battery INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3706 of 3924

AUTOMATIC DRIVE POSITIONERSE-67

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace power seat switch.

Check Rear Lifting Switch CircuitINFOID:0000000001328132

1.CHECK FUNCTION

With CONSULT-III

With “LIFT RR SW-UP, LIFT RR SW-DN” on the DATA MO NITOR, operate the rear lifting switch to check ON/

OFF operation.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Rear lifting switch operate, check voltage bet ween driver seat control unit connector and ground.

OK or NG

OK >> Rear seat lifting switch circuit is OK.

NG >> GO TO 2.

2.CHECK REAR LIFTING SWITCH HARNESS CONTINUITY

1. Disconnect driver seat control unit c onnector and power seat switch connector.

2. Check continuity between driver seat control unit connector B152 terminals 27, 40 and power seat switch connector B175

terminals 27, 40.

3. Check continuity between driver seat control unit connector B152 terminals 27, 40 and ground.

OK or NG

Connector Terminals Front lifting switch condition Continuity B175 26

61BUP Yes

Other than above No

39 DOWN Yes

Other than above No

PIIB8594E

Monitor item

[OPERATION or UNIT] Contents

LIFT RR SW–UP “ON/OFF” (ON/OFF) status judged from the RR lifter switch

(UP) signal is displayed.

LIFT RR SW–DN “ON/OFF” (ON/OFF) status judged from the RR lifter switch

(DOWN) signal is displayed.

Connector Te r m i n a l s

(Wire color) Rear lifting switch

condition Voltage (V) (Ap-

prox.)

(+) (–)

B152 27 (L)

GroundUP 0

Other than above Battery voltage

40 (L/Y) DOWN 0

Other than above Battery voltage

PIIA6099E

27 (L) – 27 (L) : Continuity should exist.

40 (L/Y) – 40 (L/Y) : Continuity should exist.

27 (L) – Ground : Continuity should not exist.

40 (L/Y) – Ground : Continuity should not exist.

PIIB8595E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3714 of 3924

AUTOMATIC DRIVE POSITIONERSE-75

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

With CONSULT-III

Make sure when the A/T selector lever is in P posit ion, “P POSI SW” on the DATA MONITOR becomes ON.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check voltage between drive seat control unit connector and ground.

OK or NG

OK >> Park position switch circuit is OK.

NG >> GO TO 2.

2.CHECK PARK POSITION SWIT CH POWER SUPPLY CIRCUIT HARNESS

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector and A/T device (park position switch) connector.

3. Check continuity between driver seat control unit connector

B152 terminal 17 and A/T device (park position switch) connec-

tor M67 terminal 3.

4. Check continuity between driver seat control unit connector B152 terminal 17 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between driver seat control unit and A/T device (park position switch).

3.CHECK A/T DEVICE (PARK POSITION SWITCH)

Check continuity between A/T devic e (park position switch) connec-

tor M67 terminal 2 and 3.

OK or NG

OK >> GO TO 4.

NG >> Replace A/T device (park position switch).

4.CHECK A/T DEVICE (PARK POSI TION SWITCH) GROUND HARNESS

Monitor item

[OPERATION or UNIT] Contents

P POSI SW “ON/

OFF” The selector lever position “P position (ON)/other than

P position (OFF)” judged from the park position switch

signal is displayed.

Connector Te r m i n a l s

(Wire color) ConditionVoltage (V)

(Approx.)

(+) (–)

B152 17 (PU) Ground Selector lever sifted to P po-

sition.

0

Selector lever other than P

position. Battery voltage

PIIA6702E

17 (PU) – 3 (R/Y) : Continuity should exist.

17 (PU) – Ground : Continuity should not exist.

PIIB9068E

Connector Terminal Condition Continuity

M67 2 3 P position Yes

Other than P position No

PIIB9069E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3715 of 3924

SE-76

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check continuity between A/T device (park position switch) connec-

tor M67 terminal 2 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between A/T device (park position switch) and ground.

Check Key Switch Circuit (With Intelligent Key)INFOID:0000000001328139

1.CHECK KEY SWITCH POWER SUPPRY CIRCUIT

With CONSULT-III

Touch “BCM”. With “IGN KEY SW” on the DATA MONITOR, Check ON/OFF operation.

*: Refer to BL-36, "

CONSULT-III Function (BCM)".

OK or NG

OK >> Key switch circuit is OK.

NG >> GO TO 2.

2.CHECK KEY SWITCH PO WER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect key switch and ignition knob switch connector.

3. Check voltage between key switch and ignition knob switch con- nector M22 terminal 3 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between key switch and fuse.

3.CHECK KEY SWITCH

Check continuity between key switch and ignition knob switch con-

nector M22 terminal 3 and 4.

OK or NG

OK >> GO TO 4.

NG >> Replace key switch and ignition knob switch.

4.CHECK HARNESS CONTINUITY

1. Disconnect key switch and ignition knob switch connector and BCM connector. 2 (B) – Ground : Continuity should exist.

PIIB9071E

Monitor item [OPERA-

TION or UNIT] Contents

IGN KEY SW

*“ON/

OFF” Key inserted (ON)/key removed (OFF) status judged

from the key-in detection switch is displayed.

3 (L/R) – Ground : Battery voltage.

PIIA5093E

Con-

nector Terminal Condition Continuity

M22 3 4 Key is inserted in ignition key cylinder. Yes

Key is removed from ignition key cylinder. No

PIIA6140E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3716 of 3924

AUTOMATIC DRIVE POSITIONERSE-77

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

2. Check continuity between key switch and ignition knob switch connector M22 terminal 4 and BCM connector M3 terminal 37.

3. Check continuity between key switch and ignition knob switch connector M22 terminal 4 and ground.

OK or NG

OK >> Key switch circuit is OK.

NG >> Repair or replace harness between key switch and igni- tion knob switch and BCM.

Check Key Switch Circui t (Without Intelligent Key)INFOID:0000000001328140

1.CHECK KEY SWITCH

With CONSULT-III

Touch “BCM”. With “IGN KEY SW” on the DATA MONITOR, Check ON/OFF operation.

*: Refer to BL-36, "

CONSULT-III Function (BCM)"

OK or NG

OK >> Key switch circuit is OK.

NG >> GO TO 2.

2.CHECK KEY SWITCH AND KEY LOCK SOLENOID POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect key switch connector.

3. Check voltage between key switch connector M23 terminal 2 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between key switch and fuse.

3.CHECK KEY SWITCH

Check continuity between key switch connector M23 terminal 1 and 2.

OK or NG

OK >> GO TO 4.

NG >> Replace key switch. 4 (B/W) – 37 (B/W) : Cont

inuity should exist.

4 (B/W) – Ground : Continuity should not exist.

PIIA5095E

Monitor item

[OPERATION or UNIT] Contents

IGN KEY SW

*“ON/

OFF” Key inserted (ON)/key removed (OFF) status judged

from the key-in detection switch is displayed.

2 (L/R) – Ground : Battery voltage.

PIIA5092E

Con-

nector Terminal Condition Continuity

M23 1 2 Key is inserted in ignition key cylinder. Yes

Key is removed from ignition key cylinder. No

PIIA6141E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3719 of 3924

SE-80

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

3. Check voltage between seat memory switch connector D22 ter-minal 5 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between fuse block (J/B) and seat memory switch.

3.CHECK HARNESS CONTINUITY

1. Disconnect driver seat control unit connector.

2. Check continuity between driv er seat control unit connector

B152 terminals 23, 36 and seat memory switch connector D22

terminals 6, 7.

3. Check continuity between driv er seat control unit connector

B152 terminals 23, 36 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness between driver seat control unit and seat memory switch.

4.CHECK SEAT MEMORY SWITCH INDICATOR SIGNAL

Check voltage between driver seat control unit connector B152 ter-

minals 23, 36 and ground.

OK or NG

OK >> Seat memory indicator lamp circuit is OK.

NG >> Replace seat memory switch.

Check UART Communication Line CircuitINFOID:0000000001328143

1.CHECK UART LINE HERNESS

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector and automatic drive positioner control unit connector.

5 (R) – Ground : Battery voltage

PIIA4595E

23 (Y/W) – 6 (PU) : Continuity should exist.

36 (Y/G) – 7 (L) : Continuity should exist.

23 (Y/W) – Ground : Continuity should not exist.

36 (Y/G) – Ground : Continuity should not exist.

PIIB8599E

23 (Y/W) – Ground : Battery voltage

36 (Y/G) – Ground : Battery voltage

PIIA5078E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3721 of 3924

SE-82

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

When voltage signal dose not appear with a constant voltage (approx. 5V), replace automatic

driver seat control unit.

When voltage signal dose not appear with a constant voltage (approx. 0V), replace driver seat

control unit.

4.CHECK DRIVER SEAT CONTROL UNIT

Dose the automatic drive positioner operate, when the driver seat control unit exchanged?

Does seat memory function operate?

YES >> Replace automatic drive positioner control unit.

NG >> Replace driver seat control unit.

Check Lumbar Support CircuitINFOID:0000000001328144

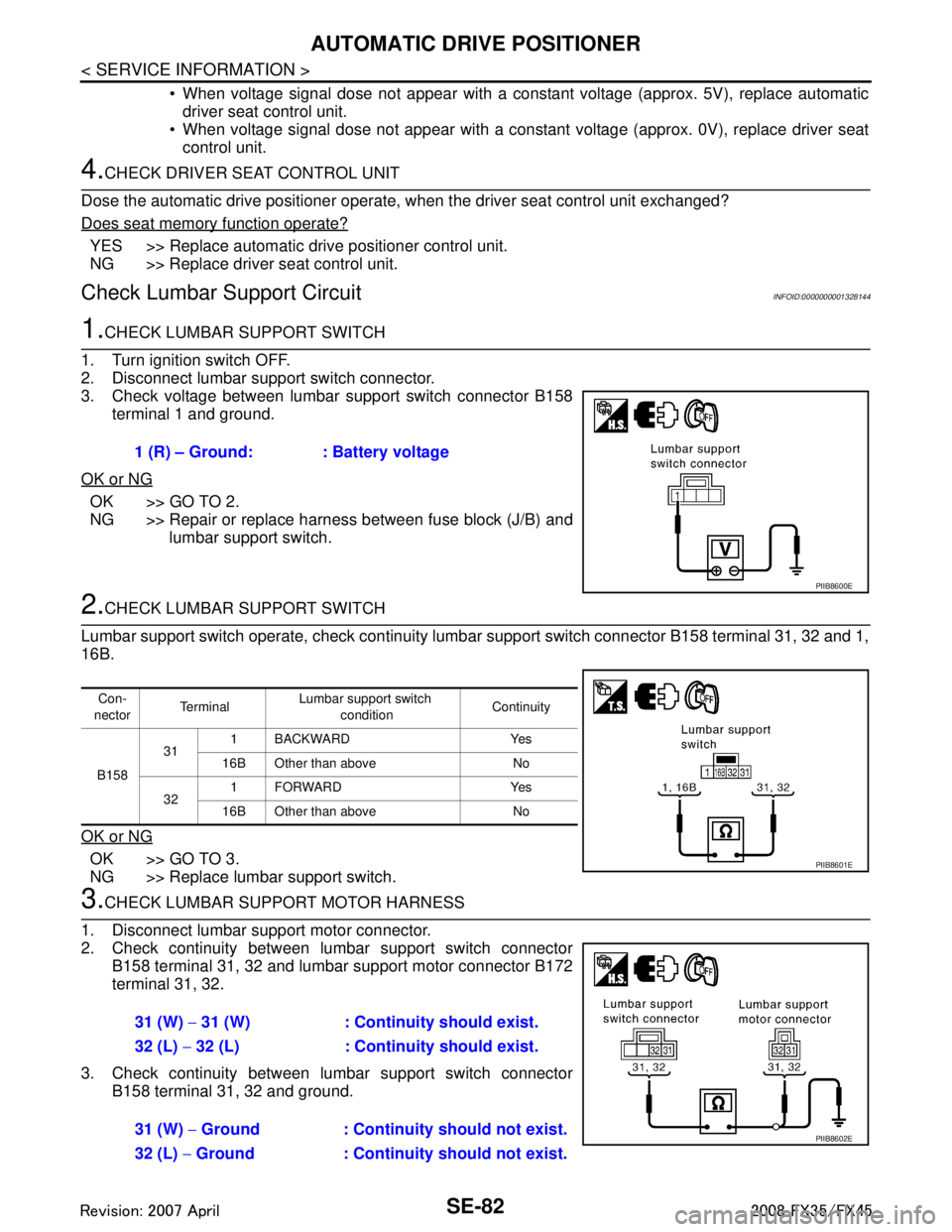

1.CHECK LUMBAR SUPPORT SWITCH

1. Turn ignition switch OFF.

2. Disconnect lumbar support switch connector.

3. Check voltage between lumbar support switch connector B158 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace harness between fuse block (J/B) and lumbar support switch.

2.CHECK LUMBAR SUPPORT SWITCH

Lumbar support switch operate, check continuity lum bar support switch connector B158 terminal 31, 32 and 1,

16B.

OK or NG

OK >> GO TO 3.

NG >> Replace lumbar support switch.

3.CHECK LUMBAR SUPPORT MOTOR HARNESS

1. Disconnect lumbar support motor connector.

2. Check continuity between lumbar support switch connector B158 terminal 31, 32 and lumbar support motor connector B172

terminal 31, 32.

3. Check continuity between lumbar support switch connector B158 terminal 31, 32 and ground.1 (R) – Ground: : Battery voltage

PIIB8600E

Con-

nector Te r m i n a l

Lumbar support switch

condition Continuity

B158 31

1 BACKWARD Yes

16B Other than above No

32 1FORWARD Yes

16B Other than above No

PIIB8601E

31 (W) − 31 (W) : Continuity should exist.

32 (L) − 32 (L) : Continuity should exist.

31 (W) − Ground : Continuity should not exist.

32 (L) − Ground : Continuity should not exist.

PIIB8602E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3729 of 3924

SE-90

< SERVICE INFORMATION >

FRONT SEAT

REMOVAL

When removing or installing the seat trim, carefully handle it to keep dirt out and avoid damage.

CAUTION:

Before removing the front seat, turn ignition switch OFF, disconnect both battery cables and wait at

least 3 minutes.

When checking the power seat circuit for continuity using a circuit tester, do not confuse its connec-

tor with the side air bag modul e connector. Such an error may cause the air bag to deploy.

Do not drop, tilt, or bump the side air bag module installing in the seat. Always handle it with care.

1. Remove the seat cushion outer finisher cover.

2. Remove the front seat belt anchor bolt. Refer to SB-3, "

Removal

and Installation of Front Seat Belt".

CAUTION:

Set the front and rear cushion lifter to the down position.

3. Remove the screw.

4. Remove the seat cushion forward finisher lid.

5. Remove the seat cushion forward finisher.

6. Remove the seat slide and lifter switch knob (1) and seat reclin- ing switch knob (2).

1. Headrest 2. Headrest holder (free) 3. Headrest holder (locked)

4. Seatback pad 5. Seatback trim 6. Seat cushion inner finisher

7. Screw 8. Seat cushion trim 9. Seat cushion pad

10. Seatback garnish 11. Nut 12. Side air bag module

13. Clip (C101) 14. Inner cloth stay 15. Lumber support device

16. Bolt 17. Seatback frame 18. Reclining device assembly

19. Seat cushion frame 20. Seat harness assembly 21. Seat adjust assembly

22. Clip (C103) 23. Seat adjust assembly cover 24. Seat cushion outer finisher

25. Seat cushion outer finisher cover 26. Lumber support switch assembly 27. Seat reclining switch knob

28. Seat slide and lifter switch knob 29. Seat control switch 30. Seat cushion forward finisher

31. Seat cushion forward finisher lid

PIIA6040E

PIIB8525E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3730 of 3924

FRONT SEATSE-91

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

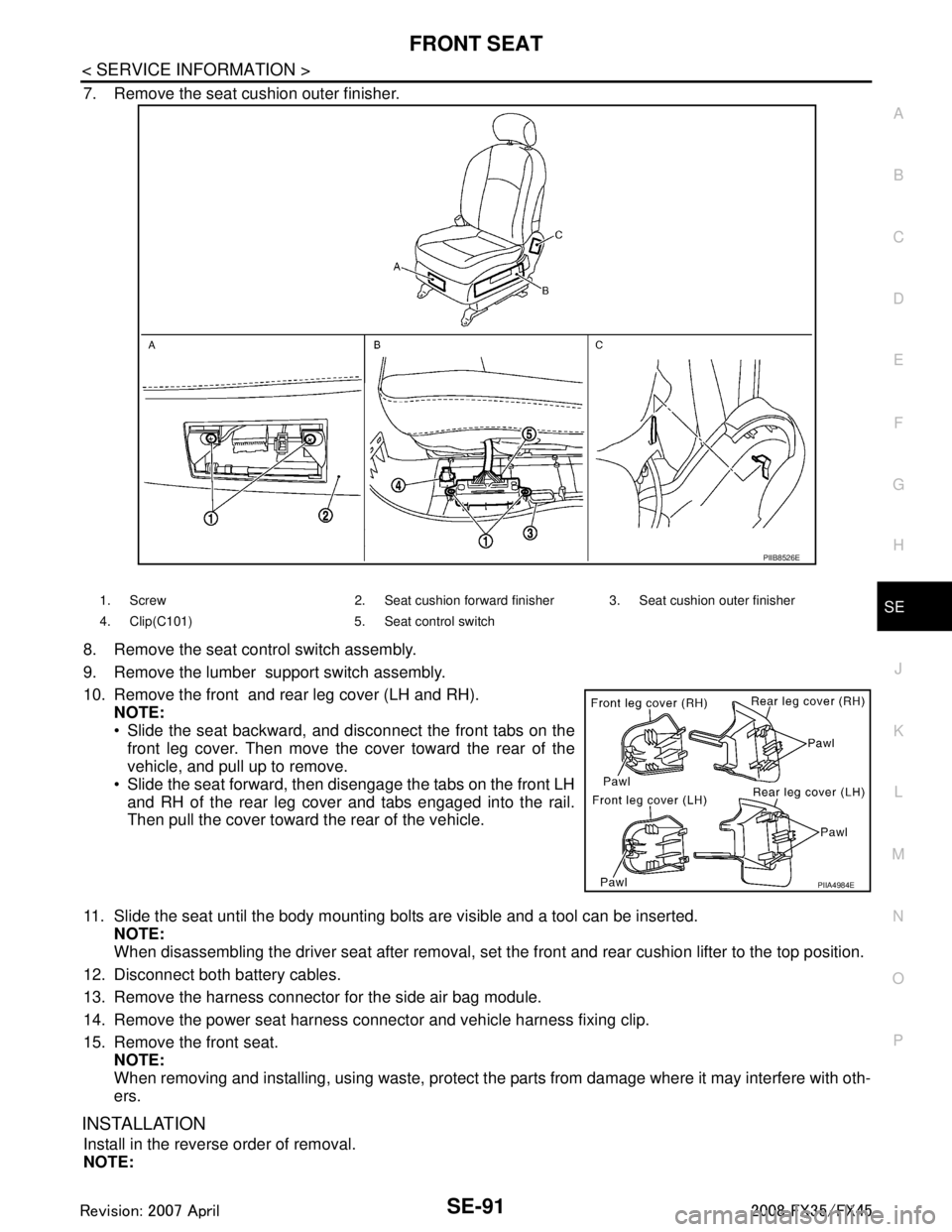

7. Remove the seat cushion outer finisher.

8. Remove the seat control switch assembly.

9. Remove the lumber support switch assembly.

10. Remove the front and rear leg cover (LH and RH). NOTE:

Slide the seat backward, and disconnect the front tabs on the

front leg cover. Then move the cover toward the rear of the

vehicle, and pull up to remove.

Slide the seat forward, then disengage the tabs on the front LH and RH of the rear leg cover and tabs engaged into the rail.

Then pull the cover toward the rear of the vehicle.

11. Slide the seat until the body mounting bolts are visible and a tool can be inserted. NOTE:

When disassembling the driver seat after removal, set the front and rear cushion lifter to the top position.

12. Disconnect both battery cables.

13. Remove the harness connector for the side air bag module.

14. Remove the power seat harness connector and vehicle harness fixing clip.

15. Remove the front seat. NOTE:

When removing and installing, using waste, protect t he parts from damage where it may interfere with oth-

ers.

INSTALLATION

Install in the reverse order of removal.

NOTE:

PIIB8526E

1. Screw 2. Seat cushion forward finisher 3. Seat cushion outer finisher

4. Clip(C101) 5. Seat control switch

PIIA4984E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3744 of 3924

PRECAUTIONSSRS-7

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612877

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for SRS "AIR BAG" and "SEAT BELT PRE-TENSIONER" Service

INFOID:0000000001327741

Do not use electrical test equipment to check SRS ci rcuits unless instructed to in this Service Manual.

Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are remov ed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, do not work on any SR S connectors or wires until at least 3 minutes have

passed.

Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

The spiral cable must be aligned with the neutral position since its rotations are limited. Do not turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Disposal, recycling, and transportation of air bag m odules and seat belt pre-tensioners should be performed

in compliance with applicable federal, state and local laws and regulations.

Occupant Classification System PrecautionINFOID:0000000001327742

Replace occupant classification system control uni t and passenger front seat cushion as an assembly.

Refer to Refer to Service Manual .

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3749 of 3924

SRS-12

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

Trouble Diagnosis IntroductionINFOID:0000000001524161

CAUTION:

Do not use electrical test equipment on any circuit related to the SRS unless instructed in this Ser-

vice Manual. SRS wiring harnesses can be identifi ed by yellow and/or orange harnesses or harness

connectors.

Do not repair, splice or modify the SRS wiring harn ess. If the harness is damaged, replace it with a

new one.

Keep ground portion clean.

DIAGNOSIS FUNCTION

The SRS self-diagnostic results can be read by us ing “AIR BAG” warning lamp and/or CONSULT-III.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system mal-

function through the operation of the “AIR BAG” warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the “AIR BAG” wa rning lamp and CONSULT-III are as follows:

HOW TO PERFORM TROUBLE DIAGNOSIS FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malf unction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Information from Customer

WHAT..... Vehicle model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Preliminary Check

Make sure the following parts are in good order.

Battery (Refer to SC-4, "

How to Handle Battery".)

Fuse (Refer to SRS-16, "

Wiring Diagram - SRS -".)

System component-to-harness connections

Work Flow

OVERALL SEQUENCE

User mode Diagnosis mode Display type

“AIR BAG” warning lamp X X ON-OFF operation CONSULT-III — X Monitoring

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C