check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3324 of 5621

![INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-261

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

HOW TO SELECT CONNECTING ROD BEARING

When New Connecting Rod and Crankshaft are Used

Check pin diameter grad INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-261

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

HOW TO SELECT CONNECTING ROD BEARING

When New Connecting Rod and Crankshaft are Used

Check pin diameter grad](/img/42/57023/w960_57023-3323.png)

CYLINDER BLOCK

EM-261

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

HOW TO SELECT CONNECTING ROD BEARING

When New Connecting Rod and Crankshaft are Used

Check pin diameter grade (“0”, “1” or “2”) on front of crankshaft, and

select connecting rod bearing of the same grade.

NOTE:

There is no grading for connecting rod big end diameter.

When Crankshaft and Connecting Rod are Reused

1. Measure the connecting rod big end diameter. Refer to EM-268, "CONNECTING ROD BIG END DIAME-

TER" .

2. Make sure that the connecting rod big end diameter is within the standard value.

3. Measure the crankshaft pin journal diameter. Refer to EM-272, "

CRANKSHAFT PIN JOURNAL DIAME-

TER" .

4. Determine the grade of crankshaft pin diameter grade by corresponding to the measured dimension in

“Crankshaft pin journal diameter” column of “Connecting Rod Bearing Selection Table”.

5. Select connecting rod bearing of the same grade.

Connecting Rod Bearing Selection Table

Unit: mm (in)

Unit: mm (in)

Under Size Bearings Usage Guide

When the specified connecting rod bearing oil clearance is not obtained with standard size connecting rod

bearings, use undersize (US) bearings.

When using undersize (US) bearing, measure the connecting rod bearing inner diameter with bearing

installed, and grind crankshaft pin so that the connecting rod bearing oil clearance satisfies the standard.

CAUTION:

In grinding crankshaft pin to use undersize bearings, keep

the fillet R [1.5 mm (0.059 in)].

Bearing undersize table

Unit: mm (in)

PBIC2374E

Connecting rod big end diameter 55.000 - 55.013 (2.1654 - 2.1659)

Crankshaft Connecting rod bearing

Crankshaft pin journal diameter Grade (Mark) Dimension (Bearing thickness range) Bearing grade No. Color

51.968 - 51.974 (2.0460 - 2.0462) 0 1.500 - 1.503 (0.0591 - 0.0592) STD 0 No color

51.962 - 51.968 (2.0457 - 2.0460) 1 1.503 - 1.506 (0.0592 - 0.0593) STD 1 Brown

51.956 - 51.962 (2.0455 - 2.0457) 2 1.506 - 1.509 (0.0593 - 0.0594) STD 2 Green

PBIC2373E

Size Thickness

US 0.25 (0.0098) 1.626 - 1.634 (0.0640 - 0.0643)

Page 3331 of 5621

![INFINITI M35 2006 Factory Service Manual EM-268

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEND AND TORSION

Check with connecting rod aligner.

If it exceeds the limit, replace connecting rod assembly.

CONNECTIN INFINITI M35 2006 Factory Service Manual EM-268

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEND AND TORSION

Check with connecting rod aligner.

If it exceeds the limit, replace connecting rod assembly.

CONNECTIN](/img/42/57023/w960_57023-3330.png)

EM-268

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEND AND TORSION

Check with connecting rod aligner.

If it exceeds the limit, replace connecting rod assembly.

CONNECTING ROD BIG END DIAMETER

Install connecting rod bearing cap without installing connecting

rod bearing, and tightening connecting rod bolts to the specified

torque. Refer to EM-254, "

ASSEMBLY" for the tightening proce-

dure.

Measure the inner diameter of connecting rod big end with

inside micrometer.

If out of the standard, replace connecting rod assembly.

CONNECTING ROD BUSHING OIL CLEARANCE

Connecting Rod Bushing Inner Diameter

Measure the inner diameter of connecting rod bushing with inside

micrometer.Bend:

Limit : 0.15 mm (0.0059 in) per 100 mm (3.94 in) length

To r s i o n :

Limit : 0.30 mm (0.012 in) per 100 mm (3.94 in) length

PBIC2077E

Standard : 55.000 - 55.013 mm (2.1654 - 2.1659 in)

PBIC1641E

Standard : 22.000 - 22.012 mm (0.8661 - 0.8666 in)

PBIC0120E

Page 3338 of 5621

![INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-275

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CRUSH HEIGHT OF MAIN BEARING

When main bearing cap is removed after being tightened to the

specified torq INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-275

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CRUSH HEIGHT OF MAIN BEARING

When main bearing cap is removed after being tightened to the

specified torq](/img/42/57023/w960_57023-3337.png)

CYLINDER BLOCK

EM-275

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CRUSH HEIGHT OF MAIN BEARING

When main bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of bear-

ing must protrude. Refer to EM-254, "

ASSEMBLY" for the tight-

ening procedure.

If the standard is not met, replace main bearings.

CRUSH HEIGHT OF CONNECTING ROD BEARING

When connecting rod bearing cap is removed after being tight-

ened to the specified torque with connecting rod bearings

installed, the tip end of bearing must protrude. Refer to EM-254,

"ASSEMBLY" for the tightening procedure.

If the standard is not met, replace connecting rod bearings.

DRIVE PLATE

Check drive plate and signal plate for deformation or cracks.

CAUTION:

Do not disassemble drive plate.

Do not place drive plate with signal plate facing down.

When handling signal plate, take care not to damage or

scratch it.

Handle signal plate in a manner that prevents it from

becoming magnetized.

If anything is found, replace drive plate.Standard : There must be crush height.

SEM502G

Standard : There must be crush height.

PBIC1646E

PBIC2367E

Page 3352 of 5621

EX-1

EXHAUST SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EX

A

EX

Revision: 2006 January2006 M35/M45

EXHAUST SYSTEM

PREPARATION ........................................................... 2

Special Service Tools ............................................... 2

Commercial Service Tools ........................................ 2

EXHAUST SYSTEM ................................................... 3

Checking Exhaust System ....................................... 3

Components ............................................................. 4

Removal and Installation .......................................... 5

REMOVAL ........................................................

..... 5INSTALLATION ..................................................... 5

INSPECTION AFTER INSTALLATION .................. 5

Components ............................................................. 6

Removal and installation .......................................... 7

REMOVAL ........................................................

..... 7

INSTALLATION ..................................................... 7

INSPECTION AFTER INSTALLATION .................. 7

Page 3354 of 5621

EXHAUST SYSTEM

EX-3

C

D

E

F

G

H

I

J

K

L

MA

EX

Revision: 2006 January2006 M35/M45

EXHAUST SYSTEMPFP:20100

Checking Exhaust SystemNBS005RJ

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage or deterioration.

If anything is found, repair or replace damaged parts.

SMA211A

Page 3356 of 5621

EXHAUST SYSTEM

EX-5

C

D

E

F

G

H

I

J

K

L

MA

EX

Revision: 2006 January2006 M35/M45

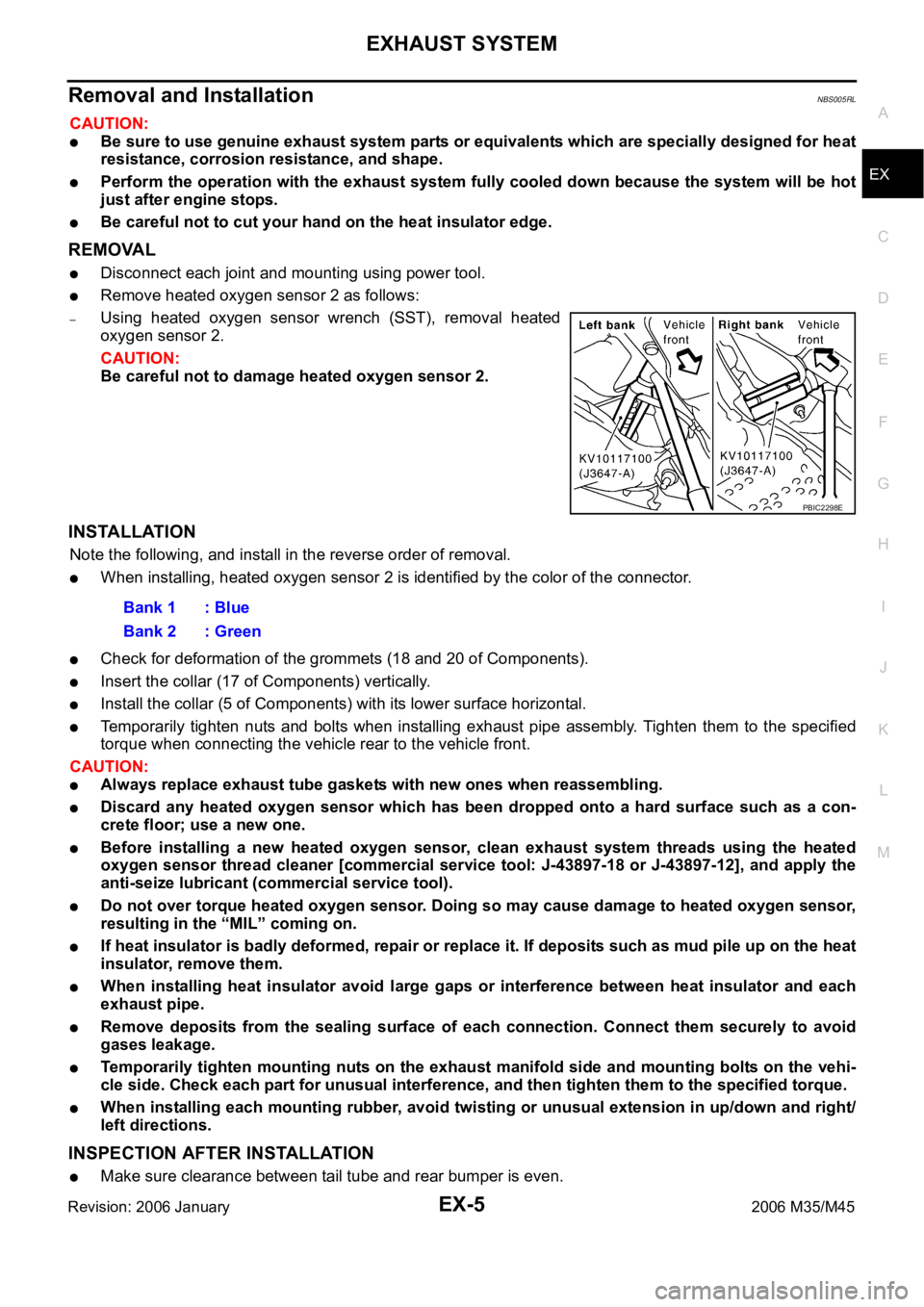

Removal and InstallationNBS005RL

CAUTION:

Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance, and shape.

Perform the operation with the exhaust system fully cooled down because the system will be hot

just after engine stops.

Be careful not to cut your hand on the heat insulator edge.

REMOVAL

Disconnect each joint and mounting using power tool.

Remove heated oxygen sensor 2 as follows:

–Using heated oxygen sensor wrench (SST), removal heated

oxygen sensor 2.

CAUTION:

Be careful not to damage heated oxygen sensor 2.

INSTALLATION

Note the following, and install in the reverse order of removal.

When installing, heated oxygen sensor 2 is identified by the color of the connector.

Check for deformation of the grommets (18 and 20 of Components).

Insert the collar (17 of Components) vertically.

Install the collar (5 of Components) with its lower surface horizontal.

Temporarily tighten nuts and bolts when installing exhaust pipe assembly. Tighten them to the specified

torque when connecting the vehicle rear to the vehicle front.

CAUTION:

Always replace exhaust tube gaskets with new ones when reassembling.

Discard any heated oxygen sensor which has been dropped onto a hard surface such as a con-

crete floor; use a new one.

Before installing a new heated oxygen sensor, clean exhaust system threads using the heated

oxygen sensor thread cleaner [commercial service tool: J-43897-18 or J-43897-12], and apply the

anti-seize lubricant (commercial service tool).

Do not over torque heated oxygen sensor. Doing so may cause damage to heated oxygen sensor,

resulting in the “MIL” coming on.

If heat insulator is badly deformed, repair or replace it. If deposits such as mud pile up on the heat

insulator, remove them.

When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

gases leakage.

Temporarily tighten mounting nuts on the exhaust manifold side and mounting bolts on the vehi-

cle side. Check each part for unusual interference, and then tighten them to the specified torque.

When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/

left directions.

INSPECTION AFTER INSTALLATION

Make sure clearance between tail tube and rear bumper is even.

PBIC2298E

Bank 1 : Blue

Bank 2 : Green

Page 3357 of 5621

EX-6

EXHAUST SYSTEM

Revision: 2006 January2006 M35/M45

With engine running, check exhaust tube joints for gas leakage and unusual noises.

Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue

stress. Improper installation could result in excessive noise and vibration.

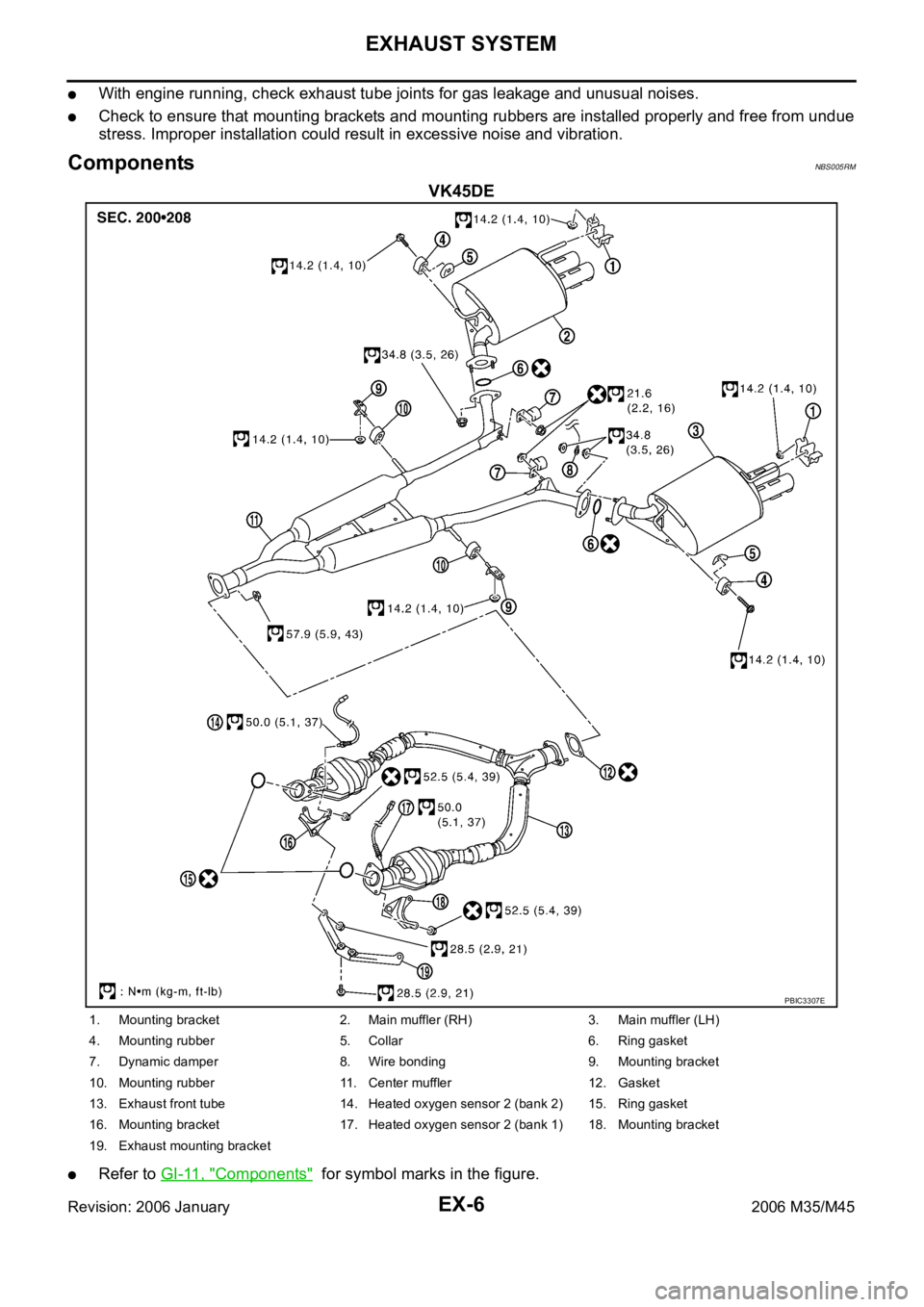

ComponentsNBS005RM

VK45DE

Refer to GI-11, "Components" for symbol marks in the figure.

PBIC3307E

1. Mounting bracket 2. Main muffler (RH) 3. Main muffler (LH)

4. Mounting rubber 5. Collar 6. Ring gasket

7. Dynamic damper 8. Wire bonding 9. Mounting bracket

10. Mounting rubber 11. Center muffler 12. Gasket

13. Exhaust front tube 14. Heated oxygen sensor 2 (bank 2) 15. Ring gasket

16. Mounting bracket 17. Heated oxygen sensor 2 (bank 1) 18. Mounting bracket

19. Exhaust mounting bracket

Page 3358 of 5621

EXHAUST SYSTEM

EX-7

C

D

E

F

G

H

I

J

K

L

MA

EX

Revision: 2006 January2006 M35/M45

Removal and installationNBS005RN

CAUTION:

Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance, and shape.

Perform the operation with the exhaust system fully cooled down because the system will be hot

just after engine stops.

Be careful not to cut your hand on the heat insulator edge.

REMOVAL

Disconnect each joint and mounting using power tool.

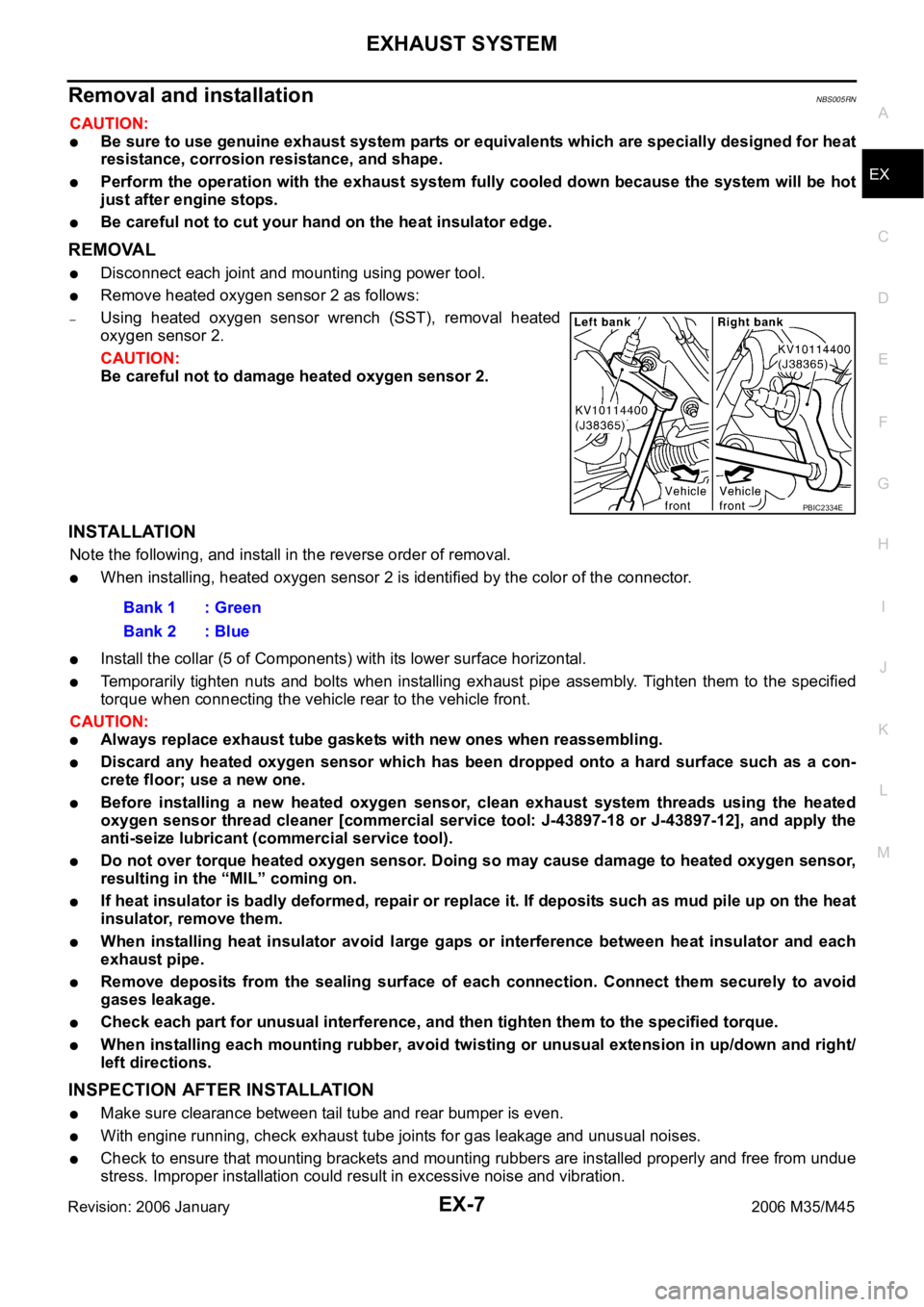

Remove heated oxygen sensor 2 as follows:

–Using heated oxygen sensor wrench (SST), removal heated

oxygen sensor 2.

CAUTION:

Be careful not to damage heated oxygen sensor 2.

INSTALLATION

Note the following, and install in the reverse order of removal.

When installing, heated oxygen sensor 2 is identified by the color of the connector.

Install the collar (5 of Components) with its lower surface horizontal.

Temporarily tighten nuts and bolts when installing exhaust pipe assembly. Tighten them to the specified

torque when connecting the vehicle rear to the vehicle front.

CAUTION:

Always replace exhaust tube gaskets with new ones when reassembling.

Discard any heated oxygen sensor which has been dropped onto a hard surface such as a con-

crete floor; use a new one.

Before installing a new heated oxygen sensor, clean exhaust system threads using the heated

oxygen sensor thread cleaner [commercial service tool: J-43897-18 or J-43897-12], and apply the

anti-seize lubricant (commercial service tool).

Do not over torque heated oxygen sensor. Doing so may cause damage to heated oxygen sensor,

resulting in the “MIL” coming on.

If heat insulator is badly deformed, repair or replace it. If deposits such as mud pile up on the heat

insulator, remove them.

When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

gases leakage.

Check each part for unusual interference, and then tighten them to the specified torque.

When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/

left directions.

INSPECTION AFTER INSTALLATION

Make sure clearance between tail tube and rear bumper is even.

With engine running, check exhaust tube joints for gas leakage and unusual noises.

Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue

stress. Improper installation could result in excessive noise and vibration.

PBIC2334E

Bank 1 : Green

Bank 2 : Blue

Page 3365 of 5621

FAX-6

FRONT WHEEL HUB AND KNUCKLE

Revision: 2006 January2006 M35/M45

5. Put matching mark on disc rotor and wheel hub and bearing

assembly, then remove disc rotor.

6. Remove cotter pin, then loosen hub lock nut with a power tool.

(AWD)

7. Separate wheel hub and bearing assembly from drive shaft by

lightly tapping the end with a hammer (suitable tool) and a wood

block, and then remove hub lock nut. (AWD)

CAUTION:

Do not place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for

housing (or joint sub-assembly), shaft and the other

parts.

NOTE:

Use a puller (suitable tool) if wheel hub and bearing assembly

and drive shaft cannot be separated even after performing the

above procedure.

8. Remove wheel hub and bearing assembly mounting bolts, and then remove splash guard and wheel hub

and bearing assembly from steering knuckle.

Steering knuckle

1. Refer to the procedure from 1 to 7 in “Wheel Hub and Bearing Assembly” FA X - 5 , "REMOVAL" .

2. Remove cotter pin (1), and then loosen the nut.

3. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

4. Remove cotter pin of transverse link and steering knuckle, and

then loosen nut.

5. Remove transverse link from steering knuckle so as not to dam-

age ball joint boot using the ball joint remover (suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from suddenly coming off.

6. Remove fixing nut and bolt with a power tool, and then remove steering knuckle from upper link. Refer to

FSU-8, "

Components" .

7. Remove wheel hub and bearing assembly mounting bolts, and then remove splash guard and wheel hub

and bearing assembly from steering knuckle.

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage. Replace if there are.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-14, "

INSPECTION AFTER REMOVAL" , “TRANSVERSE LINK”, PS-22, "INSPECTION AFTER DISAS-

SEMBLY" , “POWER STEERING GEAR”.

SDIA2608E

SDIA1821E

SGIA1183E

Page 3366 of 5621

FRONT WHEEL HUB AND KNUCKLE

FAX-7

C

E

F

G

H

I

J

K

L

MA

B

FA X

Revision: 2006 January2006 M35/M45

INSTALLATION

Installation is the reverse order of the removal. For tightening torque, refer to FAX-5, "COMPONENT" .

Perform the final tightening of each of parts under unladen conditions, which were removed when remov-

ing wheel hub and bearing assembly and steering knuckle. Check the wheel alignment. Refer to FSU-6,

"Wheel Alignment Inspection" (2WD), FSU-23, "Wheel Alignment Inspection" (AWD).

Adjust neutral position of steering angle sensor after checking the wheel alignment. Refer to BRC-6,

"Adjustment of Steering Angle Sensor Neutral Position" .

Check wheel sensor harness for proper connection. Refer to BRC-57, "WHEEL SENSOR" .

Assemble disc rotor and wheel hub and bearing assembly by

aligning each matching mark as shown in the figure when install-

ing disc rotor.

NOTE:

Refer to BR-28, "

DISC ROTOR INSPECTION" , for assembly

when removing disc without matching mark.

SDIA2608E