light INFINITI FX35 2008 Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 929 of 3924

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

BL-195

< SERVICE INFORMATION >

C

D E

F

G H

J

K L

M A

B

BL

N

O P

Trouble Diagnosis Symptom ChartINFOID:0000000001327932

*: When IVIS (NATS) detects trouble, the security indica tor lights up while electronic key is in the “ON” position.

Security Indicator InspectionINFOID:0000000001327933

*: CONSULT-III self-diagnostic results display screen “no malfunction is detected”.

Diagnosis Procedure 1INFOID:0000000001327934

Self-diagnostic results:

“CHAIN OF ECM-IMMU” is display on CONSULT-III screen

First perform the “SELF-DIAG RESULTS” in “BCM” wi th CONSULT-III, then perform the trouble diag-

nosis of malfunction system indicated “SEL F-DIAG RESULTS” of “BCM”. Refer to BCS-13, "

U1000

CAN Communication Circuit".

1.CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm that SELF-DIAGNOSTIC RESULTS “CHAIN OF ECM-IMMU” is displayed on the screen?

Does CONSULT-III screen display as shown in figure?

SYMPTOM Displayed “SELF-DIAG

RESULTS” on CON- SULT-III screen. DIAGNOSTIC PROCE-

DURE SYSTEM (Malfunctioning part or mode)

Security indicator lighting up*

Engine hard to start CHAIN OF ECM-IMMU

[P1612] Refer to

BL-195, "

Diag-

nosis Procedure 1".Open circuit in battery voltage line to BCM (NATS

IMMU) circuit

Open circuit in ignition

line to BCM (NATS IMMU) cir-

cuit

Open circuit in ground line to BCM (NATS IMMU) cir-

cuit

Open or short circuit between BCM (NATS IMMU)

and ECM communication line.

ECM

BCM (NATS IMMU)

DIFFERENCE OF KEY [P1615] Refer to

BL-197, "

Diag-

nosis Procedure 2".Unregistered key

NATS IMMU

CHAIN OF IMMU-KEY [P1614] Refer to

BL-198, "

Diag-

nosis Procedure 5".Open or short circuit between BCM (NATS IMMU)

and NATS antenna amp.

Malfunction of key ID chip

BCM (NATS IMMU)

Antenna amp.

ID DISCORD, IMM-ECM [P1611] Refer to

BL-197, "

Diag-

nosis Procedure 3"

System initialization has not yet been completed.

ECM

LOCK MODE [P1610] Refer to

BL-197, "

Diag-

nosis Procedure 4".LOCK MODE

MIL staying ON

Security indicator lighting up* DON'T ERASE BEFORE

CHECKING ENG DIAG Refer to

BL-194, "

Diag-

nosis Procedure".Engine trouble data and IVIS (NATS) trouble data

have been detected in ECM

SYMPTOM

SYSTEM

(Malfunctioning part or mode) DIAGNOSTIC PROCEDURE

Security indicator does not operate* Security indicator

Refer to BL-200, "

Diagnosis

Procedure 6".

Open circuit between Fuse and BCM (NATS IM-

MU)

Continuation of initialization mode

BCM (NATS IMMU)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 934 of 3924

BL-200

< SERVICE INFORMATION >

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

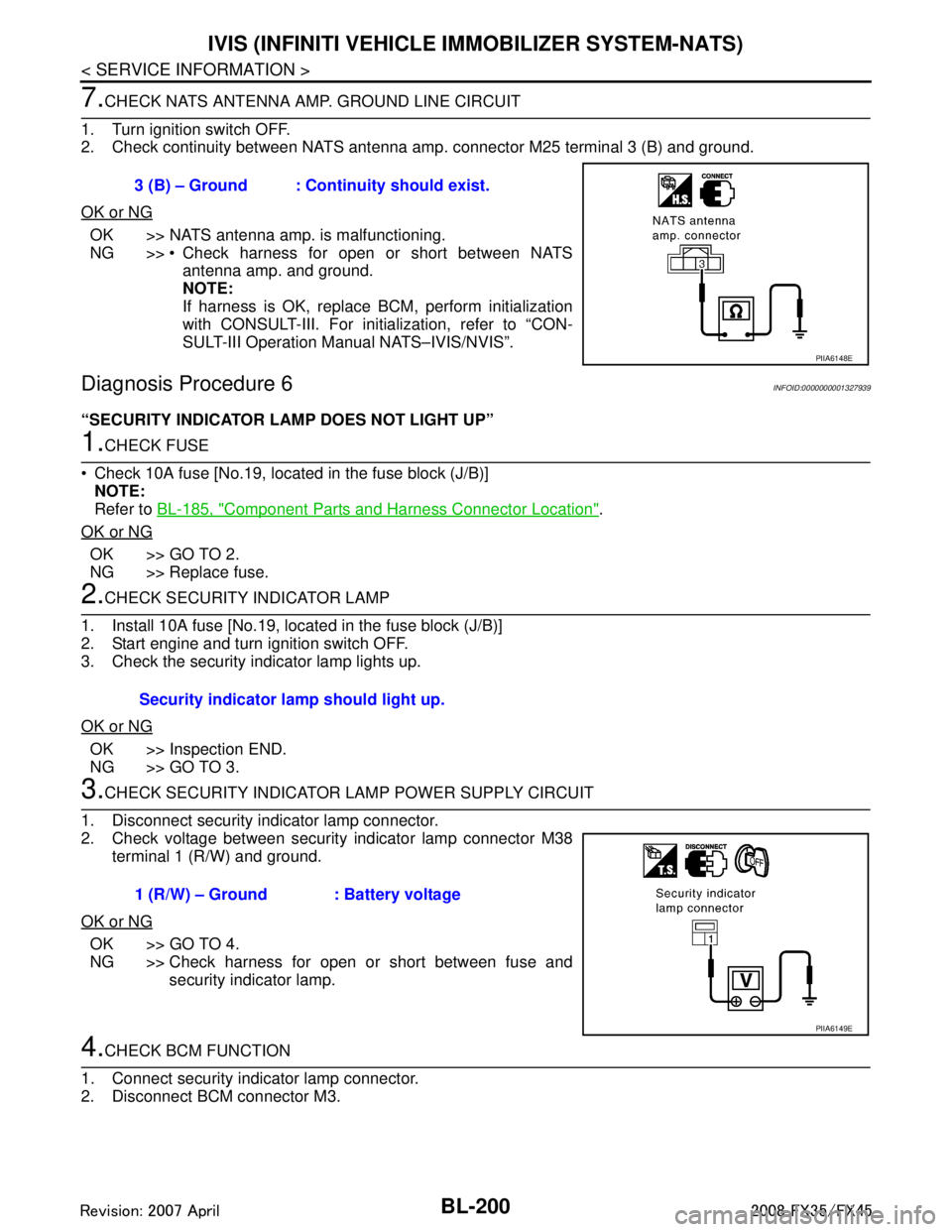

7.CHECK NATS ANTENNA AMP. GROUND LINE CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between NATS antenna am p. connector M25 terminal 3 (B) and ground.

OK or NG

OK >> NATS antenna amp. is malfunctioning.

NG >> Check harness for open or short between NATS antenna amp. and ground.

NOTE:

If harness is OK, replace BCM, perform initialization

with CONSULT-III. For initialization, refer to “CON-

SULT-III Operation Manual NATS–IVIS/NVIS”.

Diagnosis Procedure 6INFOID:0000000001327939

“SECURITY INDICATOR LAMP DOES NOT LIGHT UP”

1.CHECK FUSE

Check 10A fuse [No.19, located in the fuse block (J/B)] NOTE:

Refer to BL-185, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> Replace fuse.

2.CHECK SECURITY INDICATOR LAMP

1. Install 10A fuse [No.19, located in the fuse block (J/B)]

2. Start engine and turn ignition switch OFF.

3. Check the security indicator lamp lights up.

OK or NG

OK >> Inspection END.

NG >> GO TO 3.

3.CHECK SECURITY INDICATOR LA MP POWER SUPPLY CIRCUIT

1. Disconnect security indicator lamp connector.

2. Check voltage between security indicator lamp connector M38 terminal 1 (R/W) and ground.

OK or NG

OK >> GO TO 4.

NG >> Check harness for open or short between fuse and security indicator lamp.

4.CHECK BCM FUNCTION

1. Connect security indicator lamp connector.

2. Disconnect BCM connector M3. 3 (B) – Ground : Continuity should exist.

PIIA6148E

Security indicator lamp should light up.

1 (R/W) – Ground : Battery voltage

PIIA6149E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 937 of 3924

INTEGRATED HOMELINK TRANSMITTERBL-203

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Before conducting the procedure given below, make su re that system receiver (garage door opener, etc.)

operates with original, hand-held transmitter. If NG, re ceiver or hand-held transmitter is malfunctioning, not

vehicle related.

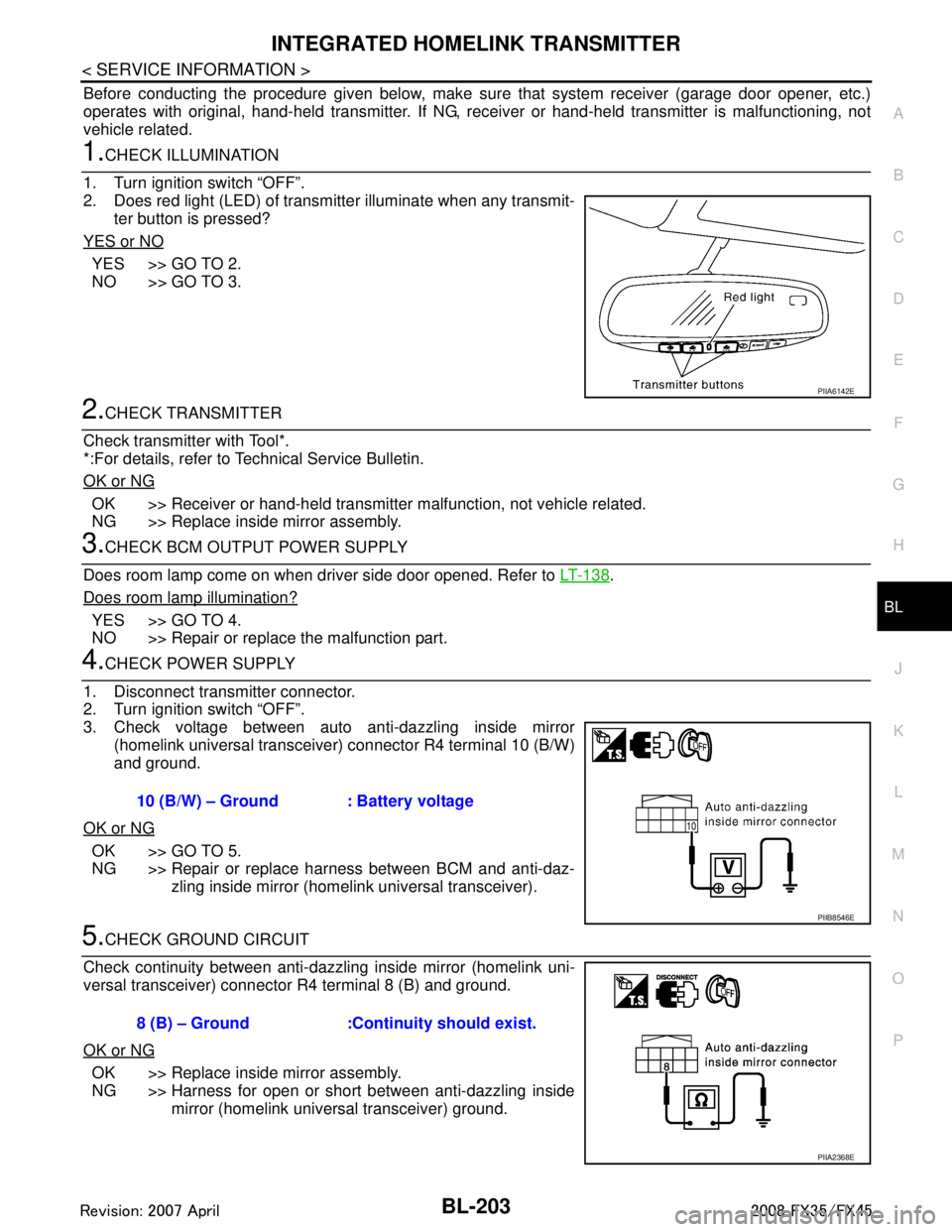

1.CHECK ILLUMINATION

1. Turn ignition switch “OFF”.

2. Does red light (LED) of transmitter illuminate when any transmit- ter button is pressed?

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK TRANSMITTER

Check transmitter with Tool*.

*:For details, refer to Technical Service Bulletin.

OK or NG

OK >> Receiver or hand-held transmitter malfunction, not vehicle related.

NG >> Replace inside mirror assembly.

3.CHECK BCM OUTPUT POWER SUPPLY

Does room lamp come on when driver side door opened. Refer to LT-138

.

Does room lamp illumination?

YES >> GO TO 4.

NO >> Repair or replace the malfunction part.

4.CHECK POWER SUPPLY

1. Disconnect transmitter connector.

2. Turn ignition switch “OFF”.

3. Check voltage between auto anti-dazzling inside mirror (homelink universal transceive r) connector R4 terminal 10 (B/W)

and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness between BCM and anti-daz- zling inside mirror (homelink universal transceiver).

5.CHECK GROUND CIRCUIT

Check continuity between anti-dazzling inside mirror (homelink uni-

versal transceiver) connector R4 terminal 8 (B) and ground.

OK or NG

OK >> Replace inside mirror assembly.

NG >> Harness for open or short between anti-dazzling inside mirror (homelink universal transceiver) ground.

PIIA6142E

10 (B/W) – Ground : Battery voltage

PIIB8546E

8 (B) – Ground :Continuity should exist.

PIIA2368E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1020 of 3924

![INFINITI FX35 2008 Repair Manual

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI INFINITI FX35 2008 Repair Manual

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI](/img/42/57017/w960_57017-1019.png)

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612923

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001327654

Recommended fluid is brake fluid “DOT 3”. Refer to MA-9.

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas such as body. If brake fluid is splashed, wipe it off and flush area with water immediately.

Do not use mineral oils such as gasoline or kerosene to clean. They will ruin rubber parts and cause improper operation.

Using a flare nut crowfoot and torque wrench, securely tighten brake tube flare nuts.

Brake system is an important safe ty part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Before working, turn ignition switch OFF and disconnect electrical

connectors of ABS actuator and elec tric unit (control unit) or bat-

tery negative terminal.

When installing brake piping, be sure to check torque.

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with

a dust collector.

Precaution for Brake ControlINFOID:0000000001327655

During VDC/TCS/ABS operation, brake pedal lightly vi brates and a mechanical noise may be heard. This is

normal.

Just after starting vehicle after turning ignition switch ON, brake pedal may vibrate or motor operating noise

may be heard from engine room. This is a normal status of operation check.

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnostic

servicing. Besides electrical system inspection, c heck booster operation, brake fluid level, and fluid leaks.

If tire size and type are used in an improper combinat ion, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

If there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, VDC/TCS/ABS

function may have a malfunction or error.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR686C

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1025 of 3924

![INFINITI FX35 2008 Repair Manual

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driv INFINITI FX35 2008 Repair Manual

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driv](/img/42/57017/w960_57017-1024.png)

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driver

steering amount and brake operation amount are detected

from steering angle sensor and pressure sensor, and the vehicle's driving status (amount of under steering /

over steering) is determined from information from G s ensor, wheel sensor, etc., and this information is used

to improve vehicle stability by controlling the braking and engine power to all four wheels.

SLIP indicator lamp flashes to inform the driver of VDC operation.

During VDC operation, body and brake pedal lightly vibrate and mechanical noises may be heard. This is

normal.

ABS warning lamp, VDC OFF indicator lamp, and SLIP indicator lamp might turn on when vehicle is subject

to strong shaking or large vibration, such as when vehi cle is on a turn table, a ship or a steep slope such as

bank while engine is running. In this case, restart engine on a normal road, and if ABS warning lamp, VDC

OFF indicator lamp, and SLIP indicator lamp turn off, there is no malfunction.

TCS

The wheel spin of the drive wheels is detected by ABS actuator and electric unit (control unit) from the wheel

speed signals from four wheels, so if wheel spin occurs , drive wheel right and left brake fluid pressure con-

trol and engine fuel cut are performed while throttle value is restricted to reduce the engi\

ne torque and

decrease the amount of wheel spin. In addition, the degree throttle is opened is controlled to achieve the

optimum engine torque.

Depending on road circumstances, the driver may have a sluggish feel. This is normal, because the opti-

mum traction has the highest priority under TCS operation.

TCS may be activated any time vehicle suddenly accelerates, suddenly down/upshifts, or is driven on a road with a varying surface friction coefficient.

During TCS operation, it informs a driver of sy stem operation by flashing SLIP indicator lamp.

ABS

The Anti-Lock Braking System is a function that detec ts wheel revolution while braking, and it improves han-

dling stability during sudden braking by electrically prev enting 4 wheel lock. Maneuverability is also improved

for avoiding obstacles.

If the electrical system malfunc tions, then the fail-safe function star ts, the ABS becomes inoperative, and

ABS warning lamp turns on.

Electrical system diagnosis by CONSULT-III is available.

During ABS operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is normal.

When starting engine, or just after starting vehicle, brake pedal may vibrate or motor operating noises may be heard from engine compartment. This is a normal status of operation check.

SFIA1160E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1026 of 3924

![INFINITI FX35 2008 Repair Manual

SYSTEM DESCRIPTIONBRC-11

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gra INFINITI FX35 2008 Repair Manual

SYSTEM DESCRIPTIONBRC-11

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gra](/img/42/57017/w960_57017-1025.png)

SYSTEM DESCRIPTIONBRC-11

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

EBD

The Electronic Brake Distribution is a function that detects subtle slippages between front and rear wheels

during braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

In case of electrical system malfunction, the fail- safe function is activated, EBD and ABS becomes inopera-

tive, and ABS warning lamp and brake warning lamp are turned on.

Electrical system diagnosis by CONSULT-III is available.

During EBD operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is normal.

When starting engine, or just after starting vehicle, brake pedal may vibrate or motor operating noises may

be heard from engine compartment. This is a normal status of operation check.

Stopping distance may be longer than that of vehicles without EBD when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

Fail-Safe FunctionINFOID:0000000001327662

VDC / TCS SYSTEM

In case of malfunction in the VDC/TCS system, VDC O FF indicator lamp and SLIP indicator lamp are turned

on, and the condition of vehicle is the same as the c ondition of vehicles without VDC/TCS system. In case of

malfunction in the VDC/TCS system, the ABS control c ontinues to operate normally without VDC/TCS control.

CAUTION:

If the fail-safe function is acti vated, then perform the self-diagnos is for VDC/TCS/ABS control system.

ABS, EBD SYSTEM

In case of electrical malfunctions with the ABS, ABS warning lamp, VDC OFF indicator lamp and SLIP indica-

tor lamp will turn on. In case of electrical malfunc tions with the EBD, brake warning lamp, ABS warning lamp,

VDC OFF indicator lamp and SLIP indicator lamp wil l turn on. Simultaneously, the VDC/TCS/ABS become one

of the following conditions of the fail-safe function.

For malfunction of ABS, only the EBD is activated and t he condition of vehicle is the same condition of vehi-

cles without TCS/ABS system.

NOTE:

ABS self-diagnosis sound may be heard. That is a no rmal condition because a self-diagnosis for “Ignition

switch ON” and “The first starting” are being performed.

For malfunction of EBD, EBD and ABS become inoperative, and the condition of vehicle is the same as the

condition of vehicles wit hout TCS/ABS, EBD system.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1047 of 3924

![INFINITI FX35 2008 Repair Manual

BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Basic Inspection

INFOID:0000000001327676

BRAKE FLUID AMOUNT, LEAKS, AND BRAKE PADS INSPECTION

1. Check fluid level in the brake reservoir INFINITI FX35 2008 Repair Manual

BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Basic Inspection

INFOID:0000000001327676

BRAKE FLUID AMOUNT, LEAKS, AND BRAKE PADS INSPECTION

1. Check fluid level in the brake reservoir](/img/42/57017/w960_57017-1046.png)

BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Basic Inspection

INFOID:0000000001327676

BRAKE FLUID AMOUNT, LEAKS, AND BRAKE PADS INSPECTION

1. Check fluid level in the brake reservoir tank. If fluid level is low, refill brake fluid.

2. Check brake piping and around ABS actuator and electric uni t (control unit) for leaks. If there is leaking or

oozing fluid, check the following items.

If ABS actuator and electric unit (control unit) connec tion is loose, tighten piping to the specified torque

and re-perform the leak inspection to make sure there are no leaks.

If there is damage to the connection flare nut or AB S actuator and electric unit (control unit) screw,

replace the damaged part and re-perform the leak inspection to make sure there are no leaks.

When there is fluid leaking or oozing from a part other than ABS actuator and electric unit (control unit)

connection, if fluid is just oozing out, use a clean cl oth to wipe off the oozing fluid and re-check for leaks.

If fluid is still oozing out, replace the damaged part.

When there is fluid leaking or oozing at ABS actuator and electric unit (control unit), if fluid is just oozing

out, use a clean cloth to wipe off oozing fluid and re-che ck for leaks. If fluid is still oozing out, replace

ABS actuator and electric unit (control unit) body.

CAUTION:

ABS actuator and electric unit (contr ol unit) body can not be disassembled.

3. Check brake pad degree of wear. Refer to BR-18, "

On-Vehicle Inspection" in “Front Disc Brake” and BR-

24, "On-Vehicle Inspection" in “Rear Disc Brake”

POWER SYSTEM TERMINAL LOOSENESS AND BATTERY INSPECTION

Make sure battery positive cable, negative cabl e and ground connection are not loose. If looseness is

detected, tighten the cables. In additi on, check the battery voltage to make sure it has not dropped and alter-

nator is normal.

ABS WARNING LAMP, VDC OFF INDICATOR LAMP, SLIP INDICATOR LAMP AND BRAKE WARN-

ING LAMP INSPECTION

Symptom Symptom description Result

Motor operation noise This is noise of motor in

side ABS actuator and electr ic unit (control unit).

Slight noise may occur during VDC, TCS, and ABS operation.

Normal

When the vehicle speed goes over 20 km/h (12.5 MPH), motor and valves

operating noise may be heard. It happens only once after ignition switch is

ON. This is a normal status of the system operation check.

System operation check noise When engine starts, slight “click” noise may be heard from engine room.

This is normal and is part of system operation check. Normal

VDC/TCS operation

(SLIP indicator lamp blinking) TCS may activate momentarily if wheel speed changes when driving over

location where friction coefficient varies, when up/downshifting, or when ful-

ly depressing accelerator pedal.

Normal

Cancel the VDC/TCS

function for the inspec-

tion on a chassis dyna-

mometer.

For inspection of speedometer or other instruments, press VDC OFF switch

to turn VDC/TCS function off.

When accelerator pedal is depressed on a chassis dynamometer (fixed

front-wheel type), vehicle speed will not increase. This is not normal. It is re-

sult of TCS being activated by stationary front wheels. Warning lamp may

also illuminate to indicate “sensor system error”. This is also normal, and is

the result of the stationary front wheels being detected. To be certain, restart

engine, and drive vehicle at 30 km/h (19 MPH) or more. Make sure warning

lamp does not illuminate.

ABS operation

(Longer stopping distance) On roads with low friction coefficients, such as snowy roads or gravel roads,

vehicles with ABS may require a longer stopping distance. Therefore, when

driving on such roads, avoid overconfidence and keep speed sufficiently

low.

Normal

Insufficient feeling of accelera-

tion Depending on road conditions, driver may feel that feeling of acceleration is

insufficient. This is because traction control, which controls engine and

brakes to achieve optimal traction, has the highest priority (for safety). As a

result, there may be times when acceleration is slightly less than usual for

the same accelerator pedal operation.

Normal

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1065 of 3924

![INFINITI FX35 2008 Repair Manual

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 M INFINITI FX35 2008 Repair Manual

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 M](/img/42/57017/w960_57017-1064.png)

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 MPH) or less.

1.CHECK ABS WARNING LAMP DISPLAY

Make sure warning lamp turns off approximately 2 seconds after the ignition switch is turned ON or when driv-

ing.

OK or NG

OK >> CHECK WHEEL SENSOR. Refer to BRC-49, "Excessive ABS Function Operation Frequency".

NG >> Perform self-diagnosis. Refer to BRC-26, "

Self-Diagnosis".

Pedal Vibration or ABS Operation Sound OccursINFOID:0000000001327696

CAUTION:

Under the following conditions, when brake pedal is lightly depressed (just place a foot on it), ABS is

activated and vibration is felt. However, this is normal.

When shifting gears

When driving on slippery road

During cornering at high speed

When passing over bumps or grooves

When pulling away just after st arting engine [at approximately 10 km/h (6 MPH) or higher]

1.SYMPTOM CHECK 1

Check if pedal vibration or operati on sound occurs when engine is started.

OK or NG

OK >> Perform self-diagnosis. Refer to BRC-26, "Self-Diagnosis".

NG >> GO TO 2.

2.SYMPTOM CHECK 2

Check symptom when electrical component (headlamps, etc.) switches are operated.

Does the symptom occur when the electrical component (head lamp, etc.) switches are operated?

YES >> Check if there is a radio, antenna, antenna lead wi re, or wiring close to ABS actuator and electric

unit (control unit) (or its wiring), and if there is, move it farther away.

NO >> CHECK WHEEL SENSOR. Refer to BRC-49, "

Excessive ABS Function Operation Frequency".

Vehicle Jerks During VDC/TCS/ABS ControlINFOID:0000000001327697

1.CHECK ENGINE SPEED SIGNAL

Perform CONSULT-III “DATA MONITOR” to check engine speed.

Is engine speed at idle 400 rpm or higher?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK ABS WARNING LAMP DISPLAY

Make sure warning lamp turns off approximately 2 seconds after the ignition switch is turned ON or when driv-

ing.

OK or NG

OK >> System is normal.

NG >> GO TO 3.

3.CHECK ECM SELF-DIAGNOSTIC RESULTS

Perform ECM self-diagnosis.

Are self-diagnosis items displayed?

YES >> Check the corresponding items. Refer to EC-89(VQ35DE), EC-666(VK45DE) in “Engine Control

(EC section)”.

NO >> GO TO 4.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1074 of 3924

![INFINITI FX35 2008 Repair Manual

PRECAUTIONSCO-3

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENS INFINITI FX35 2008 Repair Manual

PRECAUTIONSCO-3

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENS](/img/42/57017/w960_57017-1073.png)

PRECAUTIONSCO-3

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612910

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Liquid GasketINFOID:0000000001325839

REMOVAL OF LIQUID GASKET SEALING

After removing mounting nuts and bolts, separate the mating sur- face using the seal cutter (SST) and remove old liquid gasket seal-

ing.

CAUTION:

Be careful not to damage the mating surfaces.

Tap the seal cutter to insert it, and then slide it by tapping on the

side as shown in the figure.

In areas where seal cutter is difficult to use, use a plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

Remove liquid gasket completely from the groove of the liquid

gasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur- face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

PBIC0002E

PBIC0003E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1128 of 3924

DI-2

CONSULT-III Function (BCM) ................................60

Trouble Diagnosis ...................................................61

Symptom Chart .......................................................61

Power Supply and Ground Circuit Inspection .........61

Combination Meter Buzzer Circuit Inspection .........62

Front Door Switch (Driver Side) Signal Inspection ...63

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ...

64

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ...

65

Lighting Switch Signal Inspection ...........................66

Seat Belt Buckle Switch (Driver Side) Signal In-

spection ............................................................... ...

66

Component Inspection ............................................67

LANE DEPARTURE WARNING SYSTEM ........69

Precaution for Lane Departure Warning (LDW)

system ................................................................. ...

69

System Description .................................................69

Action Test ..............................................................71

Camera Aiming Adjustment ....................................71

Component Parts and Harness Connector Loca-

tion ..........................................................................

76

Schematic ...............................................................77

Wiring Diagram - LDW - .........................................78

Terminal and Reference Value for LDW Camera

Unit .........................................................................

81

CONSULT-III Function (LDW) ................................81

Trouble Diagnosis ...................................................83

Preliminary Check ..................................................84

Power Supply and Ground Circuit Inspection .........84

DTC [C1B00] CAMERA UNIT MALF ......................85

DTC [C1B01] CAM AIMING INCMP .......................85

DTC [C1B02] VHCL SPD DATA MALF ..................85

DTC [C1B03] ABNRML TEMP DETECT ................86

DTC [U1000] CAN COMM CIRCUIT ......................86

DTC [U1010] CONTROL UNIT (CAN) ....................86

LDW Chime Circuit Inspection ................................86

LDW Switch Circuit Inspection ...............................88

LDW Indicator Lamp Circuit Inspection ..................90

Turn Signal Input Inspection ................................ ...91

Electrical Component Inspection ............................91

Removal and Installation for LDW Camera Unit .....91

Removal and Installation for LDW Chime ............ ...91

Removal and Installation for LDW Switch ...............92

CAN COMMUNICATION ...................................93

System Description .............................................. ...93

CAN Communication Unit .......................................93

COMPASS .........................................................94

Precaution for Compass ...................................... ...94

System Description .................................................94

Troubleshooting ......................................................94

Zone Variation Setting Procedure ...........................95

Calibration Procedure .............................................95

Wiring Diagram - COMPAS - ..................................97

Removal and Installation of Compass ....................97

CLOCK ..............................................................98

Wiring Diagram - CLOCK - .................................. ...98

Removal and Installation of Clock ...........................98

REAR VIEW MONITOR ....................................100

System Description .............................................. .100

Component Parts and Harness Connector Loca-

tion ........................................................................

101

Schematic .............................................................102

Wiring Diagram - R/VIEW - ...................................103

Terminal and Reference Value for Rear View

Camera Control Unit .............................................

106

CONSULT-III Function (REARVIEW CAMERA) ...106

Side Distance Guideline Correction ......................107

Power Supply and Ground Circuit Inspection .......108

Rear View Is Not Displayed with the A/T Selector

Lever in R-Position ................................................

108

The Rear View Image Is Distorted ........................112

Removal and Installation of Rear View Camera

Control Unit .......................................................... .

113

Removal and Installation of Rear View Camera ...113

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C