fuel INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2866 of 3924

GI-4

< SERVICE INFORMATION >

PRECAUTIONS

To prevent serious burns:Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of or recycle drained oil or the solvent used for cleaning parts in an appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical com ponents which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, atta ch a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

Before servicing the vehicle: Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic tro uble codes, do not carelessly disconnect the harness

connectors which are related to the engine cont rol system and TCM (transmission control module)

system. The connectors should be disconnected on ly when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precaution for Three Way CatalystINFOID:0000000001325655

If a large amount of unburned fuel flows into the catalyst , the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

When checking for ignition spark or measuring engine compression, make tests quickly and only when nec- essary.

Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

SGI233

PBIC0190E

SGI234

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2867 of 3924

PRECAUTIONSGI-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precaution for Fuel (Unlead ed Premium Gasoline Recommended)INFOID:0000000001325656

VQ35DE

INFINITI recommends the use of unleaded premium gasoli ne with an octane rating of at least 91 AKI (Anti-

Knock Index) number (Research octane number 96).

If unleaded premium gasoline is not available, you may use unleaded regular gasoline with an octane rating of

at least 87AKI number (Research octane number 91), but you may notice a decrease in performance.

CAUTION:

Do not use leaded gasoli ne. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unlead ed gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fu el other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

Precaution for Fuel (Unleaded Premium Gasoline Required)INFOID:0000000001325657

VK45DE

Use unleaded premium gasoline with an octane rating of at least 91 AKI (Anti-Knock Index) number (Research

octane number 96).

If unleaded premium gasoline is not available, unleaded r egular gasoline with an octane rating of at least 87

AKI number (Research octane number 91) can be us ed, but only under the following precautions:

have the fuel tank filled only partially with unl eaded regular gasoline, and fill up with unleaded premium gas-

oline as soon as possible.

avoid full throttle driving and abrupt acceleration.

However, for maximum vehicle performance, the u se of unleaded premium gasoline is recommended.

CAUTION:

Do not use leaded gasoli ne. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unlead ed gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fu el other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

Precaution for Multiport Fuel Inject ion System or Engine Control SystemINFOID:0000000001325658

Before connecting or disconnecti ng any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

Before disconnecting pressurized fuel line from fuel pump to injec- tors, be sure to release fuel pressure.

Be careful not to jar components such as ECM and mass air flow sensor.

Precaution for HosesINFOID:0000000001325659

HOSE REMOVAL AND INSTALLATION

SGI787

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2869 of 3924

PRECAUTIONSGI-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regu-

larly.

First aid treatment should be obtai ned immediately for open cuts and wounds.

Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Prepara- tions containing lanolin replace the natural skin oils which have been removed.

Do not use gasoline, kerosene, diesel fuel, gas oil, thinners or solvents for cleaning skin.

If skin disorders develop, obtain medical advice without delay.

Where practical, degrease components prior to handling.

Where there is a risk of eye contact, eye protecti on should be worn, for example, chemical goggles or face

shields; in addition an eye wash facility should be provided.

Precaution for the EnvironmentINFOID:0000000001325661

In servicing the vehicle, it may be necessary to use, dispose of or recycle hazardous, flammable, or poisonous

materials, such as gasoline, refrigerant gas, solvents, oil, oil filter, air bag modules, seat belt pretensioners,

etc. Disposal, recycling, and transportation of any haz ardous materials should be performed in compliance

with applicable federal, state and local laws and regulations.

Precaution for Air ConditioningINFOID:0000000001325662

Use an approved refrigerant recovery unit any time t he air conditioning system must be discharged. Refer to

ATC/MTC section “HFC-134a (R-134a) Service Procedure”, “REFRIGERANT LINES” for specific instructions.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2900 of 3924

GI-38

< SERVICE INFORMATION >

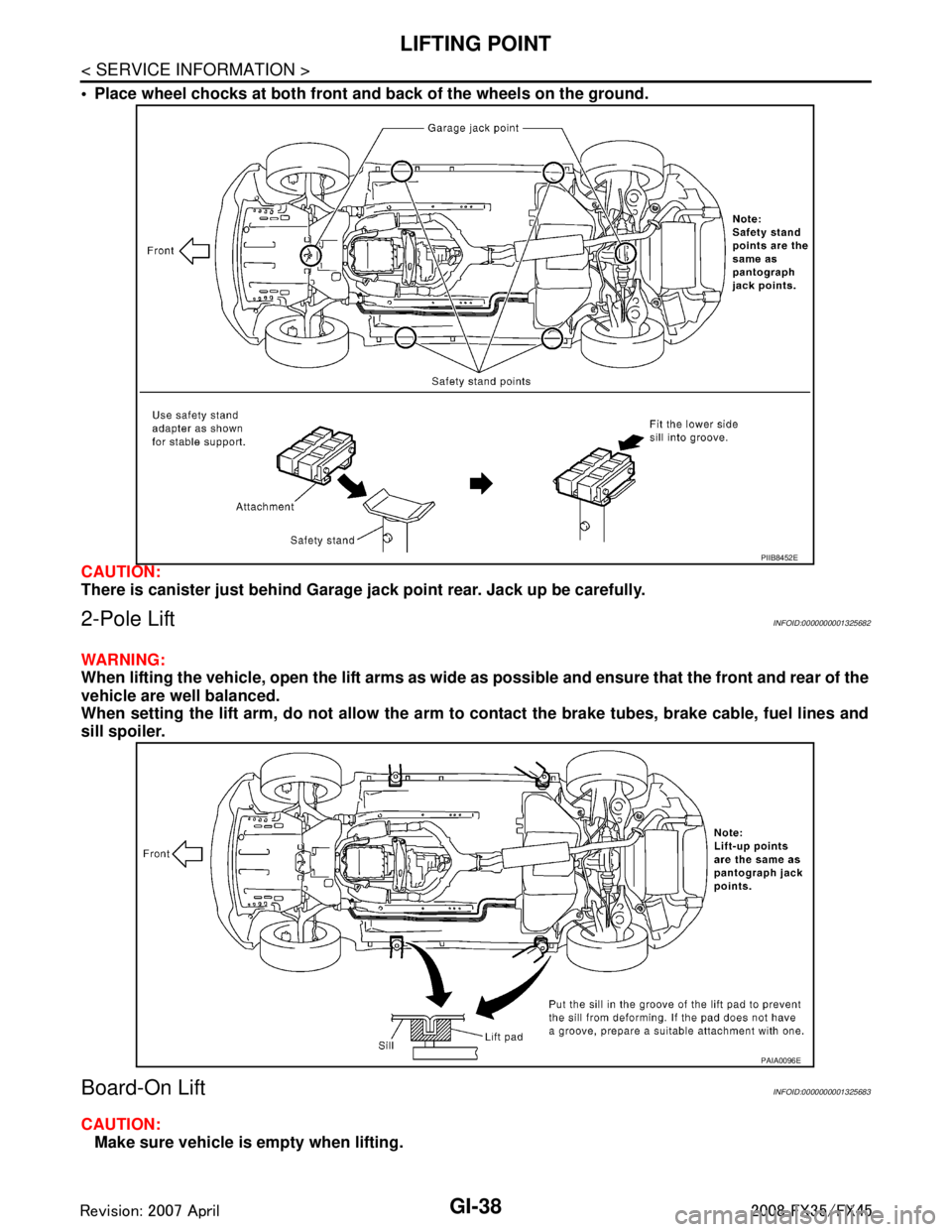

LIFTING POINT

Place wheel chocks at both front and back of the wheels on the ground.

CAUTION:

There is canister just behind Garage jack point rear. Jack up be carefully.

2-Pole LiftINFOID:0000000001325682

WARNING:

When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear of the

vehicle are well balanced.

When setting the lift arm, do no t allow the arm to contact the brake tubes, brake cable, fuel lines and

sill spoiler.

Board-On LiftINFOID:0000000001325683

CAUTION: Make sure vehicle is empty when lifting.

PIIB8452E

PAIA0096E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2910 of 3924

GI-48

< SERVICE INFORMATION >

TERMINOLOGY

TERMINOLOGY

SAE J1930 Terminology ListINFOID:0000000001325691

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old te rms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATION OLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONS ULT-II DLC for CONSULT-II Diagno stic connector for CONSULT-II

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memory EEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2911 of 3924

TERMINOLOGYGI-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Exhaust gas recirculation control-BPT

valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memory FEEPROM ***

Flash erasable programmable read only

memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulato r *** Pressure regulator

Fuel pressure regulator control solenoid

valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulato r IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valve IACV-AAC valve Auxiliary

air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valve IACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold su rface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2912 of 3924

GI-50

< SERVICE INFORMATION >

TERMINOLOGY

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switchPark/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain cont rol module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valve PAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection sys-

tem *** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

system TWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3064 of 3924

![INFINITI FX35 2008 Service Manual

LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000001328636

Refer to

LAN-13, "How to Use C INFINITI FX35 2008 Service Manual

LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000001328636

Refer to

LAN-13, "How to Use C](/img/42/57017/w960_57017-3063.png)

LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000001328636

Refer to

LAN-13, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

TYPE 1/TYPE 2

NOTE:

Refer to LAN-37, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

PKID0615E

Signal name/Connecting unitECM

DISP TCM

BCM

I-KEY

STRG M&AABS

ADP

IPDM-E

A/C compressor feedback signal T R

A/C compressor request signal T R

Accelerator pedal position signal T R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R

Cooling fan speed request signal T R

Engine coolant temperature signal T R

Engine speed signal T R R R R

Engine status signal T R

Fuel consumption monitor signal TR

RT

Malfunctioning indicator lamp signal T R

Wide open throttle position signal T R

A/C switch/indicator signal TR

RT

System setting signal TR R

RT T

A/T CHECK indicator lamp signal T R

A/T self-diagnosis signal R T

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3065 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISLAN-45

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Current gear position signal T R

Manual mode indicator signal T R

Output shaft revolution signal R T

P range si INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISLAN-45

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Current gear position signal T R

Manual mode indicator signal T R

Output shaft revolution signal R T

P range si](/img/42/57017/w960_57017-3064.png)

TROUBLE DIAGNOSISLAN-45

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Current gear position signal T R

Manual mode indicator signal T R

Output shaft revolution signal R T

P range signal T R R

Shift position indicator signal T R

Turbine revolution signal R T

A/C switch signal R T

Buzzer output signal TR

TR

Blower fan motor switch signal R T

Day time running light request signal T R

Door lock/unlock status signal T R

Door switch signal R T R R R R

Front fog light request signal T R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal T R R

Key fob door unlock signal T R

Key fob ID signal T R

Key switch signal T R

Low beam request signal T R

Oil pressure switch signal RT

TR

Position light request signal T R R

Rear window defogger switch signal T R

Run flat tire warning lamp signal T R

Sleep wake up signal TRRR

RT

Theft warning horn request signal T R

Tire pressure warn ing lamp signal T R

Turn indicator signal T R

Alarm request signal R T

Back door open request signal R T

Door lock/unlock request signal R T

Ignition knob switch signal R T

Key warning signal T R

Power window open request signal R T

Steering angle sensor signal T R

Distance to empty signal R T

Fuel level low warning signal R T

Fuel level sensor signal R T

Manual mode shift down signal R T Signal name/Connecting unit

ECM

DISP TCM

BCM

I-KEY

STRG

M&AABS

ADP

IPDM-E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3066 of 3924

![INFINITI FX35 2008 Service Manual

LAN-46

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not

used by usual service work, thus it is omitted.

TYPE 3

NOTE:

Refer to LAN-37, "

Abbre INFINITI FX35 2008 Service Manual

LAN-46

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not

used by usual service work, thus it is omitted.

TYPE 3

NOTE:

Refer to LAN-37, "

Abbre](/img/42/57017/w960_57017-3065.png)

LAN-46

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not

used by usual service work, thus it is omitted.

TYPE 3

NOTE:

Refer to LAN-37, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

Manual mode shift up signal R T

Manual mode signal R T

Not manual mode signal R T

Snow mode switch signal R T

Stop lamp switch signal R T

Turn LED burnout status signal R T

Vehicle speed signal RT

RRRRR T R

A/T shift schedule change demand signal R T

ABS operation signal T

ABS warning lamp signal RT

Brake warning lamp signal RT

SLIP indicator lamp signal RT

TCS operation signal T

VDC OFF indicator lamp signal R T

VDC OFF switch signal T

VDC operation signal T

Front wiper stop position signal R T

High beam status signal R T

Hood switch signal R T

Low beam status signal R T

Rear window defogger control signal R R T Signal name/Connecting unit

ECM

DISP TCM

BCM

I-KEY

STRG M&AABS

ADP

IPDM-E

Signal name/Connecting unitECM

DISP ICC

TCM

BCM

I-KEY

LANE

STRG M&AABS

LASER ADP

IPDM-E

A/C compressor feedback signal T R

A/C compressor request signal T R

Accelerator pedal position signal T R R R

ASCD OD cancel request signal T R

ASCD operation signal T R

Battery voltage signal T R

Closed throttle position signal T R R

Cooling fan speed request signal T R

Engine coolant temperature signal T R

Engine speed signal T R R R R R

Engine status signal T R

Fuel consumption monitor signal TR

RT

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C