sensor INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 7 of 3924

ACCELERATOR CONTROL SYSTEMACC-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

ACC

NP

O

ACCELERATOR CONTROL SYSTEM

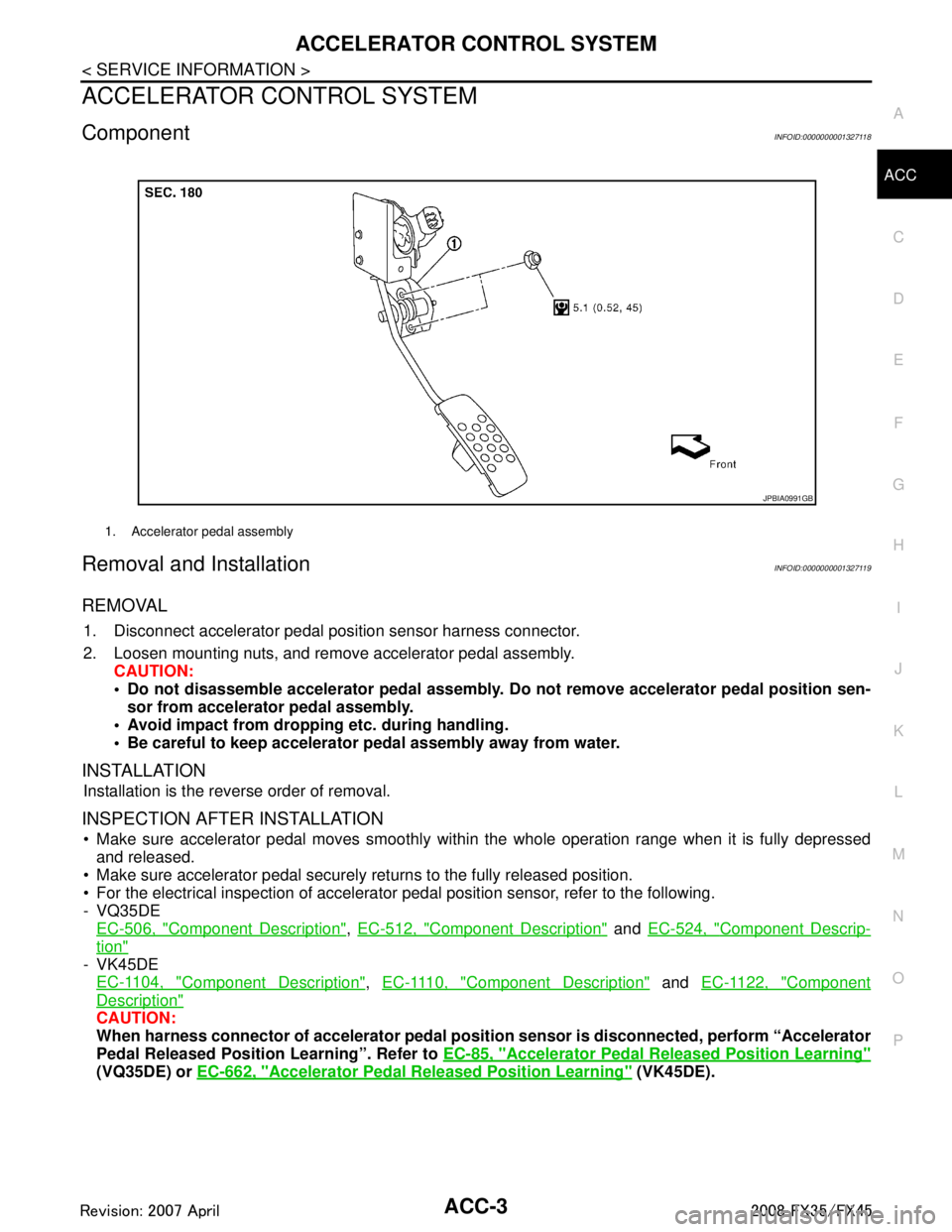

ComponentINFOID:0000000001327118

Removal and InstallationINFOID:0000000001327119

REMOVAL

1. Disconnect accelerator pedal position sensor harness connector.

2. Loosen mounting nuts, and remove accelerator pedal assembly.

CAUTION:

Do not disassemble accelerator pedal assembly. Do not remove accelerator pedal position sen-sor from accelerator pedal assembly.

Avoid impact from dropping etc. during handling.

Be careful to keep accelerator pedal assembly away from water.

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

Make sure accelerator pedal moves smoothly within the whole operation range when it is fully depressed and released.

Make sure accelerator pedal securely returns to the fully released position.

For the electrical inspection of accelerator pedal position sensor, refer to the following.

- VQ35DE EC-506, "

Component Description", EC-512, "Component Description" and EC-524, "Component Descrip-

tion"

- VK45DE

EC-1104, "

Component Description", EC-1110, "Component Description" and EC-1122, "Component

Description"

CAUTION:

When harness connector of accelerator pedal posi tion sensor is disconnected, perform “Accelerator

Pedal Released Position Learning”. Refer to EC-85, "

Accelerator Pedal Released Position Learning"

(VQ35DE) or EC-662, "Accelerator Pedal Released Position Learning" (VK45DE).

1. Accelerator pedal assembly

JPBIA0991GB

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 8 of 3924

ACS-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION ACS

A

B

ACS

N

O P

CONTENTS

AUTO CRUISE CONTROL SYSTEM

ASCD

SERVICE INFORMATION .. ..........................

3

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ........................................................... .....

3

Description .......................................................... ......3

ICC

SERVICE INFORMATION .. ..........................

4

DTC INDEX ..................................................... .....4

DTC 11 - 65 ......................................................... ......4

DTC 74 - 109 .............................................................4

PRECAUTIONS ...................................................5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Precaution for ICC System Service ...........................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

DESCRIPTION ....................................................7

Outline ................................................................. ......7

Functional Diagram ...................................................7

Component Description .............................................9

CAN Communication .................................................9

Switch Operation .....................................................10

ICC System Display ................................................10

ACTION TEST ....................................................11

ICC System Running Test ................................... ....11

LASER BEAM AIMING ADJUSTMENT .............14

Outline ................................................................. ....14

Preparation ..............................................................14

Outline of Adjustment Procedure ............................14

Setting the ICC Target Board ..................................14

Aiming Adjustment ..................................................16

ELECTRICAL UNITS LOCATION ....................18

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

18

WIRING DIAGRAM ...........................................19

Schematic ................................................................19

Wiring Diagram - ICC - ............................................20

TERMINALS AND REFERENCE VALUE .........27

Terminal and Reference Value for ICC Unit ............27

Terminal and Reference Value for ICC Sensor ... ....28

TROUBLE DIAGNOSIS — GENERAL DE-

SCRIPTION .......................................................

29

Work Flow ................................................................29

CONSULT-III Function (ICC) ...................................29

Self-Diagnostic Function ..........................................32

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

35

Diagnostic Trouble Code (DTC) Chart ....................35

DTC 11 CONTROL UNIT ........................................36

DTC 20 CAN COMM CIRCUIT ................................36

DTC 31 POWER SUPPLY CIR, DTC 34 POWER

SUPPLY CIR 2 ........................................................

37

DTC 41 VHCL SPEED SE CIRC .............................37

DTC 43 ABS/TCS/VDC CIRC .................................38

DTC 45 BRAKE SW/STOP L SW ............................38

DTC 46 OPERATION SW CIRC ......................... ....40

DTC 61 PRESS SEN CIRCUIT ...............................41

DTC 62 BOOSTER SOL/V CIRCUIT .................. ....42

DTC 63 RELEASE SW CIRCUIT ............................43

DTC 65 PRESSURE CONTRO L .............................45

DTC 74 LASER BEAM OFF CNTR ..................... ....45

DTC 90 STOP LAMP RLY FIX ................................46

DTC 92 ECM CIRCUIT ............................................50

DTC 96 NP RANGE ................................................51

DTC 97 AT CIRCUIT ...............................................52

DTC 98 GEAR POSITION .......................................52

DTC 102 RADAR STAIN .........................................53

DTC 103 LASER SENSOR FAIL .............................53

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 9 of 3924

ACS-2

DTC 104 LASER AIMING INCMP ..........................54

DTC 107 LASER COMM FAIL ...............................54

DTC 109 LASER HIGH TEMP ...............................54

TROUBLE DIAGNOSIS FOR SYMPTOMS .......55

Symptom Chart .................................................... ...55

Symptom 1 MAIN Switch Does Not Turn ON*1,

MAIN Switch Does Not Turn OFF*2 ..................... ...55

Symptom 2 ICC System Cannot Be Set (MAIN

Switch Turns ON/OFF) ........................................ ...

56

Symptom 3 ICC System Cannot Be Operated by

CANCEL Switch, RESUME/ACCELERATE

Switch or DISTANCE Switch ..................................

56

Symptom 4 ICC System Is Not Cancelled When

the A/T Selector Lever Is in Other Than "D" and

"M" Position ............................................................

57

Symptom 5 Chime Does Not Sound .......................57

Symptom 6 Driving Force Is Hunting ......................58

Symptom 7 ICC System Frequently Cannot De-

tect the Vehicle Ahead/ Detection Zone Is Short . ...

58

Symptom 8 the System Does Not Detect the Vehi-

cle Ahead at All .......................................................

59

SELF-DIAGNOSIS BY ICC SYSTEM DISPLAY

WILL NOT RUN ......................................................

59

ELECTRICAL COMPONENT INSPECTION .....63

ICC Steering Switch ............................................. ...63

Booster Solenoid .....................................................63

Release Switch .......................................................63

ICC Brake Switch and Stop Lamp Switch ...............64

ICC Brake Hold Relay .............................................64

REMOVAL AND INSTALLATION .....................65

ICC Unit ............................................................... ...65

ICC Sensor .............................................................65

ICC Steering Switch ................................................66

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 11 of 3924

![INFINITI FX35 2008 Service Manual

ACS-4

< SERVICE INFORMATION >[ICC]

DTC INDEX

SERVICE INFORMATION

DTC INDEX

DTC 11 - 65INFOID:0000000001544468

DTC 74 - 109INFOID:0000000001544469

DTC Items (CONSULT screen terms) Reference

11 CONTROL INFINITI FX35 2008 Service Manual

ACS-4

< SERVICE INFORMATION >[ICC]

DTC INDEX

SERVICE INFORMATION

DTC INDEX

DTC 11 - 65INFOID:0000000001544468

DTC 74 - 109INFOID:0000000001544469

DTC Items (CONSULT screen terms) Reference

11 CONTROL](/img/42/57017/w960_57017-10.png)

ACS-4

< SERVICE INFORMATION >[ICC]

DTC INDEX

SERVICE INFORMATION

DTC INDEX

DTC 11 - 65INFOID:0000000001544468

DTC 74 - 109INFOID:0000000001544469

DTC Items (CONSULT screen terms) Reference

11 CONTROL UNIT ACS-36, "

DTC 11 CONTROL UNIT"

20 CAN COMM CIRCUIT ACS-36, "DTC 20 CAN COMM CIRCUIT"

31 POWER SUPPLY CIR

ACS-37, "DTC 31 POWER SUPPLY CIR, DTC 34 POWER SUPPLY CIR 2"34 POWER SUPPLY CIR 2

41 VHCL SPEED SE CIRCACS-37, "

DTC 41 VHCL SPEED SE CIRC"

43 ABS/TCS/VDC CIRCACS-38, "DTC 43 ABS/TCS/VDC CIRC"

45 BRAKE SW/STOP L SWACS-38, "DTC 45 BRAKE SW/STOP L SW"

46 OPERATION SW CIRCACS-40, "DTC 46 OPERATION SW CIRC"

61 PRESS SEN SIRCUITACS-41, "DTC 61 PRESS SEN CIRCUIT"

62 BOOSTER SOL/V CIRCUITACS-42, "DTC 62 BOOSTER SOL/V CIRCUIT"

63 RELEASE SW CIRCUITACS-43, "DTC 63 RELEASE SW CIRCUIT"

65 PRESSURE CONTROLACS-45, "DTC 65 PRESSURE CONTROL"

DTC Items (CONSULT screen terms) Reference

74 LASER BEAM OFF CNTR ACS-45, "

DTC 74 LASER BEAM OFF CNTR"

90 STOP LAMP RLY FIXACS-46, "DTC 90 STOP LAMP RLY FIX"

92 ECM CIRCUITACS-50, "DTC 92 ECM CIRCUIT"

96 NP RANGEACS-51, "DTC 96 NP RANGE"

97 AT CIRCUITACS-52, "DTC 97 AT CIRCUIT"

98 GEAR POSITIONACS-52, "DTC 98 GEAR POSITION"

102 RADAR STAIN ACS-53, "DTC 102 RADAR STAIN"

103 LASER SENSOR FAILACS-53, "DTC 103 LASER SENSOR FAIL"

104 LASER AIMING INCMPACS-54, "DTC 104 LASER AIMING INCMP"

107 LASER COMM FAILACS-54, "DTC 107 LASER COMM FAIL"

109 LASER HIGH TEMPACS-54, "DTC 109 LASER HIGH TEMP"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 12 of 3924

![INFINITI FX35 2008 Service Manual

PRECAUTIONSACS-5

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000 INFINITI FX35 2008 Service Manual

PRECAUTIONSACS-5

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000](/img/42/57017/w960_57017-11.png)

PRECAUTIONSACS-5

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612901

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for ICC System ServiceINFOID:0000000001328803

Never look straight into the laser beam discharger when adjusting laser beam aiming.

Turn the MAIN switch OFF in conditions similar to dr iving, such as free rollers or a chassis dynamometer.

Do not use the ICC sensor removing from v ehicle, disassemble, or remodel the sensor.

Erase DTC when replacing parts of ICC system, then c heck the operation of ICC system after adjusting laser

beam aiming if necessary.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 14 of 3924

![INFINITI FX35 2008 Service Manual

DESCRIPTIONACS-7

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DESCRIPTION

OutlineINFOID:0000000001328805

The Intelligent Cruise Control (ICC) system automatically maintains a sele INFINITI FX35 2008 Service Manual

DESCRIPTIONACS-7

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DESCRIPTION

OutlineINFOID:0000000001328805

The Intelligent Cruise Control (ICC) system automatically maintains a sele](/img/42/57017/w960_57017-13.png)

DESCRIPTIONACS-7

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DESCRIPTION

OutlineINFOID:0000000001328805

The Intelligent Cruise Control (ICC) system automatically maintains a selected distance from the vehicle

ahead according to that vehicle's speed, or at the set speed, if the road ahead is clear.

The ICC function has two cruise control modes and brake assist (with preview function).

VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE

With vehicle-to-vehicle distance control mode, the driver can maintain the same speed as other vehicles with-

out the constant need to adjust the set speed as the driver would with a normal cruise control system.

The system is intended to enhance the operation of the vehicle when following the vehicle traveling in the

same lane and direction.

If the distance sensor detects a sl ower moving vehicle ahead, the system wil l reduce speed so that the vehicle

ahead can be followed at the selected distance.

The system automatically controls the throttle and applie s the brakes (up to 25% of vehicle braking power) if

necessary.

The detection range of the sensor is approximately 120 m (390 ft) ahead.

Refer to Owner's Manual for Intelligent Cruise Control System operating instructions.

CONVENTIONAL (FIXED SPEED) CRUISE CONTROL MODE

Conventional (fixed speed) cruise contro l mode is cruising at preset speeds.

Refer to Owner's Manual for Intelligent Cruise Control System operating instructions.

BRAKE ASSIST (WITH PREVIEW FUNCTION)

When the force applied to brake pedal exceeds a certain level, the Brake Assist is activated and generates a

greater braking force than that of a convent ional brake booster even with light pedal force.

When the Preview Function identifies the need to apply the sudden brake by sensing the vehicle ahead in the

same lane and the distance and relative speed from it, it applies the brake pre-pressure before driver depress

the brake pedal and improves brake re sponse by reducing its free play.

Refer to Owner's Manual for BRAKE ASSIST (W ITH PREVIEW FUNCTION) operating instructions.

Functional DiagramINFOID:0000000001328806

Items of input/output signal to be checked with CONSULT-III

PKIC8700E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 15 of 3924

![INFINITI FX35 2008 Service Manual

ACS-8

< SERVICE INFORMATION >[ICC]

DESCRIPTION

DATA MONITOR INPUT ITEM LIST

DATA MONITOR OUTPUT ITEM LIST

InputData monitored

Item [unit] CAN Description

ECM THRTL OPENING

[%]

×Indicates throttle a INFINITI FX35 2008 Service Manual

ACS-8

< SERVICE INFORMATION >[ICC]

DESCRIPTION

DATA MONITOR INPUT ITEM LIST

DATA MONITOR OUTPUT ITEM LIST

InputData monitored

Item [unit] CAN Description

ECM THRTL OPENING

[%]

×Indicates throttle a](/img/42/57017/w960_57017-14.png)

ACS-8

< SERVICE INFORMATION >[ICC]

DESCRIPTION

DATA MONITOR INPUT ITEM LIST

DATA MONITOR OUTPUT ITEM LIST

InputData monitored

Item [unit] CAN Description

ECM THRTL OPENING

[%]

×Indicates throttle angle read by ICC unit through CAN communication (ECM transmits

throttle angle through CAN communication).

ENGINE RPM

[rpm] ×

Indicates engine speed read by ICC unit through CAN communication (ECM transmits

engine speed through CAN communication).

MAIN SW

[On/Off] ×Indicates [On/Off] status as judged from steering switch signal (ECM transmits steering

switch signal through CAN communication).

SET/COAST SW

[On/Off] ×Indicates [On/Off] status as judged from steering switch signal (ECM transmits steering

switch signal through CAN communication).

CANCEL SW

[On/Off] ×

Indicates [On/Off] status as judged from steering switch signal (ECM transmits steering

switch signal through CAN communication).

RESUME/ACC SW

[On/Off] ×Indicates [On/Off] status as judged from steering switch signal (ECM transmits steering

switch signal through CAN communication).

IDLE SW

[On/Off] ×Indicates [On/Off] status of idle switch read by ICC unit through CAN communication

(ECM transmits ON/OFF status through CAN communication).

TCM VHCL SPD AT

[km/h] or [mph]

×Indicates vehicle speed calculated from AT vehicle speed sensor by ICC unit through

CAN communication (TCM transmits AT vehicle speed sensor signal through CAN com-

munication).

GEAR

[1, 2, 3, 4, 5] ×Indicates AT gear position read by ICC unit through CAN communication (TCM transmits

gear position through CAN communication).

D RANGE SW

[On/Off] ×

Indicates [On/Off] status of “D” position read by ICC unit through CAN communication

(TCM transmits ON/OFF condition of “D” position through CAN communication).

NP RANGE SW

[On/Off] ×Indicates PNP switch signal read by ICC unit through CAN communication (TCM trans-

mits PNP switch signal through CAN communication).

ABS actuator

and electric

unit (control

unit) VHCL SPEED SE

[km/h] or [mph]

×Indicates vehicle speed calculated from wheel sensor by ICC unit through CAN commu-

nication (ABS actuator and electr

ic unit (control unit) transmits wheel speed sensor signal

through CAN communication).

BCM WIPER SW

[Off/Low/High]

×Indicates wiper [Off/Low/High] status (BCM transmits front wiper request signal through

CAN commun

ication).

Brake pres-

sure sensor PRESS SENS

[bar]

Indicates brake fluid pressure value calculated from signal voltage of pressure sensor.

Release

switch RELEASE SW NO

[On/Off]

Indicates [On/Off] status as judged from release switch signal.

ON when brake is depressed.

OFF when brake is not depressed.

RELEASE SW NC

[On/Off] Indicates [On/Off] status as judged from release switch signal.

ON when brake is not depressed.

OFF when brake is depressed.

ICC brake

switch BRAKE SW

[On/Off]

Indicates [On/Off] status as judged from ICC brake switch signal.

Sto p l am p

switchSTOP LAMP SW

[On/Off]

Indicates [On/Off] status as judged from stop lamp switch signal.

Output Data monitored

Item [unit] CAN Description

ICC warning

chime BUZZER O/P

[On/Off]

×

Indicates [On/Off] status of ICC warning chime output.

ICC brake hold

relay STP LMP DRIVE

[On/Off]

Indicates [On/Off] status of brake hold relay drive output.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 16 of 3924

![INFINITI FX35 2008 Service Manual

DESCRIPTIONACS-9

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ACTIVE TEST ITEM LIST

Component DescriptionINFOID:0000000001328807

CAN CommunicationINFOID:0000000001328808

CAN (Contr INFINITI FX35 2008 Service Manual

DESCRIPTIONACS-9

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ACTIVE TEST ITEM LIST

Component DescriptionINFOID:0000000001328807

CAN CommunicationINFOID:0000000001328808

CAN (Contr](/img/42/57017/w960_57017-15.png)

DESCRIPTIONACS-9

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

ACTIVE TEST ITEM LIST

Component DescriptionINFOID:0000000001328807

CAN CommunicationINFOID:0000000001328808

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tric control units are equipped onto a vehicle, and eac h control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT

Refer to LAN-43, "CAN System Specification Chart".

Output CONSULT-III ICC

[ACTIVE TEST]

Item CAN Description

Combination

meter ICC BUZZER 1

×Able to start ICC warning chime with a driving signal from ICC unit.

METER LAMP ×Able to turn ICC system display ON with a driving signal from ICC unit.

ICC brake hold

relay STOP LAMP Able to start ICC brake hold relay with a driving signal from ICC unit.

Booster sole-

noid BOOSTER SOL/V

3

Able to start booster solenoid with a driving signal from ICC unit.

ComponentVehicle-to-

vehicle

distance

control mode Conventional

(fixed speed)

cruise

control mode Brake assis

(with preview function) Description

ICC unit ××× Operates electric throttle control actuator and brake

booster based on that sensor signals and CAN commu-

nication data, then controls vehicle distance.

ICC sensor ×× Irradiates laser beam, and receives reflected laser beam

to measure distance from preceding vehicle.

ECM ××× Transmits throttle position signal and ICC steering switch

signal to ICC unit through CAN communication.

ABS actuator and electric

unit (control unit) ××× Transmits wheel speed sensor signal to ICC unit through

CAN communication.

Brake pressure sensor ×× Detects fluid pressure in master cylinder.

Brake booster ×× Adjusts brake fluid pressure, based on command from

ICC unit.

BCM × Transmit front wiper request signal to ICC unit through

CAN communication.

TCM ×× Transmits gear position signal and output shaft revolu-

tion signal to ICC unit through CAN communication.

Unified meter and A/C amp. ××× Receives ICC system display signal, ICC warning lamp

signal and buzzer output signal from ICC unit through

CAN communication.

ICC brake switch, stop lamp

switch ××× Transmit operating signal to ICC unit when touching

brake pedal. ICC unit cancels cruise system at driver's

brake operation.

ICC brake hold relay × Receives stop lamp driving signal from ICC unit, and

turns stop lamp ON.

Parking brake switch ×× The cruise system is cancelled when applied.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 21 of 3924

![INFINITI FX35 2008 Service Manual

ACS-14

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

OutlineINFOID:0000000001328812

Adjust the laser beam aiming every time the ICC sensor is removed or insta INFINITI FX35 2008 Service Manual

ACS-14

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

OutlineINFOID:0000000001328812

Adjust the laser beam aiming every time the ICC sensor is removed or insta](/img/42/57017/w960_57017-20.png)

ACS-14

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

OutlineINFOID:0000000001328812

Adjust the laser beam aiming every time the ICC sensor is removed or installed.

CAUTION:

Adjust laser beam aiming at a horizontal place as

far as 12 m (39 ft) forward the vehicle can be seen.

Adjust laser beam aiming 5 seconds after starting engine.

Never view ICC sensor integrated un it body window directly during laser beam aiming adjustment.

Follow the CONSULT-III when adju sting the laser beam aiming (laser beam aiming adjustment can-

not be operated without CONSULT-III).

Never ride on vehicle during l aser beam aiming adjustment.

Idle and turn headlamps OFF duri ng laser beam aiming adjustment.

PreparationINFOID:0000000001328813

Adjust the tire pressure to the specified value.

See that there is no load in the vehicle.

Coolant, engine oil filled up to correct level and full fuel tank.

Shift the gear into “P” position and release the parking brake.

Clean the ICC sensor with a soft cloth.

Outline of Adjustment ProcedureINFOID:0000000001328814

1. Set up the ICC target board [KV99110100 (J-45718)].

2. Adjust the sensor following the procedure on CONSUL T-III. (Turn manually the screw for up-down position

adjustment. ICC sensor automatically adjust the right-left position.)

Setting the ICC Target BoardINFOID:0000000001328815

Accurate ICC target board setting is required for the laser beam aiming adjustment.

CAUTION:

ICC system does not function normally if laser beam aiming is not accurate.

ADJUSTING HEIGHT OF THE TARGET

1. Attach a triangle scale at the center.

SKIA6179E

SKIA5974E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 22 of 3924

![INFINITI FX35 2008 Service Manual

LASER BEAM AIMING ADJUSTMENTACS-15

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

2. Adjust the height of the target board stand so that the point of the triangle aims the cent er of INFINITI FX35 2008 Service Manual

LASER BEAM AIMING ADJUSTMENTACS-15

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

2. Adjust the height of the target board stand so that the point of the triangle aims the cent er of](/img/42/57017/w960_57017-21.png)

LASER BEAM AIMING ADJUSTMENTACS-15

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

2. Adjust the height of the target board stand so that the point of the triangle aims the cent er of the ICC sensor.

ADJUSTING THE RIGHT-LEFT POSITION OF THE TARGET

1. Attach a scale [at least 350 mm (14 in) or longer] or stick as

shown in the figure.

2. Suspend a thread with weight on the tip of the thread to 310 mm (12.2 in) left side of the target board from the center of the target

board on top.

SETTING THE TARGET

1. Suspend a thread with weight on tip to splice the cent er of the front and rear bumpers. Then, mark the

center point on the ground as each weight points.

2. Link the front and rear bumpers center points ma rked on the ground, and mark a point 5 m (16.4 ft) ahead

of the sensor, on the extended line of the previous lin k line of the bumper center points. Then, adjust the

position of the target board so that the weight come on the top of the marked point [5 m (16.4 ft) ahead of

the sensor] and face to the vehicle.

3. Adjust the position of the target board so that the extended line that links the center of the rear window glass (the center of the

rear window defogger pattern) and the center of the windshield

(the setting part of the room mirror) align with the weight sus-

pended from the board.

4. Remove the thread suspended to the left side of board and sus- pend a thread with weight on tip on the center of the target

board. Then mark the point of weight on the ground.

SKIA6180E

SKIA1211E

SKIA5975E

SKIA1213E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C