lock INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2920 of 3924

SQUEAK AND RATTLE TROUBLE DIAGNOSESGW-7

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle.Operate the vehicle under the same

conditions as when the noise originallyoccurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001327958

Refer to Table of Contents for specific component removal and installationinformation.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolat e a squeak or rattle. If you saturatet he area with silicone, you will not

be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to thecenter console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on startsand stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put intothe trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2921 of 3924

GW-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulatingthe item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knockingnoise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicatingthe conditions can isolate most of these

incidents. Repairs usually consistof insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the pos ition the seatis in and the load placed on the seat when

the noise is present. These conditionsshould be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspectedcomponents while duplicating the condi-

tions under which the noise occurs.Most of these incidents can be repaired by repositioning the component

orapplying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or onthe engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2928 of 3924

POWER WINDOW SYSTEMGW-15

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

POWER WINDOW SYSTEM

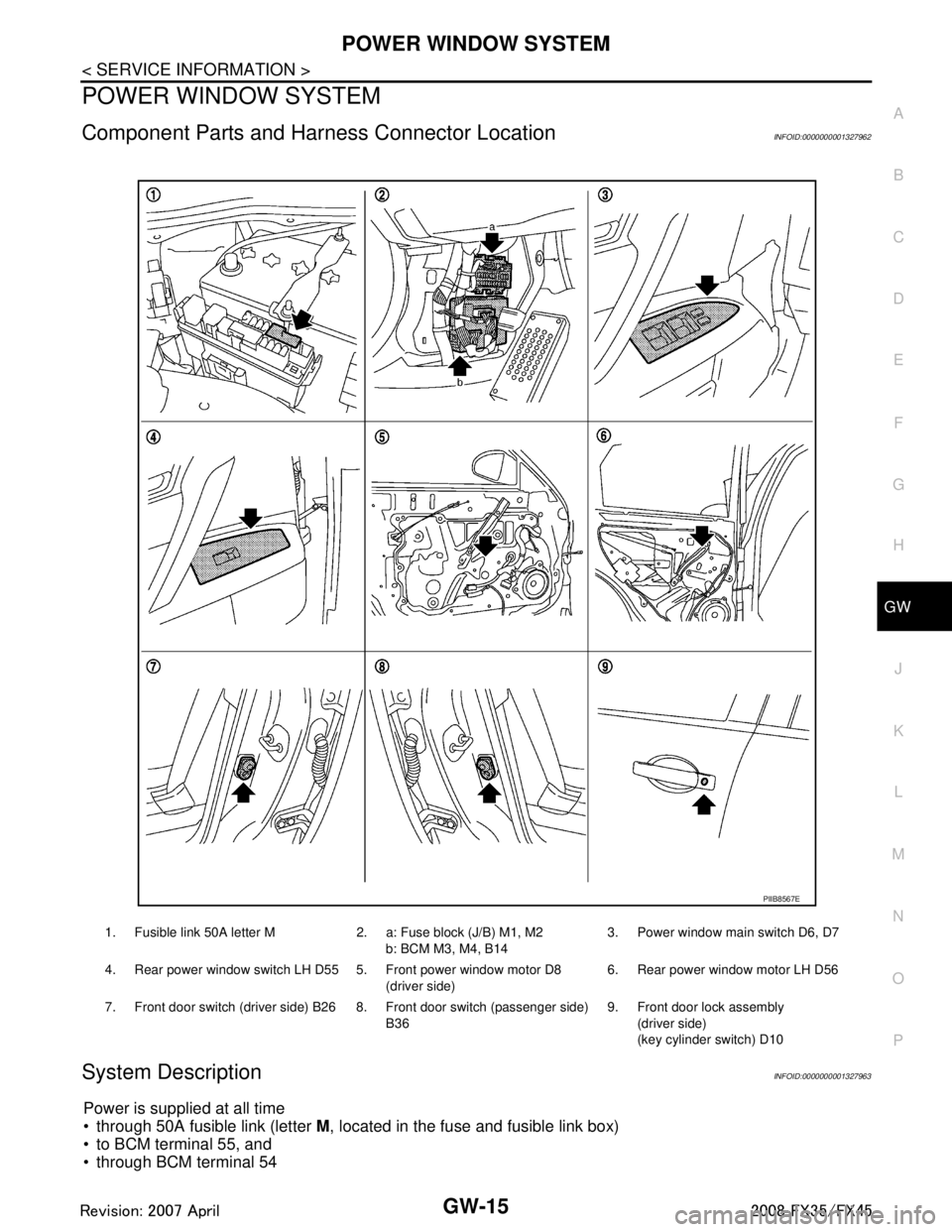

Component Parts and Har ness Connector LocationINFOID:0000000001327962

System DescriptionINFOID:0000000001327963

Power is supplied at all time

through 50A fusible link (letter M, located in the fuse and fusible link box)

to BCM terminal 55, and

through BCM terminal 54

1. Fusible link 50A letter M 2. a: Fuse block (J/B) M1, M2

b: BCM M3, M4, B143. Power window main switch D6, D7

4. Rear power window switch LH D55 5. Front power window motor D8 (driver side)6. Rear power window motor LH D56

7. Front door switch (driver side) B26 8. Front door switch (passenger side) B369. Front door lock assembly

(driver side)

(key cylinder switch) D10

PIIB8567E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2929 of 3924

GW-16

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

to power window main switch terminal 19

to front power window switch (passenger side) terminal 10.

through 15A fuse [No. 22, located in the fuse block (J/B)]

to BCM terminal 42.

With ignition switch in ON or START position,

Power is supplied

through 15A fuse [No. 1, located in the fuse block (J/B)]

to BCM terminal 38, and

trough BCM terminal 53

to power window main switch terminal 10

to rear power window switch (LH and RH) terminal 1.

Ground supplied

to BCM terminal 49 and 52

through body grounds M35, M45 and M85.

to power window main switch terminal 17

through body grounds M35, M45 and M85.

to front power window switch (passenger side) terminal 11

through body grounds M35, M45 and M85.

MANUAL OPERATION

Front Driver Side Door

WINDOW UP

When the front LH switch in the power window main switch is pressed in the up position,

Power is supplied

through power window main switch terminal 8

to front power window motor (driver side) terminal 2.

Ground is supplied

to front power window motor (driver side) terminal 1

through power window main switch terminal 11.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the front LH switch in the power window main switch is pressed in the down position

Power is supplied

through power window main switch terminal 11

to front power window motor (driver side) terminal 1.

Ground is supplied

to front power window motor (driver side) terminal 2

through power window main switch terminal 8.

Then, the motor lowers the window until the switch is released.

Front Passenger Side Door

FRONT POWER WINDOW SWITCH (P ASSENGER SIDE) OPERATION

WINDOW UP

When the front power window switch (pass enger side) is pressed in the up position

Power is supplied

through front power window switch (passenger side) terminal 8

to front power window motor (passenger side) terminal 2.

Ground is supplied

to front power window motor (passenger side) terminal 1

through front power window switch (passenger side) terminal 9.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the front power window switch (passenger side) is pressed in the down position

Power is supplied

through front power window switch (passenger side) terminal 9

to front power window motor (passenger side) terminal 1.

Ground is supplied

to front power window motor (passenger side) terminal 2

through front power window switch (passenger side) terminal 8.

Then, the motor lowers the window until the switch is released.

POWER WINDOW MAIN SWITCH OPERATION

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2931 of 3924

GW-18

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

The one is applied only for front doors and the other is for all doors.

POWER WINDOW SERIAL LINK

Power window main switch, front power window switch (passenger side), and BCM transmit and receive the

signal by power window serial link.

The under mentioned signal is transmitted from BCM to power window main switch and front power window

switch (passenger side)

Keyless power window down signal.

The under mentioned signal is transmitted from power window main switch to front power window switch (pas-

senger side)

Front passenger side door window operation signal.

Power window control by key cylinder switch signal.

Power window lock signal.

Retained power operation signal.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for driver side door window.

When the lock position, ground of the rear power window switches in the power window main switch is discon-

nected. The power window lock signal is transmitted to front power window switch (passenger side) by power

window serial link. This prevents t he power window motors from operating.

RETAINED POWER OPERATION

When the ignition switch is turned to the OFF position from ON or START position.

Power is supplied for 45 seconds

through BCM terminal 53

to power window main switch terminal 10

to rear power window switch (LH and RH) terminals 1.

When power and ground are supplied, the BCM conti nues to be energized, and the power window can be

operated.

The retained power operation is canceled when the driver or passenger side door is opened.

RAP signal period can be changed by CONSULT-III. Refer to GW-26, "

CONSULT-III Function".

ANTI-PINCH SYSTEM

Power window main switch and front power window switch (passenger side) monitors the power window motor

operation and the power window position (full closed or other) for driver side and passenger side power win-

dow by the signals from encoder and limit switch in front power window motor (driver side and passenger

side).

When power window main switch detects inte rruption during the following close operation,

automatic close operation when igniti on switch is in the “ON” position

automatic close operation during retained power operation

manual close operation during retained power operation

power window main switch or front power window swit ch (passenger side) controls each power window motor

for open and the power window will be lowered about 150 mm (5.91 in).

POWER WINDOW CONTROL BY THE KEY CYLINDER SWITCH

When ignition key switch is OFF, front power window can be opened or closed by turning the key cylinder

switch UNLOCK / LOCK position more than 1.5 second over condition.

Power window can be opened as the door key cylinder is kept fully turning to the UNLOCK position.

Power window can be closed as the door key cylinder is kept fully turning to the LOCK position.

The power window DOWN stops when the following operations are carried out.

While performing open / close the window, power window is stopped at the position as the door key cylinder is placed on NEUTRAL.

When the ignition switch is turned ON while the power window DOWN is operated.

CAN Communication System DescriptionINFOID:0000000001327964

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2937 of 3924

GW-24

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

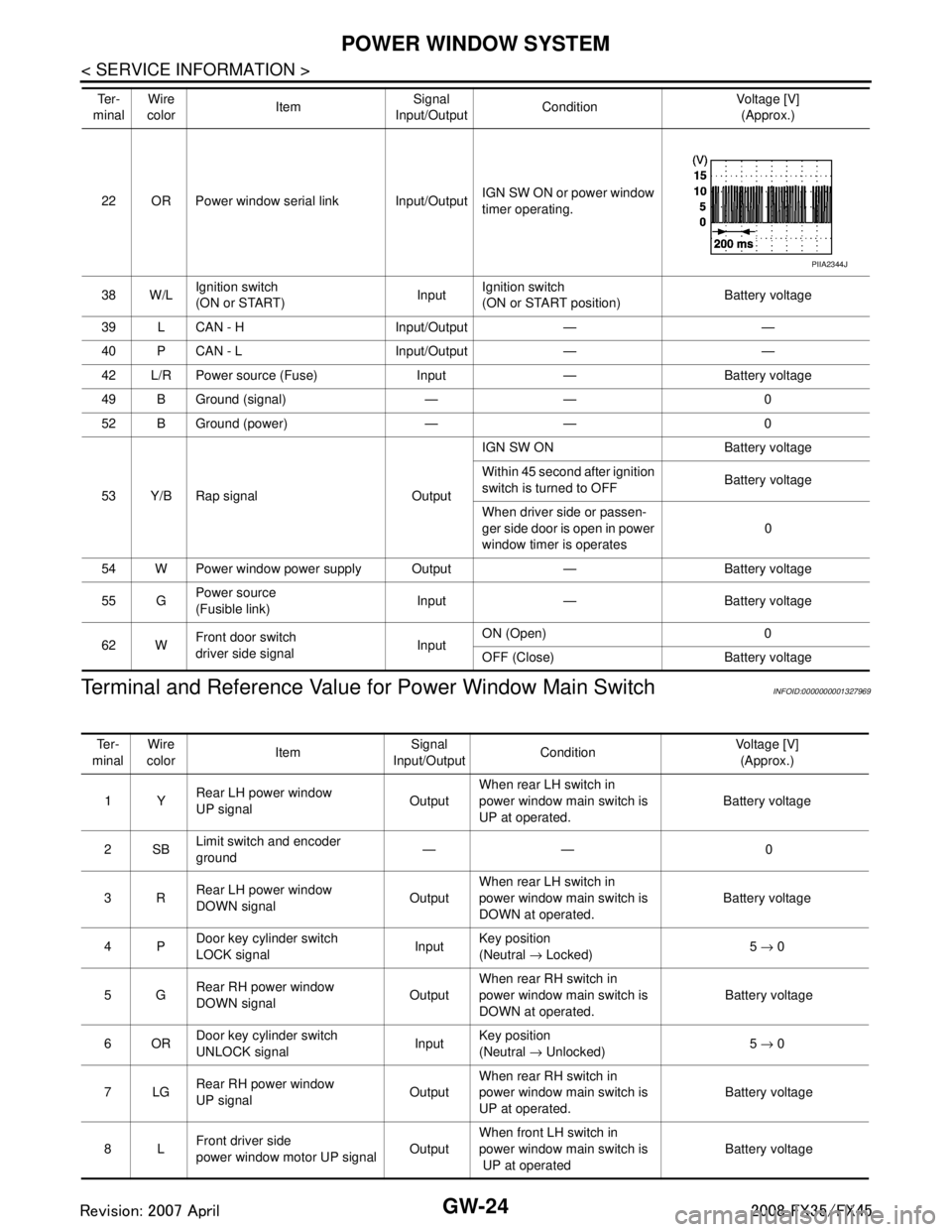

Terminal and Reference Value for Power Window Main Switch

INFOID:0000000001327969

22 OR Power window serial link Input/Output IGN SW ON or power window

timer operating.

38 W/L Ignition switch

(ON or START) InputIgnition switch

(ON or START position) Battery voltage

39 L CAN - H Input/Output — —

40 P CAN - L Input/Output — —

42 L/R Power source (Fuse) Input — Battery voltage

49 B Ground (signal) — — 0

52 B Ground (power) — — 0

53 Y/B Rap signal Output IGN SW ON Battery voltage

Within 45 second after ignition

switch is turned to OFF

Battery voltage

When driver side or passen-

ger side door is open in power

window timer is operates 0

54 W Power window power supply Output — Battery voltage

55 G Power source

(Fusible link)

Input — Battery voltage

62 W Front door switch

driver side signal InputON (Open) 0

OFF (Close) Battery voltage

Te r -

minal Wire

color Item Signal

Input/Output Condition Voltage [V]

(Approx.)

PIIA2344J

Te r -

minal Wire

color Item Signal

Input/Output Condition Voltage [V]

(Approx.)

1Y Rear LH power window

UP signal OutputWhen rear LH switch in

power window main switch is

UP at operated. Battery voltage

2SB Limit switch and encoder

ground —— 0

3R Rear LH power window

DOWN signal OutputWhen rear LH switch in

power window main switch is

DOWN at operated. Battery voltage

4P Door key cylinder switch

LOCK signal InputKey position

(Neutral

→ Locked) 5

→ 0

5G Rear RH power window

DOWN signal OutputWhen rear RH switch in

power window main switch is

DOWN at operated. Battery voltage

6OR Door key cylinder switch

UNLOCK signal Input

Key position

(Neutral

→ Unlocked) 5

→ 0

7LG Rear RH power window

UP signal OutputWhen rear RH switch in

power window main switch is

UP at operated. Battery voltage

8L Front driver side

power window motor UP signal

OutputWhen front LH switch in

power window main switch is

UP at operated

Battery voltage

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2941 of 3924

![INFINITI FX35 2008 Service Manual

GW-28

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Check BCM Power Suppl y and Ground Circuit

INFOID:0000000001327974

1.CHECK FUSE

Check 15A fuse [No. 1, located in fuse block (J/B)]

Check 15A fus INFINITI FX35 2008 Service Manual

GW-28

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Check BCM Power Suppl y and Ground Circuit

INFOID:0000000001327974

1.CHECK FUSE

Check 15A fuse [No. 1, located in fuse block (J/B)]

Check 15A fus](/img/42/57017/w960_57017-2940.png)

GW-28

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Check BCM Power Suppl y and Ground Circuit

INFOID:0000000001327974

1.CHECK FUSE

Check 15A fuse [No. 1, located in fuse block (J/B)]

Check 15A fuse [No. 22, located in fuse block (J/B)]

Check 50A fusible link (letter M, located in the fuse and fusible link box).

NOTE:

Refer to GW-15, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3

.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between BCM connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Check BCM power supply circuit for open or short.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM connector M4 terminal 49, 52 and ground.

OK or NG

OK >> Power supply and ground circuit are OK.

NG >> Check BCM ground circuit for open or short.

Check Power Window Main S witch Power Supply CircuitINFOID:0000000001327975

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

Power window lock switch does not function Check power window lock switch GW-46

Auto operation does not operate but manual operates normally

(driver side)1. Check encoder ci

rcuit (driver side) GW-39

2. Replace power window main switch. —

Auto operation does not operate but manual operates normally

(passenger side) 1. Check encoder circuit (passenger side)

GW-40

2. Replace front power window switch (passen-

ger side) —

Symptom Repair order Refer to page

Connector

Terminal (Wire color)

Condition of

ignition switchVoltage [V]

(Approx.)

(+) (–)

M3 38 (W/L) GroundON

Battery

voltage

M4 42 (L/R)

OFF

55 (G)

PIIB1383E

49 (B) – Ground : Conti nuity should exist.

52 (B) – Ground : Conti nuity should exist.

PIIA6161E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2957 of 3924

GW-44

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

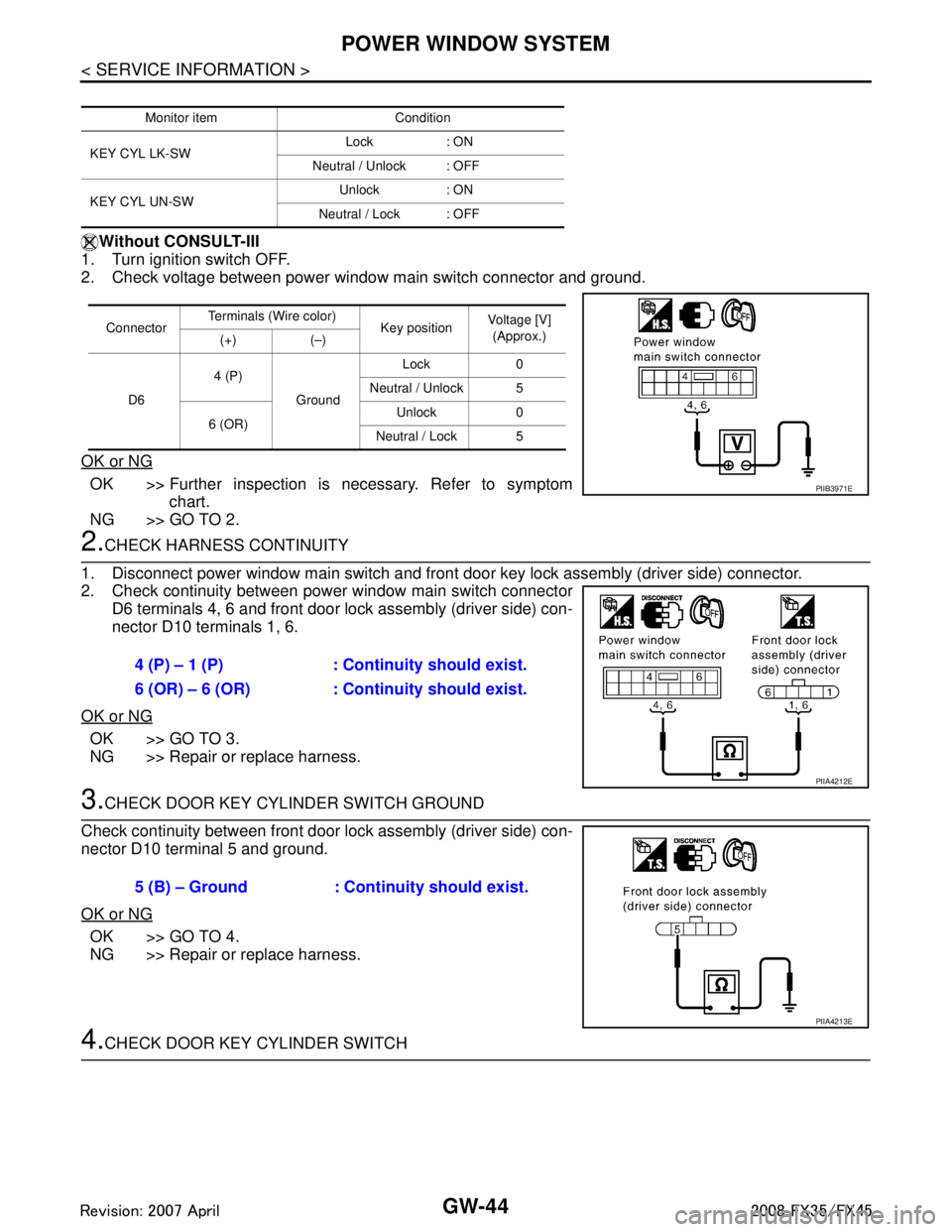

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check voltage between power window main switch connector and ground.

OK or NG

OK >> Further inspection is necessary. Refer to symptom chart.

NG >> GO TO 2.

2.CHECK HARNESS CONTINUITY

1. Disconnect power window main switch and front door key lock assembly (driver side) connector.

2. Check continuity between power window main switch connector D6 terminals 4, 6 and front door lock assembly (driver side) con-

nector D10 terminals 1, 6.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK DOOR KEY CYLINDER SWITCH GROUND

Check continuity between front door lock assembly (driver side) con-

nector D10 terminal 5 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK DOOR KEY CYLINDER SWITCH

Monitor item Condition

KEY CYL LK-SW Lock : ON

Neutral / Unlock : OFF

KEY CYL UN-SW Unlock : ON

Neutral / Lock : OFF

Connector Terminals (Wire color)

Key position Voltage [V]

(Approx.)

(+) (–)

D6 4 (P)

Ground Lock 0

Neutral / Unlock 5

6 (OR) Unlock 0

Neutral / Lock 5

PIIB3971E

4 (P) – 1 (P) : Conti nuity should exist.

6 (OR) – 6 (OR) : Cont inuity should exist.

PIIA4212E

5 (B) – Ground : Continuity should exist.

PIIA4213E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2958 of 3924

POWER WINDOW SYSTEMGW-45

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

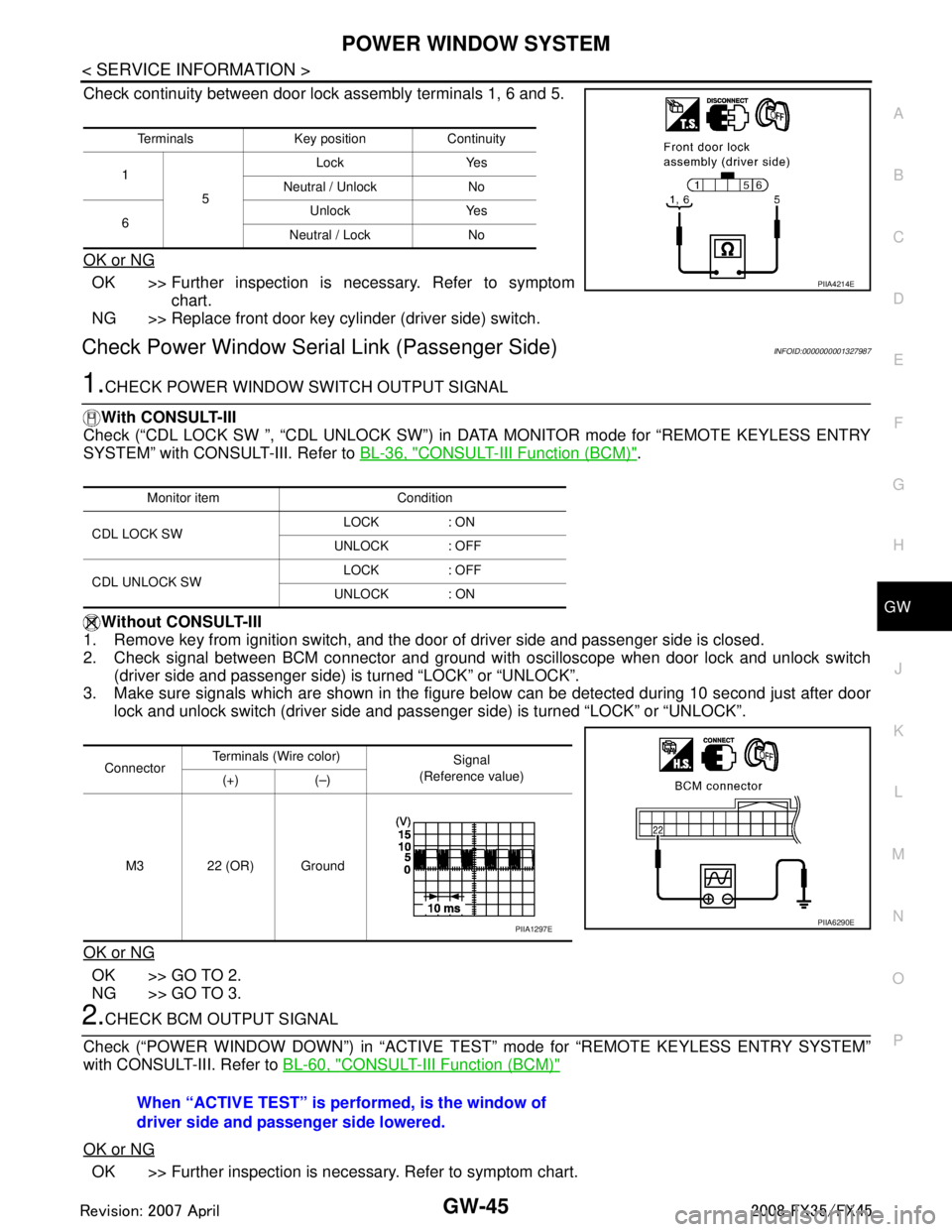

Check continuity between door lock assembly terminals 1, 6 and 5.

OK or NG

OK >> Further inspection is necessary. Refer to symptom chart.

NG >> Replace front door key cylinder (driver side) switch.

Check Power Window Serial Link (Passenger Side)INFOID:0000000001327987

1.CHECK POWER WINDOW SWITCH OUTPUT SIGNAL

With CONSULT-III

Check (“CDL LOCK SW ”, “CDL UNLOCK SW”) in DATA MONITOR mode for “REMOTE KEYLESS ENTRY

SYSTEM” with CONSULT-III. Refer to BL-36, "

CONSULT-III Function (BCM)".

Without CONSULT-III

1. Remove key from ignition switch, and the door of driver side and passenger side is closed.

2. Check signal between BCM connector and ground wit h oscilloscope when door lock and unlock switch

(driver side and passenger side) is turned “LOCK” or “UNLOCK”.

3. Make sure signals which are shown in the figure below can be detected during 10 second just after door

lock and unlock switch (driver side and passenger side) is turned “LOCK” or “UNLOCK”.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK BCM OUTPUT SIGNAL

Check (“POWER WINDOW DOWN”) in “ACTIVE T EST” mode for “REMOTE KEYLESS ENTRY SYSTEM”

with CONSULT-III. Refer to BL-60, "

CONSULT-III Function (BCM)"

OK or NG

OK >> Further inspection is necessary. Refer to symptom chart.

Terminals Key position Continuity

1 5 Lock Yes

Neutral / Unlock No

6 Unlock Yes

Neutral / Lock No

PIIA4214E

Monitor item Condition

CDL LOCK SW LOCK : ON

UNLOCK : OFF

CDL UNLOCK SW LOCK : OFF

UNLOCK : ON

Connector Terminals (W

ire color)

Signal

(Reference value)

(+) (–)

M3 22 (OR) Ground

PIIA6290EPIIA1297E

When “ACTIVE TEST” is performed, is the window of

driver side and passenger side lowered.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2959 of 3924

GW-46

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

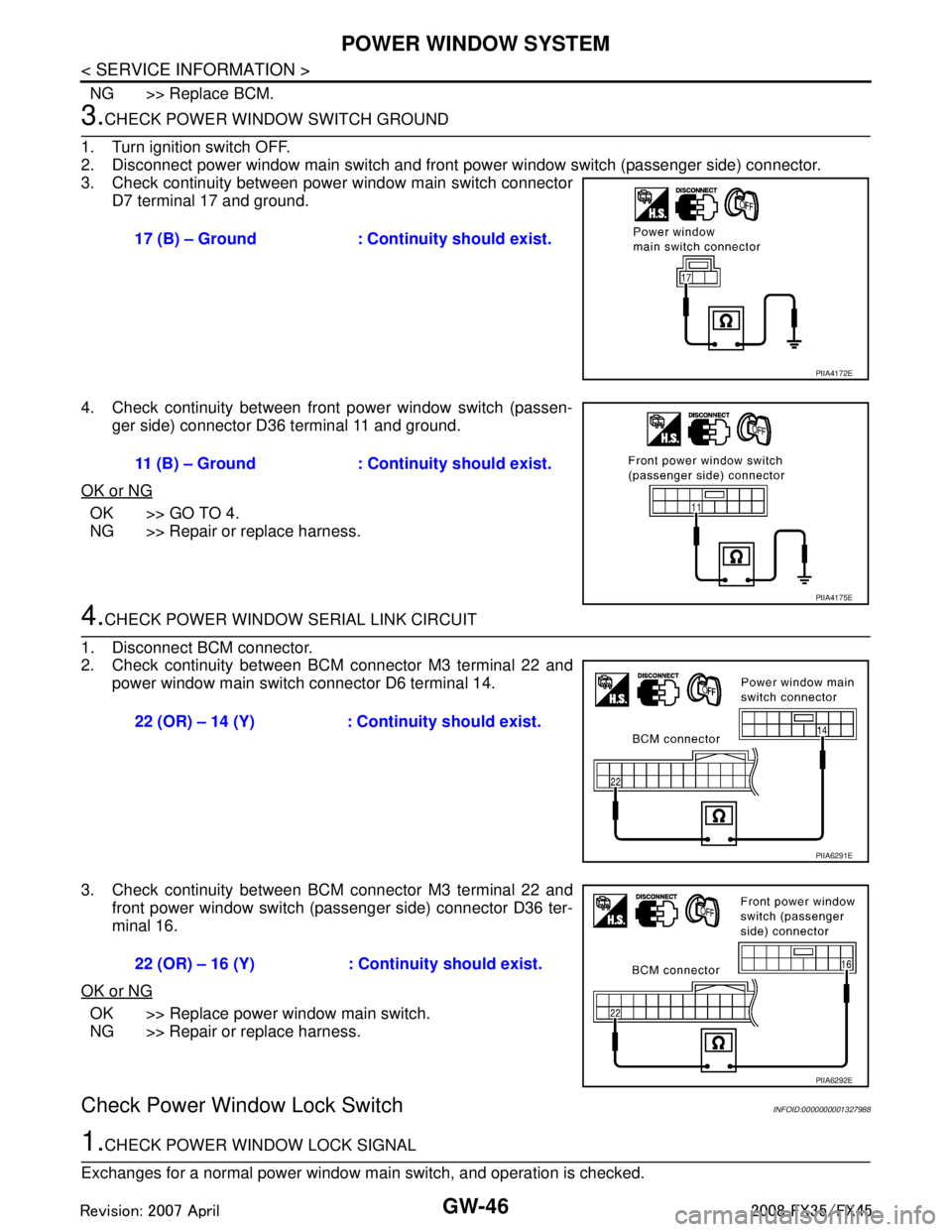

NG >> Replace BCM.

3.CHECK POWER WINDOW SWITCH GROUND

1. Turn ignition switch OFF.

2. Disconnect power window main switch and front power window switch (passenger side) connector.

3. Check continuity between power window main switch connector D7 terminal 17 and ground.

4. Check continuity between front power window switch (passen- ger side) connector D36 terminal 11 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK POWER WINDOW SERIAL LINK CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM connector M3 terminal 22 and power window main switch connector D6 terminal 14.

3. Check continuity between BCM connector M3 terminal 22 and front power window switch (passenger side) connector D36 ter-

minal 16.

OK or NG

OK >> Replace power window main switch.

NG >> Repair or replace harness.

Check Power Window Lock SwitchINFOID:0000000001327988

1.CHECK POWER WINDOW LOCK SIGNAL

Exchanges for a normal power window main switch, and operation is checked. 17 (B) – Ground : Continuity should exist.

PIIA4172E

11 (B) – Ground : Continuity should exist.

PIIA4175E

22 (OR) – 14 (Y) : Cont

inuity should exist.

PIIA6291E

22 (OR) – 16 (Y) : Cont inuity should exist.

PIIA6292E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C