brake light INFINITI M35 2006 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4528 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-101

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

7. CHECK DAYTIME LIGHT RELAY SIGNAL

1. Connect IPDM E/R connector.

2. Install daytime light relay.

3. Turn ignition switch ON.

4. Applied parking brake.

5. Check voltage between IPDM E/R harness connector E9 termi-

nal 58 and ground.

6. Start engine and release parking break. Headlamp switch OFF.

7. Check voltage between IPDM E/R harness connector E9 termi-

nal 58 and ground.

OK or NG

OK >> Check connecting condition daytime relay harness con-

nector.

NG >> GO TO 8.

8. CHECK CAN COMMUNICATIONS

Select “BCM” by CONSULT-II, and perform self-diagnosis for “BCM”.

Displayed self-diagnosis results

NO DTC>>Replace BCM. Refer to BCS-17, "Removal and Installa-

tion of BCM" .

CAN COMM CIRCUIT>>Check BCM CAN communication system.

Refer to BCS-15, "

CAN Communication Inspection

Using CONSULT-II (Self-Diagnosis)" . 58 – Ground : Battery voltage

58 – Ground : Approx. 0V

SKIB4747E

SKIA1039E

Page 4920 of 5621

HARNESS

PG-93

C

D

E

F

G

H

I

J

L

MA

B

PG

Revision: 2006 January2006 M35/M45

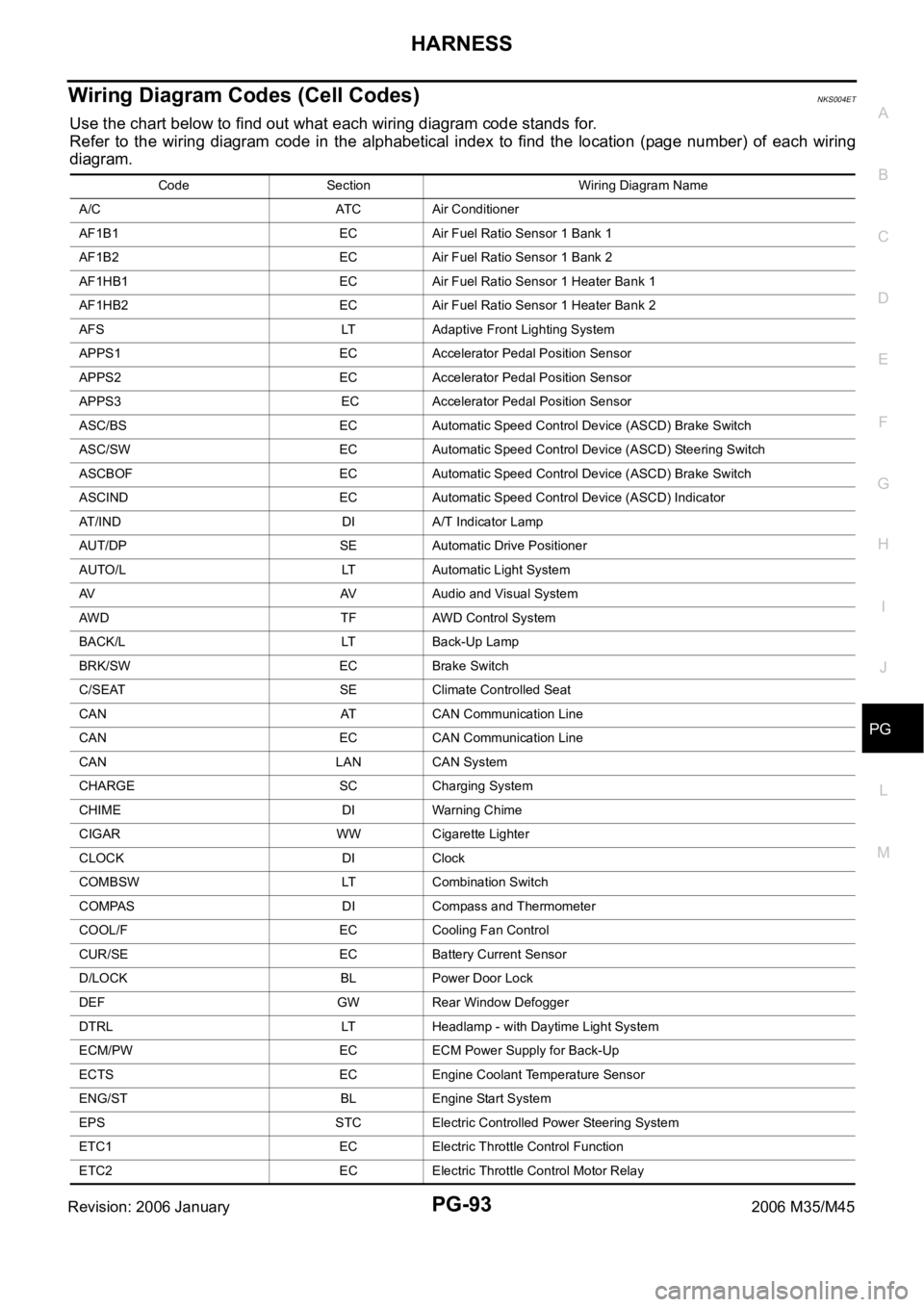

Wiring Diagram Codes (Cell Codes) NKS004ET

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

Code Section Wiring Diagram Name

A/C ATC Air Conditioner

AF1B1 EC Air Fuel Ratio Sensor 1 Bank 1

AF1B2 EC Air Fuel Ratio Sensor 1 Bank 2

AF1HB1 EC Air Fuel Ratio Sensor 1 Heater Bank 1

AF1HB2 EC Air Fuel Ratio Sensor 1 Heater Bank 2

AFS LT Adaptive Front Lighting System

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC Automatic Speed Control Device (ASCD) Brake Switch

ASC/SW EC Automatic Speed Control Device (ASCD) Steering Switch

ASCBOF EC Automatic Speed Control Device (ASCD) Brake Switch

ASCIND EC Automatic Speed Control Device (ASCD) Indicator

AT/IND DI A/T Indicator Lamp

AUT/DP SE Automatic Drive Positioner

AUTO/L LT Automatic Light System

AV AV Audio and Visual System

AWD TF AWD Control System

BACK/L LT Back-Up Lamp

BRK/SW EC Brake Switch

C/SEAT SE Climate Controlled Seat

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CIGAR WW Cigarette Lighter

CLOCK DI Clock

COMBSW LT Combination Switch

COMPAS DI Compass and Thermometer

COOL/F EC Cooling Fan Control

CUR/SE EC Battery Current Sensor

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - with Daytime Light System

ECM/PW EC ECM Power Supply for Back-Up

ECTS EC Engine Coolant Temperature Sensor

ENG/ST BL Engine Start System

EPS STC Electric Controlled Power Steering System

ETC1 EC Electric Throttle Control Function

ETC2 EC Electric Throttle Control Motor Relay

Page 4963 of 5621

PS-10

STEERING WHEEL

Revision: 2006 January2006 M35/M45

STEERING WHEELPFP:48430

On-Vehicle Inspection and ServiceNGS000D8

CHECKING CONDITION OF INSTALLATION

Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

Check steering gear assembly mounting bolts and nut for looseness. Refer to PS-18, "COMPONENTS" .

CHECKING STEERING WHEEL PLAY

Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on

the outer circumference.

When the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

Perform neutral position inspection after wheel alignment. Refer to FSU-6, "Wheel Alignment Inspection"

(2WD), FSU-23, "Wheel Alignment Inspection" (AWD).

Set vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if

steering wheel is not in the neutral position.

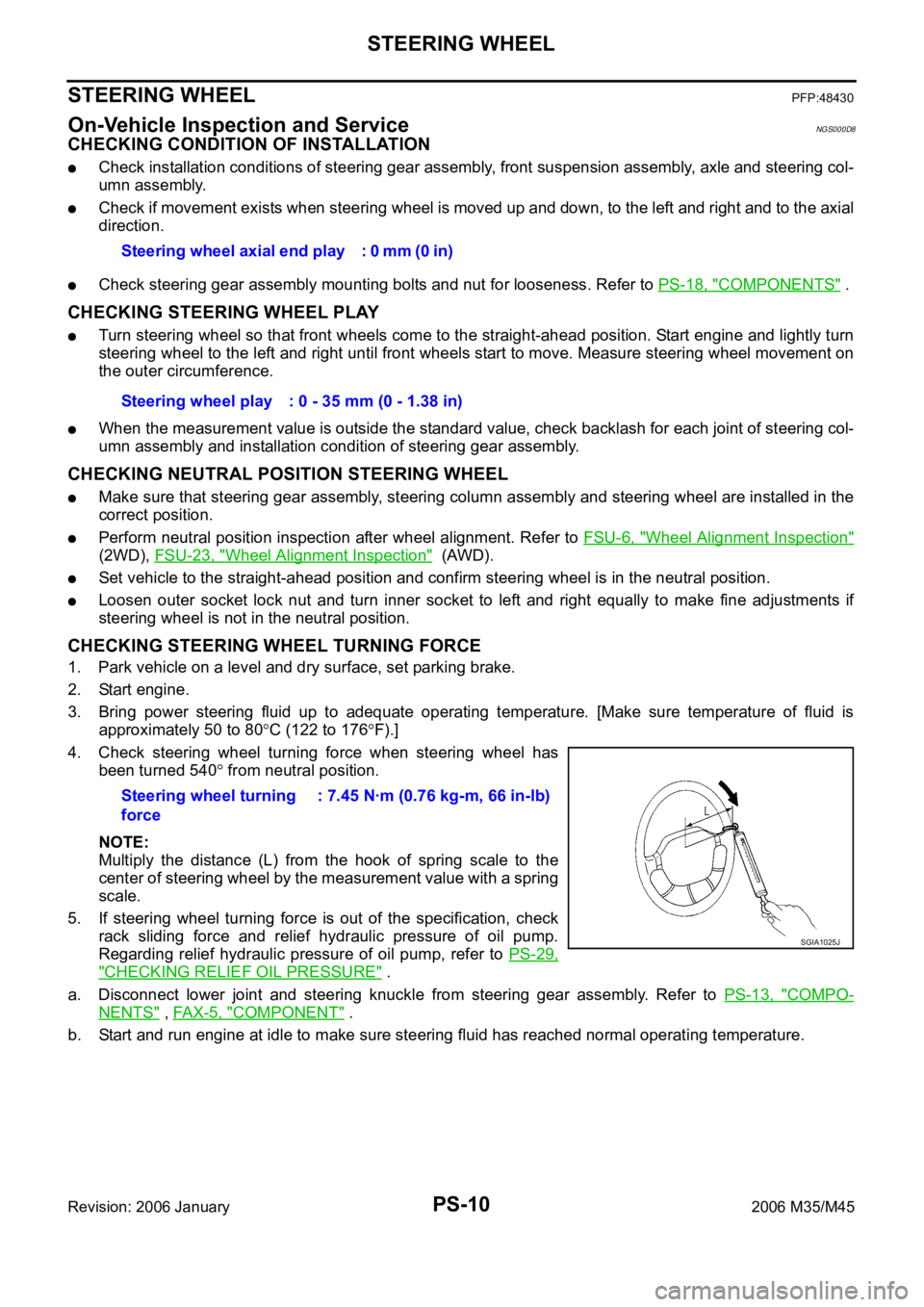

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 50 to 80

C (122 to 176F).]

4. Check steering wheel turning force when steering wheel has

been turned 540

from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring scale to the

center of steering wheel by the measurement value with a spring

scale.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer to PS-29,

"CHECKING RELIEF OIL PRESSURE" .

a. Disconnect lower joint and steering knuckle from steering gear assembly. Refer to PS-13, "

COMPO-

NENTS" , FAX-5, "COMPONENT" .

b. Start and run engine at idle to make sure steering fluid has reached normal operating temperature. Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel turning

force: 7.45 Nꞏm (0.76 kg-m, 66 in-lb)

SGIA1025J

Page 5005 of 5621

RAX-6

WHEEL HUB

Revision: 2006 January2006 M35/M45

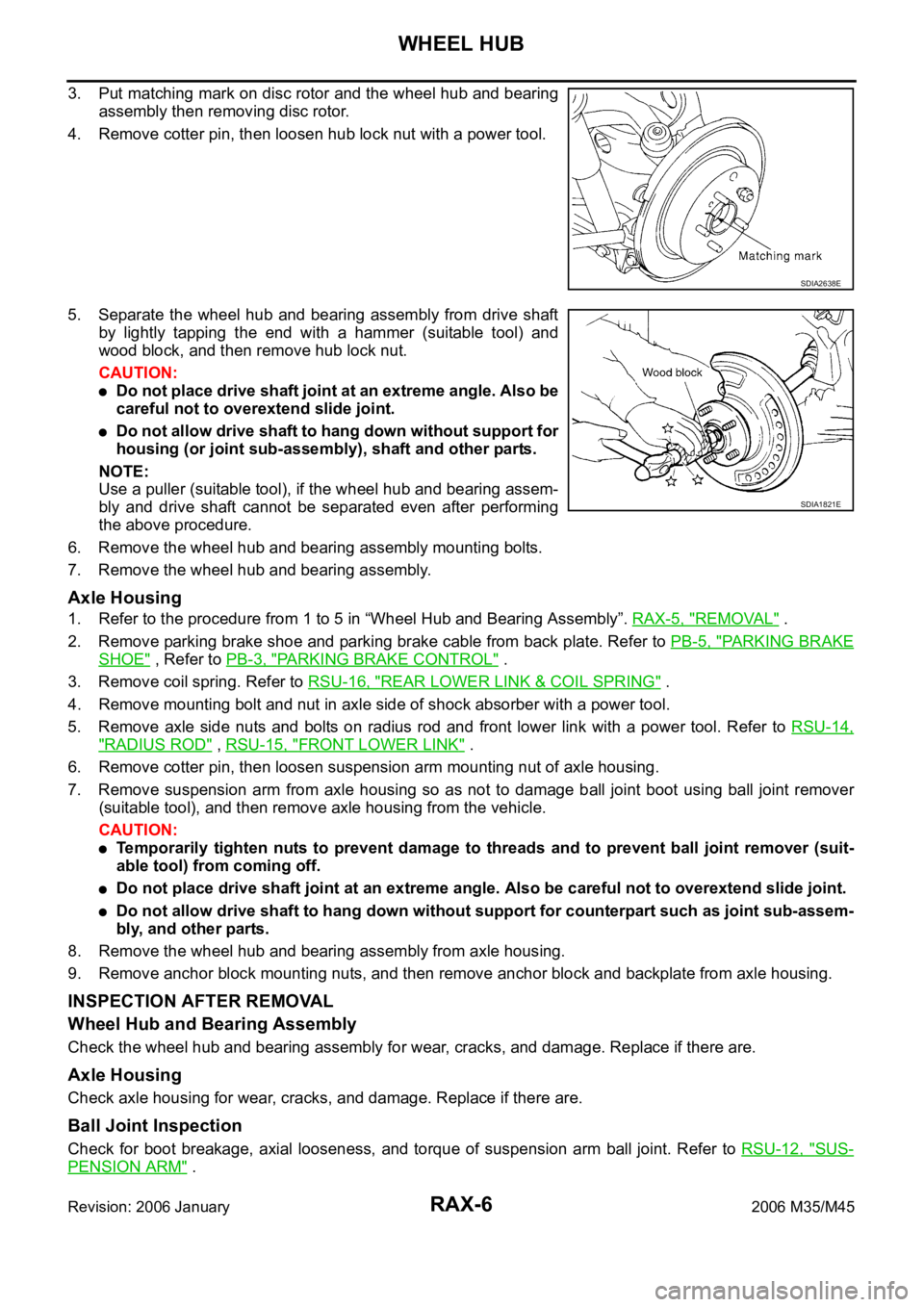

3. Put matching mark on disc rotor and the wheel hub and bearing

assembly then removing disc rotor.

4. Remove cotter pin, then loosen hub lock nut with a power tool.

5. Separate the wheel hub and bearing assembly from drive shaft

by lightly tapping the end with a hammer (suitable tool) and

wood block, and then remove hub lock nut.

CAUTION:

Do not place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for

housing (or joint sub-assembly), shaft and other parts.

NOTE:

Use a puller (suitable tool), if the wheel hub and bearing assem-

bly and drive shaft cannot be separated even after performing

the above procedure.

6. Remove the wheel hub and bearing assembly mounting bolts.

7. Remove the wheel hub and bearing assembly.

Axle Housing

1. Refer to the procedure from 1 to 5 in “Wheel Hub and Bearing Assembly”. RAX-5, "REMOVAL" .

2. Remove parking brake shoe and parking brake cable from back plate. Refer to PB-5, "

PA R K I N G B R A K E

SHOE" , Refer to PB-3, "PARKING BRAKE CONTROL" .

3. Remove coil spring. Refer to RSU-16, "

REAR LOWER LINK & COIL SPRING" .

4. Remove mounting bolt and nut in axle side of shock absorber with a power tool.

5. Remove axle side nuts and bolts on radius rod and front lower link with a power tool. Refer to RSU-14,

"RADIUS ROD" , RSU-15, "FRONT LOWER LINK" .

6. Remove cotter pin, then loosen suspension arm mounting nut of axle housing.

7. Remove suspension arm from axle housing so as not to damage ball joint boot using ball joint remover

(suitable tool), and then remove axle housing from the vehicle.

CAUTION:

Temporarily tighten nuts to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from coming off.

Do not place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for counterpart such as joint sub-assem-

bly, and other parts.

8. Remove the wheel hub and bearing assembly from axle housing.

9. Remove anchor block mounting nuts, and then remove anchor block and backplate from axle housing.

INSPECTION AFTER REMOVAL

Wheel Hub and Bearing Assembly

Check the wheel hub and bearing assembly for wear, cracks, and damage. Replace if there are.

Axle Housing

Check axle housing for wear, cracks, and damage. Replace if there are.

Ball Joint Inspection

Check for boot breakage, axial looseness, and torque of suspension arm ball joint. Refer to RSU-12, "SUS-

PENSION ARM" .

SDIA2638E

SDIA1821E

Page 5112 of 5621

PRE-CRASH SEAT BELT

SB-13

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

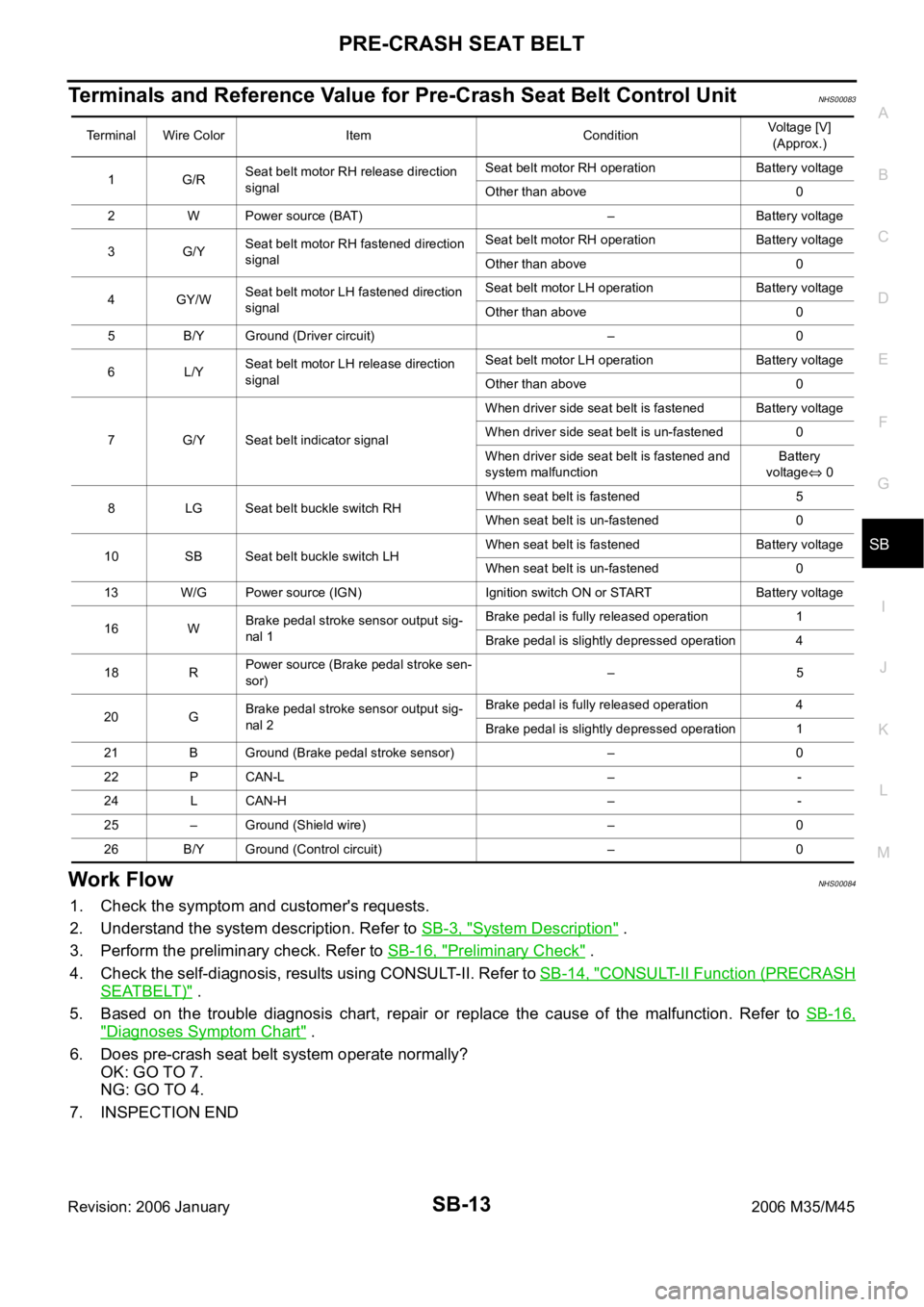

Terminals and Reference Value for Pre-Crash Seat Belt Control UnitNHS00083

Work FlowNHS00084

1. Check the symptom and customer's requests.

2. Understand the system description. Refer to SB-3, "

System Description" .

3. Perform the preliminary check. Refer to SB-16, "

Preliminary Check" .

4. Check the self-diagnosis, results using CONSULT-II. Refer to SB-14, "

CONSULT-II Function (PRECRASH

SEATBELT)" .

5. Based on the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to SB-16,

"Diagnoses Symptom Chart" .

6. Does pre-crash seat belt system operate normally?

OK: GO TO 7.

NG: GO TO 4.

7. INSPECTION END

Terminal Wire Color Item ConditionVoltage [V]

(Approx.)

1G/RSeat belt motor RH release direction

signalSeat belt motor RH operation Battery voltage

Other than above 0

2 W Power source (BAT) – Battery voltage

3G/YSeat belt motor RH fastened direction

signalSeat belt motor RH operation Battery voltage

Other than above 0

4GY/WSeat belt motor LH fastened direction

signalSeat belt motor LH operation Battery voltage

Other than above 0

5 B/Y Ground (Driver circuit) – 0

6L/YSeat belt motor LH release direction

signalSeat belt motor LH operation Battery voltage

Other than above 0

7 G/Y Seat belt indicator signalWhen driver side seat belt is fastened Battery voltage

When driver side seat belt is un-fastened 0

When driver side seat belt is fastened and

system malfunctionBattery

voltage

0

8 LG Seat belt buckle switch RHWhen seat belt is fastened 5

When seat belt is un-fastened 0

10 SB Seat belt buckle switch LHWhen seat belt is fastened Battery voltage

When seat belt is un-fastened 0

13 W/G Power source (IGN) Ignition switch ON or START Battery voltage

16 WBrake pedal stroke sensor output sig-

nal 1Brake pedal is fully released operation 1

Brake pedal is slightly depressed operation 4

18 RPower source (Brake pedal stroke sen-

sor)

–5

20 GBrake pedal stroke sensor output sig-

nal 2Brake pedal is fully released operation 4

Brake pedal is slightly depressed operation 1

21 B Ground (Brake pedal stroke sensor) – 0

22 P CAN-L – -

24 L CAN-H – -

25 – Ground (Shield wire) – 0

26 B/Y Ground (Control circuit) – 0

Page 5501 of 5621

TF-36

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

3. CHECK SYSTEM FOR AWD SOLENOID

Perform trouble diagnosis for AWD solenoid system. Refer to TF-28, "

AWD Solenoid" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4. CHECK ELECTRIC CONTROLLED COUPLING

1. Turn ignition switch “OFF”.

2. Set the selector lever to “N” (neutral) position and disengage the parking brake.

3. Lift up the vehicle.

4. Rotate the rear propeller shaft by hand.

5. Hold front propeller shaft lightly.

Does front propeller shaft rotate?

YES >> Replace electric controlled coupling for mechanical malfunction (clutch sticking etc.). Refer to TF-

45, "Disassembly and Assembly" .

NO >> GO TO 5.

5. SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

6. CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e s" .

OK or NG

OK >>INSPECTION END

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

Vehicle Does Not Enter AWD Mode Even Though AWD Warning Lamp Turned to

OFF

NDS000DX

DIAGNOSTIC PROCEDURE

1. CHECK AWD WARNING LANP

Turn ignition switch “ON”. (Do not start engine.)

Does AWD warning lamp turn on?

YES >> GO TO 2.

NO >> Go to TF-33, "

AWD Warning Lamp Does Not Turn ON When The Ignition Switch Is Turned to ON"

.

2. CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-22, "

SELF-DIAG RESULT MODE" .

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-32, "CAN Communication

Line" .

NO >> GO TO 3.