Fuse INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 2930 of 5621

![INFINITI M35 2006 Factory Service Manual DTC P2A00, P2A03 A/F SENSOR 1

EC-1387

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P2A00, P2A03 A/F SENSOR 1PFP:22693

Component DescriptionNBS005PD

The air fuel ratio (A/F INFINITI M35 2006 Factory Service Manual DTC P2A00, P2A03 A/F SENSOR 1

EC-1387

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P2A00, P2A03 A/F SENSOR 1PFP:22693

Component DescriptionNBS005PD

The air fuel ratio (A/F](/img/42/57023/w960_57023-2929.png)

DTC P2A00, P2A03 A/F SENSOR 1

EC-1387

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P2A00, P2A03 A/F SENSOR 1PFP:22693

Component DescriptionNBS005PD

The air fuel ratio (A/F) sensor 1 is a planar dual-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is the combination of a

Nernst concentration cell (sensor cell) with an oxygen-pump cell,

which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range (0.7 <

< air).

The exhaust gas components diffuse through the diffusion gap at the

electrode of the oxygen pump and Nernst concentration cell, where

they are brought to thermodynamic balance.

An electronic circuit controls the pump current through the oxygen-

pump cell so that the composition of the exhaust gas in the diffusion

gap remains constant at = 1. Therefore, the A/F sensor 1 is able to

indicate air/fuel ratio by this pumping of current. In addition, a heater

is integrated in the sensor to ensure the required operating tempera-

ture of 700 - 800

C (1,292 - 1,472F).

CONSULT-II Reference Value in Data Monitor ModeNBS005PE

Specification data are reference values.

On Board Diagnosis LogicNBS005PF

To judge the malfunction, the A/F signal computed by ECM from the A/F sensor 1 signal is monitored not to be

shifted to LEAN side or RICH side.

DTC Confirmation ProcedureNBS005PG

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON and select “SELF-LEARNING CONT” in “WORK SUPPORT” mode with CON-

SULT-II.

SEF579Z

SEF580Z

MONITOR ITEM CONDITION SPECIFICATION

A/F SEN1 (B1)

A/F SEN1 (B2)

Engine: After warming up Maintaining engine speed at 2,000 rpm Fluctuates around 1.5 V

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P2A00

2A00

(Bank 1)

Air fuel ratio (A/F) sensor 1

circuit range/performance

The output voltage computed by ECM from the

A/F sensor 1 signal is shifted to the lean side

for a specified period.

The A/F signal computed by ECM from the A/F

sensor 1 signal is shifted to the rich side for a

specified period.

A/F sensor 1

A/F sensor 1 heater

Fuel pressure

Fuel injector

Intake air leaks P2A03

2A03

(Bank 2)

Page 2938 of 5621

![INFINITI M35 2006 Factory Service Manual DTC P2A00, P2A03 A/F SENSOR 1

EC-1395

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

5. CHECK HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect A/F sensor 1 harness c INFINITI M35 2006 Factory Service Manual DTC P2A00, P2A03 A/F SENSOR 1

EC-1395

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

5. CHECK HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect A/F sensor 1 harness c](/img/42/57023/w960_57023-2937.png)

DTC P2A00, P2A03 A/F SENSOR 1

EC-1395

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

5. CHECK HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect A/F sensor 1 harness connector.

3. Check harness connector for water.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace harness connector.

6. CHECK A/F SENSOR 1 POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between A/F sensor 1 terminal 3 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 8.

NG >> GO TO 7.

7. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E12, F3

IPDM E/R harness connector E7

15A fuse

Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

: Vehicle front 1. A/F sensor 1 (bank 2)

harness connector2. A/F sensor 1 (bank 1)

harness connector

Water should not exit.

PBIB2715E

Voltage: Battery voltage

PBIB1683E

Page 2961 of 5621

![INFINITI M35 2006 Factory Service Manual EC-1418

[VK45DE]

IGNITION SIGNAL

Revision: 2006 January2006 M35/M45

3. Check resistance between ignition coil terminals as follows.

4. If NG, replace ignition coil with power transistor.

If OK, go to INFINITI M35 2006 Factory Service Manual EC-1418

[VK45DE]

IGNITION SIGNAL

Revision: 2006 January2006 M35/M45

3. Check resistance between ignition coil terminals as follows.

4. If NG, replace ignition coil with power transistor.

If OK, go to](/img/42/57023/w960_57023-2960.png)

EC-1418

[VK45DE]

IGNITION SIGNAL

Revision: 2006 January2006 M35/M45

3. Check resistance between ignition coil terminals as follows.

4. If NG, replace ignition coil with power transistor.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Reconnect all harness connectors disconnected.

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-II to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

8. Start engine.

9. After engine stalls, crank it two or three times to release all fuel

pressure.

10. Turn ignition switch OFF.

11. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

12. Remove ignition coil and spark plug of the cylinder to be checked.

13. Crank engine for five seconds or more to remove combustion gas in the cylinder.

14. Connect spark plug and harness connector to ignition coil.

15. Fix ignition coil using a rope etc. with gap of 13 - 17 mm

between the edge of the spark plug and grounded metal portion

as shown in the figure.

16. Crank engine for about three seconds, and check whether spark

is generated between the spark plug and the grounded metal

portion.

CAUTION:

Do not approach to the spark plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the electrical discharge voltage

becomes 20kV or more.

It might cause to damage the ignition coil if the gap of more than 17 mm is taken.

NOTE:

When the gap is less than 13 mm, the spark might be generated even if the coil is malfunctioning.

17. If NG, replace ignition coil with power transistor.

CONDENSER

1. Turn ignition switch OFF.

2. Disconnect condenser harness connector.

Terminal No. (Polarity) Resistance [at 25C (77F)]

1 and 2 Except 0 or

1 and 3

Except 0

2 and 3

Spark should be generated.

PBIB0847E

PBIB2697E

PBIB2325E

Page 2967 of 5621

![INFINITI M35 2006 Factory Service Manual EC-1424

[VK45DE]

FUEL INJECTOR

Revision: 2006 January2006 M35/M45

4. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors M72, F102

Harness connectors F52, F251

Harness connectors F51, F INFINITI M35 2006 Factory Service Manual EC-1424

[VK45DE]

FUEL INJECTOR

Revision: 2006 January2006 M35/M45

4. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors M72, F102

Harness connectors F52, F251

Harness connectors F51, F](/img/42/57023/w960_57023-2966.png)

EC-1424

[VK45DE]

FUEL INJECTOR

Revision: 2006 January2006 M35/M45

4. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors M72, F102

Harness connectors F52, F251

Harness connectors F51, F271

Fuse block (J/B) connector M4

15A fuse

Harness for open or short between harness connector F51 and fuse

Harness for open or short between harness connector F52 and fuse

Harness for open or short between harness connector F51 and ECM

Harness for open or short between harness connector F52 and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

5. CHECK FUNCTION OF FUEL INJECTOR-II

Provide battery voltage between the following terminals, and then

interrupt it. Listen to each fuel injector operating sound.

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

Cylinder Harness connectorterminal

(+) (–)

1

F251 53

32

51

76

2

F271 53

42

61

86

Operating sound should exist.

PBIB2449E

Page 2973 of 5621

![INFINITI M35 2006 Factory Service Manual EC-1430

[VK45DE]

FUEL PUMP

Revision: 2006 January2006 M35/M45

3. CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

Check voltage between IPDM E/R terminal 40 and ground with

CONSULT-II or tester.

OK or INFINITI M35 2006 Factory Service Manual EC-1430

[VK45DE]

FUEL PUMP

Revision: 2006 January2006 M35/M45

3. CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

Check voltage between IPDM E/R terminal 40 and ground with

CONSULT-II or tester.

OK or](/img/42/57023/w960_57023-2972.png)

EC-1430

[VK45DE]

FUEL PUMP

Revision: 2006 January2006 M35/M45

3. CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

Check voltage between IPDM E/R terminal 40 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 15.

4. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E108, M15

Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

5. CHECK CONDENSER POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Disconnect condenser harness connector.

4. Turn ignition switch ON.

5. Check voltage between condenser terminal 1 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 9.

NG >> GO TO 6.

6. CHECK 15A FUSE

1. Turn ignition switch OFF.

2. Disconnect 15A fuse.

3. Check 15A fuse.

OK or NG

OK >> GO TO 7.

NG >> Replace fuse.Voltage: Battery voltage

PBIB1926E

Voltage: Battery voltage should exist for 1 second

after ignition switch is turned ON.

PBIB0624E

Page 2988 of 5621

![INFINITI M35 2006 Factory Service Manual ICC BRAKE SWITCH

EC-1445

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

4. DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E102

10A fuse

Harness for o INFINITI M35 2006 Factory Service Manual ICC BRAKE SWITCH

EC-1445

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

4. DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E102

10A fuse

Harness for o](/img/42/57023/w960_57023-2987.png)

ICC BRAKE SWITCH

EC-1445

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

4. DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E102

10A fuse

Harness for open or short between ICC brake switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

5. CHECK ICC BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ICC brake switch terminal 2 and ECM terminal 108.

Refer Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E108, M15

Harness for open or short between ICC brake switch and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

7. CHECK ICC BRAKE SWITCH

Refer to EC-1447, "

Component Inspection" .

OK or NG

OK >> GO TO 15.

NG >> Replace ICC brake switch.

8. CHECK DTC WITH ICC UNIT

Refer to ACS-39, "

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS" .

OK or NG

OK >> GO TO 9.

NG >> Repair or replace.Continuity should exist.

Page 2990 of 5621

![INFINITI M35 2006 Factory Service Manual ICC BRAKE SWITCH

EC-1447

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

10. DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E101

10A fuse

Harness for INFINITI M35 2006 Factory Service Manual ICC BRAKE SWITCH

EC-1447

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

10. DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E101

10A fuse

Harness for](/img/42/57023/w960_57023-2989.png)

ICC BRAKE SWITCH

EC-1447

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

10. DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E101

10A fuse

Harness for open or short between battery and stop lamp switch

Harness for open or short between battery and ICC brake hold relay

>> Repair open circuit or short to ground or short to power in harness or connectors.

11 . CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between the following;

ECM terminal 101 and stop lamp switch terminal 2,

ECM terminal 101 and ICC brake hold relay terminal 5.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> GO TO 12.

12. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E108, M15

Harness for open or short between ECM and stop lamp switch

Harness for open or short between ECM and ICC brake hold relay

>> Repair open circuit or short to ground or short to power in harness or connectors.

13. CHECK STOP LAMP SWITCH

Refer to EC-1447, "

Component Inspection" .

OK or NG

OK >> GO TO 14.

NG >> Replace stop lamp switch.

14. CHECK ICC BRAKE HOLD RELAY

Refer to EC-1447, "

Component Inspection" .

OK >> GO TO 15.

NG >> Replace ICC brake hold relay.

15. CHECK INTERMITTENT INCIDENT

Refer to EC-878, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

>>INSPECTION END

Component InspectionNBS005QI

ICC BRAKE SWITCH

1. Turn ignition switch OFF.Continuity should exist.

Page 2996 of 5621

![INFINITI M35 2006 Factory Service Manual ASCD BRAKE SWITCH

EC-1453

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

3. CHECK ASCD BRAKE SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD brake sw INFINITI M35 2006 Factory Service Manual ASCD BRAKE SWITCH

EC-1453

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

3. CHECK ASCD BRAKE SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD brake sw](/img/42/57023/w960_57023-2995.png)

ASCD BRAKE SWITCH

EC-1453

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

3. CHECK ASCD BRAKE SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch (2) harness connector.

–Stop lamp switch (1)

3. Turn ignition switch ON.

4. Check voltage between ASCD brake switch terminal 1 and

ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4. DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E102

10A fuse

Harness for open or short between ASCD brake switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

5. CHECK ASCD BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 108 and ASCD brake switch terminal 2.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E108, M15

Harness for open or short between ECM and ASCD brake switch

>> Repair open circuit or short to ground or short to power in harness or connectors.

PBIB2705E

Voltage: Battery voltage

PBIB0857E

Continuity should exist.

Page 2997 of 5621

![INFINITI M35 2006 Factory Service Manual EC-1454

[VK45DE]

ASCD BRAKE SWITCH

Revision: 2006 January2006 M35/M45

7. CHECK ASCD BRAKE SWITCH

Refer to EC-1318, "

Component Inspection"

OK or NG

OK >> GO TO 13.

NG >> Replace ASCD brake s INFINITI M35 2006 Factory Service Manual EC-1454

[VK45DE]

ASCD BRAKE SWITCH

Revision: 2006 January2006 M35/M45

7. CHECK ASCD BRAKE SWITCH

Refer to EC-1318, "

Component Inspection"

OK or NG

OK >> GO TO 13.

NG >> Replace ASCD brake s](/img/42/57023/w960_57023-2996.png)

EC-1454

[VK45DE]

ASCD BRAKE SWITCH

Revision: 2006 January2006 M35/M45

7. CHECK ASCD BRAKE SWITCH

Refer to EC-1318, "

Component Inspection"

OK or NG

OK >> GO TO 13.

NG >> Replace ASCD brake switch.

8. CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch (1) harness connector.

–ASCD brake switch (2)

3. Check voltage between stop lamp switch terminal 1 and ground

with CONSULT -II or tester.

OK or NG

OK >> GO TO 10.

NG >> GO TO 9.

9. DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E101

10A fuse

Harness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

10. CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 101 and stop lamp switch terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

PBIB2705E

Voltage: Battery voltage

PBIA9488J

Continuity should exist.

Page 3006 of 5621

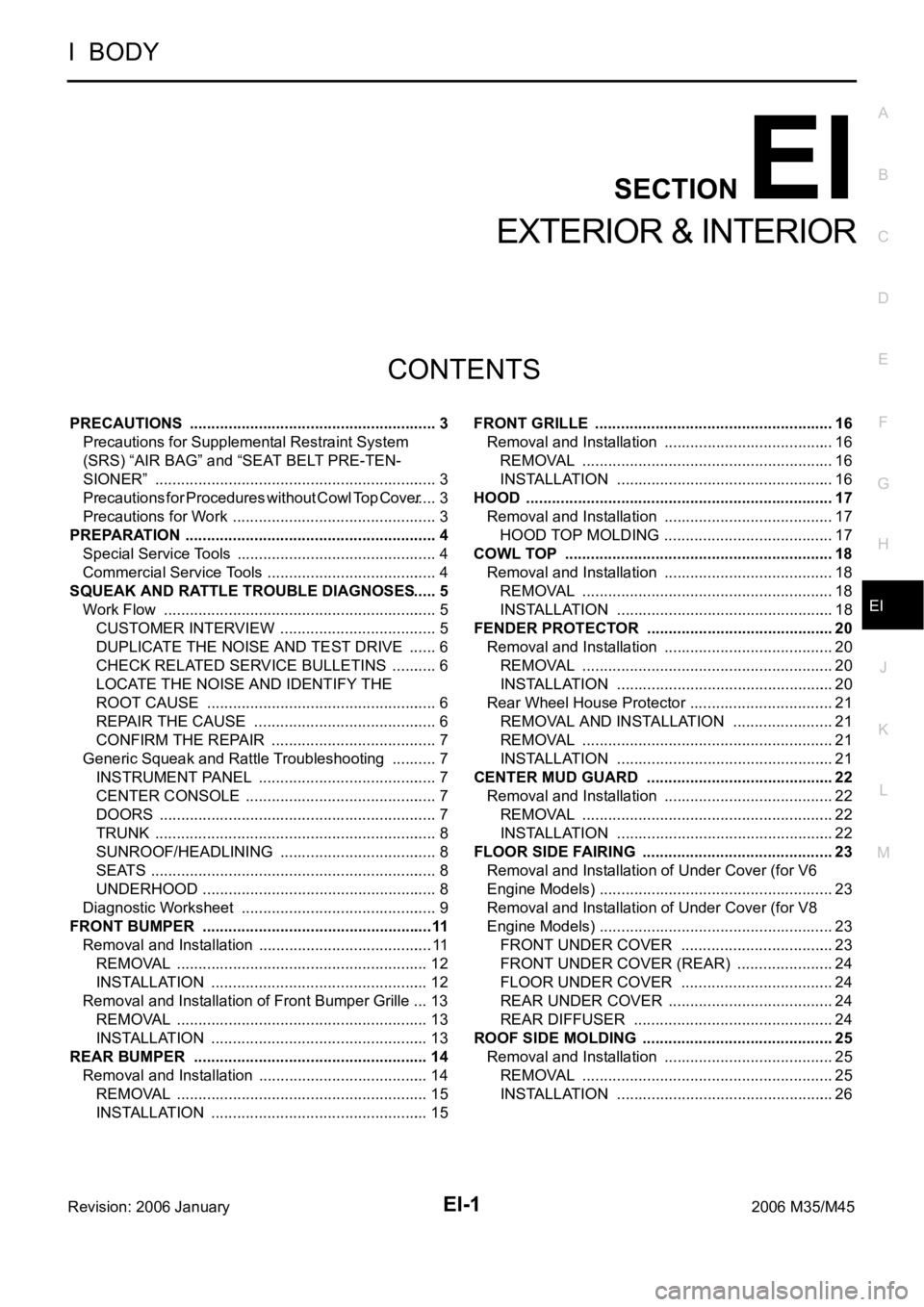

EI-1

EXTERIOR & INTERIOR

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION EI

A

B

EI

Revision: 2006 January2006 M35/M45

EXTERIOR & INTERIOR

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover ..... 3

Precautions for Work ...........................................

..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

FRONT BUMPER ......................................................11

Removal and Installation ......................................... 11

REMOVAL ........................................................

... 12

INSTALLATION ................................................... 12

Removal and Installation of Front Bumper Grille ... 13

REMOVAL ........................................................

... 13

INSTALLATION ................................................... 13

REAR BUMPER ....................................................

... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 15

INSTALLATION ................................................... 15FRONT GRILLE ........................................................ 16

Removal and Installation ........................................ 16

REMOVAL ........................................................

... 16

INSTALLATION ................................................... 16

HOOD ........................................................................ 17

Removal and Installation ........................................ 17

HOOD TOP MOLDING ........................................ 17

COWL TOP ............................................................... 18

Removal and Installation ........................................ 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................

... 18

FENDER PROTECTOR ............................................ 20

Removal and Installation ........................................ 20

REMOVAL ........................................................

... 20

INSTALLATION ................................................... 20

Rear Wheel House Protector .................................. 21

REMOVAL AND INSTALLATION ........................ 21

REMOVAL ........................................................

... 21

INSTALLATION ................................................... 21

CENTER MUD GUARD ............................................ 22

Removal and Installation ........................................ 22

REMOVAL ........................................................

... 22

INSTALLATION ................................................... 22

FLOOR SIDE FAIRING ............................................. 23

Removal and Installation of Under Cover (for V6

Engine Models) ....................................................... 23

Removal and Installation of Under Cover (for V8

Engine Models) ....................................................... 23

FRONT UNDER COVER .................................... 23

FRONT UNDER COVER (REAR) ....................... 24

FLOOR UNDER COVER .................................... 24

REAR UNDER COVER ....................................... 24

REAR DIFFUSER ............................................... 24

ROOF SIDE MOLDING ............................................. 25

Removal and Installation ........................................ 25

REMOVAL ........................................................

... 25

INSTALLATION ................................................... 26