steering wheel INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4779 of 5621

MA-2Revision: 2006 January2006 M35/M45 ROTOR ................................................................ 36

CALIPER ............................................................. 36

PAD ..................................................................... 36

Checking Steering Gear and Linkage ..................... 36

STEERING GEAR ............................................... 36

STEERING LINKAGE .......................................... 36

Checking Power Steering Fluid and Lines .............. 37

Axle and Suspension Parts ..................................... 37

Drive Shaft .............................................................. 38

Lubricating Locks, Hinges and Hood Latch ............ 38

Checking Seat Belt, Buckles, Retractors, Anchors

and Adjusters .......................................................... 39

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 40

Standard and Limit .................................................. 40

BELT DEFLECTION AND TENSION (VQ35DE) ... 40

BELT DEFLECTION AND TENSION (VK45DE) ... 40

ENGINE COOLANT CAPACITY (APPROXI-MATE) (VQ35DE) ................................................ 40

ENGINE COOLANT CAPACITY (APPROXI-

MATE) (VK45DE) ................................................. 40

RADIATOR ........................................................... 40

ENGINE OIL CAPACITY (APPROXIMATE)

(VQ35DE) ............................................................ 40

ENGINE OIL CAPACITY (APPROXIMATE)

(VK45DE) ............................................................. 41

SPARK PLUG (PLATINUM-TIPPED TYPE)

(VQ35DE) ............................................................ 41

SPARK PLUG (PLATINUM-TIPPED TYPE)

(VK45DE) ............................................................. 41

WHEEL BALANCE .............................................. 41

Page 4782 of 5621

GENERAL MAINTENANCE

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

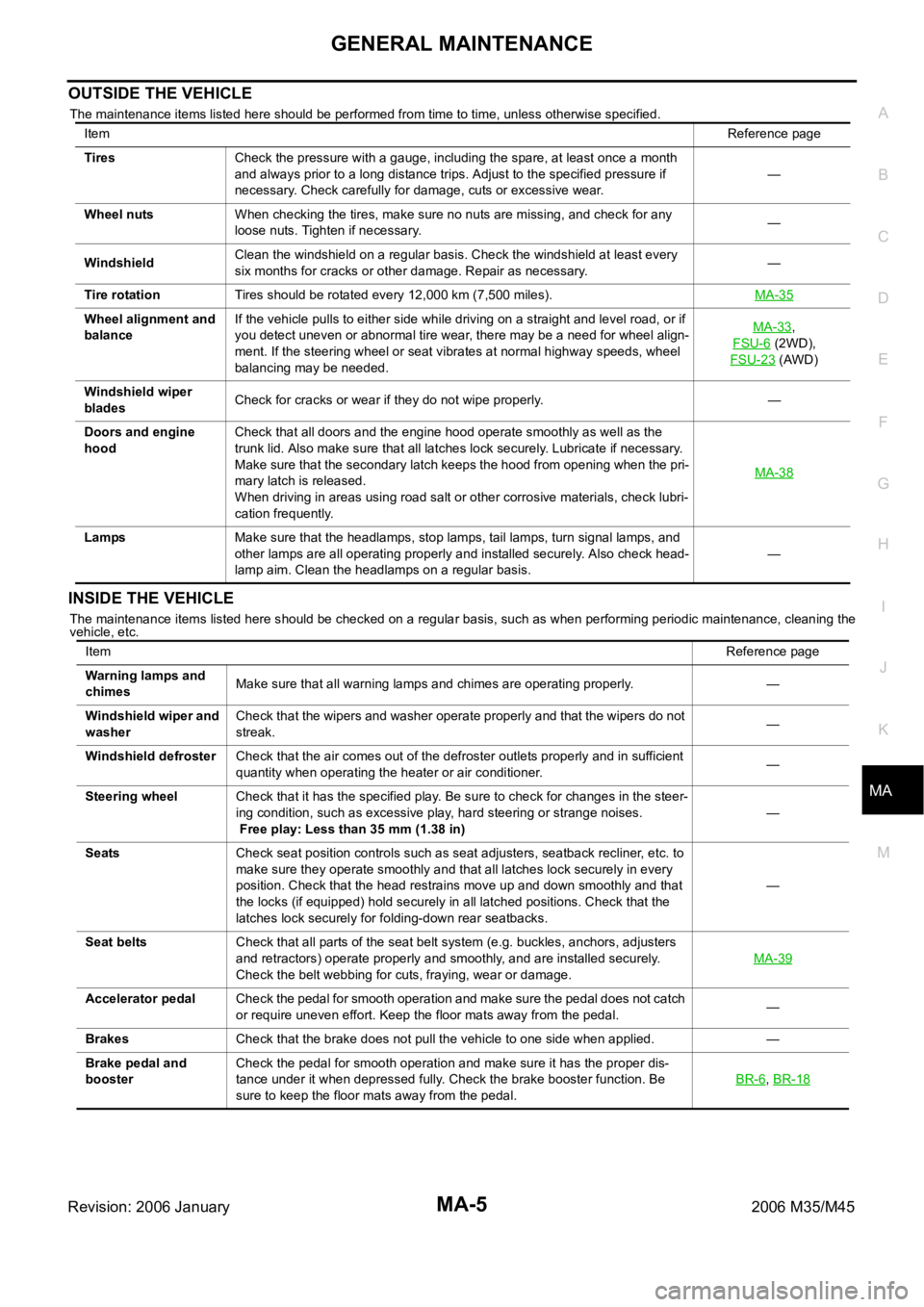

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.ItemReference page

TiresCheck the pressure with a gauge, including the spare, at least once a month

and always prior to a long distance trips. Adjust to the specified pressure if

necessary. Check carefully for damage, cuts or excessive wear.—

Wheel nutsWhen checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.—

WindshieldClean the windshield on a regular basis. Check the windshield at least every

six months for cracks or other damage. Repair as necessary.—

Tire rotationTires should be rotated every 12,000 km (7,500 miles).MA-35

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel

balancing may be needed.MA-33,

FSU-6

(2WD),

FSU-23

(AWD)

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly. —

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the

trunk lid. Also make sure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the pri-

mary latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently.MA-38

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

ItemReference page

Warning lamps and

chimesMake sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.—

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner.—

Steering wheelCheck that it has the specified play. Be sure to check for changes in the steer-

ing condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for folding-down rear seatbacks.—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.MA-39

Accelerator pedalCheck the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal.—

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

boosterCheck the pedal for smooth operation and make sure it has the proper dis-

tance under it when depressed fully. Check the brake booster function. Be

sure to keep the floor mats away from the pedal.BR-6

, BR-18

Page 4814 of 5621

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

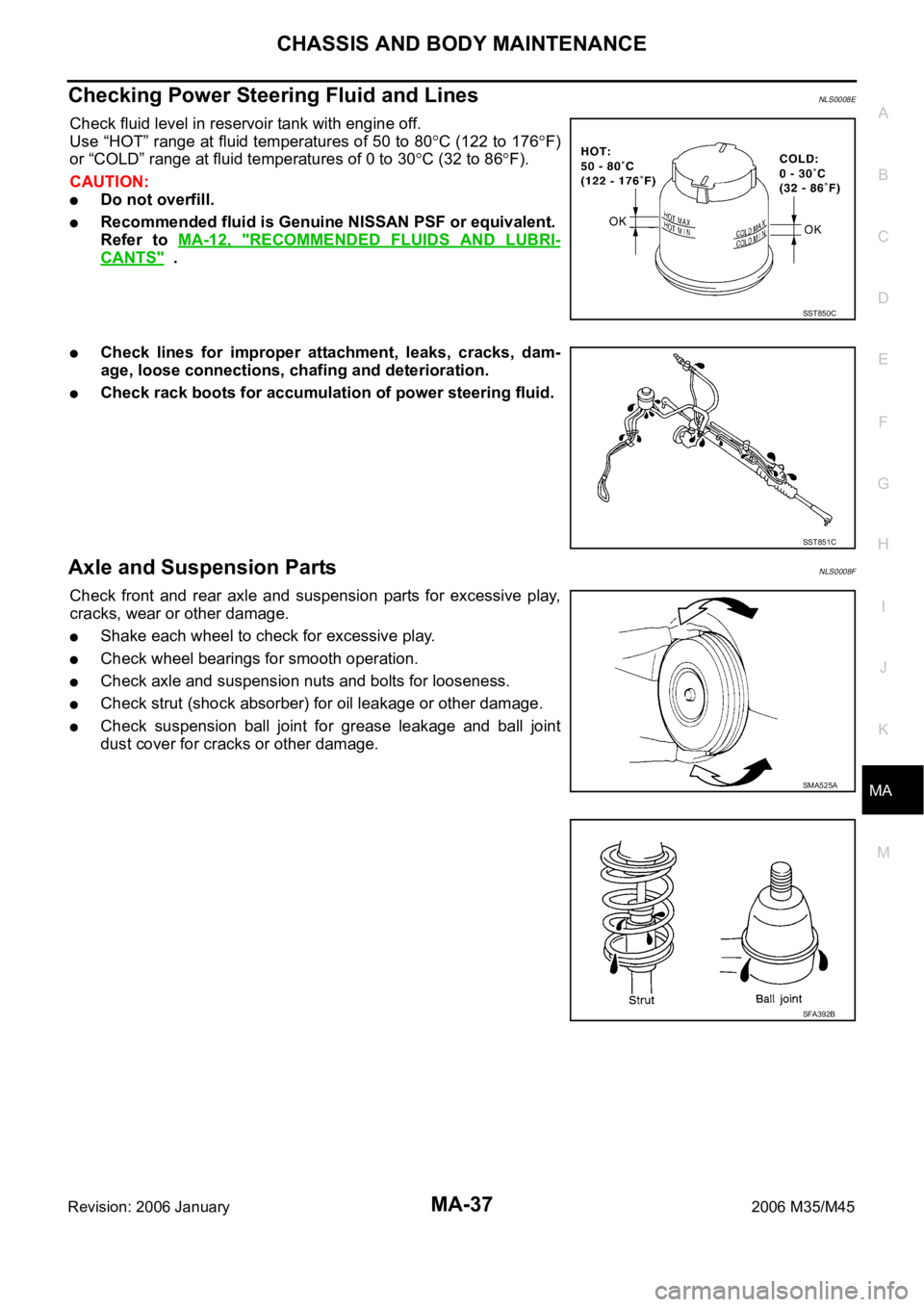

Checking Power Steering Fluid and LinesNLS0008E

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80

C (122 to 176F)

or “COLD” range at fluid temperatures of 0 to 30

C (32 to 86F).

CAUTION:

Do not overfill.

Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to MA-12, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS" .

Check lines for improper attachment, leaks, cracks, dam-

age, loose connections, chafing and deterioration.

Check rack boots for accumulation of power steering fluid.

Axle and Suspension PartsNLS0008F

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

Shake each wheel to check for excessive play.

Check wheel bearings for smooth operation.

Check axle and suspension nuts and bolts for looseness.

Check strut (shock absorber) for oil leakage or other damage.

Check suspension ball joint for grease leakage and ball joint

dust cover for cracks or other damage.

SST850C

SST851C

SMA525A

SFA392B

Page 4942 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PR-3

C

E

F

G

H

I

J

K

L

MA

B

PR

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNDS000E9

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: Applicable Reference pageFront

PR-4—

—

—

—

PR-4PR-5

NVH in FFD and RFD section

NVH in FAX, RAX, FSU and RSU section

NVH in WT section

NVH in WT section

NVH in RAX section

NVH in BR section

NVH in PS section

RearPR-6PR-10—

PR-7—

PR-6PR-9

Possible cause and SUSPECTED PARTS

Uneven rotating torque

Center bearing improper installation

Excessive center bearing axial end play

Center bearing mounting (insulator) cracks, damage or deterioration

Excessive joint angle

Rotation imbalance

Excessive runout

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomNoiseShake

Vibration

Page 4954 of 5621

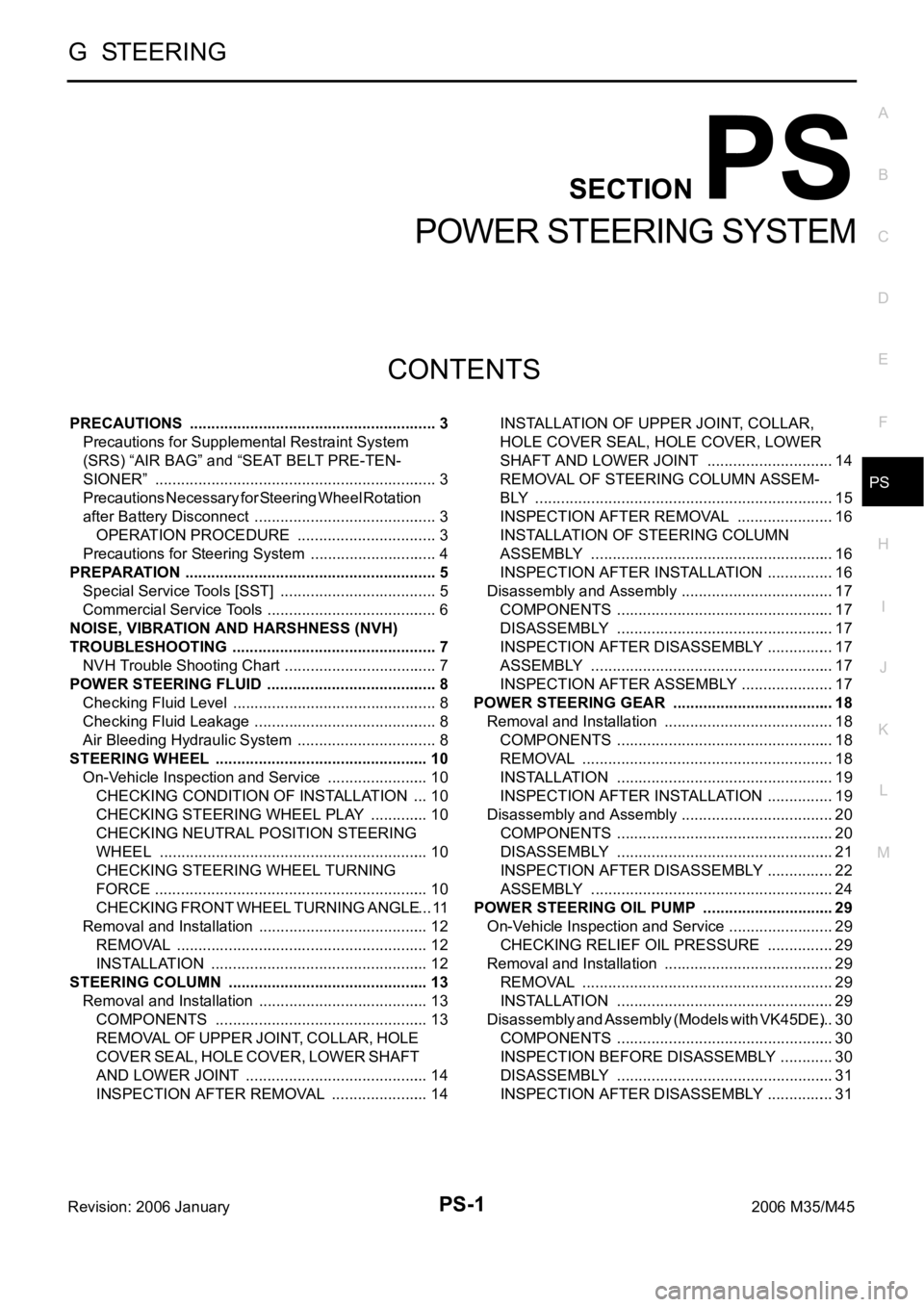

PS-1

POWER STEERING SYSTEM

G STEERING

CONTENTS

C

D

E

F

H

I

J

K

L

M

SECTION PS

A

B

PS

Revision: 2006 January2006 M35/M45

POWER STEERING SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 3

OPERATION PROCEDURE ................................. 3

Precautions for Steering System .............................. 4

PREPARATION ........................................................... 5

Special Service Tools [SST] ..................................... 5

Commercial Service Tools ........................................ 6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Trouble Shooting Chart .................................... 7

POWER STEERING FLUID ........................................ 8

Checking Fluid Level ...........................................

..... 8

Checking Fluid Leakage ........................................... 8

Air Bleeding Hydraulic System ................................. 8

STEERING WHEEL .................................................. 10

On-Vehicle Inspection and Service ........................ 10

CHECKING CONDITION OF INSTALLATION .... 10

CHECKING STEERING WHEEL PLAY .............. 10

CHECKING NEUTRAL POSITION STEERING

WHEEL ............................................................... 10

CHECKING STEERING WHEEL TURNING

FORCE ................................................................ 10

CHECKING FRONT WHEEL TURNING ANGLE .... 11

Removal and Installation ........................................ 12

REMOVAL ........................................................

... 12

INSTALLATION ................................................... 12

STEERING COLUMN ............................................... 13

Removal and Installation ........................................ 13

COMPONENTS .................................................. 13

REMOVAL OF UPPER JOINT, COLLAR, HOLE

COVER SEAL, HOLE COVER, LOWER SHAFT

AND LOWER JOINT ........................................... 14

INSPECTION AFTER REMOVAL ....................... 14INSTALLATION OF UPPER JOINT, COLLAR,

HOLE COVER SEAL, HOLE COVER, LOWER

SHAFT AND LOWER JOINT .............................. 14

REMOVAL OF STEERING COLUMN ASSEM-

BLY ...................................................................... 15

INSPECTION AFTER REMOVAL ....................... 16

INSTALLATION OF STEERING COLUMN

ASSEMBLY ......................................................... 16

INSPECTION AFTER INSTALLATION ................ 16

Disassembly and Assembly .................................... 17

COMPONENTS ................................................... 17

DISASSEMBLY ................................................... 17

INSPECTION AFTER DISASSEMBLY ................ 17

ASSEMBLY ......................................................... 17

INSPECTION AFTER ASSEMBLY ...................... 17

POWER STEERING GEAR ...................................... 18

Removal and Installation ........................................ 18

COMPONENTS ................................................... 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ................ 19

Disassembly and Assembly .................................

... 20

COMPONENTS ................................................... 20

DISASSEMBLY ................................................... 21

INSPECTION AFTER DISASSEMBLY ................ 22

ASSEMBLY ......................................................... 24

POWER STEERING OIL PUMP ............................... 29

On-Vehicle Inspection and Service ......................... 29

CHECKING RELIEF OIL PRESSURE ................ 29

Removal and Installation ........................................ 29

REMOVAL ........................................................

... 29

INSTALLATION ................................................... 29

Disassembly and Assembly (Models with VK45DE) ... 30

COMPONENTS ................................................... 30

INSPECTION BEFORE DISASSEMBLY ............. 30

DISASSEMBLY ................................................... 31

INSPECTION AFTER DISASSEMBLY ................ 31

Page 4955 of 5621

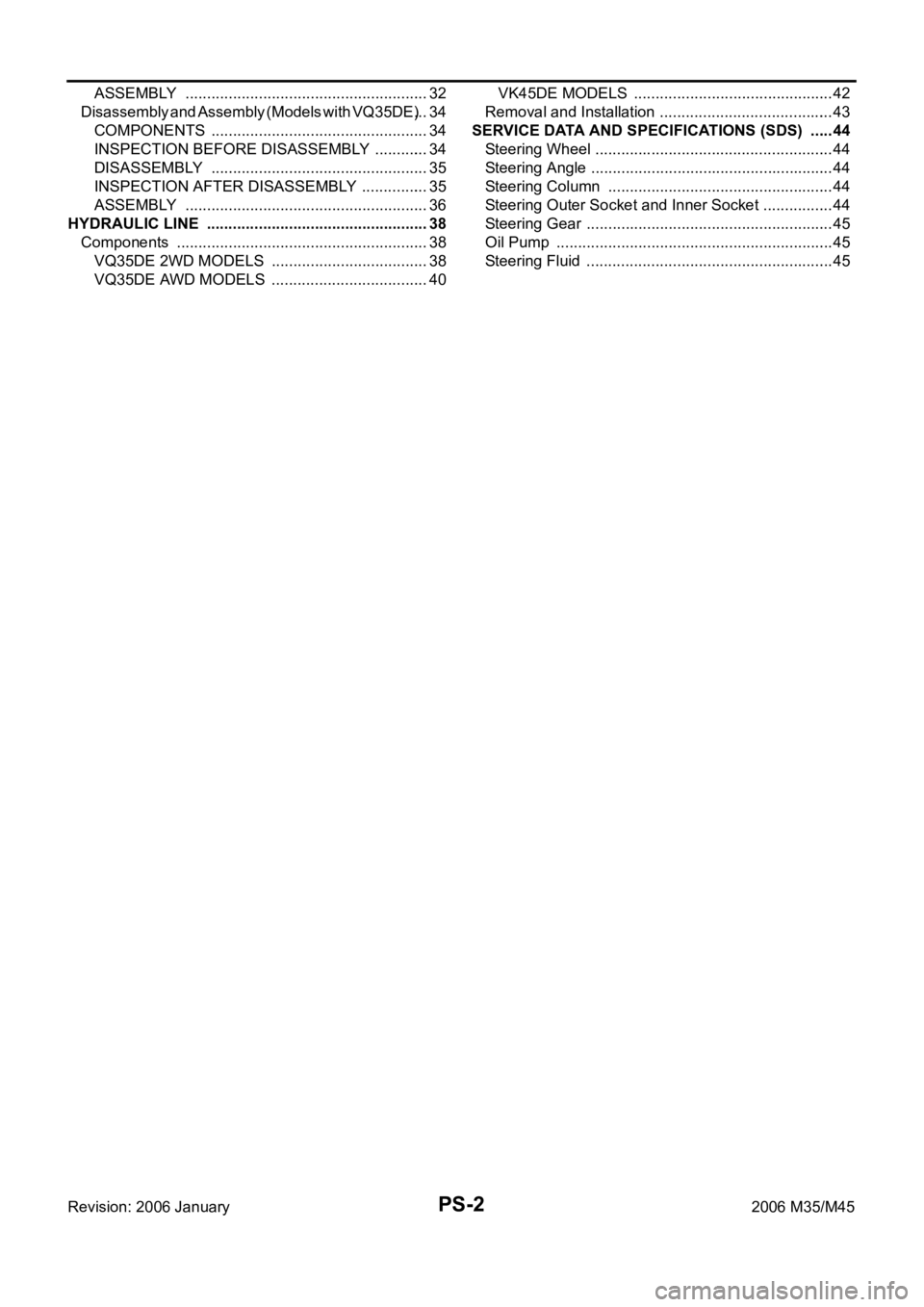

PS-2Revision: 2006 January2006 M35/M45 ASSEMBLY ......................................................... 32

Disassembly and Assembly (Models with VQ35DE) ... 34

COMPONENTS ................................................... 34

INSPECTION BEFORE DISASSEMBLY ............. 34

DISASSEMBLY ................................................... 35

INSPECTION AFTER DISASSEMBLY ................ 35

ASSEMBLY ......................................................... 36

HYDRAULIC LINE .................................................

... 38

Components ........................................................... 38

VQ35DE 2WD MODELS ..................................... 38

VQ35DE AWD MODELS ..................................... 40VK45DE MODELS ............................................... 42

Removal and Installation ......................................... 43

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 44

Steering Wheel ........................................................ 44

Steering Angle ......................................................... 44

Steering Column ..................................................... 44

Steering Outer Socket and Inner Socket ................. 44

Steering Gear .......................................................... 45

Oil Pump ................................................................. 45

Steering Fluid .......................................................... 45

Page 4956 of 5621

PRECAUTIONS

PS-3

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NGS000CZ

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions Necessary for Steering Wheel Rotation after Battery DisconnectNGS000D0

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK

position, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-II.

Page 4957 of 5621

PS-4

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Steering SystemNGS000D1

In case of removing steering gear assembly, make the final tightening with grounded and unloaded vehi-

cle condition, and then check wheel alignment.

Observe the following precautions when disassembling.

–Before disassembly, thoroughly clean the outside of the unit.

–Disassembly should be done in a clean work area. It is important to prevent the internal parts from becom-

ing contaminated by dirt or other foreign matter.

–For easier and proper assembly, place disassembled parts in order on a parts rack.

–Use nylon cloth or paper towels to clean the parts; common shop rags can leave lint that might interfere

with their operation.

–Do not reuse non-reusable parts.

–Before assembling, apply the specified grease to the directed parts.

Page 4958 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

PS-5

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NGS000D2

The actual shapes of Kent-Moore tools may differ from those of sp INFINITI M35 2006 Factory Service Manual PREPARATION

PS-5

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NGS000D2

The actual shapes of Kent-Moore tools may differ from those of sp](/img/42/57023/w960_57023-4957.png)

PREPARATION

PS-5

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NGS000D2

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST27180001

(J-25726-A)

Steering wheel pullerRemoving steering wheel

ST3127S000

(See J-25765-A)

Preload gauge

1. GG9103000

(J-25765-A)

To r q u e w r e n c h

2. HT62940000

(–)

Socket adapter

3. HT62900000

(–)

Socket adapterInspecting of rotating torque for ball joint

KV48104400

(–)

Teflon ring correcting tool

a: 50 mm (1.97 in) dia.

b: 36 mm (1.42 in) dia.

c: 100 mm (3.94 in)Installing rack Teflon ring

KV48103400

(–)

Preload adapterInspecting rotating torque

KV48103500

(J-26357)

Pressure gaugeMeasuring oil pump relief pressure

S-NT544

S-NT541

S-NT550

ZZA0824D

S-NT547

Page 4960 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PS-7

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Trouble Shooting ChartNGS000D4

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

PS-8PS-8PS-23PS-23PS-23PS-8PS-10PS-10

EM-15

,EM-174PS-10—

PS-22PS-16PS-13PS-20

NVH in PR section

NVH in RFD section

NVH in FAX, RAX, FSU, RSU section

NVH in WT section

NVH in WT section

NVH in FAX section

NVH in BR section

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer socket ball joint swinging force

Outer socket ball joint rotating torque

Outer socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom SteeringNoise

Shake

Vibration

Shimmy

Judder