cooling system INFINITI FX35 2008 Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2663 of 3924

![INFINITI FX35 2008 Repair Manual

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-179

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD AND THREE WAY CATALYST

ComponentINFOID:0000000001325776

Refer to

GI INFINITI FX35 2008 Repair Manual

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-179

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD AND THREE WAY CATALYST

ComponentINFOID:0000000001325776

Refer to

GI](/img/42/57017/w960_57017-2662.png)

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-179

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD AND THREE WAY CATALYST

ComponentINFOID:0000000001325776

Refer to

GI-8, "Component" for symbols in the figure.

Removal and InstallationINFOID:0000000001325777

REMOVAL

WARNING:

Perform the work, when the exhaust and cooling system h ave completely cooled down.

1. Remove engine cover with power tool. Refer to EM-169, "

Component".

2. Remove front and rear engine undercovers with power tool.

3. Remove air duct (inlet), air cleaner case and mass air flow sensor assembly, air duct and resonator assembly. Refer to EM-173, "

Component".

4. Remove front cross bar. Refer to FSU-5, "

On-Vehicle Inspection and Service".

5. Drain engine coolant from radiator. Refer to CO-37, "

Changing Engine Coolant".

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

1. Air fuel ratio sensor 1 (bank 2) 2. Exhaust manifold cover (right bank) 3. Exhaust manifold (right bank)

4. Gasket 5. Exhaust manifold (left bank) 6. Exhaust manifold cover (left bank)

7. Air fuel ratio sensor 1 (bank 1) 8. Three way catalyst cover (right bank) 9. Three way catalyst (right bank)

10. Heated oxygen sensor 2 (bank 2) 11. Gasket 12. Three way catalyst cover (left bank)

13. Heated oxygen sensor 2 (bank 1) 14. Three way catalyst (left bank) 15. Mounting bracket

16. Mounting bracket

A. Protrusion for installation confirma-

tion.

: Above

PBIC4549E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2694 of 3924

![INFINITI FX35 2008 Repair Manual

EM-210

< SERVICE INFORMATION >[VK45DE]

TIMING CHAIN

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in guide may gen-

erate a pounding noise during and jus INFINITI FX35 2008 Repair Manual

EM-210

< SERVICE INFORMATION >[VK45DE]

TIMING CHAIN

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in guide may gen-

erate a pounding noise during and jus](/img/42/57017/w960_57017-2693.png)

EM-210

< SERVICE INFORMATION >[VK45DE]

TIMING CHAIN

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in guide may gen-

erate a pounding noise during and just after engine start. However, this does not indicate an unusualness.

Noise will stop after hydraulic pressure rises.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The followings are procedures for checking fluids leak, lubricates leak and exhaust gases leak. Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-9, "

Fluids and Lubricants"

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leak age of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applic able lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid. power steering fluid, brake fluid, etc. Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2724 of 3924

![INFINITI FX35 2008 Repair Manual

EM-240

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

Avoid damage to and oil/grease smearing or

spills onto engine mounting insulator.

4. Remove alternator. Refer to SC-19, "

System Description INFINITI FX35 2008 Repair Manual

EM-240

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

Avoid damage to and oil/grease smearing or

spills onto engine mounting insulator.

4. Remove alternator. Refer to SC-19, "

System Description](/img/42/57017/w960_57017-2723.png)

EM-240

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

Avoid damage to and oil/grease smearing or

spills onto engine mounting insulator.

4. Remove alternator. Refer to SC-19, "

System Description".

5. Remove starter motor. Refer to SC-8, "

System Description".

6. Separate engine from transmission assembly. Refer to AT-243, "

Removal and Installation (AWD Models)".

7. Remove front final drive from engine. Refer to FFD-14, "

Removal and Installation (VQ35DE Models)".

8. Remove engine mounting insulators (RH and LH) and brackets (RH and LH) from engine with power tool.

9. Remove engine rear member and engine mounting insulator (rear) from transmission.

INSTALLATION

Note the following, and install in the reverse order of removal.

Do not allow engine mounting insulator to be damage and careful no engine oil gets on it.

For a location with a positioning pin, insert it securely into hole of mating part.

For a part with a specified installation orientation, refer to component figure in "Removal and Installation".

When installing engine mounting brackets (RH and LH) on cylinder

block, tighten two upper bolts (show n as “A” in the figure) first.

Then tighten two lower bolts (shown as “B” in the figure).

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The followings are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-9, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leak age of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applic able lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid. power steering fluid, brake fluid, etc.

PBIC2365E

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2903 of 3924

TOW TRUCK TOWINGGI-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

AWD MODELS

INFINITI recommends that a dolly be used as illustrated when towing AWD models.

CAUTION:

Never tow AWD models with any of the wheels on the ground as this may cause serious and expen-

sive damage to the powertrain.

Vehicle Recovery (Freeing a Stuck Vehicle)INFOID:0000000001325685

Securely install the vehicle recovery hook stored with jacking tools.

Make sure that the hook is properly secured in the stored place after

use.

WARNING:

Stand clear of a stuck vehicle.

Do not spin your tires at high speed. This could cause them to

explode and result in serious injury. Parts of your vehicle

could also overheat and be damaged.

CAUTION:

Tow chains or cables must be attached only to the vehicle recovery hooks or main struct ural members of the vehicle.

Otherwise, the vehicle body will be damaged.

Do not use the vehicle tie downs to free a vehicle stuck in

sand, snow, mud, etc. Never to w the vehicle using the vehicle

tie downs or recovery hooks.

Always pull the cable straight out from the front of the vehicle.

Never pull on the hook at an angle.

Pulling devices should be rout ed so they do not touch any

part of the suspension, steer ing, brake or cooling systems.

Pulling devices such as ropes or canvas straps are not rec- ommended for use in vehicle towing or recovery.

AUTOMATIC TRANSMISSION

To tow a vehicle equipped with an automatic tr ansmission, an appropriate vehicle dolly MUST be placed under

the towed vehicle's drive wheels. Always follow the dolly manufacture's recommendations when using their

product.

If the vehicle is stuck in sand, snow , mud, etc., use the following procedure:

1. Turn off the Vehicle Dynamic Control System.

2. Make sure the area in front and behind the vehicle is clear of obstructions.

PAIA0098E

PAIA0099E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3030 of 3924

![INFINITI FX35 2008 Repair Manual

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support m INFINITI FX35 2008 Repair Manual

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support m](/img/42/57017/w960_57017-3029.png)

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support monitor (on-boar d diagnosis function) are used for detecting root

cause.

MONITOR ITEM (CONSULT-III)

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni- tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning the ignition switch OFF.)

EPS control unit The steeri ng effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

DTC

Self-diagnosis item

(CONSULT-III indication) DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUIT When ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) for 2 seconds or more.

Refer to LAN-13

.

When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUIT When ECM is not transmitting or receiving CAN

communication signal other than OBD (emis-

sion-related diagnosis) for 2 seconds or more.

U1002 SYSTEM COMM When a control unit is not transmitting or receiv-

ing CAN communication signal for 2 seconds or

less. Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit.

U1010 CONTROL UNIT [CAN] When an error is detected during the initial diag-

nosis for CAN controller of each control unit. Replace the control unit

indicating “U1010”.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3064 of 3924

![INFINITI FX35 2008 Repair Manual

LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000001328636

Refer to

LAN-13, "How to Use C INFINITI FX35 2008 Repair Manual

LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000001328636

Refer to

LAN-13, "How to Use C](/img/42/57017/w960_57017-3063.png)

LAN-44

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000001328636

Refer to

LAN-13, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

TYPE 1/TYPE 2

NOTE:

Refer to LAN-37, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

PKID0615E

Signal name/Connecting unitECM

DISP TCM

BCM

I-KEY

STRG M&AABS

ADP

IPDM-E

A/C compressor feedback signal T R

A/C compressor request signal T R

Accelerator pedal position signal T R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R

Cooling fan speed request signal T R

Engine coolant temperature signal T R

Engine speed signal T R R R R

Engine status signal T R

Fuel consumption monitor signal TR

RT

Malfunctioning indicator lamp signal T R

Wide open throttle position signal T R

A/C switch/indicator signal TR

RT

System setting signal TR R

RT T

A/T CHECK indicator lamp signal T R

A/T self-diagnosis signal R T

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3069 of 3924

![INFINITI FX35 2008 Repair Manual

TROUBLE DIAGNOSISLAN-49

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 4/TY INFINITI FX35 2008 Repair Manual

TROUBLE DIAGNOSISLAN-49

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 4/TY](/img/42/57017/w960_57017-3068.png)

TROUBLE DIAGNOSISLAN-49

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 4/TYPE 5/TYPE 7

NOTE:

Refer to LAN-37, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

Signal name/Connecting unitECM

4WD

DISP TCM

BCM

I-KEY

STRG M&AABS

ADP

IPDM-E

A/C compressor feedback signal T R

A/C compressor request signal T R

Accelerator pedal position signal T R R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R

Cooling fan speed request signal T R

Engine coolant temperature signal T R

Engine speed signal T R R R R R

Engine status signal T R

Fuel consumption monitor signal TR

RT

Malfunction indicator lamp signal T R

Wide open throttle position signal T R

AWD warning lamp signal T R

A/C switch/indicator signal TR

RT

System setting signal TR R

RT T

A/T CHECK indicato r lamp signal T R

A/T self-diagnosis signal R T

Current gear position signal T R

Manual mode indicator signal T R

Output shaft revolution signal R T

P range signal T R R

Shift position indicator signal T R

Turbine revolution signal R T

A/C switch signal R T

Buzzer output signal TR

TR

Blower fan motor switch signal R T

Day time running light request signal T R

Door lock/unlock status signal T R

Door switch signal R T R R R R

Front fog light request signal T R

Front wiper request signal T R

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3071 of 3924

![INFINITI FX35 2008 Repair Manual

TROUBLE DIAGNOSISLAN-51

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYP INFINITI FX35 2008 Repair Manual

TROUBLE DIAGNOSISLAN-51

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYP](/img/42/57017/w960_57017-3070.png)

TROUBLE DIAGNOSISLAN-51

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 6/TYPE 8

NOTE:

Refer to LAN-37, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

VDC OFF indicator lamp signal RT

VDC OFF switch signal T

VDC operation signal T

Front wiper stop position signal R T

High beam status signal R T

Hood switch signal R T

Low beam status signal R T

Rear window defogger control signal R R T Signal name/Connecting unit

ECM

4WD

DISP TCM

BCM

I-KEY

STRG M&AABS

ADP

IPDM-E

Signal name/Connecting unitECM

4WD

DISP ICC

TCM

BCM

I-KEY

LANE

STRG M&AABS

LASER

ADP

IPDM-E

A/C compressor feedback signal T R

A/C compressor request signal T R

Accelerator pedal position signal T R R R R

ASCD OD cancel request signal T R

ASCD operation signal T R

Battery voltage signal T R

Closed throttle position signal T R R

Cooling fan speed request signal T R

Engine coolant temperature signal T R

Engine speed signal T RRRR RR

Engine status signal T R

Fuel consumption monitor signal TR

RT

ICC steering switch signal T R

Malfunction indicator lamp signal T R

Snow mode switch signal RT

TR

Wide open throttle position signal T R

AWD warning lamp signal T R

A/C switch/indicator signal TR

RT

System setting signal TR R

RT T

Buzzer output signal TR

TR

TR

ICC OD cancel request signal T R

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3326 of 3924

RECOMMENDED FLUIDS AND LUBRICANTSMA-9

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and LubricantsINFOID:0000000001328897

*1: For further details, see “Engine Oil Recommendation”.

*2: Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and

automatic transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new

vehicle limited warranty.

*3: For hot climates, viscosity SAE 90 is suitable for ambient temperatures above 0 °C (32 °F).

*4: Canada NISSAN Au tomatic Transmission Fluid or DEXRON

TM VI type ATF may also be used.

*5: Available in mainland U.S.A. through your INFINITI dealer.

Engine Oil RecommendationINFOID:0000000001328898

NISSAN recommends the use of an energy conser ving oil in order to improve fuel economy.

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubri-

cant Standardization and Approval Committee (ILSAC) certification and SAE viscosity standard. These oils

have the API certification mark on the front of the c ontainer. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

Capacity (Approximate)

Recommended Fluids/Lubricants

US measure Imp mea-

sure Liter

Engine oil

Drain and

refill With oil fil-

ter change

VK45DE 6-1/8 qt 5-1/8 qt 5.8

Engine oil with API Certification Mark*1

Viscosity SAE 5W-30

VQ35DE 5 qt 4 - 1/8 qt 4.7

Without oil

filter

change VK45DE 5-1/2 qt 4-5/8 qt 5.2

VQ35DE 4-5/8 qt 3-7/8 qt 4.4

Dry engine (Overhaul) VK45DE 7-3/8 qt 6-1/8 qt 7.0

VQ35DE 5-3/4 qt 4-3/4 qt 5.4

Cooling

system With res-

ervoir tank

VK45DE 10-5/8 qt 8-3/4 qt 10.0

Genuine NISSAN Long Life Antifreeze/ Coolant

or equivalent

VQ35DE 9-1/8 qt 7-5/8 qt 8.6

Reservoir

tank VK45DE 7/8 qt 3/4 qt 0.8

VQ35DE 7/8 qt 3/4 qt 0.8

Automatic transmission fluid 10-7/8 qt 9-1/8 qt 10.3 Genuine NISSAN Matic J ATF *2

Differential gear oil Front 1-3/8 pt 1-1/8 pt 0.65 Genuine NI

SSAN Differential Oil Hypoid Super

GL-5 80W-90 or API GL-5, Viscosity SAE 80W-

90 *3

Rear 3 pt 2-1/2 pt 1.40

Transfer fluid 2-5/8 pt 2-1/4 pt 1.25 Genuine NISSAN Matic D ATF (Continental U.S.

and Alaska) or Canada NISSAN Automatic

Transmission Fluid or equivalent (if available)

Power steering fluid (PSF) 1-1/8 qt 7/8 qt 1.0 Genuine NISSAN PSF or equivalent*4

Brake fluid — — — Genuine NISSAN Super He

avy Duty Brake Flu-

id*5 or equivalent

DOT 3 (US FMVSS No. 116)

Multi-purpose grease — — — NLGI No. 2 (Lithium soap base)

Windshield washer fluid — — — Genuine NISSAN Windshie

ld Washer Concen-

trate Cleaner & Antifreeze or equivalent

Fuel

recommendation VK45DE — — —

Refer to

GI-5, "

Precaution for Fuel (Unleaded

Premium Gasoline Required)"

VQ35DE——— Refer to

GI-5, "Precaution for Fuel (Unleaded

Premium Gasoline Recommended)"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3327 of 3924

MA-10

< SERVICE INFORMATION >

RECOMMENDED FLUIDS AND LUBRICANTS

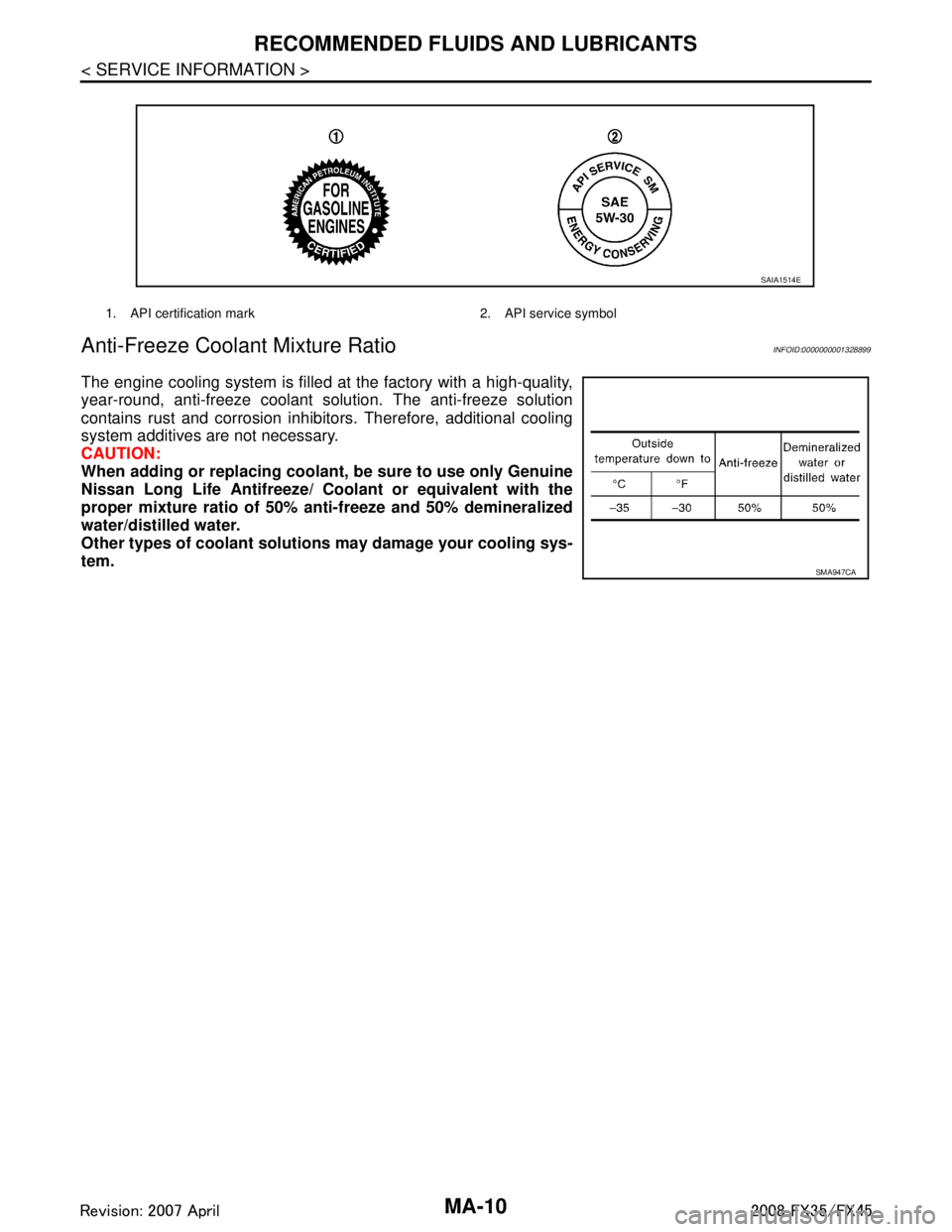

Anti-Freeze Coolant Mixture Ratio

INFOID:0000000001328899

The engine cooling system is filled at the factory with a high-quality,

year-round, anti-freeze coolant so lution. The anti-freeze solution

contains rust and corrosion inhibitors. Therefore, additional cooling

system additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only Genuine

Nissan Long Life Antifreeze/ Coolant or equivalent with the

proper mixture ratio of 50% an ti-freeze and 50% demineralized

water/distilled water.

Other types of coolant solutions may damage your cooling sys-

tem.

1. API certification mark 2. API service symbol

SAIA1514E

SMA947CA

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C