service INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 388 of 3924

ASSEMBLYAT-315

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

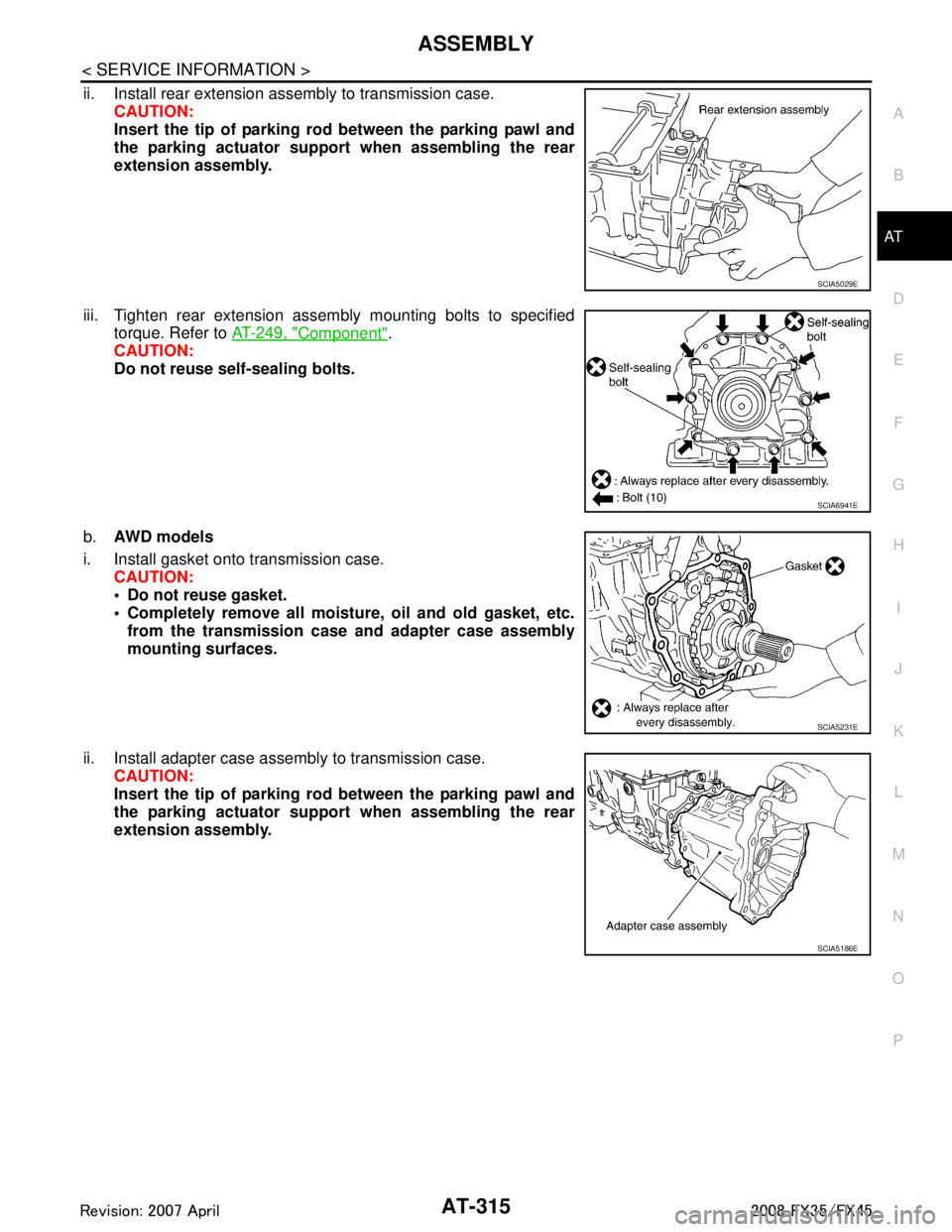

ii. Install rear extension assembly to transmission case. CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator suppor t when assembling the rear

extension assembly.

iii. Tighten rear extension assembly mounting bolts to specified torque. Refer to AT-249, "

Component".

CAUTION:

Do not reuse self-sealing bolts.

b. AWD m od e l s

i. Install gasket onto transmission case. CAUTION:

Do not reuse gasket.

Completely remove all moistu re, oil and old gasket, etc.

from the transmission case and adapter case assembly

mounting surfaces.

ii. Install adapter case assembly to transmission case. CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator suppor t when assembling the rear

extension assembly.

SCIA5029E

SCIA6941E

SCIA5231E

SCIA5186E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 389 of 3924

![INFINITI FX35 2008 Service Manual

AT-316

< SERVICE INFORMATION >

ASSEMBLY

iii. Tighten adapter case assembly mounting bolts (1) to specifiedtorque. [With bracket (2).] Refer to AT-249, "

Component".

: Bolt (10)

CAUTION:

Do not reuse INFINITI FX35 2008 Service Manual

AT-316

< SERVICE INFORMATION >

ASSEMBLY

iii. Tighten adapter case assembly mounting bolts (1) to specifiedtorque. [With bracket (2).] Refer to AT-249, "

Component".

: Bolt (10)

CAUTION:

Do not reuse](/img/42/57017/w960_57017-388.png)

AT-316

< SERVICE INFORMATION >

ASSEMBLY

iii. Tighten adapter case assembly mounting bolts (1) to specifiedtorque. [With bracket (2).] Refer to AT-249, "

Component".

: Bolt (10)

CAUTION:

Do not reuse self-sealing bolts (3).

Refer to GI section to mark sure icons (symbol marks) in the fig-

ure. Refer to GI-8, "

Component".

35. Install needle bearing in drum support. CAUTION:

Take care with the direction of needle bearing. Refer to

AT-264, "

Location of Adjusting Sh ims, Needle Bearings,

Thrust Washers and Snap Rings".

Apply petroleum jelly to needle bearing.

36. Install direct clutch assembly in reverse brake. CAUTION:

Make sure that drum support edge surface and direct clutch

inner boss edge surface come to almost same place.

37. Install high and low reverse clutch assembly in direct clutch.

SCIA7210E

SCIA5198E

SCIA5019E

SCIA2306E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 390 of 3924

ASSEMBLYAT-317

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

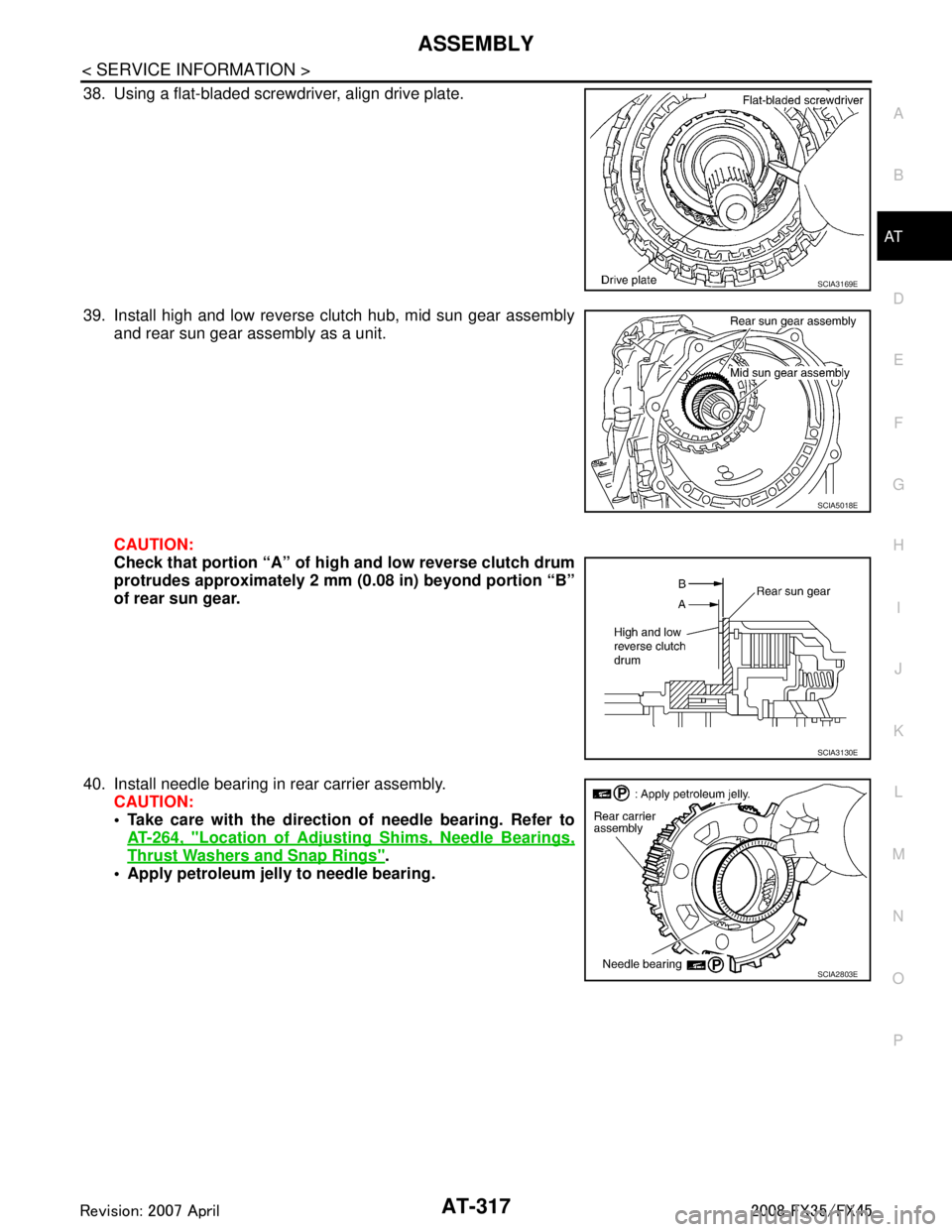

38. Using a flat-bladed screwdriver, align drive plate.

39. Install high and low reverse clutch hub, mid sun gear assembly and rear sun gear assembly as a unit.

CAUTION:

Check that portion “A” of high and low reverse clutch drum

protrudes approximately 2 mm (0 .08 in) beyond portion “B”

of rear sun gear.

40. Install needle bearing in rear carrier assembly. CAUTION:

Take care with the direction of needle bearing. Refer toAT-264, "

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings".

Apply petroleum jelly to needle bearing.

SCIA3169E

SCIA5018E

SCIA3130E

SCIA2803E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 391 of 3924

AT-318

< SERVICE INFORMATION >

ASSEMBLY

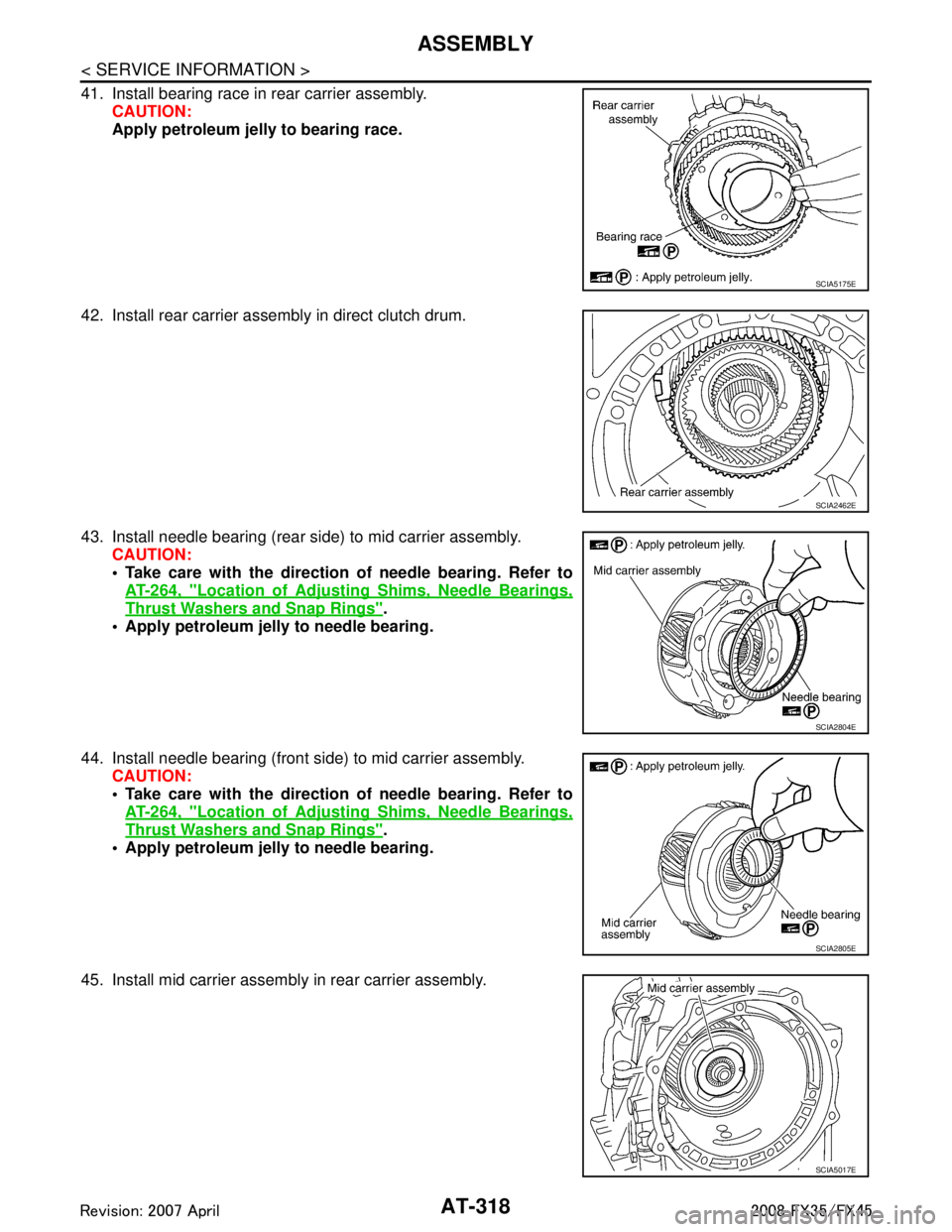

41. Install bearing race in rear carrier assembly.CAUTION:

Apply petroleum jelly to bearing race.

42. Install rear carrier assembly in direct clutch drum.

43. Install needle bearing (rear side) to mid carrier assembly. CAUTION:

Take care with the direction of needle bearing. Refer toAT-264, "

Location of Adjusting Sh ims, Needle Bearings,

Thrust Washers and Snap Rings".

Apply petroleum jelly to needle bearing.

44. Install needle bearing (front side) to mid carrier assembly. CAUTION:

Take care with the direction of needle bearing. Refer toAT-264, "

Location of Adjusting Sh ims, Needle Bearings,

Thrust Washers and Snap Rings".

Apply petroleum jelly to needle bearing.

45. Install mid carrier assembly in rear carrier assembly.

SCIA5175E

SCIA2462E

SCIA2804E

SCIA2805E

SCIA5017E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 392 of 3924

ASSEMBLYAT-319

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

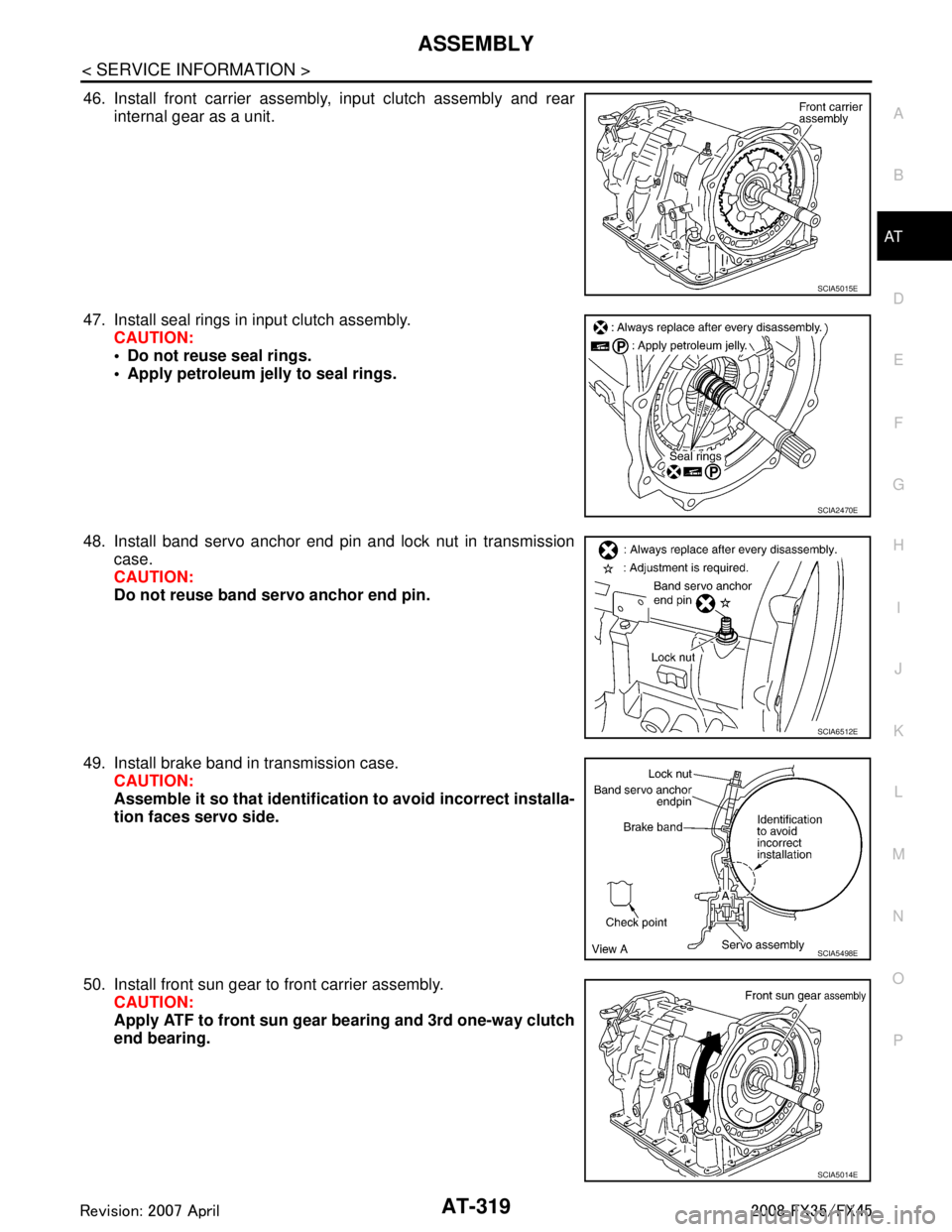

46. Install front carrier assembly, input clutch assembly and rear internal gear as a unit.

47. Install seal rings in input clutch assembly. CAUTION:

Do not reuse seal rings.

Apply petroleum jelly to seal rings.

48. Install band servo anchor end pin and lock nut in transmission case.

CAUTION:

Do not reuse band servo anchor end pin.

49. Install brake band in transmission case. CAUTION:

Assemble it so that identificatio n to avoid incorrect installa-

tion faces servo side.

50. Install front sun gear to front carrier assembly. CAUTION:

Apply ATF to front sun gear bearing and 3rd one-way clutch

end bearing.

SCIA5015E

SCIA2470E

SCIA6512E

SCIA5498E

SCIA5014E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 393 of 3924

AT-320

< SERVICE INFORMATION >

ASSEMBLY

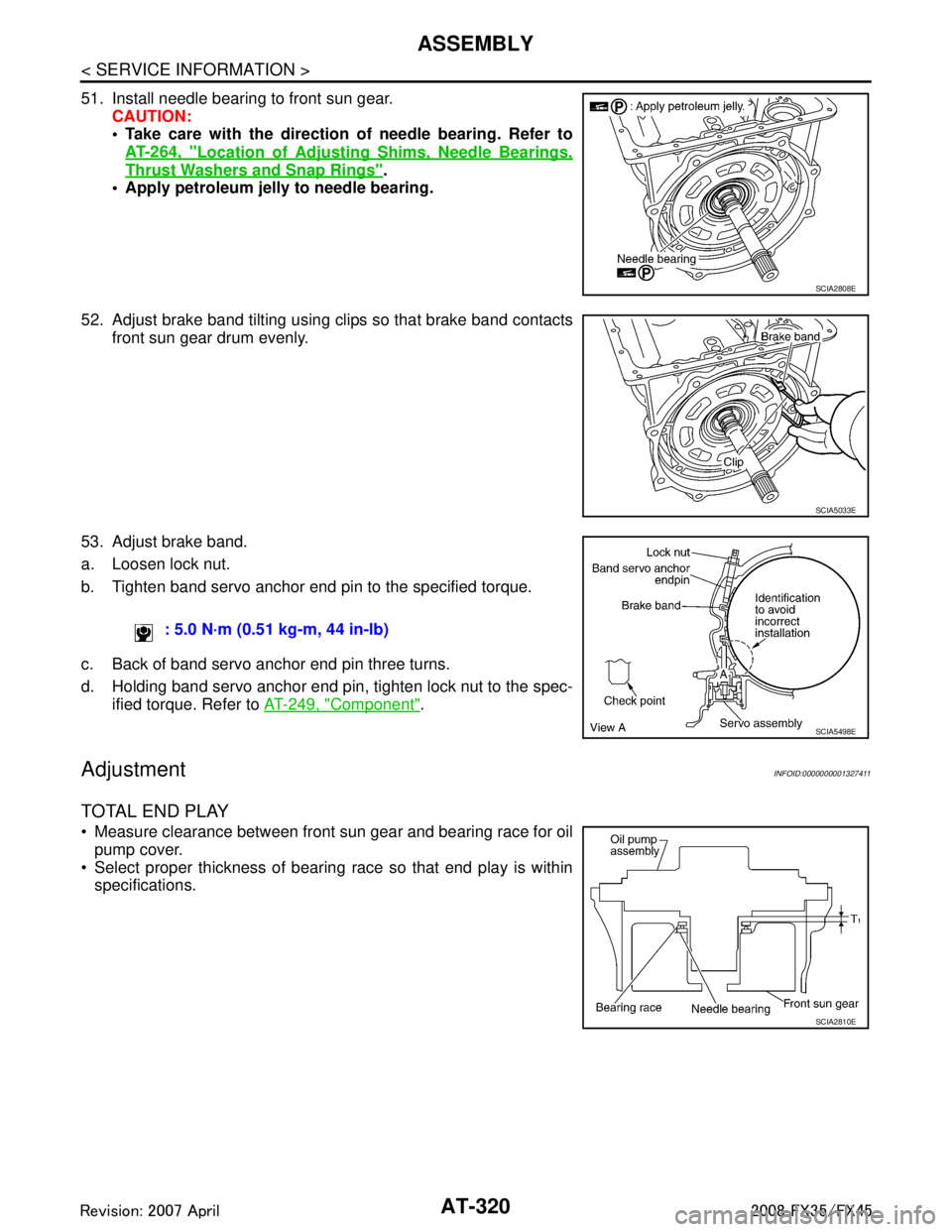

51. Install needle bearing to front sun gear.CAUTION:

Take care with the direction of needle bearing. Refer toAT-264, "

Location of Adjusting Sh ims, Needle Bearings,

Thrust Washers and Snap Rings".

Apply petroleum jelly to needle bearing.

52. Adjust brake band tilting using clips so that brake band contacts front sun gear drum evenly.

53. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to the specified torque.

c. Back of band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to the spec- ified torque. Refer to AT-249, "

Component".

AdjustmentINFOID:0000000001327411

TOTAL END PLAY

Measure clearance between front sun gear and bearing race for oil

pump cover.

Select proper thickness of bearing race so that end play is within specifications.

SCIA2808E

SCIA5033E

: 5.0 N·m (0.51 kg-m, 44 in-lb)

SCIA5498E

SCIA2810E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 394 of 3924

ASSEMBLYAT-321

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

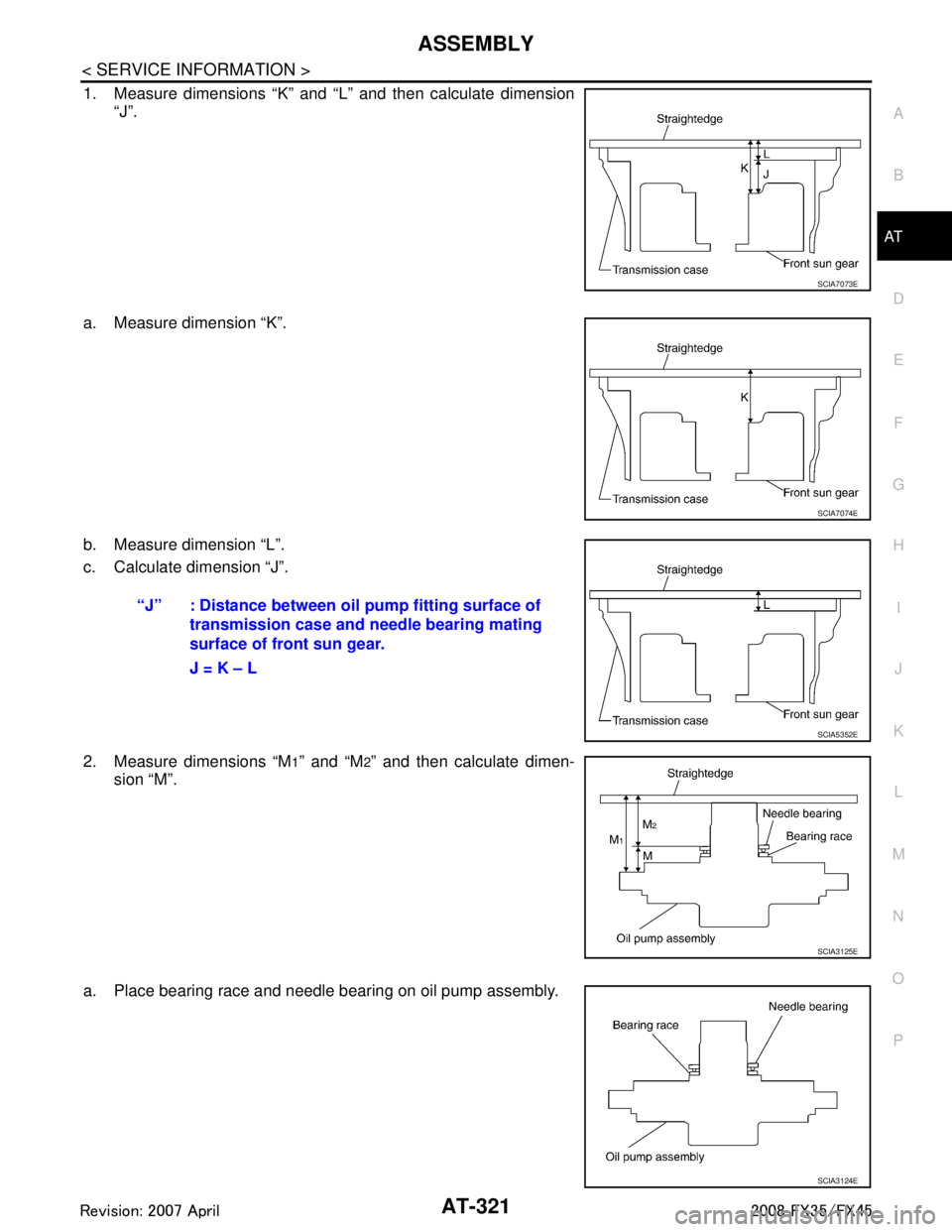

1. Measure dimensions “K” and “L” and then calculate dimension “J”.

a. Measure dimension “K”.

b. Measure dimension “L”.

c. Calculate dimension “J”.

2. Measure dimensions “M

1” and “M2” and then calculate dimen-

sion “M”.

a. Place bearing race and needle bearing on oil pump assembly.

SCIA7073E

SCIA7074E

“J” : Distance between oil pump fitting surface of transmission case and n eedle bearing mating

surface of front sun gear.

J = K – L

SCIA5352E

SCIA3125E

SCIA3124E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 395 of 3924

AT-322

< SERVICE INFORMATION >

ASSEMBLY

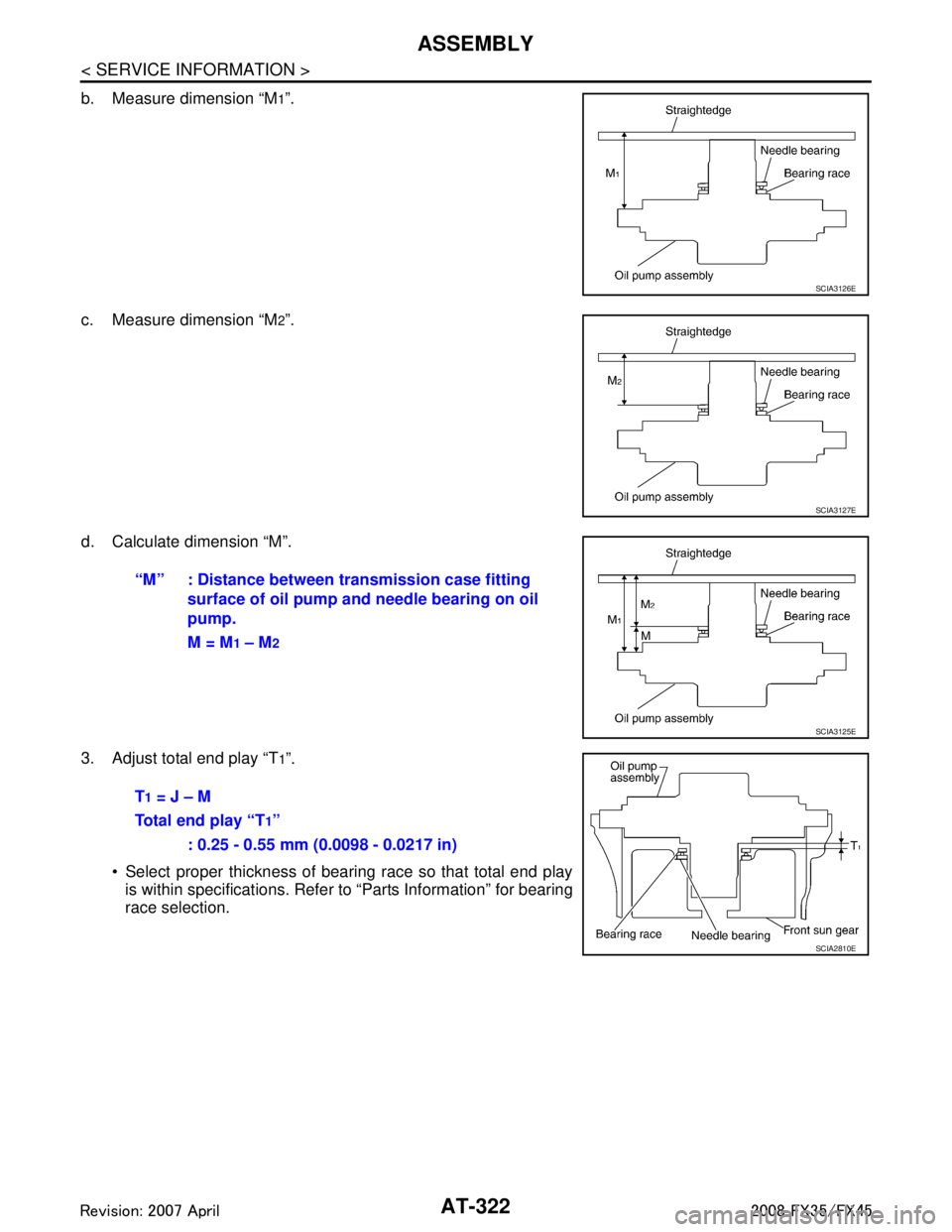

b. Measure dimension “M1”.

c. Measure dimension “M

2”.

d. Calculate dimension “M”.

3. Adjust total end play “T

1”.

Select proper thickness of bearing race so that total end play is within specifications. Refer to “Parts Information” for bearing

race selection.

SCIA3126E

SCIA3127E

“M” : Distance between transmission case fitting

surface of oil pump and needle bearing on oil

pump.

M = M

1 – M2

SCIA3125E

T1 = J – M

Total end play “T

1”

: 0.25 - 0.55 mm (0.0098 - 0.0217 in)

SCIA2810E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 396 of 3924

ASSEMBLYAT-323

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Assembly (2)INFOID:0000000001327412

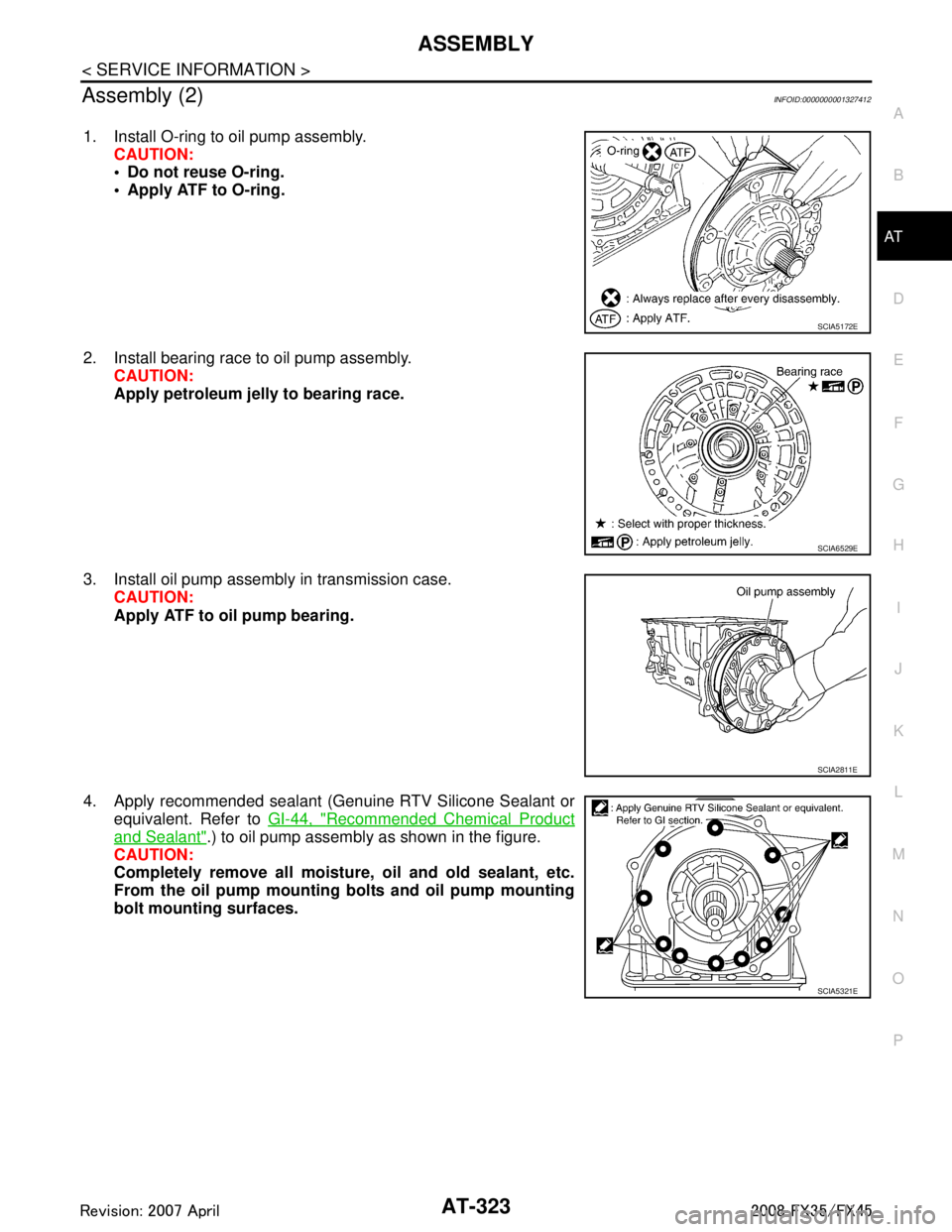

1. Install O-ring to oil pump assembly. CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

2. Install bearing race to oil pump assembly. CAUTION:

Apply petroleum jelly to bearing race.

3. Install oil pump assembly in transmission case. CAUTION:

Apply ATF to oil pump bearing.

4. Apply recommended sealant (Genuine RTV Silicone Sealant or equivalent. Refer to GI-44, "

Recommended Chemical Product

and Sealant".) to oil pump assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

From the oil pump mounting bolts and oil pump mounting

bolt mounting surfaces.

SCIA5172E

SCIA6529E

SCIA2811E

SCIA5321E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 397 of 3924

AT-324

< SERVICE INFORMATION >

ASSEMBLY

5. Tighten oil pump mounting bolts to specified torque. Refer to AT-

249, "Component".

CAUTION:

Apply ATF to oil pump bushing.

6. Install O-ring to input clutch assembly. CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

7. Install converter housing to transmission case, and then tighten converter housing mounting bolts (1) to the specified torque.

Refer to AT-249, "

Component".

: Bolt (8)

CAUTION:

Do not reuse self-sealing bolt (2).

8. Make sure that brake band does not close turbine revolution sensor hole.

9. Install control valve with TCM.

a. Connect TCM connector and park/neutral position switch con- nector.

SCIA2300E

SCIA5011E

SCIA7985E

SCIA5034E

SCIA5449E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C