Oil INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2803 of 3924

FFD-12

< SERVICE INFORMATION >

SIDE OIL SEAL

SIDE OIL SEAL

Removal and InstallationINFOID:0000000001327484

NOTE:

Left side oil seal is attached to engine assembly. Replace it when front final drive assembly is removed

from vehicle.

REMOVAL

Right Side:

1. Remove the front drive shaft. Refer to FAX-16, "Removal and Installation (Right Side)".

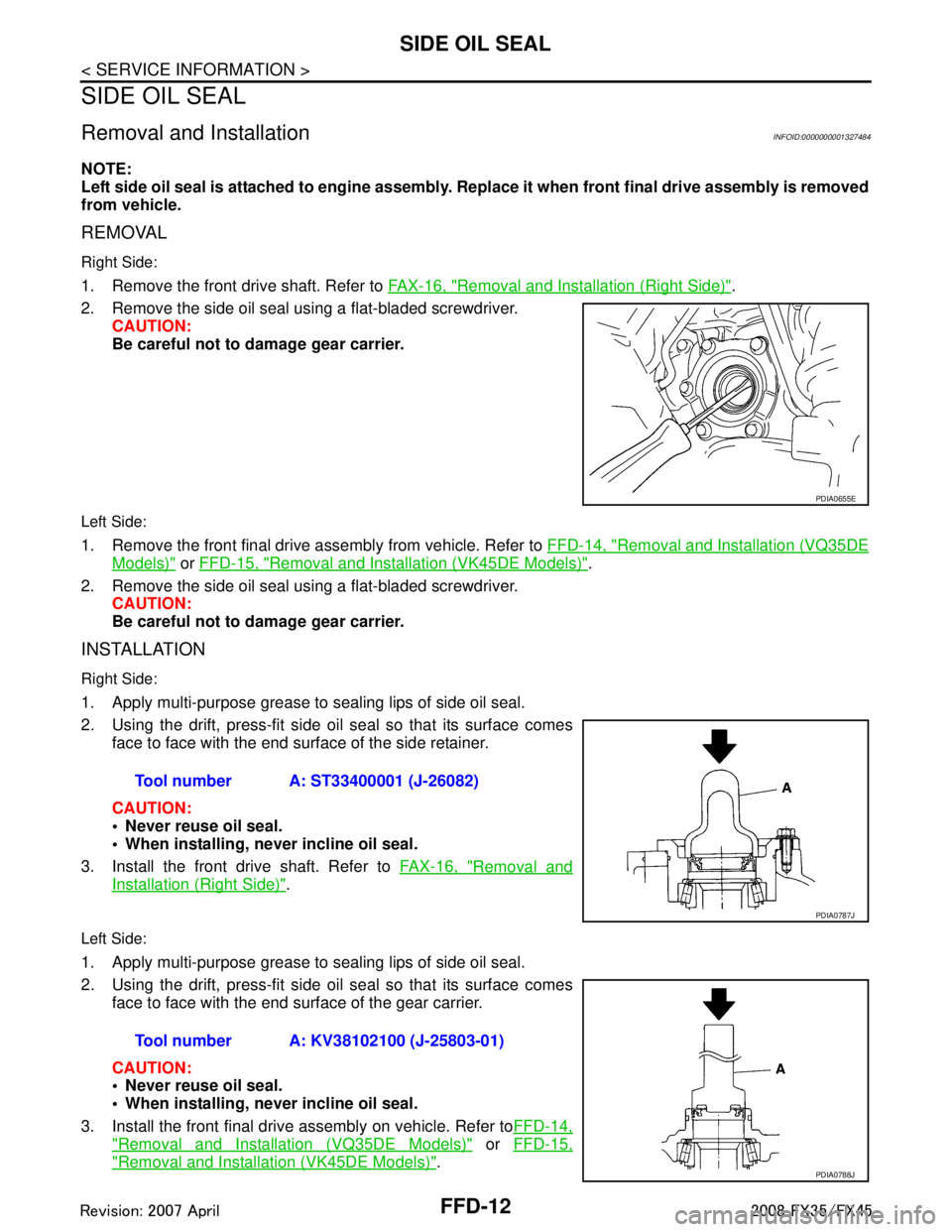

2. Remove the side oil seal using a flat-bladed screwdriver. CAUTION:

Be careful not to damage gear carrier.

Left Side:

1. Remove the front final drive assembly from vehicle. Refer to FFD-14, "Removal and Installation (VQ35DE

Models)" or FFD-15, "Removal and Installation (VK45DE Models)".

2. Remove the side oil seal using a flat-bladed screwdriver. CAUTION:

Be careful not to damage gear carrier.

INSTALLATION

Right Side:

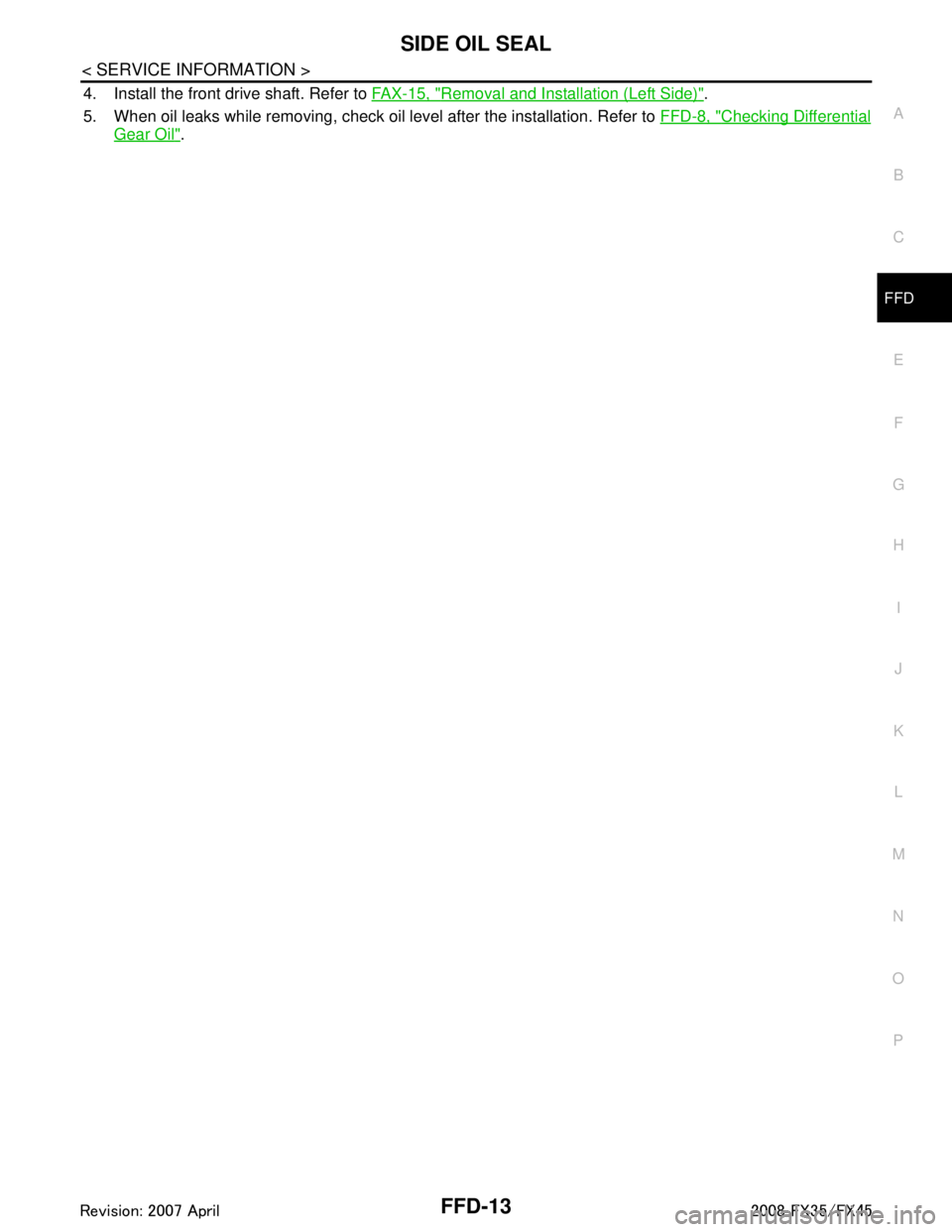

1. Apply multi-purpose grease to sealing lips of side oil seal.

2. Using the drift, press-fit side oil seal so that its surface comesface to face with the end surface of the side retainer.

CAUTION:

Never reuse oil seal.

When installing, n ever incline oil seal.

3. Install the front drive shaft. Refer to FAX-16, "

Removal and

Installation (Right Side)".

Left Side:

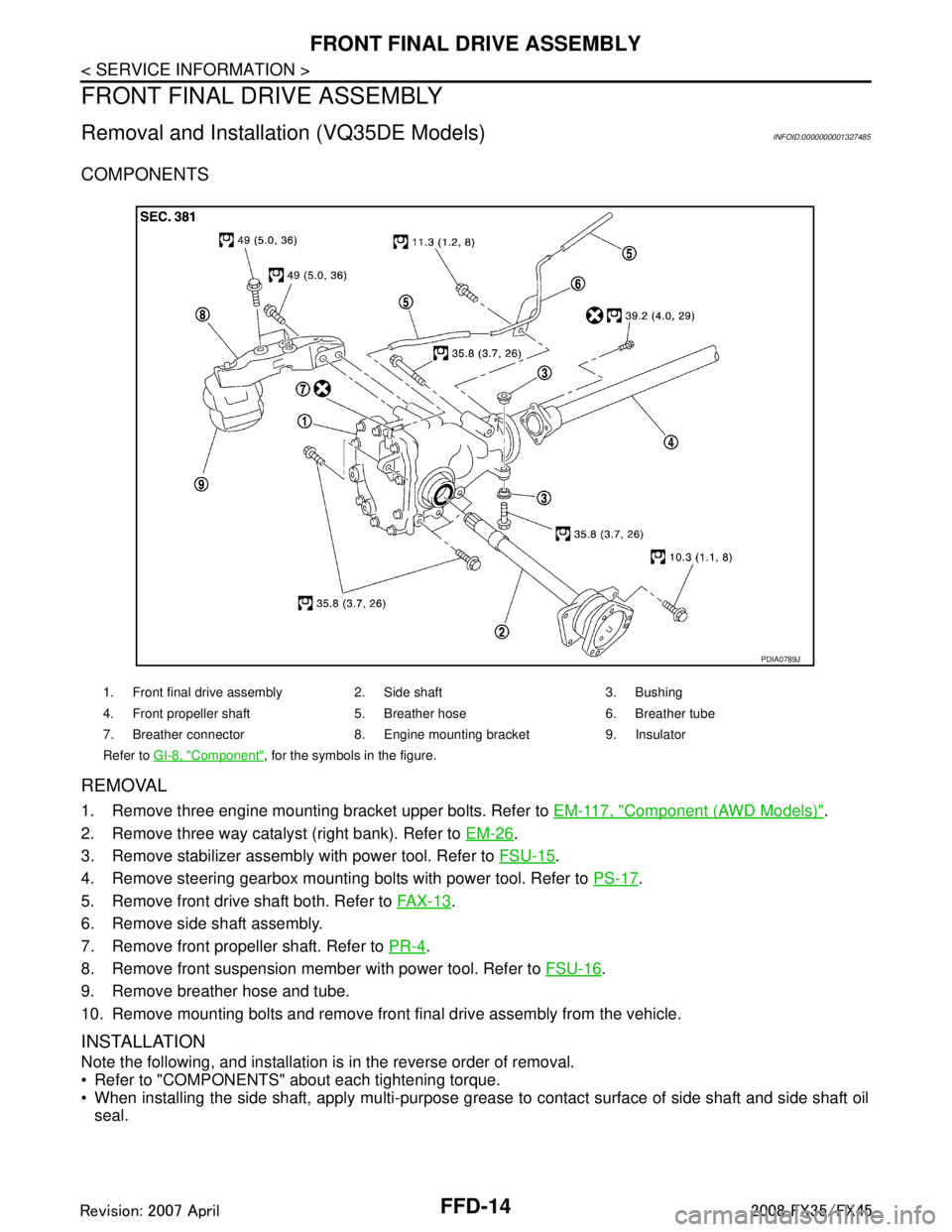

1. Apply multi-purpose grease to sealing lips of side oil seal.

2. Using the drift, press-fit side oil seal so that its surface comes

face to face with the end surface of the gear carrier.

CAUTION:

Never reuse oil seal.

When installing, n ever incline oil seal.

3. Install the front final drive assembly on vehicle. Refer to FFD-14,

"Removal and Installation (VQ35DE Models)" or FFD-15,

"Removal and Installation (VK45DE Models)".

PDIA0655E

Tool number A: ST33400001 (J-26082)

PDIA0787J

Tool number A: KV38102100 (J-25803-01)

PDIA0788J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2804 of 3924

SIDE OIL SEALFFD-13

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

4. Install the front drive shaft. Refer to FAX-15, "Removal and Installation (Left Side)".

5. When oil leaks while removing, check oil level after the installation. Refer to FFD-8, "

Checking Differential

Gear Oil".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2805 of 3924

FFD-14

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

FRONT FINAL DRIVE ASSEMBLY

Removal and Installation (VQ35DE Models)INFOID:0000000001327485

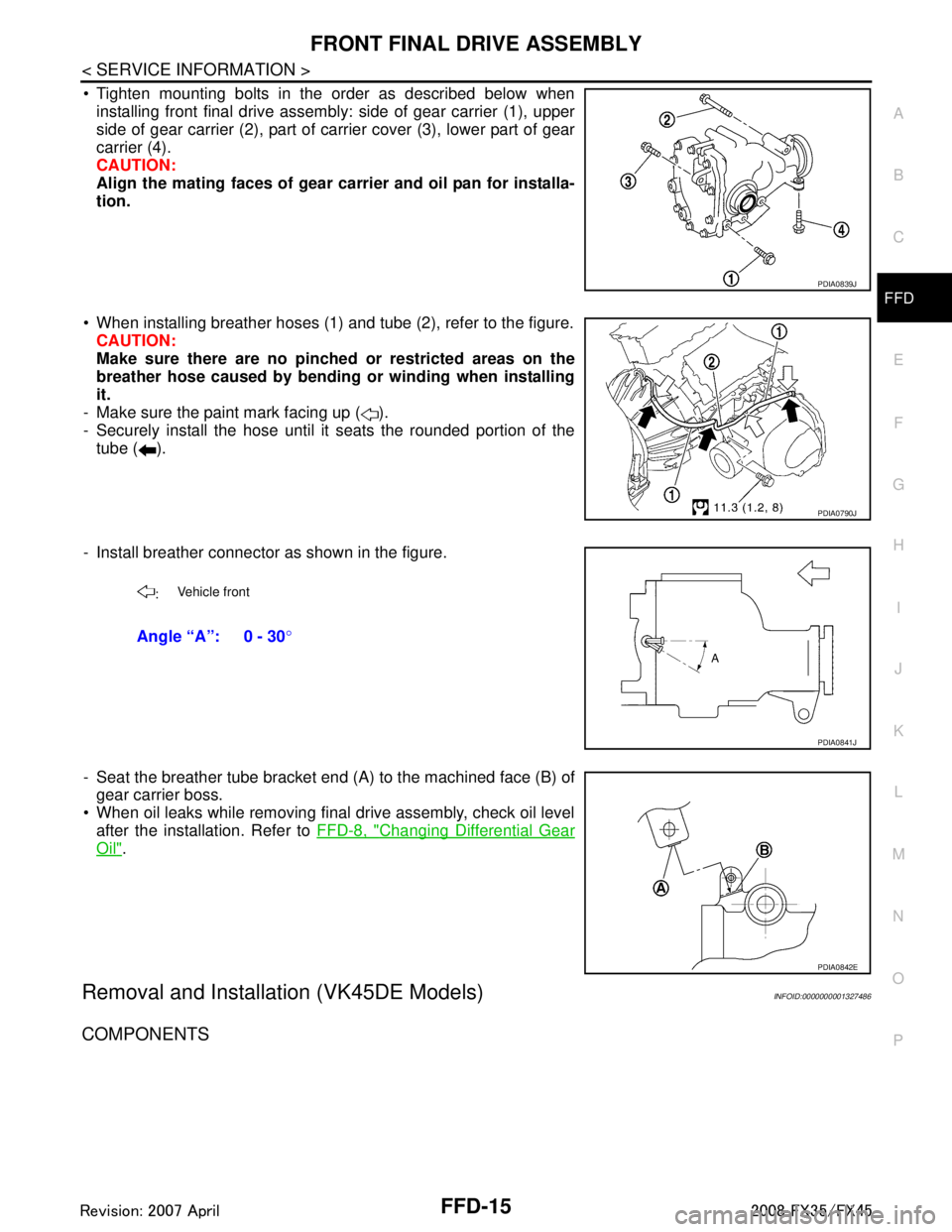

COMPONENTS

REMOVAL

1. Remove three engine mounting bracket upper bolts. Refer to EM-117, "Component (AWD Models)".

2. Remove three way catalyst (right bank). Refer to EM-26

.

3. Remove stabilizer assembly with power tool. Refer to FSU-15

.

4. Remove steering gearbox mounting bolts with power tool. Refer to PS-17

.

5. Remove front drive shaft both. Refer to FA X - 1 3

.

6. Remove side shaft assembly.

7. Remove front propeller shaft. Refer to PR-4

.

8. Remove front suspension member with power tool. Refer to FSU-16

.

9. Remove breather hose and tube.

10. Remove mounting bolts and remove front final drive assembly from the vehicle.

INSTALLATION

Note the following, and installation is in the reverse order of removal.

Refer to "COMPONENTS" about each tightening torque.

When installing the side shaft, apply multi-purpose grease to contact surface of side shaft and side shaft oil

seal.

1. Front final drive assembly 2. Side shaft 3. Bushing

4. Front propeller shaft 5. Breather hose 6. Breather tube

7. Breather connector 8. Engine mounting bracket 9. Insulator

Refer to GI-8, "

Component", for the symbols in the figure.

PDIA0789J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2806 of 3924

FRONT FINAL DRIVE ASSEMBLYFFD-15

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

Tighten mounting bolts in the order as described below when installing front final drive assembly: side of gear carrier (1), upper

side of gear carrier (2), part of ca rrier cover (3), lower part of gear

carrier (4).

CAUTION:

Align the mating faces of gear car rier and oil pan for installa-

tion.

When installing breather hoses (1) and tube (2), refer to the figure. CAUTION:

Make sure there are no pinched or restricted areas on the

breather hose caused by bending or winding when installing

it.

- Make sure the paint mark facing up ( ).

- Securely install the hose until it seats the rounded portion of the

tube ( ).

- Install breather connector as shown in the figure.

- Seat the breather tube bracket end (A) to the machined face (B) of gear carrier boss.

When oil leaks while removing final drive assembly, check oil level after the installation. Refer to FFD-8, "

Changing Differential Gear

Oil".

Removal and Installation (VK45DE Models)INFOID:0000000001327486

COMPONENTS

PDIA0839J

PDIA0790J

:Vehicle front

Angle “A”: 0 - 30

°

PDIA0841J

PDIA0842E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2807 of 3924

FFD-16

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

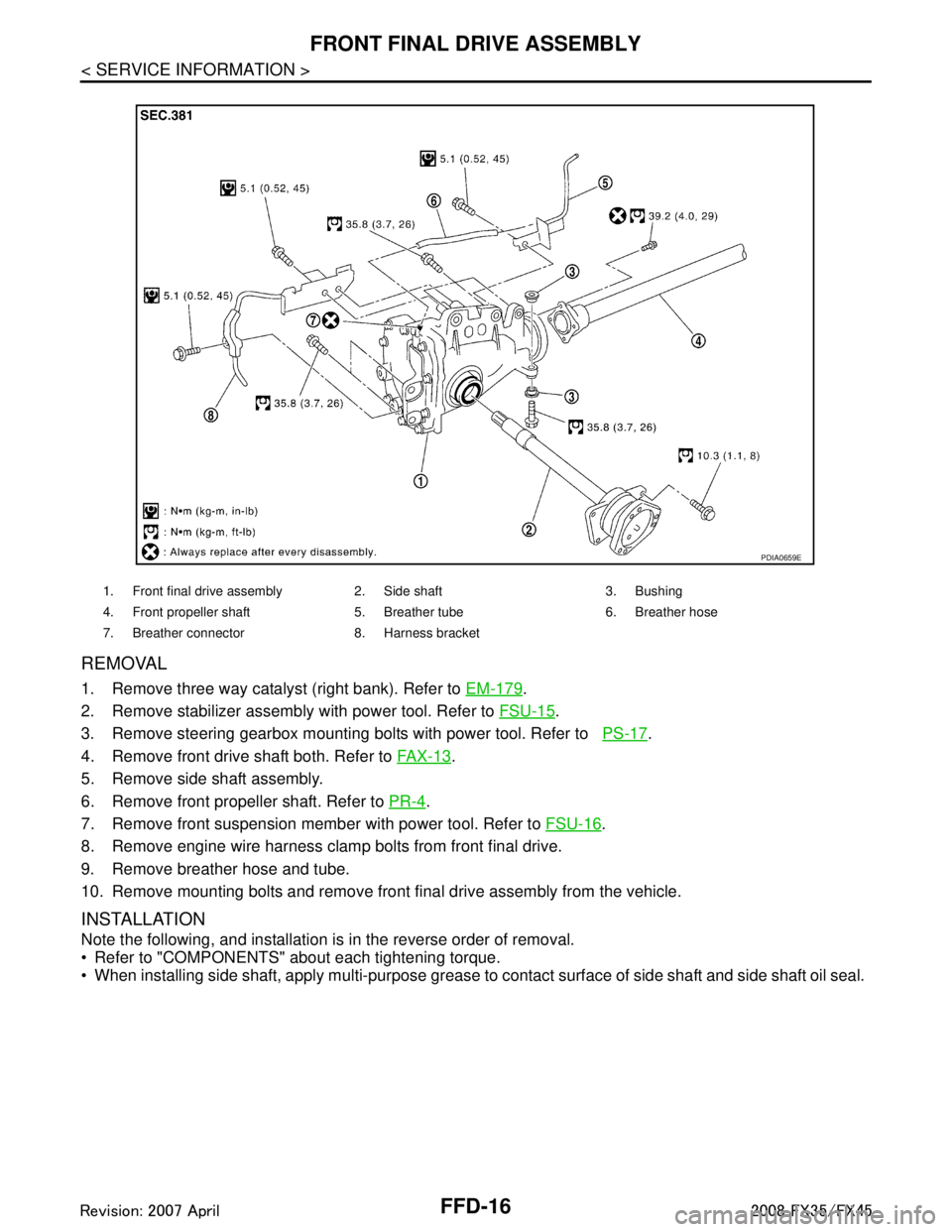

REMOVAL

1. Remove three way catalyst (right bank). Refer to EM-179.

2. Remove stabilizer assembly with power tool. Refer to FSU-15

.

3. Remove steering gearbox mounting bolts with power tool. Refer to PS-17

.

4. Remove front drive shaft both. Refer to FA X - 1 3

.

5. Remove side shaft assembly.

6. Remove front propeller shaft. Refer to PR-4

.

7. Remove front suspension member with power tool. Refer to FSU-16

.

8. Remove engine wire harness clamp bolts from front final drive.

9. Remove breather hose and tube.

10. Remove mounting bolts and remove front final drive assembly from the vehicle.

INSTALLATION

Note the following, and installation is in the reverse order of removal.

Refer to "COMPONENTS" about each tightening torque.

When installing side shaft, apply multi-purpose grease to contact surface of side shaft and side shaft oil seal.

1. Front final drive assembly 2. Side shaft 3. Bushing

4. Front propeller shaft 5. Breather tube 6. Breather hose

7. Breather connector 8. Harness bracket

PDIA0659E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2808 of 3924

FRONT FINAL DRIVE ASSEMBLYFFD-17

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

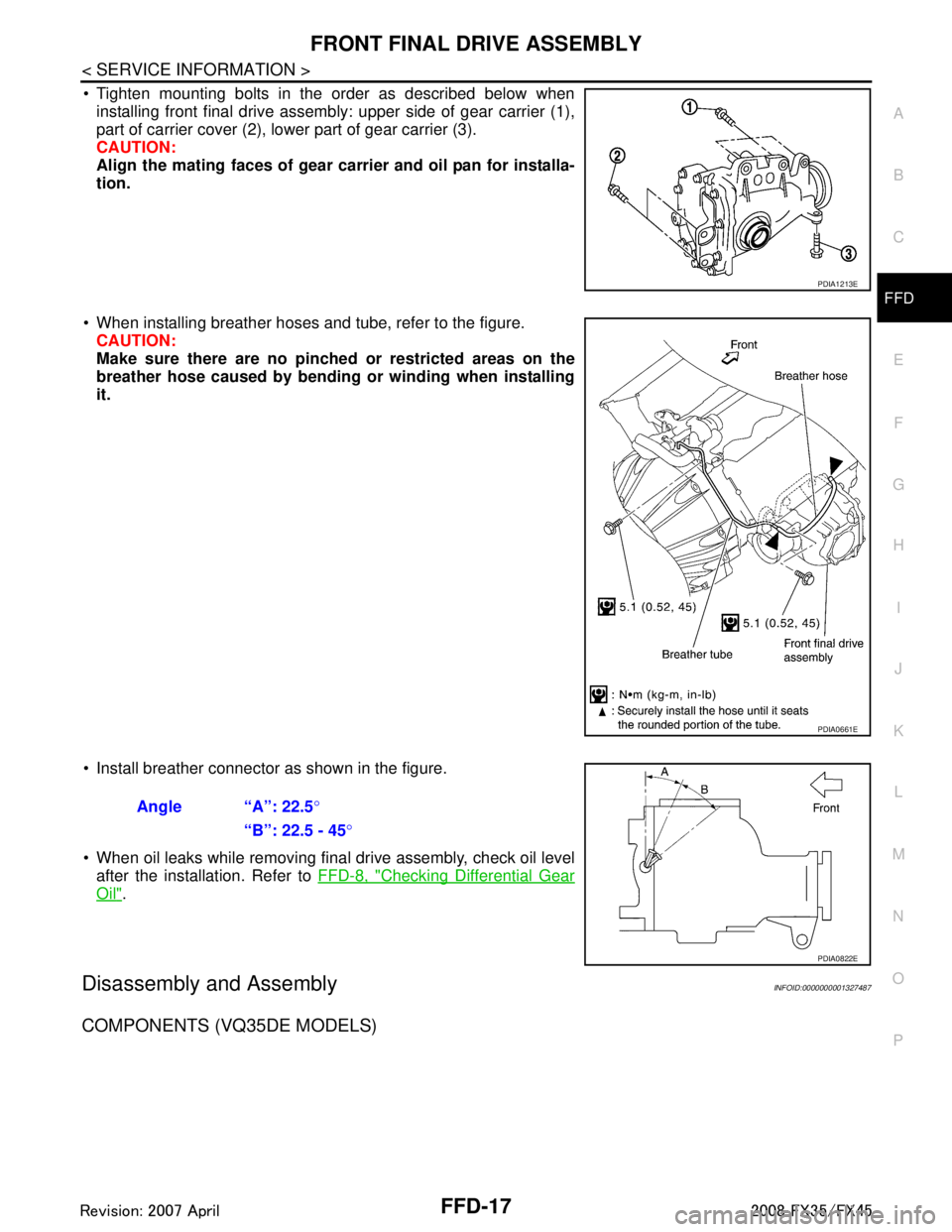

Tighten mounting bolts in the order as described below when installing front final drive assembly: upper side of gear carrier (1),

part of carrier cover (2), lower part of gear carrier (3).

CAUTION:

Align the mating faces of gear car rier and oil pan for installa-

tion.

When installing breather hoses and tube, refer to the figure. CAUTION:

Make sure there are no pinched or restricted areas on the

breather hose caused by bending or winding when installing

it.

Install breather connector as shown in the figure.

When oil leaks while removing final drive assembly, check oil level after the installation. Refer to FFD-8, "

Checking Differential Gear

Oil".

Disassembly and AssemblyINFOID:0000000001327487

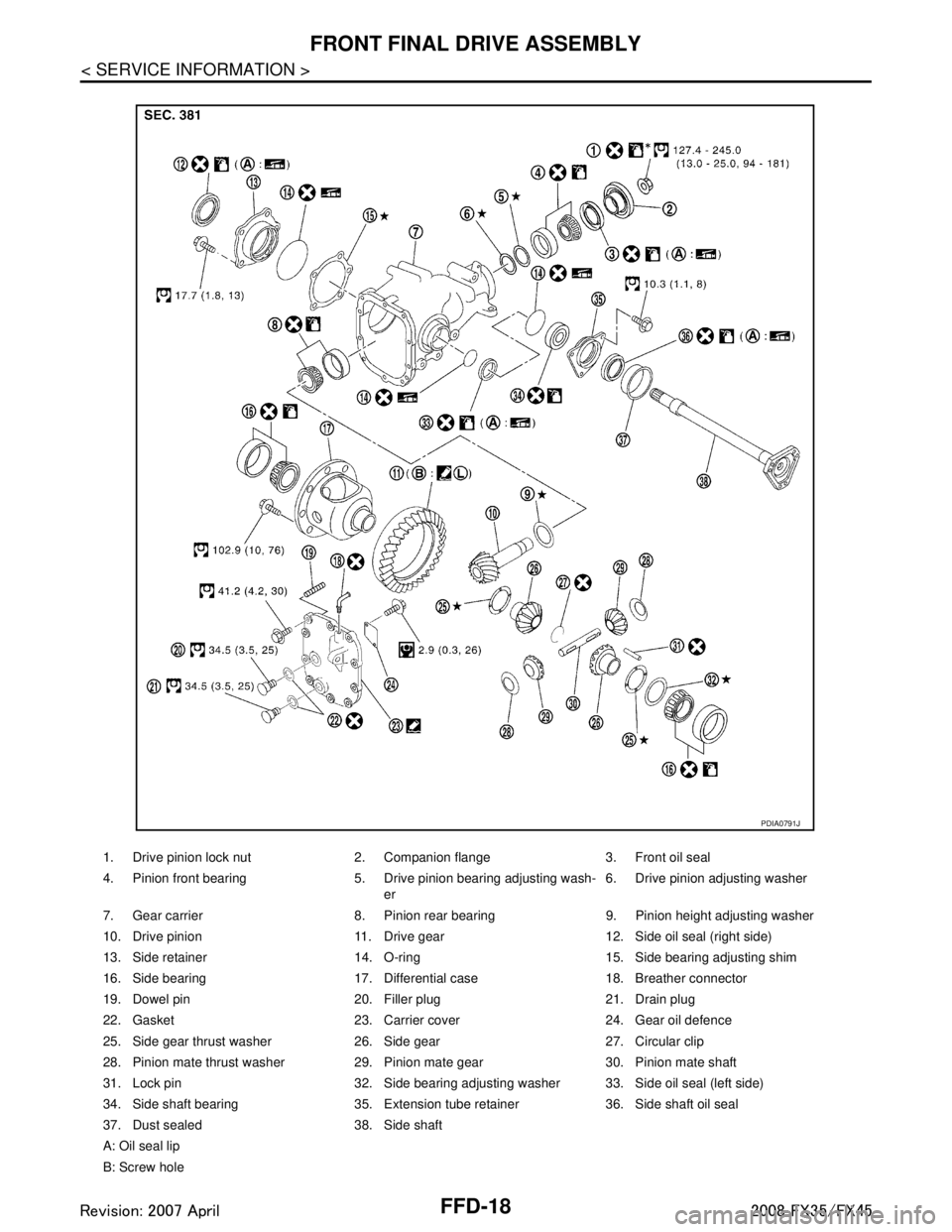

COMPONENTS (VQ35DE MODELS)

PDIA1213E

PDIA0661E

Angle “A”: 22.5°

“B”: 22.5 - 45 °

PDIA0822E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2809 of 3924

FFD-18

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

1. Drive pinion lock nut 2. Companion flange 3. Front oil seal

4. Pinion front bearing 5. Drive pinion bearing adjusting wash-er6. Drive pinion adjusting washer

7. Gear carrier 8. Pinion rear bearing 9. Pinion height adjusting washer

10. Drive pinion 11. Drive gear 12. Side oil seal (right side)

13. Side retainer 14. O-ring 15. Side bearing adjusting shim

16. Side bearing 17. Differential case 18. Breather connector

19. Dowel pin 20. Filler plug 21. Drain plug

22. Gasket 23. Carrier cover 24. Gear oil defence

25. Side gear thrust washer 26. Side gear 27. Circular clip

28. Pinion mate thrust washer 29. Pinion mate gear 30. Pinion mate shaft

31. Lock pin 32. Side bearing adjusting washer 33. Side oil seal (left side)

34. Side shaft bearing 35. Extension tube retainer 36. Side shaft oil seal

37. Dust sealed 38. Side shaft

A: Oil seal lip

B: Screw hole

PDIA0791J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2810 of 3924

FRONT FINAL DRIVE ASSEMBLYFFD-19

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

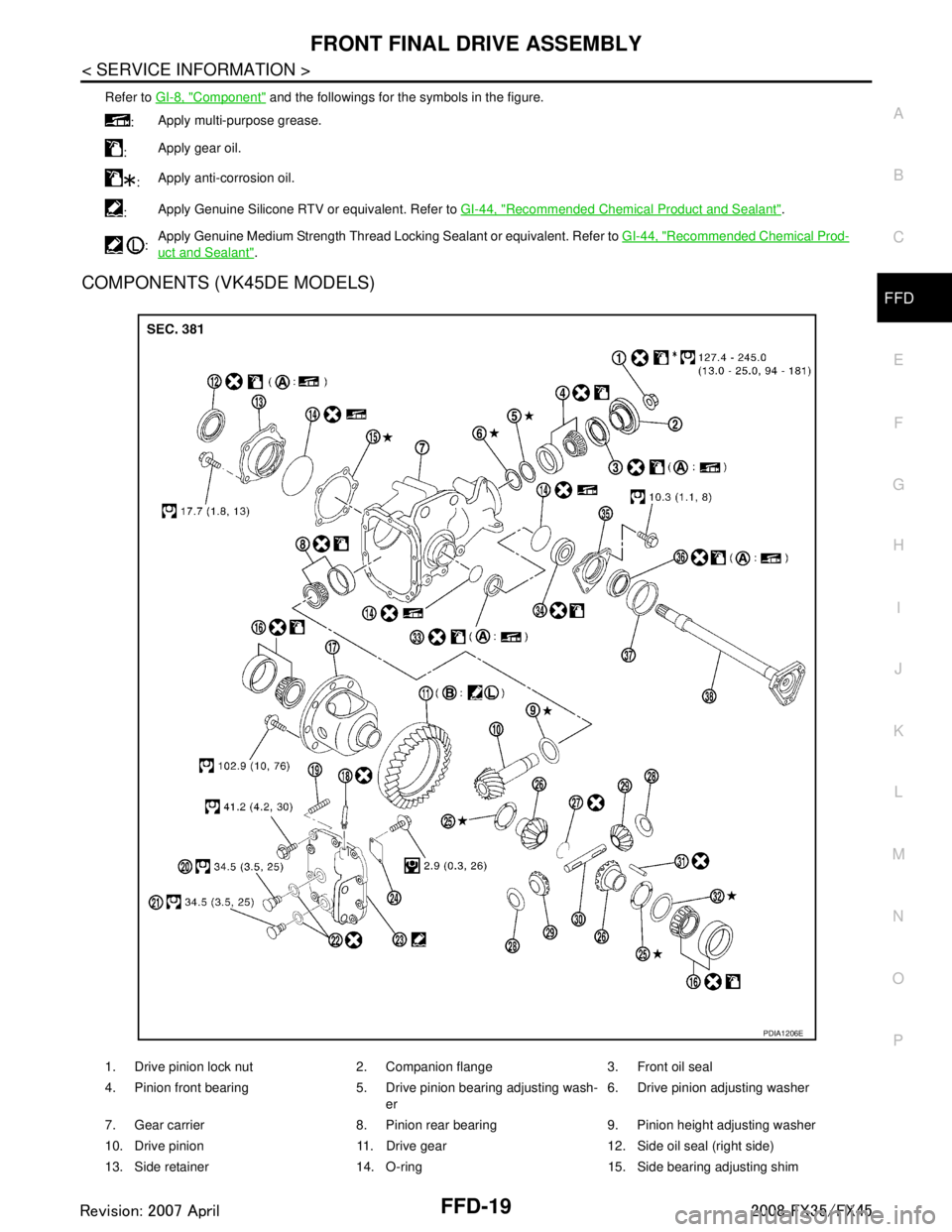

O PCOMPONENTS (VK45DE MODELS)

Refer to GI-8, "Component" and the followings for the symbols in the figure.

: Apply multi-purpose grease.

: Apply gear oil.

: Apply anti-corrosion oil.

: Apply Genuine Silicone RTV or equivalent. Refer to

GI-44, "

Recommended Chemical Product and Sealant".

: Apply Genuine Medium Strength Thread Locking Sealant or equivalent. Refer to

GI-44, "

Recommended Chemical Prod-

uct and Sealant".

1. Drive pinion lock nut 2. Companion flange 3. Front oil seal

4. Pinion front bearing 5. Drive pinion bearing adjusting wash-

er6. Drive pinion adjusting washer

7. Gear carrier 8. Pinion rear bearing 9. Pinion height adjusting washer

10. Drive pinion 11. Drive gear 12. Side oil seal (right side)

13. Side retainer 14. O-ring 15. Side bearing adjusting shim

PDIA1206E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2811 of 3924

FFD-20

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

Before inspection and adjustment, drain gear oil.

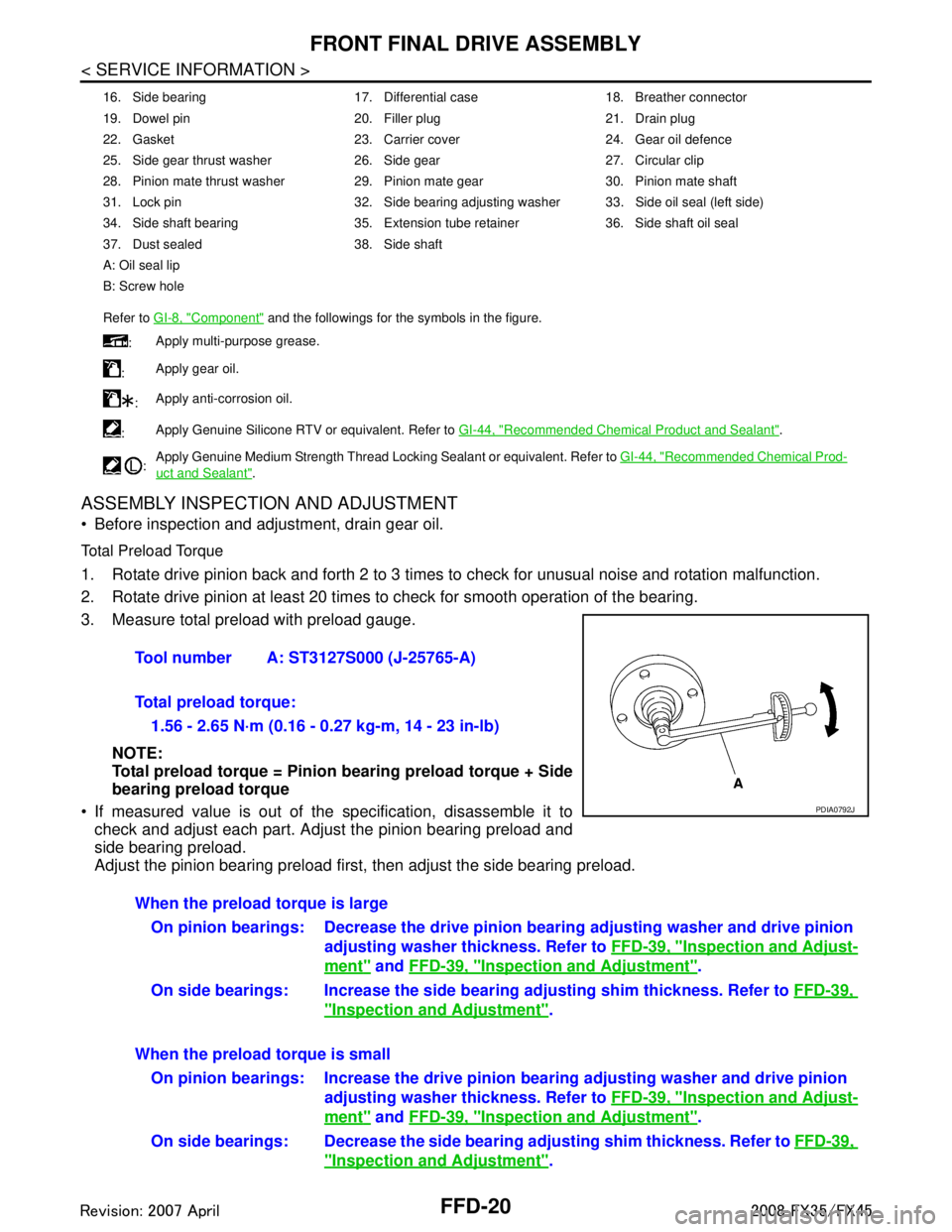

Total Preload Torque

1. Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

2. Rotate drive pinion at least 20 times to check for smooth operation of the bearing.

3. Measure total preload with preload gauge.NOTE:

Total preload torque = Pinion bearing preload torque + Side

bearing preload torque

If measured value is out of the specification, disassemble it to check and adjust each part. Adjust the pinion bearing preload and

side bearing preload.

Adjust the pinion bearing preload first, then adjust the side bearing preload.

16. Side bearing 17. Differential case 18. Breather connector

19. Dowel pin 20. Filler plug 21. Drain plug

22. Gasket 23. Carrier cover 24. Gear oil defence

25. Side gear thrust washer 26. Side gear 27. Circular clip

28. Pinion mate thrust washer 29. Pinion mate gear 30. Pinion mate shaft

31. Lock pin 32. Side bearing adjusting washer 33. Side oil seal (left side)

34. Side shaft bearing 35. Extension tube retainer 36. Side shaft oil seal

37. Dust sealed 38. Side shaft

A: Oil seal lip

B: Screw hole

Refer to GI-8, "

Component" and the followings for the symbols in the figure.

: Apply multi-purpose grease.

: Apply gear oil.

: Apply anti-corrosion oil.

: Apply Genuine Silicone RTV or equivalent. Refer to

GI-44, "

Recommended Chemical Product and Sealant".

: Apply Genuine Medium Strength Thread Locking Sealant or equivalent. Refer to

GI-44, "

Recommended Chemical Prod-

uct and Sealant".

Tool number A: ST3127S000 (J-25765-A)

Total preload torque:

1.56 - 2.65 N·m (0.16 - 0.27 kg-m, 14 - 23 in-lb)

PDIA0792J

When the preload torque is largeOn pinion bearings: Decrease the drive pinion bearing adjusting washer and drive pinion

adjusting washer thickness. Refer to FFD-39, "

Inspection and Adjust-

ment" and FFD-39, "Inspection and Adjustment".

On side bearings: Increase the side bear ing adjusting shim thickness. Refer to FFD-39,

"Inspection and Adjustment".

When the preload torque is small On pinion bearings: Increase the drive pinion bearing adjusting washer and drive pinion

adjusting washer thickness. Refer to FFD-39, "

Inspection and Adjust-

ment" and FFD-39, "Inspection and Adjustment".

On side bearings: Decrease the side bearin g adjusting shim thickness. Refer to FFD-39,

"Inspection and Adjustment".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2815 of 3924

FFD-24

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

b. If the runout value is still outside of the limit after the phase has been changed, possible cause will be an

assembly malfunction of drive pinion and pinion bearing and malfunction of pinion bearing. Check for

these items and repair if necessary.

c. If the runout value is still outside of the limit after the check and repair, replace companion flange.

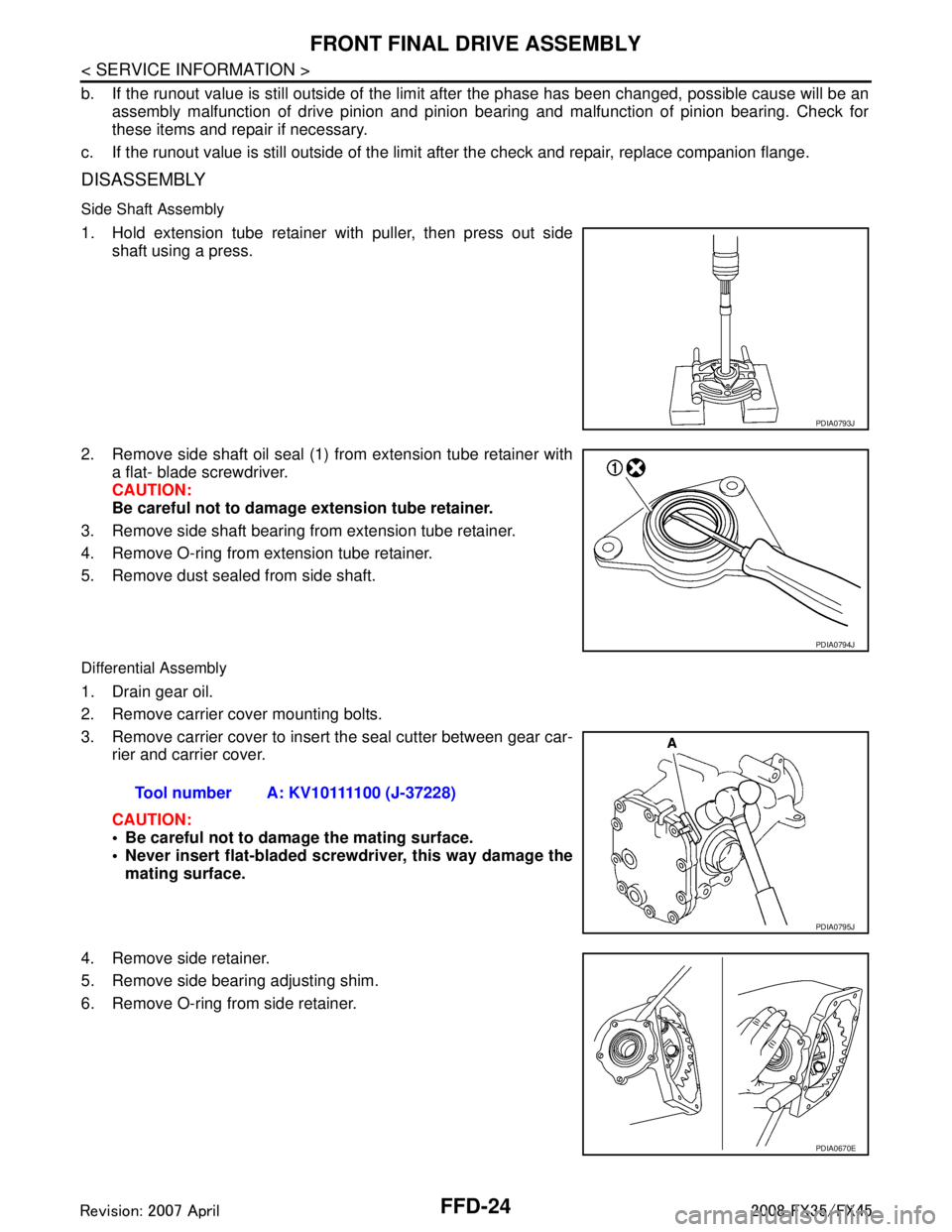

DISASSEMBLY

Side Shaft Assembly

1. Hold extension tube retainer with puller, then press out side shaft using a press.

2. Remove side shaft oil seal (1) from extension tube retainer with a flat- blade screwdriver.

CAUTION:

Be careful not to damage extension tube retainer.

3. Remove side shaft bearing from extension tube retainer.

4. Remove O-ring from extension tube retainer.

5. Remove dust sealed from side shaft.

Differential Assembly

1. Drain gear oil.

2. Remove carrier cover mounting bolts.

3. Remove carrier cover to insert the seal cutter between gear car- rier and carrier cover.

CAUTION:

Be careful not to damage the mating surface.

Never insert flat-bladed screwdriver, this way damage the

mating surface.

4. Remove side retainer.

5. Remove side bearing adjusting shim.

6. Remove O-ring from side retainer.

PDIA0793J

PDIA0794J

Tool number A: KV10111100 (J-37228)

PDIA0795J

PDIA0670E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C