torque INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3309 of 5621

![INFINITI M35 2006 Factory Service Manual EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CA INFINITI M35 2006 Factory Service Manual EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CA](/img/42/57023/w960_57023-3308.png)

EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CAUTION:

When pulling out harnesses, take care not to damage harnesses and connectors.

After temporarily securing, cover connectors with vinyl or similar material to protect against for-

eign material adhesion.

Vehicle Underbody

1. Remove A/T fluid cooler hoses and power steering oil pump oil cooler hoses.

Install plug to avoid leakage of A/T fluid and power steering fluid.

2. Disconnect heated oxygen sensor 2 harness. Refer to EX-3, "

EXHAUST SYSTEM" .

3. Remove exhaust front tube with power tool. Refer to EX-3, "

EXHAUST SYSTEM" .

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to PS-13, "

STEERING COLUMN" .

5. Separate steering outer sockets from steering knuckle. Refer to PS-18, "

POWER STEERING GEAR" .

6. Remove A/T control rod at control device assembly side. Then temporarily secure it on transmission, so

that it does not sag. Refer to AT-222, "

SHIFT CONTROL SYSTEM" .

7. Remove rear plate cover from oil pan. Then remove bolts fixing drive plate to torque converter. Refer to

EM-187, "

OIL PAN AND OIL STRAINER" and AT-271, "TRANSMISSION ASSEMBLY" .

8. Remove transmission joint bolts which pierce at oil pan lower rear side. Refer to AT- 2 7 1 , "

TRANSMIS-

SION ASSEMBLY" .

9. Remove lower ends of left and right strut from transverse link. Refer to FSU-6, "

FRONT SUSPENSION

ASSEMBLY" .

10. Remove transverse link mounting bolts at knuckle side. Refer to FSU-14, "

TRANSVERSE LINK" .

11. Remove front stabilizer at transverse link side. Refer to FSU-6, "

FRONT SUSPENSION ASSEMBLY" .

12. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPELLER SHAFT" .

Removal Work

1. Use manual lift table caddy (commercial service tool) or equiva-

lently rigid tool such as transmission jack. Securely support bot-

tom of suspension member and transmission assembly.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove engine rear member mounting bolts.

3. Remove front suspension member mounting nuts and bolts with power tool. Refer to FSU-6, "

FRONT

SUSPENSION ASSEMBLY" .

4. Carefully lower jack, or raise lift to remove engine, transmission and front suspension member assembly.

When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with vehicle.

Make sure that all connection points have been disconnected.

Keep in mind the center of vehicle gravity changes. If necessary, use jack(s) to support vehicle

at rear jacking point(s) to prevent it from falling it off the lift.

PBIC0804E

Page 3317 of 5621

![INFINITI M35 2006 Factory Service Manual EM-254

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

19. If pilot converter must be removed, remove it from the rear end

of the crankshaft using pilot bushing puller (SST).

ASSEMBLY

1. F INFINITI M35 2006 Factory Service Manual EM-254

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

19. If pilot converter must be removed, remove it from the rear end

of the crankshaft using pilot bushing puller (SST).

ASSEMBLY

1. F](/img/42/57023/w960_57023-3316.png)

EM-254

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

19. If pilot converter must be removed, remove it from the rear end

of the crankshaft using pilot bushing puller (SST).

ASSEMBLY

1. Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

CAUTION:

Use a goggles to protect your eye.

2. Install each plug to the cylinder block. (Only screwed-type plugs

are shown in the figure.)

Apply sealant to the thread of each plug “A” and “D”.

Use Genuine High Strength Locking Sealant or equiva-

lent. Refer to GI-48, "

RECOMMENDED CHEMICAL PROD-

UCTS AND SEALANTS".

Apply sealant to the thread of each plug “B” and “C”.

Use Anaerobic Liquid Gasket or equivalent. Refer to GI-

48, "RECOMMENDED CHEMICAL PRODUCTS AND SEAL-

ANTS".

Replace copper washers with new ones.

Tighten each plug as specified below.

3. Install main bearings and thrust bearings as follows:

a. Remove dust, dirt and oil on the bearing mating surfaces of cylinder block and main bearing caps.

b. Install thrust bearings to the both sides of the No. 3 journal hous-

ing on cylinder block and main bearing cap.

Install thrust bearings with the oil groove facing the crankshaft

arm (outside).

Install thrust bearing with a protrusion on one end on cylinder

block, and thrust bearing with a protrusion at center on main

bearing cap. Align each protrusion with mating notch.

PBIC0092E

PBIC1265E

Part Washer Tightening torque

A Yes 53.9 Nꞏm (5.5 kg-m, 40 ft-lb)

B No 19.6 Nꞏm (2.0 kg-m, 15 ft-lb)

C Yes 62.7 Nꞏm (6.4 kg-m, 46 ft-lb)

D Yes 62.7 Nꞏm (6.4 kg-m, 46 ft-lb)

PBIC2368E

Page 3331 of 5621

![INFINITI M35 2006 Factory Service Manual EM-268

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEND AND TORSION

Check with connecting rod aligner.

If it exceeds the limit, replace connecting rod assembly.

CONNECTIN INFINITI M35 2006 Factory Service Manual EM-268

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEND AND TORSION

Check with connecting rod aligner.

If it exceeds the limit, replace connecting rod assembly.

CONNECTIN](/img/42/57023/w960_57023-3330.png)

EM-268

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEND AND TORSION

Check with connecting rod aligner.

If it exceeds the limit, replace connecting rod assembly.

CONNECTING ROD BIG END DIAMETER

Install connecting rod bearing cap without installing connecting

rod bearing, and tightening connecting rod bolts to the specified

torque. Refer to EM-254, "

ASSEMBLY" for the tightening proce-

dure.

Measure the inner diameter of connecting rod big end with

inside micrometer.

If out of the standard, replace connecting rod assembly.

CONNECTING ROD BUSHING OIL CLEARANCE

Connecting Rod Bushing Inner Diameter

Measure the inner diameter of connecting rod bushing with inside

micrometer.Bend:

Limit : 0.15 mm (0.0059 in) per 100 mm (3.94 in) length

To r s i o n :

Limit : 0.30 mm (0.012 in) per 100 mm (3.94 in) length

PBIC2077E

Standard : 55.000 - 55.013 mm (2.1654 - 2.1659 in)

PBIC1641E

Standard : 22.000 - 22.012 mm (0.8661 - 0.8666 in)

PBIC0120E

Page 3333 of 5621

![INFINITI M35 2006 Factory Service Manual EM-270

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

Measure the distortion on the cylinder block upper face at some

different points in six directions with straightedge and feele INFINITI M35 2006 Factory Service Manual EM-270

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

Measure the distortion on the cylinder block upper face at some

different points in six directions with straightedge and feele](/img/42/57023/w960_57023-3332.png)

EM-270

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

Measure the distortion on the cylinder block upper face at some

different points in six directions with straightedge and feeler

gauge.

If it exceeds the limit, replace cylinder block.

MAIN BEARING HOUSING INNER DIAMETER

Install main bearing caps and main bearing without installing

main bearings, and tighten main bearing cap bolts to the speci-

fied torque. Refer to EM-254, "

ASSEMBLY" for the tightening

procedure.

Measure the inner diameter of main bearing housing with bore

gauge.

If out of the standard, replace cylinder block and main bearing

caps as assembly.

NOTE:

Cylinder block cannot be replaced as a single part, because it is

machined together with main bearing caps.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder Bore Inner Diameter

Using bore gauge, measure cylinder bore for wear, out-of-round

and taper at six different points on each cylinder. (“X” and “Y”

directions at “A”, “B” and “C”) (“X” is in longitudinal direction of

engine)

If the measured value exceeds the limit, or if there are scratches

and/or seizure on the cylinder inner wall, hone or re-bore the

inner wall.

Oversize piston is provided. When using oversize piston, re-

bore cylinder so that the clearance of the piston-to-cylinder bore

satisfies the standard.

CAUTION:

When using oversize piston, use oversize pistons for all

cylinders with oversize piston rings.Limit : 0.1 mm (0.004 in)

SEM123C

Standard : 68.944 - 68.968 mm (2.7143 - 2.7153 in)

PBIC1643E

Standard inner diameter:

93.000 - 93.030 mm (3.6614 - 3.6626 in)

Wear limit:

0.2 mm (0.008 in)

Out-of-round (Difference between “X” and “Y”):

0.015 mm (0.0006 in)

Taper limit (Difference between “A” and “C”):

0.01 mm (0.0004 in)

Oversize (OS) : 0.2 mm (0.008 in)

PBIC3827E

PBIC0124E

Page 3334 of 5621

![INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-271

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Piston Skirt Diameter

Measure the outer diameter of piston skirt with micrometer.

Measure point “H” (Dis INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-271

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Piston Skirt Diameter

Measure the outer diameter of piston skirt with micrometer.

Measure point “H” (Dis](/img/42/57023/w960_57023-3333.png)

CYLINDER BLOCK

EM-271

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Piston Skirt Diameter

Measure the outer diameter of piston skirt with micrometer.

Measure point “H” (Distance from the top): 42 mm (1.65 in)

Piston to Cylinder Bore Clearance

Calculate by piston skirt diameter and cylinder bore inner diameter (direction “Y”, position “B”).

(Clearance) = (Cylinder bore inner diameter) – (Piston skirt diameter).

If the calculated value exceeds the limit, replace piston and piston pin assembly. Refer to EM-260, "HOW

TO SELECT PISTON" .

Re-boring Cylinder Bore

1. Cylinder bore size is determined by adding piston to cylinder bore clearance to piston skirt diameter.

2. Install main bearing caps and main bearing, and tighten to the specified torque. Otherwise, cylinder bores

may be distorted in final assembly.

3. Cut cylinder bores.

NOTE:

When any cylinder needs boring, all other cylinders must also be bored.

Do not cut too much out of cylinder bore at a time. Cut only 0.05 mm (0.0020 in) or so in diameter at a

time.

4. Hone cylinders to obtain the specified piston to cylinder bore clearance.

5. Measure finished cylinder bore for the out-of-round and taper.

NOTE:

Measurement should be done after cylinder bore cools down.

CRANKSHAFT MAIN JOURNAL DIAMETER

Measure the outer diameter of crankshaft main journals with micrometer. Standard

: 92.980 - 93.010 mm (3.6606 - 3.6618 in)

PBIC0125E

PBIC0126E

Standard : 0.010 - 0.030 mm (0.0004 - 0.0012 in)

Limit : 0.08 mm (0.0031 in)

Re-bored size calculation: D = A + B – C

where,

D: Bored diameter

A: Piston skirt diameter as measured

B: Piston to cylinder bore clearance (standard value)

C: Honing allowance 0.02 mm (0.0008 in)

Page 3336 of 5621

![INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-273

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Install connecting rod bearings to connectin INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-273

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Install connecting rod bearings to connectin](/img/42/57023/w960_57023-3335.png)

CYLINDER BLOCK

EM-273

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Install connecting rod bearings to connecting rod and cap, and

tighten connecting rod bolts to the specified torque. Refer to

EM-254, "

ASSEMBLY" for the tightening procedure.

Measure the inner diameter of connecting rod bearing with

inside micrometer.

(Bearing oil clearance) = (Connecting rod bearing inner diameter) –

(Crankshaft pin journal diameter)

If the calculated value exceeds the limit, select proper connecting rod bearing according to connecting rod

big end diameter and crankshaft pin journal diameter to obtain the specified bearing oil clearance. Refer

to EM-261, "

HOW TO SELECT CONNECTING ROD BEARING" .

Method of Using Plastigage

Remove oil and dust on crankshaft pin journal and the surfaces of each bearing completely.

Cut plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

Install connecting rod bearings to connecting rod and cap, and tighten connecting rod bolts to the speci-

fied torque. Refer to EM-254, "

ASSEMBLY" for the tightening procedure.

CAUTION:

Do not rotate crankshaft.

Remove connecting rod bearing cap and bearing, and using

scale on plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.Standard : 0.020 - 0.045 mm (0.0008 - 0.0018 in)

(actual clearance)

Limit : 0.055 mm (0.0022 in)

PBIC1642E

PBIC1149E

Page 3337 of 5621

![INFINITI M35 2006 Factory Service Manual EM-274

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

MAIN BEARING OIL CLEARANCE

Method by Calculation

Install main bearings to cylinder block and main bearing caps,

and tighten INFINITI M35 2006 Factory Service Manual EM-274

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

MAIN BEARING OIL CLEARANCE

Method by Calculation

Install main bearings to cylinder block and main bearing caps,

and tighten](/img/42/57023/w960_57023-3336.png)

EM-274

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

MAIN BEARING OIL CLEARANCE

Method by Calculation

Install main bearings to cylinder block and main bearing caps,

and tighten main bearing cap bolts with main bearing to the

specified torque. Refer to EM-254, "

ASSEMBLY" for the tighten-

ing procedure.

Measure the inner diameter of main bearing with bore gauge.

(Bearing clearance) = (Main bearing inner diameter) – (Crankshaft main journal diameter)

If the calculated value exceeds the limit, select proper main bearing according to main bearing inner diam-

eter and crankshaft main journal diameter to obtain the specified bearing oil clearance. Refer to EM-262,

"HOW TO SELECT MAIN BEARING" .

Method of Using Plastigage

Remove oil and dust on crankshaft main journal and the surfaces of each bearing completely.

Cut plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

Install main bearings to cylinder block and main bearing caps, and tighten main bearing bolts with main

bearing to the specified torque. Refer to EM-254, "

ASSEMBLY" for the tightening procedure.

CAUTION:

Do not rotate crankshaft.

Remove main bearing caps and bearings, and using scale on

plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

PBIC1644E

Standard

No . 1 and 5 journal : 0.001 - 0.011 mm (0.00004 - 0.0004 in)

No. 2, 3 and 4 journal : 0.007 - 0.017 mm (0.0003 - 0.0007 in)

Limit

No. 1 and 5 journal : 0.021 mm (0.0008 in)

No. 2, 3 and 4 journal : 0.027 mm (0.0011 in)

PBIC1149E

Page 3338 of 5621

![INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-275

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CRUSH HEIGHT OF MAIN BEARING

When main bearing cap is removed after being tightened to the

specified torq INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-275

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CRUSH HEIGHT OF MAIN BEARING

When main bearing cap is removed after being tightened to the

specified torq](/img/42/57023/w960_57023-3337.png)

CYLINDER BLOCK

EM-275

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CRUSH HEIGHT OF MAIN BEARING

When main bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of bear-

ing must protrude. Refer to EM-254, "

ASSEMBLY" for the tight-

ening procedure.

If the standard is not met, replace main bearings.

CRUSH HEIGHT OF CONNECTING ROD BEARING

When connecting rod bearing cap is removed after being tight-

ened to the specified torque with connecting rod bearings

installed, the tip end of bearing must protrude. Refer to EM-254,

"ASSEMBLY" for the tightening procedure.

If the standard is not met, replace connecting rod bearings.

DRIVE PLATE

Check drive plate and signal plate for deformation or cracks.

CAUTION:

Do not disassemble drive plate.

Do not place drive plate with signal plate facing down.

When handling signal plate, take care not to damage or

scratch it.

Handle signal plate in a manner that prevents it from

becoming magnetized.

If anything is found, replace drive plate.Standard : There must be crush height.

SEM502G

Standard : There must be crush height.

PBIC1646E

PBIC2367E

Page 3356 of 5621

EXHAUST SYSTEM

EX-5

C

D

E

F

G

H

I

J

K

L

MA

EX

Revision: 2006 January2006 M35/M45

Removal and InstallationNBS005RL

CAUTION:

Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance, and shape.

Perform the operation with the exhaust system fully cooled down because the system will be hot

just after engine stops.

Be careful not to cut your hand on the heat insulator edge.

REMOVAL

Disconnect each joint and mounting using power tool.

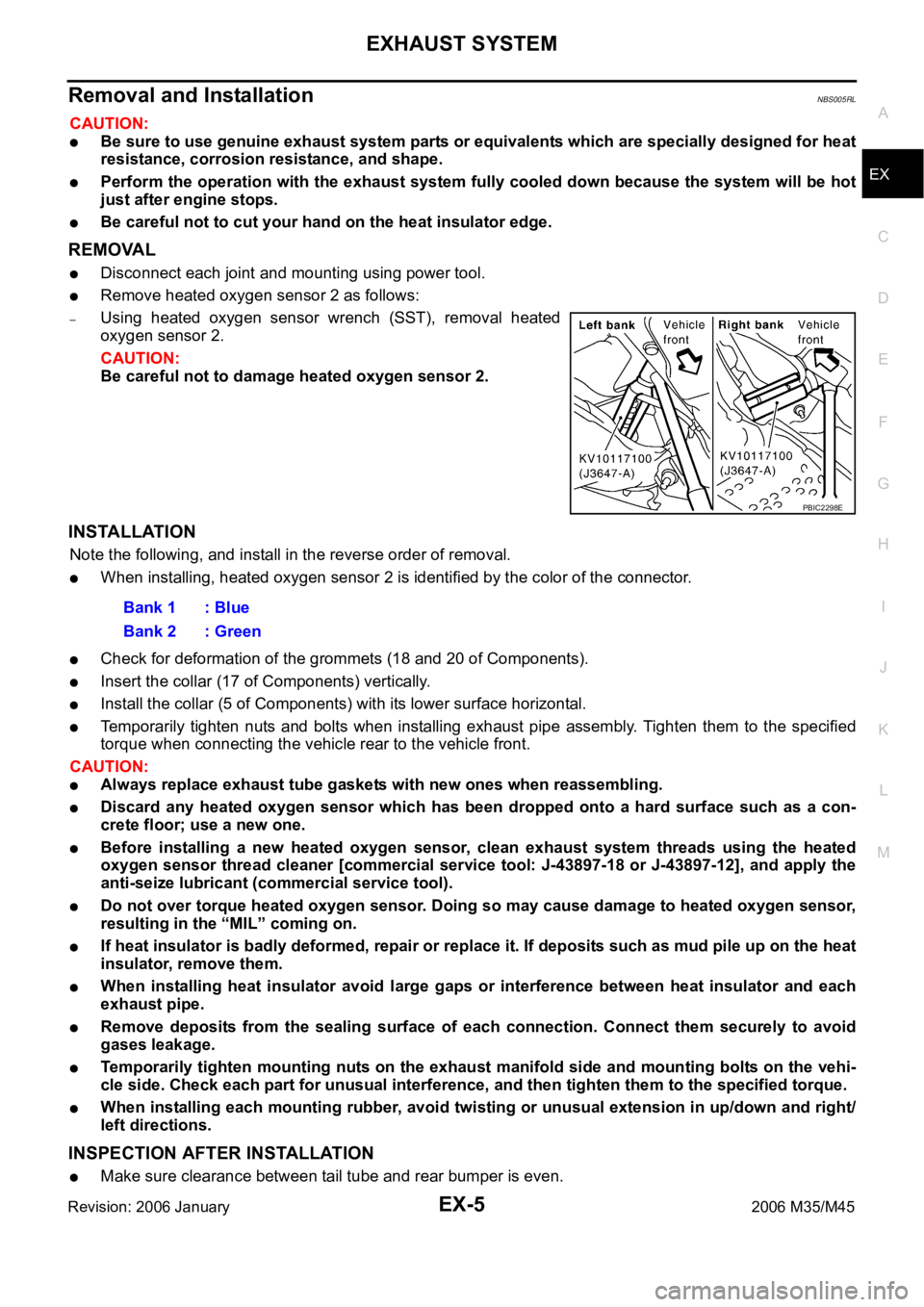

Remove heated oxygen sensor 2 as follows:

–Using heated oxygen sensor wrench (SST), removal heated

oxygen sensor 2.

CAUTION:

Be careful not to damage heated oxygen sensor 2.

INSTALLATION

Note the following, and install in the reverse order of removal.

When installing, heated oxygen sensor 2 is identified by the color of the connector.

Check for deformation of the grommets (18 and 20 of Components).

Insert the collar (17 of Components) vertically.

Install the collar (5 of Components) with its lower surface horizontal.

Temporarily tighten nuts and bolts when installing exhaust pipe assembly. Tighten them to the specified

torque when connecting the vehicle rear to the vehicle front.

CAUTION:

Always replace exhaust tube gaskets with new ones when reassembling.

Discard any heated oxygen sensor which has been dropped onto a hard surface such as a con-

crete floor; use a new one.

Before installing a new heated oxygen sensor, clean exhaust system threads using the heated

oxygen sensor thread cleaner [commercial service tool: J-43897-18 or J-43897-12], and apply the

anti-seize lubricant (commercial service tool).

Do not over torque heated oxygen sensor. Doing so may cause damage to heated oxygen sensor,

resulting in the “MIL” coming on.

If heat insulator is badly deformed, repair or replace it. If deposits such as mud pile up on the heat

insulator, remove them.

When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

gases leakage.

Temporarily tighten mounting nuts on the exhaust manifold side and mounting bolts on the vehi-

cle side. Check each part for unusual interference, and then tighten them to the specified torque.

When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/

left directions.

INSPECTION AFTER INSTALLATION

Make sure clearance between tail tube and rear bumper is even.

PBIC2298E

Bank 1 : Blue

Bank 2 : Green

Page 3358 of 5621

EXHAUST SYSTEM

EX-7

C

D

E

F

G

H

I

J

K

L

MA

EX

Revision: 2006 January2006 M35/M45

Removal and installationNBS005RN

CAUTION:

Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance, and shape.

Perform the operation with the exhaust system fully cooled down because the system will be hot

just after engine stops.

Be careful not to cut your hand on the heat insulator edge.

REMOVAL

Disconnect each joint and mounting using power tool.

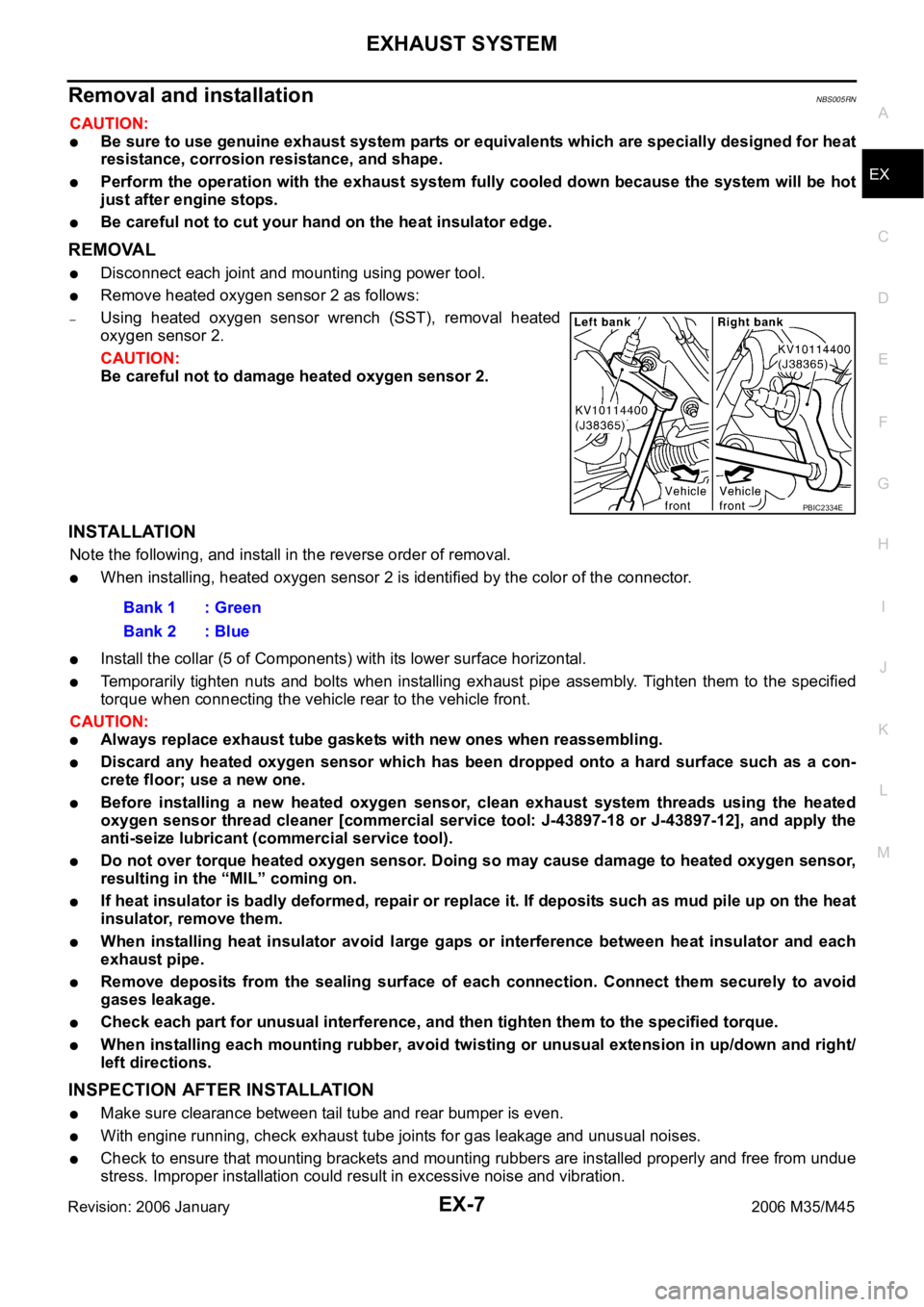

Remove heated oxygen sensor 2 as follows:

–Using heated oxygen sensor wrench (SST), removal heated

oxygen sensor 2.

CAUTION:

Be careful not to damage heated oxygen sensor 2.

INSTALLATION

Note the following, and install in the reverse order of removal.

When installing, heated oxygen sensor 2 is identified by the color of the connector.

Install the collar (5 of Components) with its lower surface horizontal.

Temporarily tighten nuts and bolts when installing exhaust pipe assembly. Tighten them to the specified

torque when connecting the vehicle rear to the vehicle front.

CAUTION:

Always replace exhaust tube gaskets with new ones when reassembling.

Discard any heated oxygen sensor which has been dropped onto a hard surface such as a con-

crete floor; use a new one.

Before installing a new heated oxygen sensor, clean exhaust system threads using the heated

oxygen sensor thread cleaner [commercial service tool: J-43897-18 or J-43897-12], and apply the

anti-seize lubricant (commercial service tool).

Do not over torque heated oxygen sensor. Doing so may cause damage to heated oxygen sensor,

resulting in the “MIL” coming on.

If heat insulator is badly deformed, repair or replace it. If deposits such as mud pile up on the heat

insulator, remove them.

When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

gases leakage.

Check each part for unusual interference, and then tighten them to the specified torque.

When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/

left directions.

INSPECTION AFTER INSTALLATION

Make sure clearance between tail tube and rear bumper is even.

With engine running, check exhaust tube joints for gas leakage and unusual noises.

Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue

stress. Improper installation could result in excessive noise and vibration.

PBIC2334E

Bank 1 : Green

Bank 2 : Blue