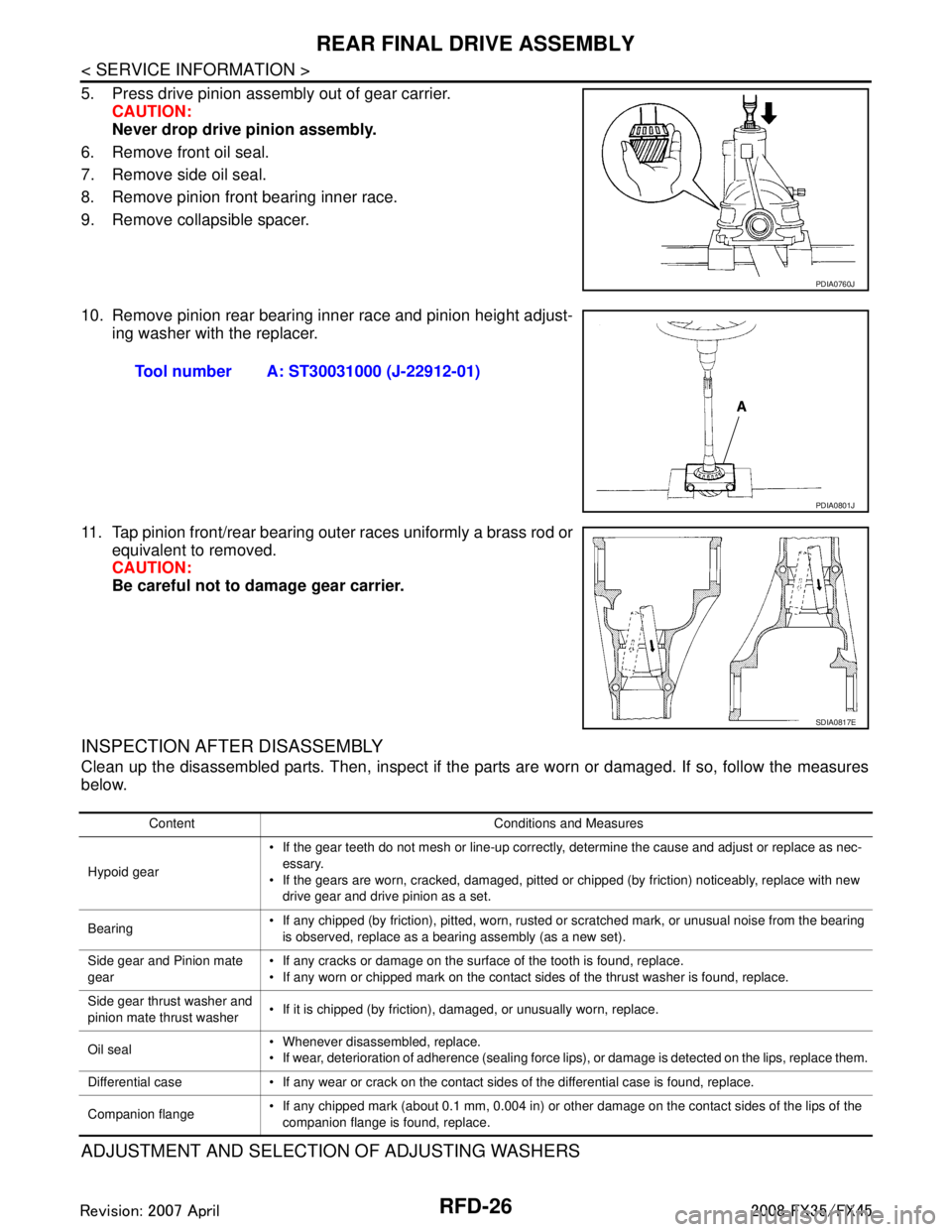

5. Press drive pinion assembly out of gear carrier.CAUTION:

Never drop drive pinion assembly.

6. Remove front oil seal.

7. Remove side oil seal.

8. Remove pinion front bearing inner race.

9. Remove collapsible spacer.

10. Remove pinion rear bearing inner race and pinion height adjust- ing washer with the replacer.

11. Tap pinion front/rear bearing outer races uniformly a brass rod or equivalent to removed.

CAUTION:

Be careful not to damage gear carrier.

INSPECTION AFTER DISASSEMBLY

Clean up the disassembled parts. Then, inspect if the parts are worn or damaged. If so, follow the measures

below.

ADJUSTMENT AND SELECTION OF ADJUSTING WASHERS

PDIA0760J

Tool number A: ST30031000 (J-22912-01)

PDIA0801J

SDIA0817E

Content Conditions and Measures

Hypoid gear If the gear teeth do not mesh or line-up correctly, determine the cause and adjust or replace as nec-

essary.

If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new drive gear and drive pinion as a set.

Bearing If any chipped (by friction), pitted, worn, rusted or scratched mark, or unusual noise from the bearing

is observed, replace as a bearing assembly (as a new set).

Side gear and Pinion mate

gear If any cracks or damage on the surface of the tooth is found, replace.

If any worn or chipped mark on the contact sides of the thrust washer is found, replace.

Side gear thrust washer and

pinion mate thrust washer If it is chipped (by friction), damaged, or unusually worn, replace.

Oil seal Whenever disassembled, replace.

If wear, deterioration of adherence (sealing force lips), or damage is detected on the lips, replace them.

Differential case If any wear or crack on the contact sides of the differential case is found, replace.

Companion flange If any chipped mark (about 0.1 mm, 0.004 in) or other damage on the contact sides of the lips of the

companion flange is found, replace.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3570 of 3924

RFD-28

< SERVICE INFORMATION >

REAR FINAL DRIVE ASSEMBLY

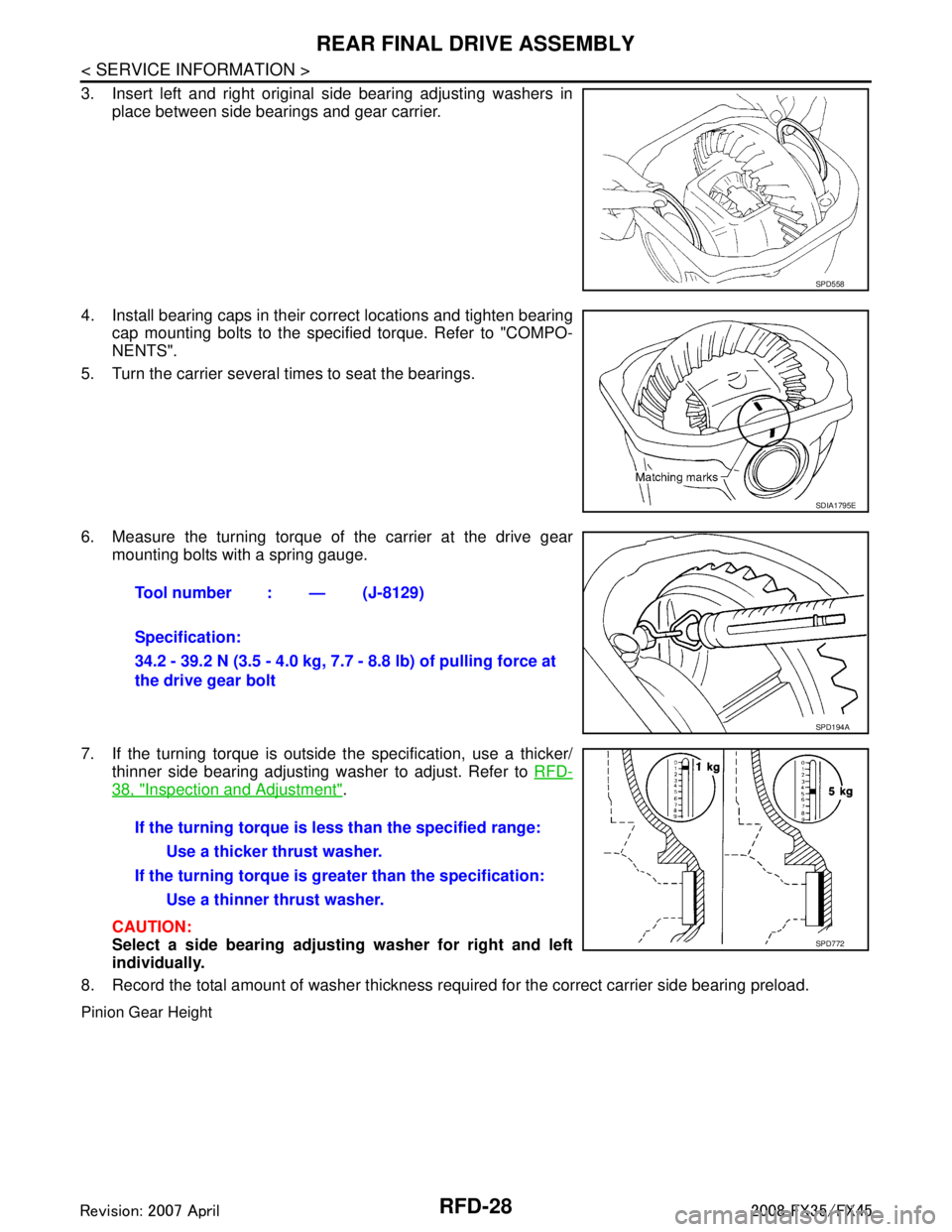

3. Insert left and right original side bearing adjusting washers inplace between side bearings and gear carrier.

4. Install bearing caps in their correct locations and tighten bearing cap mounting bolts to the specified torque. Refer to "COMPO-

NENTS".

5. Turn the carrier several times to seat the bearings.

6. Measure the turning torque of the carrier at the drive gear mounting bolts with a spring gauge.

7. If the turning torque is outside the specification, use a thicker/ thinner side bearing adjusting washer to adjust. Refer to RFD-

38, "Inspection and Adjustment".

CAUTION:

Select a side bearing adjust ing washer for right and left

individually.

8. Record the total amount of washer thickness required for the correct carrier side bearing preload.

Pinion Gear Height

SPD558

SDIA1795E

Tool number : — (J-8129)

Specification:

34.2 - 39.2 N (3.5 - 4.0 kg, 7.7 - 8.8 lb) of pulling force at

the drive gear bolt

SPD194A

If the turning torque is l ess than the specified range:

Use a thicker thrust washer.

If the turning torque is gr eater than the specification:

Use a thinner thrust washer.

SPD772

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3573 of 3924

REAR FINAL DRIVE ASSEMBLYRFD-31

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

RFD

N

O P

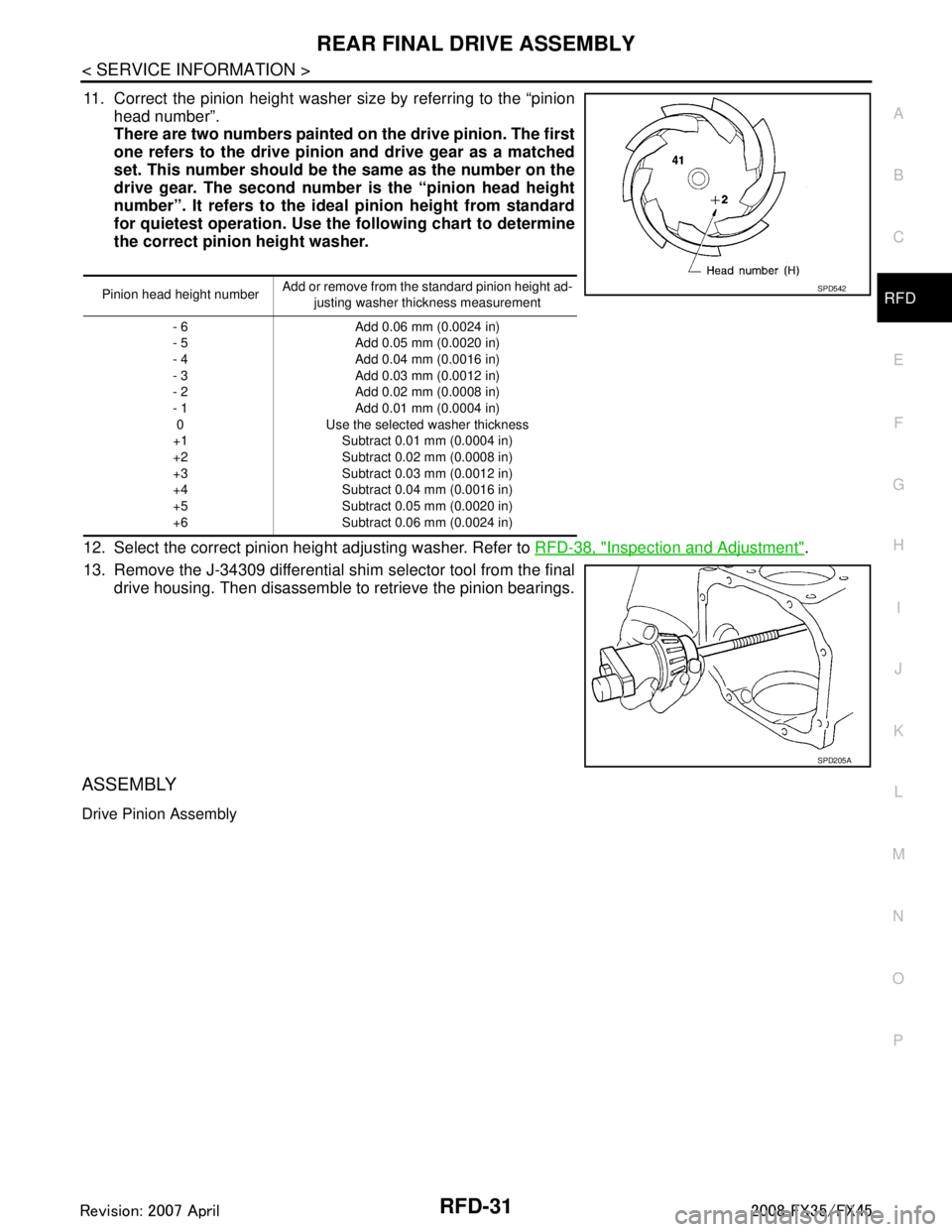

11. Correct the pinion height washer size by referring to the “pinion head number”.

There are two numbers painted on the drive pinion. The first

one refers to the drive pinion and drive gear as a matched

set. This number should be the same as the number on the

drive gear. The second number is the “pinion head height

number”. It refers to the ideal pinion height from standard

for quietest operation. Use th e following chart to determine

the correct pinion height washer.

12. Select the correct pinion height adjusting washer. Refer to RFD-38, "

Inspection and Adjustment".

13. Remove the J-34309 differential shim selector tool from the final drive housing. Then disassemble to retrieve the pinion bearings.

ASSEMBLY

Drive Pinion Assembly

Pinion head height number Add or remove from the standard pinion height ad-

justing washer thickness measurement

- 6

- 5

- 4

- 3

- 2

- 1 0

+1

+2

+3

+4

+5

+6 Add 0.06 mm (0.0024 in)

Add 0.05 mm (0.0020 in)

Add 0.04 mm (0.0016 in)

Add 0.03 mm (0.0012 in)

Add 0.02 mm (0.0008 in)

Add 0.01 mm (0.0004 in)

Use the selected washer thickness Subtract 0.01 mm (0.0004 in)

Subtract 0.02 mm (0.0008 in)

Subtract 0.03 mm (0.0012 in)

Subtract 0.04 mm (0.0016 in)

Subtract 0.05 mm (0.0020 in)

Subtract 0.06 mm (0.0024 in)SPD542

SPD205A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3918 of 3924

REAR WIPER AND WASHER SYSTEMWW-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

Washer Nozzle AdjustmentINFOID:0000000001328592

Adjust spray positions as shown in the figure.

Unit: mm (in)

Insert a needle or suitable tool into the nozzle hole and move it to adjust the spray position.

Washer Tube LayoutINFOID:0000000001328593

Removal and Installation of Washer NozzleINFOID:0000000001328594

REMOVAL

Spray position h (height) (width)φ

S

A, B 2.5 (0.098) 80 (3.15) 30 (1.18)

SKIA5088E

Adjustable range : ± 15 ° (In any direction)

SKIA5087E

PKIC9709E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C