section pg INFINITI FX35 2008 Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1016 of 3924

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

SERVICE INFORMATION .. ..........................

3

DTC INDEX ..................................................... .....3

C1101-C1116 ...................................................... ......3

C1120-C1136 ............................................................3

C1140-C1170 ............................................................3

U1000 ........................................................................4

PRECAUTIONS ...................................................5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Precaution for Brake System ....................................5

Precaution for Brake Control .....................................5

PREPARATION ...................................................7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................7

ON-VEHICLE SERVICE ......................................8

Adjustment of Steering Angle Sensor Neutral Po-

sition .................................................................... ......

8

Calibration of Decel G Sensor (AWD Models) ..........8

SYSTEM DESCRIPTION ................................ ....10

Schematic ........................................................... ....10

Functions .................................................................10

Fail-Safe Function ...................................................11

Hydraulic Circuit Diagram .......................................12

CAN Communication ...............................................12

TROUBLE DIAGNOSIS .....................................13

Fail-Safe Function ............................................... ....13

How to Proceed with Diagnosis ..............................13

Component Part Location .......................................16

Schematic ...............................................................17

Wiring Diagram - VDC - ..........................................18

Control Unit Input/Output Signal Standard ..............23

CONSULT-III Functions (ABS) ................................26

Self-Diagnosis ..................................................... ....26

Data Monitor ........................................................ ....28

Active Test ...............................................................30

For Fast and Accurate Diagnosis ............................31

Basic Inspection ......................................................32

TROUBLE DIAGNOSIS FOR SYSTEM ............34

DTC C1101 RR RH SENSOR-1 ..............................34

DTC C1102 RR LH SENSOR-1 ..............................35

DTC C1103 FR RH SENSOR-1 ..............................35

DTC C1104 FR LH SENSOR-1 ...............................35

DTC C1105 RR RH SENSOR-2 ..............................36

DTC C1106 RR LH SENSOR-2 ..............................36

DTC C1107 FR RH SENSOR-2 ..............................36

DTC C1108 FR LH SENSOR-2 ...............................36

DTC C1109 BATTERY VOLTAGE [ABNORMAL] ....36

DTC C1110 CONTROLLER FAILURE ....................37

DTC C1111 PUMP MOTOR ....................................37

DTC C1113 G-SENSOR .........................................38

DTC C1115 ABS SENSOR [ABNORMAL SIG-

NAL] .........................................................................

39

DTC C1116 STOP LAMP SW .................................39

DTC C1120 FR LH IN ABS SOL .............................40

DTC C1121 FR LH OUT ABS SOL .........................41

DTC C1122 FR RH IN ABS SOL ......................... ....41

DTC C1123 FR RH OUT ABS SOL .........................42

DTC C1124 RR LH IN ABS SOL .............................42

DTC C1125 RR LH OUT ABS SOL ..................... ....42

DTC C1126 RR RH IN ABS SOL ............................42

DTC C1127 RR RH OUT ABS SOL ........................42

DTC C1130 ENGINE SIGNAL 1 .......................... ....42

DTC C1131 ENGINE SIGNAL 2 ..............................42

DTC C1132 ENGINE SIGNAL 3 ..............................42

DTC C1133 ENGINE SIGNAL 4 ..............................42

DTC C1136 ENGINE SIGNAL 6 ..............................42

DTC C1140 ACTUATOR RLY .................................43

DTC C1142 PRESS SEN CIRCUIT ........................43

DTC C1143 ST ANG SEN CIRCUIT ................... ....44

DTC C1144 ST ANG SEN SIGNAL .........................45

DTC C1145 YAW RATE SENSOR ..........................46

DTC C1146 SIDE G-SEN CIRCUIT ........................46

DTC C1155 BR FLUID LEVEL LOW .......................46

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1065 of 3924

![INFINITI FX35 2008 Workshop Manual

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 M INFINITI FX35 2008 Workshop Manual

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 M](/img/42/57017/w960_57017-1064.png)

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 MPH) or less.

1.CHECK ABS WARNING LAMP DISPLAY

Make sure warning lamp turns off approximately 2 seconds after the ignition switch is turned ON or when driv-

ing.

OK or NG

OK >> CHECK WHEEL SENSOR. Refer to BRC-49, "Excessive ABS Function Operation Frequency".

NG >> Perform self-diagnosis. Refer to BRC-26, "

Self-Diagnosis".

Pedal Vibration or ABS Operation Sound OccursINFOID:0000000001327696

CAUTION:

Under the following conditions, when brake pedal is lightly depressed (just place a foot on it), ABS is

activated and vibration is felt. However, this is normal.

When shifting gears

When driving on slippery road

During cornering at high speed

When passing over bumps or grooves

When pulling away just after st arting engine [at approximately 10 km/h (6 MPH) or higher]

1.SYMPTOM CHECK 1

Check if pedal vibration or operati on sound occurs when engine is started.

OK or NG

OK >> Perform self-diagnosis. Refer to BRC-26, "Self-Diagnosis".

NG >> GO TO 2.

2.SYMPTOM CHECK 2

Check symptom when electrical component (headlamps, etc.) switches are operated.

Does the symptom occur when the electrical component (head lamp, etc.) switches are operated?

YES >> Check if there is a radio, antenna, antenna lead wi re, or wiring close to ABS actuator and electric

unit (control unit) (or its wiring), and if there is, move it farther away.

NO >> CHECK WHEEL SENSOR. Refer to BRC-49, "

Excessive ABS Function Operation Frequency".

Vehicle Jerks During VDC/TCS/ABS ControlINFOID:0000000001327697

1.CHECK ENGINE SPEED SIGNAL

Perform CONSULT-III “DATA MONITOR” to check engine speed.

Is engine speed at idle 400 rpm or higher?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK ABS WARNING LAMP DISPLAY

Make sure warning lamp turns off approximately 2 seconds after the ignition switch is turned ON or when driv-

ing.

OK or NG

OK >> System is normal.

NG >> GO TO 3.

3.CHECK ECM SELF-DIAGNOSTIC RESULTS

Perform ECM self-diagnosis.

Are self-diagnosis items displayed?

YES >> Check the corresponding items. Refer to EC-89(VQ35DE), EC-666(VK45DE) in “Engine Control

(EC section)”.

NO >> GO TO 4.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1072 of 3924

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

VQ35DE

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Liquid Gasket .....................................3

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

OVERHEATING CAUSE ANALYSIS ..................7

Troubleshooting Chart ......................................... ......7

COOLING SYSTEM ....................................... .....9

Cooling Circuit ..................................................... ......9

System Chart ............................................................9

ENGINE COOLANT ...........................................10

Inspection ............................................................ ....10

Changing Engine Coolant .......................................10

RADIATOR .........................................................13

Component .......................................................... ....13

Removal and Installation .........................................13

Checking Radiator Cap ...........................................14

Checking Radiator ...................................................15

RADIATOR (ALUMINUM TYPE) ........................16

Component .......................................................... ....16

Disassembly and Assembly ....................................16

COOLING FAN ...................................................20

Component .......................................................... ....20

Removal and Installation .........................................20

Disassembly and Assembly ....................................20

WATER PUMP ...................................................22

Component .......................................................... ....22

Removal and Installation .........................................22

WATER INLET AND THERMOSTAT ASSEM-

BLY ....................................................................

27

Component .......................................................... ....27

Removal and Installation .........................................27

WATER OUTLET AND WATER PIPING ..........29

Component ..............................................................29

Removal and Installation .........................................29

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

31

Standard and Limit ..................................................31

VK45DE

SERVICE INFORMATION .. .........................

32

PRECAUTIONS .................................................32

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

32

PREPARATION .................................................33

Special Service Tool ................................................33

Commercial Service Tool ........................................33

OVERHEATING CAUSE ANALYSIS ................34

Troubleshooting Chart .............................................34

COOLING SYSTEM ..........................................36

Cooling Circuit .........................................................36

System Chart ...........................................................36

ENGINE COOLANT ..........................................37

Inspection ................................................................37

Changing Engine Coolant ........................................37

RADIATOR ....................................... .................40

Component .......................................................... ....40

Removal and Installation .........................................40

Checking Radiator Cap ...........................................42

Checking Radiator ...................................................43

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1127 of 3924

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................3

DTC INDEX ..................................................... .....3

U1000 - U1010 .................................................... ......3

B2202 - B2205 ..........................................................3

C1B00 - C1B03 .........................................................3

PRECAUTION .....................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

COMBINATION METERS ...................................5

System Description ............................................. ......5

Component Parts and Harness Connector Loca-

tion ............................................................................

8

Arrangement of Combination Meter ..........................9

Circuit Diagram .......................................................10

Wiring Diagram - METER - .....................................11

Terminal and Reference Value for Combination

Meter .......................................................................

13

Terminal and Reference Value for Unified Meter

and A/C Amp ...........................................................

14

Self-Diagnosis Mode of Combination Meter ............14

CONSULT-III Function (METER/M&A) ...................15

Trouble Diagnosis ...................................................15

Symptom Chart .......................................................16

Power Supply and Ground Circuit Inspection .........16

Vehicle Speed Signal Inspection .............................17

Engine Speed Signal Inspection .............................18

Engine Coolant Temperature Signal Inspection ......19

Fuel Level Sensor Signal Inspection .......................19

Fuel Gauge Pointer Fluctuates, Indicator Wrong

Value or Varies ........................................................

21

Fuel Gauge Does Not Move to FULL Position ........21

Odo/Trip Meter and Illumination Control Switch In-

spection ............................................................... ....

21

Electrical Component Inspection .............................21

Removal and Installation of Combination Meter .....22

Disassembly and Assembly of Combination Meter

....

23

Removal and Installation of Odo/Trip Meter and Il-

lumination Control Switch .................................... ....

24

UNIFIED METER AND A/C AMP ......................26

System Description ..................................................26

Schematic ................................................................27

CONSULT-III Function (METER/M&A) ....................27

Power Supply and Ground Circuit Inspection ..........29

DTC [U1000] CAN Communication Circuit ..............30

DTC [B2202] Meter Commun ication Circuit ............30

DTC [B2205] Vehicle Speed Circuit .................... ....32

Removal and Installation of Unified Meter and A/C

Amp .........................................................................

32

WARNING LAMPS ............................................34

System Description .............................................. ....34

Schematic ................................................................35

Wiring Diagram - WARN - .......................................36

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

43

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

45

Component Inspection .............................................46

A/T INDICATOR ................................................47

System Description ..................................................47

Wiring Diagram - AT/IND - .......................................48

A/T Indicator Is Malfunction .....................................49

WARNING CHIME .............................................51

System Description .............................................. ....51

Component Parts and Harness Connector Loca-

tion ...........................................................................

53

Schematic ................................................................54

Wiring Diagram - CHIME - .......................................55

Terminal and Reference Value for BCM ..................57

Terminal and Reference Value for Unified Meter

and A/C Amp. ...................................................... ....

59

Terminal and Reference Value for Combination

Meter .......................................................................

59

CONSULT-III Function (METER/M&A) ....................60

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1152 of 3924

DI-26

< SERVICE INFORMATION >

UNIFIED METER AND A/C AMP

UNIFIED METER AND A/C AMP

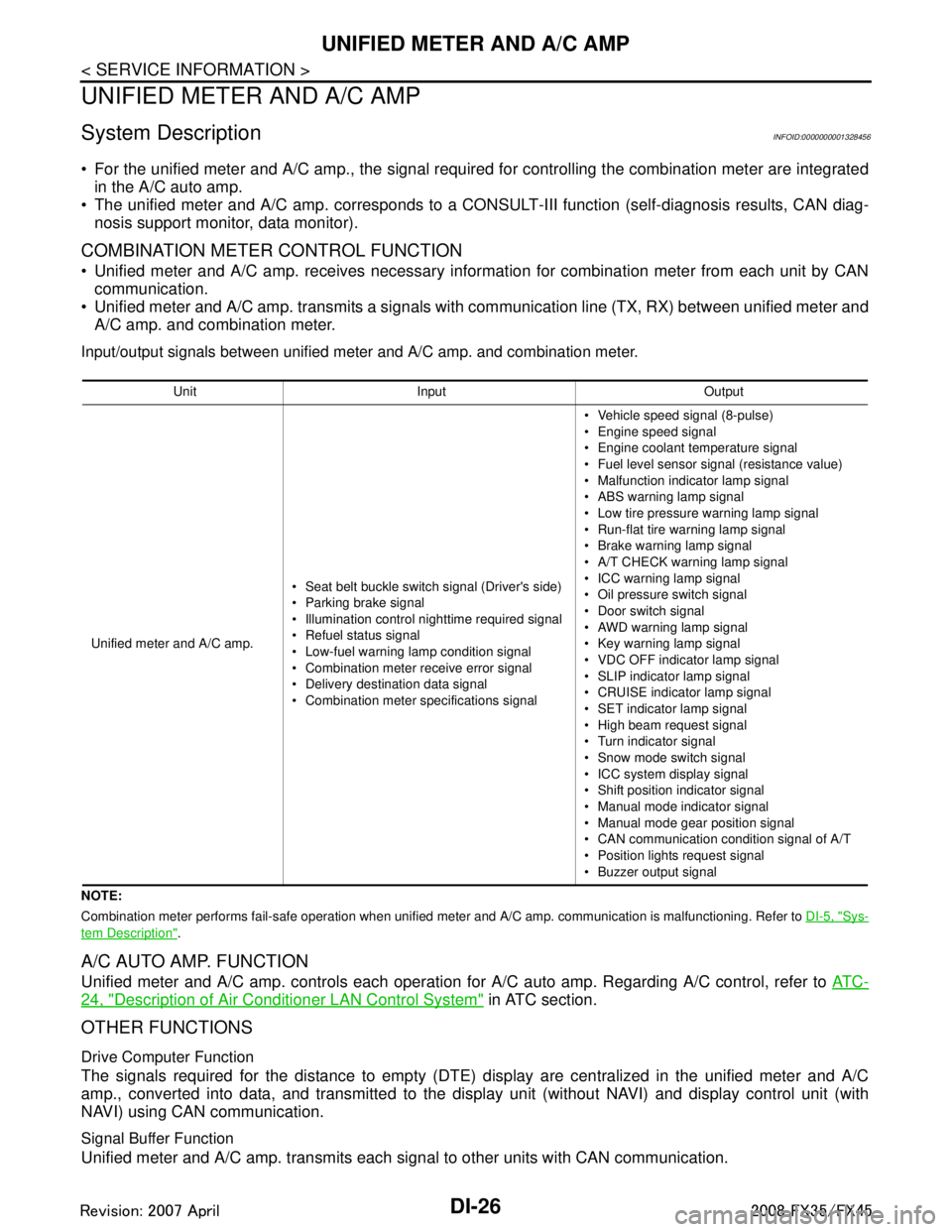

System DescriptionINFOID:0000000001328456

For the unified meter and A/C amp., the signal required for controlling the combination meter are integrated

in the A/C auto amp.

The unified meter and A/C amp. corresponds to a CONS ULT-III function (self-diagnosis results, CAN diag-

nosis support monitor, data monitor).

COMBINATION METER CONTROL FUNCTION

Unified meter and A/C amp. receives necessary information for combination meter from each unit by CAN communication.

Unified meter and A/C amp. transmits a signals with communication line (TX, RX) between unified meter and A/C amp. and combination meter.

Input/output signals between unified meter and A/C amp. and combination meter.

NOTE:

Combination meter performs fail-safe operation when unified meter and A/C amp. communication is malfunctioning. Refer to DI-5, "

Sys-

tem Description".

A/C AUTO AMP. FUNCTION

Unified meter and A/C amp. controls each operation for A/C auto amp. Regarding A/C control, refer to AT C -

24, "Description of Air Conditioner LAN Control System" in ATC section.

OTHER FUNCTIONS

Drive Computer Function

The signals required for the distance to empty (DTE) display are centralized in the unified meter and A/C

amp., converted into data, and transmitted to the disp lay unit (without NAVI) and display control unit (with

NAVI) using CAN communication.

Signal Buffer Function

Unified meter and A/C amp. transmits each signal to other units with CAN communication.

Unit Input Output

Unified meter and A/C amp. Seat belt buckle switch signal (Driver's side)

Parking brake signal

Illumination control nighttime required signal

Refuel status signal

Low-fuel warning lamp condition signal

Combination meter receive error signal

Delivery destination data signal

Combination meter specifications signal Vehicle speed signal (8-pulse)

Engine speed signal

Engine coolant temperature signal

Fuel level sensor signal (resistance value)

Malfunction indicator lamp signal

ABS warning lamp signal

Low tire pressure warning lamp signal

Run-flat tire wa

rning lamp signal

Brake warning lamp signal

A/T CHECK warning lamp signal

ICC warning lamp signal

Oil pressure switch signal

Door switch signal

AWD warning lamp signal

Key warning lamp signal

VDC OFF indicator lamp signal

SLIP indicator lamp signal

CRUISE indicator lamp signal

SET indicator lamp signal

High beam request signal

Turn indicator signal

Snow mode switch signal

ICC system display signal

Shift position indicator signal

Manual mode indicator signal

Manual mode gear position signal

CAN communication condition signal of A/T

Position lights request signal

Buzzer output signal

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1235 of 3924

REAR VIEW MONITORDI-109

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

YES >> GO TO 2.

NO >> Check back-up lamp system. Refer to LT-116, "

Wiring Diagram - BACK/L -" in LT section.

2.CHECK REVERSE POSITION INPUT SIGNAL

With CONSULT-III

1. Select “Data Monitor” of “REARVIEW CAMERA”.

2. Operate ignition switch with “R POSI SIG” of “Data Monitor” and check operate status.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Shift A/T selector lever to R position.

5. Check voltage between rear view camera control unit harness

connector M48 terminal 4 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between rear view camera control unit and back-up lamp relay.

3.CHECK DISPLAY CONTROL UNIT OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Check voltage between rear view camera control unit harness connector M48 terminal 5 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK DISPLAY CO NTROL UNIT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect display control unit connector.

3. Check continuity between rear view camera control unit harness connector M48 terminal 5 and display control unit harness con-

nector M75 terminal 8.

4. Check continuity between rear view camera control unit harness connector M48 terminal 5 and ground.

OK or NG

OK >> Replace display control unit.

NG >> Repair harness or connector.

5.CHECK CONTROL 1 SIGNAL

1. Turn ignition switch OFF.

2. Connect rear view camera control unit connector. 4 – Ground : Battery voltage

SKIA5086E

5 – Ground : Approx. 5 V

SKIA7148E

5 – 8 : Continuity should exist.

5 – Ground : Continuity should not exist.

SKIA7149E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1241 of 3924

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VQ35DE

SERVICE INFORMATION .. .........................

17

INDEX FOR DTC ............................................ ....17

DTC No. Index .................................................... ....17

Alphabetical Index ...................................................20

PRECAUTIONS ..................................................25

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

25

Precaution for Procedure without Cowl Top Cover ....25

On Board Diagnosis (OBD) System of Engine and

A/T ...........................................................................

25

Precaution ...............................................................26

PREPARATION ..................................................29

Special Service Tool ........................................... ....29

Commercial Service Tool ........................................30

ENGINE CONTROL SYSTEM ............................31

Schematic ........................................................... ....31

Multiport Fuel Injection (MFI) System .....................31

Electronic Ignition (EI) System ................................34

Fuel Cut Control (at No Load and High Engine

Speed) .....................................................................

34

AIR CONDITIONING CUT CONTROL ...............36

Input/Output Signal Chart .................................... ....36

System Description .................................................36

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

37

System Description ............................................. ....37

Component Description ...........................................38

CAN COMMUNICATION ....................................39

System Description ............................................. ....39

EVAPORATIVE EMISSION SYSTEM ................40

Description .......................................................... ....40

Component Inspection ......................................... ....42

Removal and Installation .........................................44

How to Detect Fuel Vapor Leakage .........................44

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ......................................................

46

System Description ..................................................46

Diagnosis Procedure ...............................................46

Component Inspection .............................................48

POSITIVE CRANKCASE VENTILATION .........51

Description ...............................................................51

Component Inspection .............................................51

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) .......................................................

53

Description ...............................................................53

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....54

Introduction ..............................................................54

Two Trip Detection Logic .........................................54

Emission-Related Diagnostic Information ................55

Malfunction Indicator Lamp (MIL) ............................71

OBD System Operation Chart .................................74

BASIC SERVICE PROCEDURE .......................80

Basic Inspection ......................................................80

Idle Speed and Ignition Timing Check .....................84

Procedure After Replacing ECM .............................84

VIN Registration ......................................................84

Accelerator Pedal Released Position Learning .......85

Throttle Valve Closed Position Learning .................85

Idle Air Volume Learning .........................................85

Fuel Pressure Check ...............................................87

TROUBLE DIAGNOSIS ....................................89

Trouble Diagnosis Introduction ................................89

DTC Inspection Priority Chart ..................................93

Fail-Safe Chart ........................................................95

Symptom Matrix Chart .............................................96

Engine Control Component Parts Location ...........100

Vacuum Hose Drawing ..........................................106

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1332 of 3924

![INFINITI FX35 2008 Workshop Manual

EC-92

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS

Are they within the SP value?

Ye s > > G O T O 9 .

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBL

E DIAGNOSIS - SPECIFICATION VALUE

De INFINITI FX35 2008 Workshop Manual

EC-92

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS

Are they within the SP value?

Ye s > > G O T O 9 .

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBL

E DIAGNOSIS - SPECIFICATION VALUE

De](/img/42/57017/w960_57017-1331.png)

EC-92

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS

Are they within the SP value?

Ye s > > G O T O 9 .

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBL

E DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to EC-131

.

Is malfunctioning part detected?

Ye s > > G O T O 11 .

No >> GO TO 9.

9.DETECT MALFUNCTIONING SYSTEM BY SYMPTOM MATRIX CHART

Detect malfunctioning system according to EC-96, "

Symptom Matrix Chart" based on the confirmed symptom

in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 10.

10.DETECT MALFUNCTIONING PA RT BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure in EC section described based on open circuit inspection. A short circuit inspection

is also required for the circuit check in the Diagnostic Procedure. For details, refer to Circuit Inspection in GI-

25, "How to Perform Efficient Diagnosis for an Electrical Incident".

Is malfunctioning part detected?

Ye s > > G O T O 11 .

No >> Monitor input data from related sensors or check voltage of related ECM terminals using CON-

SULT-III. Refer to EC-127, "

CONSULT-III Reference Value in Data Monitor Mode", EC-109, "ECM

Terminal and Reference Value".

11 .REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnostic Procedure again after repair and replace- ment.

3. Check DTC. If DTC is displayed, erase it, refer to EC-55, "

Emission-Related Diagnostic Information".

>> GO TO 12.

12.FINAL CHECK

When DTC was detected in step 2, perform DTC Conf irmation Procedure or Overall Function Check again,

and then make sure that the malfunction have been repaired securely.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and make sure

that the symptom is not detected.

OK or NG

NG (DTC*1 is detected)>>GO TO 10.

NG (Symptom remains)>>GO TO 6.

OK >> 1. Before returning the vehicle to the customer, make sure to erase unnecessary DTC*

1 in ECM

and TCM (Transmission Control Module). (Refer to EC-55, "

Emission-Related Diagnostic

Information" and AT-38, "OBD-II Diagnostic Trouble Code (DTC)".)

2. If the completion of SRT is needed, drive vehicl e under the specific driving pattern. Refer to

EC-55, "

Emission-Related Diagnostic Information".

3. INSPECTION END

*1: Include 1st trip DTC.

*2: Include 1st trip freeze frame data.

DIAGNOSTIC WORKSHEET

Description

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1367 of 3924

![INFINITI FX35 2008 Workshop Manual

TROUBLE DIAGNOSISEC-127

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Connect GST to data link connector, which is located under LH

dash panel near the hood opener handle.

3. Tu INFINITI FX35 2008 Workshop Manual

TROUBLE DIAGNOSISEC-127

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Connect GST to data link connector, which is located under LH

dash panel near the hood opener handle.

3. Tu](/img/42/57017/w960_57017-1366.png)

TROUBLE DIAGNOSISEC-127

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Connect GST to data link connector, which is located under LH

dash panel near the hood opener handle.

3. Turn ignition switch ON.

4. Enter the program according to instruction on the screen or in the operation manual.

(*: Regarding GST screens in this section, sample screens are

shown.)

5. Perform each diagnostic mode according to each service proce- dure.

For further information, see th e GST Operation Manual of

the tool maker.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000001325938

Remarks:

● Specification data are reference values.

● Specification data are output/input values which ar e detected or supplied by the ECM at the connector.

* Specification data may not be directly relat ed to their components signals/values/operations.

i.e. Adjust ignition timing with a timi ng light before monitoring IGN TIMING, because the monitor may show the specification data in spite of the

ignition timing not being adjusted to the s pecification data. This IGN TIMING monitors the data calculated by the ECM according to the signals

input from the camshaft position sensor an d other ignition timing related sensors.

PBIB1570E

SEF398S

SEF416S

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED Run engine and compare CONSULT-III value with the tachometer indica-

tion. Almost the same speed as the

tachometer indication.

MAS A/F SE-B1 See EC-131

.

B/FUEL SCHDL See EC-131

.

A/F ALPHA-B1

A/F ALPHA-B2 See

EC-131

.

COOLAN TEMP/S Engine: After warming up More than 70 °C (158 °F)

A/F SEN1 (B1)

A/F SEN1 (B2) Engine: After warming up Maintaining engine speed at 2,000 rpm Fluctuates around 1.5 V

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1909 of 3924

![INFINITI FX35 2008 Workshop Manual

TROUBLE DIAGNOSISEC-669

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Are they within the SP value?

Yes >> GO TO 9.

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS INFINITI FX35 2008 Workshop Manual

TROUBLE DIAGNOSISEC-669

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Are they within the SP value?

Yes >> GO TO 9.

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS](/img/42/57017/w960_57017-1908.png)

TROUBLE DIAGNOSISEC-669

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Are they within the SP value?

Yes >> GO TO 9.

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to EC-709

.

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> GO TO 9.

9.DETECT MALFUNCTIONING SYST EM BY SYMPTOM MATRIX CHART

Detect malfunctioning system according to EC-673, "

Symptom Matrix Chart" based on the confirmed symptom

in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 10.

10.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure in EC section described based on open circuit inspection. A short circuit inspection

is also required for the circuit check in the Diagnostic Procedure. For details, refer to Circuit Inspection in GI-

25, "How to Perform Efficient Diagnosis for an Electrical Incident".

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> Monitor input data from related sensors or check voltage of related ECM terminals using CON-

SULT-III. Refer to EC-705, "

CONSULT-III Reference Value in Data Monitor Mode", EC-687, "ECM

Terminal and Reference Value".

11 .REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnostic Procedure again after repair and replace-

ment.

3. Check DTC. If DTC is displayed, erase it, refer to EC-633, "

Emission-related Diagnostic Information".

>> GO TO 12.

12.FINAL CHECK

When DTC was detected in step 2, perform DTC Confirmation Procedure or Overall Function Check again,

and then make sure that the malfunction have been repaired securely.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and make sure

that the symptom is not detected.

OK or NG

NG (DTC*1 is detected)>>GO TO 10.

NG (Symptom remains)>>GO TO 6.

OK >> 1. Before returning the vehicle to the customer, make sure to erase unnecessary DTC*

1 in ECM

and TCM (Transmission Control Module). (Refer to EC-633, "

Emission-related Diagnostic

Information" and AT-38, "OBD-II Diagnostic Trouble Code (DTC)".)

2. If the completion of SRT is needed, drive vehicl e under the specific driving pattern. Refer to

EC-633, "

Emission-related Diagnostic Information".

3. INSPECTION END

*1: Include 1st trip DTC.

*2: Include 1st trip freeze frame data.

DIAGNOSTIC WORKSHEET

Description

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C