check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3574 of 5621

POWER WINDOW SYSTEM

GW-55

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

3. CHECK DOOR KEY CYLINDER SWITCH GROUND

Check continuity between front door lock assembly (driver side) connector ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4. CHECK DOOR KEY CYLINDER SWITCH

Check front door lock assembly (driver side).

OK or NG

OK >> Further inspection is necessary. Refer to symptom

chart.

NG >> Replace front door key cylinder (driver side) switch.

Front door lock

assembly

(driver side)

connectorTerminal

GroundContinuity

D14 4 Yes

PIIB5974E

Te r m i n a l

Key position Continuity

Front door lock assembly

(driver side)

5

4Unlock Yes

Neutral / Lock No

6Lock Yes

Neutral / Unlock No

PIIB5975E

Page 3575 of 5621

GW-56

POWER WINDOW SYSTEM

Revision: 2006 January2006 M35/M45

Power Window Serial Link Check (Passenger Side)NIS00223

1. CHECK POWER WINDOW SWITCH OUTPUT SIGNAL

With CONSULT-II

Check (“CDL LOCK SW ”, “CDL UNLOCK SW”) in DATA MONITOR mode for “POWER DOOR LOCK SYS-

TEM” with CONSULT-II. Refer to GW-31, "

DATE MONITOR" .

Without CONSULT-II

1. Remove key from ignition switch, and the door of driver side and passenger side is closed.

2. Check signal between BCM connector and ground with oscilloscope when door lock and unlock switch

(driver side and passenger side) is turned “LOCK” or “UNLOCK”.

3. Make sure signals which are shown in the figure below can be detected during 10 second just after door

lock and unlock switch (driver side and passenger side) is turned “LOCK” or “UNLOCK”.

OK or NG

OK >> Power window serial link is OK.

NG >> GO TO 2.

Monitor item Condition

CDL LOCK SW LOCK : ON

UNLOCK : OFF

CDL UNLOCK SW LOCK : OFF

UNLOCK : ON

PIIA7068E

Terminal

Signal

(Reference value) (+)

(–)

BCM connector Terminal

M1 22 Ground

PIIB5957EPIIA1297E

Page 3576 of 5621

POWER WINDOW SYSTEM

GW-57

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

2. CHECK POWER WINDOW SWITCH GROUND

1. Turn ignition switch OFF.

2. Disconnect power window main switch and front power window switch (passenger side) connector.

3. Check continuity between power window main switch connector and ground.

4. Check continuity between power window sub-switch (front passenger side) connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3. CHECK POWER WINDOW SERIAL LINK CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM connector and power window main switch connector.

3. Check continuity between BCM connector and power window sub-switch (front passenger side) connec-

tor.

OK or NG

OK >> Replace power window main switch.

NG >> Repair or replace harness.

Power window main

switch connectorTerminal

GroundContinuity

D11 17 Yes

PIIB5937E

Power window

sub-switch

(front passenger side)

connectorTerminal

GroundContinuity

D46 11 Yes

PIIB5941E

AB

Continuity

BCM connector TerminalPower window

main switch

connectorTerminal

M1 22 D10 14 Yes

PIIB5958E

AB

Continuity

BCM connector TerminalPower window

sub- switch

(front passenger side)

connectorTerminal

M1 22 D46 16 Yes

PIIB5959E

Page 3577 of 5621

GW-58

POWER WINDOW SYSTEM

Revision: 2006 January2006 M35/M45

Power Window Serial Link Check (Rear LH or RH)NIS00224

1. CHECK POWER WINDOW SWITCH

Change with operative power window sub-switch (rear LH or RH).

Whether operates normally is confirmed?

YES >> Replace power window sub-switch (rear LH or RH).

NO >> GO TO 2.

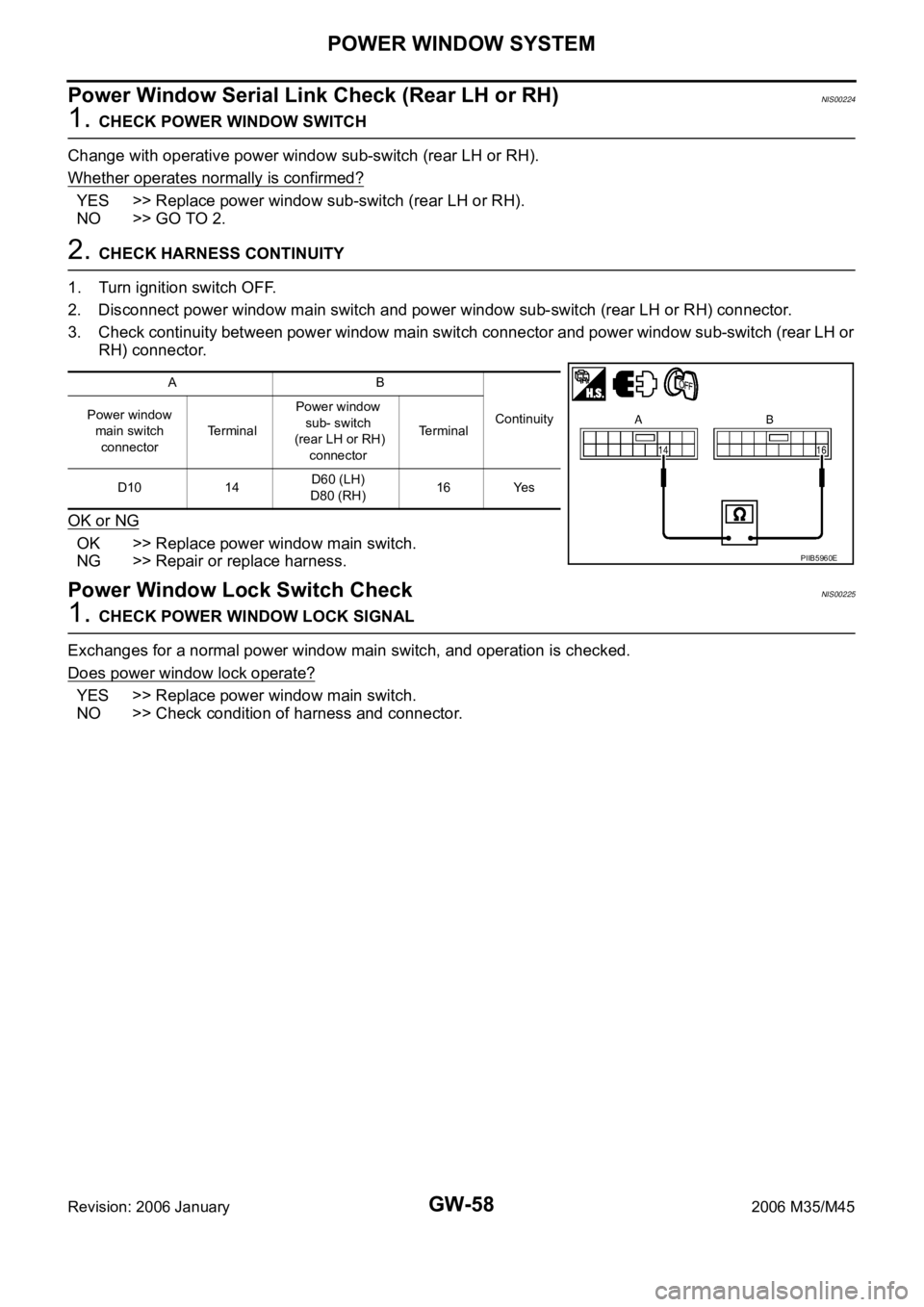

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect power window main switch and power window sub-switch (rear LH or RH) connector.

3. Check continuity between power window main switch connector and power window sub-switch (rear LH or

RH) connector.

OK or NG

OK >> Replace power window main switch.

NG >> Repair or replace harness.

Power Window Lock Switch CheckNIS00225

1. CHECK POWER WINDOW LOCK SIGNAL

Exchanges for a normal power window main switch, and operation is checked.

Does power window lock operate?

YES >> Replace power window main switch.

NO >> Check condition of harness and connector.

AB

Continuity Power window

main switch

connectorTe r m i n a lPower window

sub- switch

(rear LH or RH)

connectorTerminal

D10 14D60 (LH)

D80 (RH)16 Yes

PIIB5960E

Page 3584 of 5621

FRONT DOOR GLASS AND REGULATOR

GW-65

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

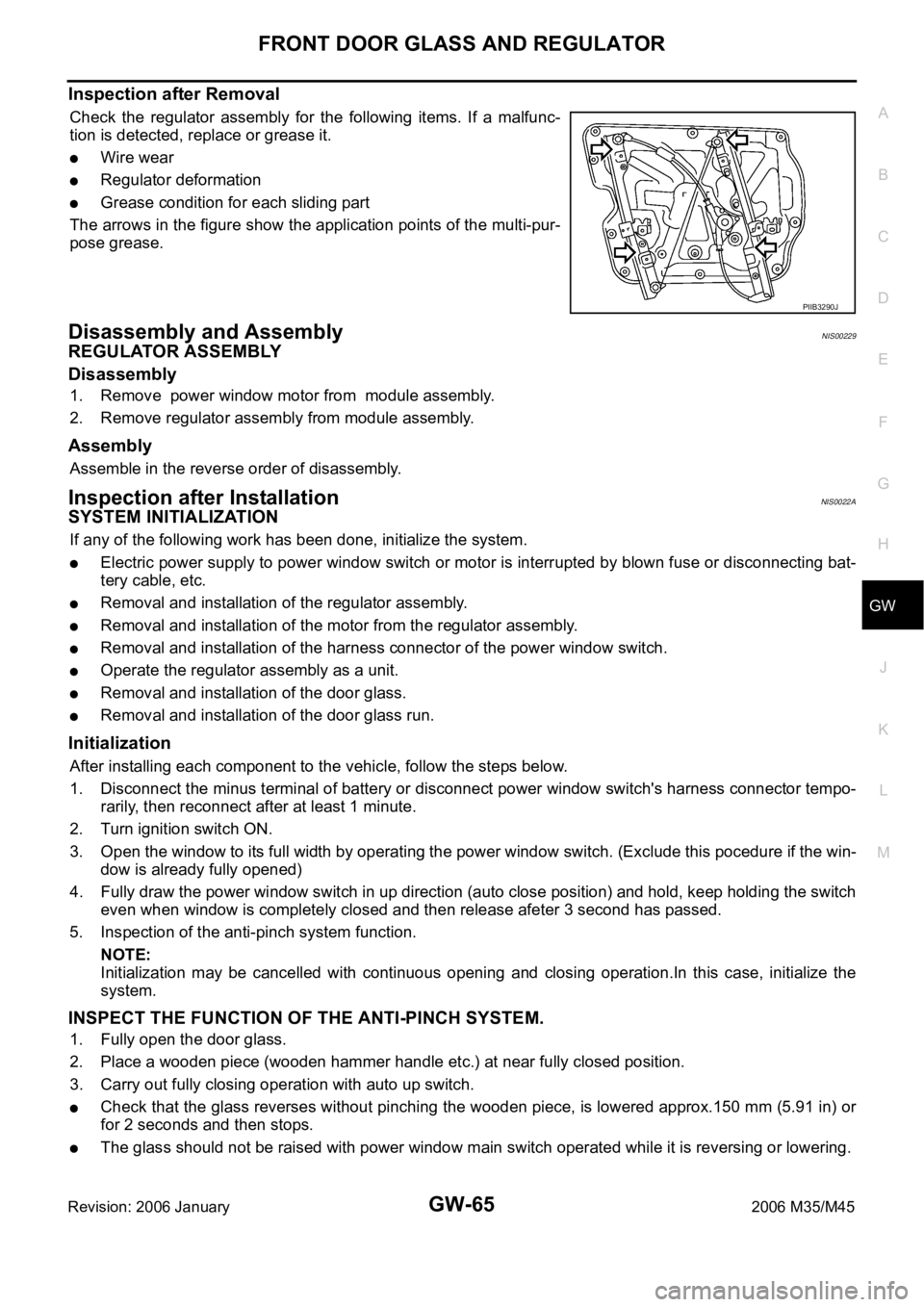

Inspection after Removal

Check the regulator assembly for the following items. If a malfunc-

tion is detected, replace or grease it.

Wire wear

Regulator deformation

Grease condition for each sliding part

The arrows in the figure show the application points of the multi-pur-

pose grease.

Disassembly and AssemblyNIS00229

REGULATOR ASSEMBLY

Disassembly

1. Remove power window motor from module assembly.

2. Remove regulator assembly from module assembly.

Assembly

Assemble in the reverse order of disassembly.

Inspection after InstallationNIS0022A

SYSTEM INITIALIZATION

If any of the following work has been done, initialize the system.

Electric power supply to power window switch or motor is interrupted by blown fuse or disconnecting bat-

tery cable, etc.

Removal and installation of the regulator assembly.

Removal and installation of the motor from the regulator assembly.

Removal and installation of the harness connector of the power window switch.

Operate the regulator assembly as a unit.

Removal and installation of the door glass.

Removal and installation of the door glass run.

Initialization

After installing each component to the vehicle, follow the steps below.

1. Disconnect the minus terminal of battery or disconnect power window switch's harness connector tempo-

rarily, then reconnect after at least 1 minute.

2. Turn ignition switch ON.

3. Open the window to its full width by operating the power window switch. (Exclude this pocedure if the win-

dow is already fully opened)

4. Fully draw the power window switch in up direction (auto close position) and hold, keep holding the switch

even when window is completely closed and then release afeter 3 second has passed.

5. Inspection of the anti-pinch system function.

NOTE:

Initialization may be cancelled with continuous opening and closing operation.In this case, initialize the

system.

INSPECT THE FUNCTION OF THE ANTI-PINCH SYSTEM.

1. Fully open the door glass.

2. Place a wooden piece (wooden hammer handle etc.) at near fully closed position.

3. Carry out fully closing operation with auto up switch.

Check that the glass reverses without pinching the wooden piece, is lowered approx.150 mm (5.91 in) or

for 2 seconds and then stops.

The glass should not be raised with power window main switch operated while it is reversing or lowering.

PIIB3290J

Page 3585 of 5621

GW-66

FRONT DOOR GLASS AND REGULATOR

Revision: 2006 January2006 M35/M45

CAUTION:

Do not inspect with pinching a part of worker's body, a hand etc. Work carefully not to be pinched.

Check that auto up function is normal before inspection following the system initialization.

FITTING INSPECTION

Make sure the glass is securely fit into the glass run groove.

Lower the glass slightly [approx. 10 to 20 mm (0.39 to 0.79 in)] and make sure the clearance to the sash is

parallel. If the clearance between the glass and sash is not parallel, loosen the regulator mounting bolts,

guide rail mounting bolts, and glass and guide rail mounting bolts to correct the glass position.

Page 3588 of 5621

REAR DOOR GLASS AND REGULATOR

GW-69

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

3. Operate the power window switch to raise/lower the door win-

dow until the glass mounting bolts can be seen.

4. Remove the glass mounting bolts.

5. Raise up the door glass and hold with a suction lifter A.

6. Disconnect the connector for the regulator assembly.

7. Remove the regulator mounting bolts, and remove the regulator

from the door panel.

Installation

Install in the reverse order of removal.

Inspection after Removal

Check the regulator assembly for the following items. If a malfunction is detected, replace or grease it.

Gear wear

Regulator deformation

Grease condition for each sliding part

The arrows in the figure show the application points of the multi-pur-

pose grease.

PIIB3297J

PIIB3511J

PIIB3298J

PIIB3299J

Page 3589 of 5621

GW-70

REAR DOOR GLASS AND REGULATOR

Revision: 2006 January2006 M35/M45

Disassembly and AssemblyNIS0022C

REGULATOR ASSEMBLY

Disassembly

Remove power window motor from regulator assembly.

Assembly

Assemble in the reverse order of disassembly.

Inspection after InstallationNIS0022D

SYSTEM INITIALIZATION

If any of the following work has been done, initialize the system.

Electric power sauce to power window switch or motor is interrupted by broken fuse or disconnecting bat-

tery cable, etc.

Removal and installation of the regulator assembly.

Removal and installation of the motor from the regulator assembly.

Removal and installation of the harness connector of the power window switch.

Operate the regulator assembly as a unit.

Removal and installation of the door glass.

Removal and installation of the door glass run.

Initialization

After installing each component to the vehicle, follow the steps below.

1. Disconnect the minus terminal of battery or disconnect power window switch's harness connector tempo-

rarily, then reconnect after at least 1 minute.

2. Turn ignition switch ON.

3. Open the window to its full width by operating the power window switch. (Exclude this pocedure if the win-

dow is already fully opened)

4. Fully draw the power window switch in up direction (auto close position) and hold, keep holding the switch

even when window is completely closed and then release afeter 3 second has passed.

5. Inspection of the anti-pinch system function.

NOTE:

Initialization may be cancelled with continuous opening and closing operation.In this case, initialize the

system.

INSPECT THE FUNCTION OF THE ANTI-PINCH SYSTEM

1. Fully open the door glass.

2. Place a wooden piece (wooden hammer handle etc.) at near fully closed position.

3. Carry out fully closing operation with auto up switch.

Check that the glass reverses without pinching the wooden piece, is lowered approx.150mm (5.91in) or

for 2 seconds and then stops.

The glass should not be raised with power window main switch operated while it is reversing or lowering.

CAUTION:

Do not inspect with pinching a part of worker's body, a hand etc. Work carefully not to be pinched.

Check that auto up function is normal before inspection following the system initialization.

FITTING INSPECTION

Make sure the glass is securely fit into the glass run groove.

Lower the glass slightly [approx. 10 to 20 mm (0.39 to 0.79 in)], and make sure the clearance to the sash

is parallel. If the clearance between the glass and sash is not parallel, loosen the regulator mounting bolts,

guide rail mounting bolts, and glass and carrier plate mounting bolts to correct the glass position.

Page 3603 of 5621

GW-84

REAR WINDOW DEFOGGER

Revision: 2006 January2006 M35/M45

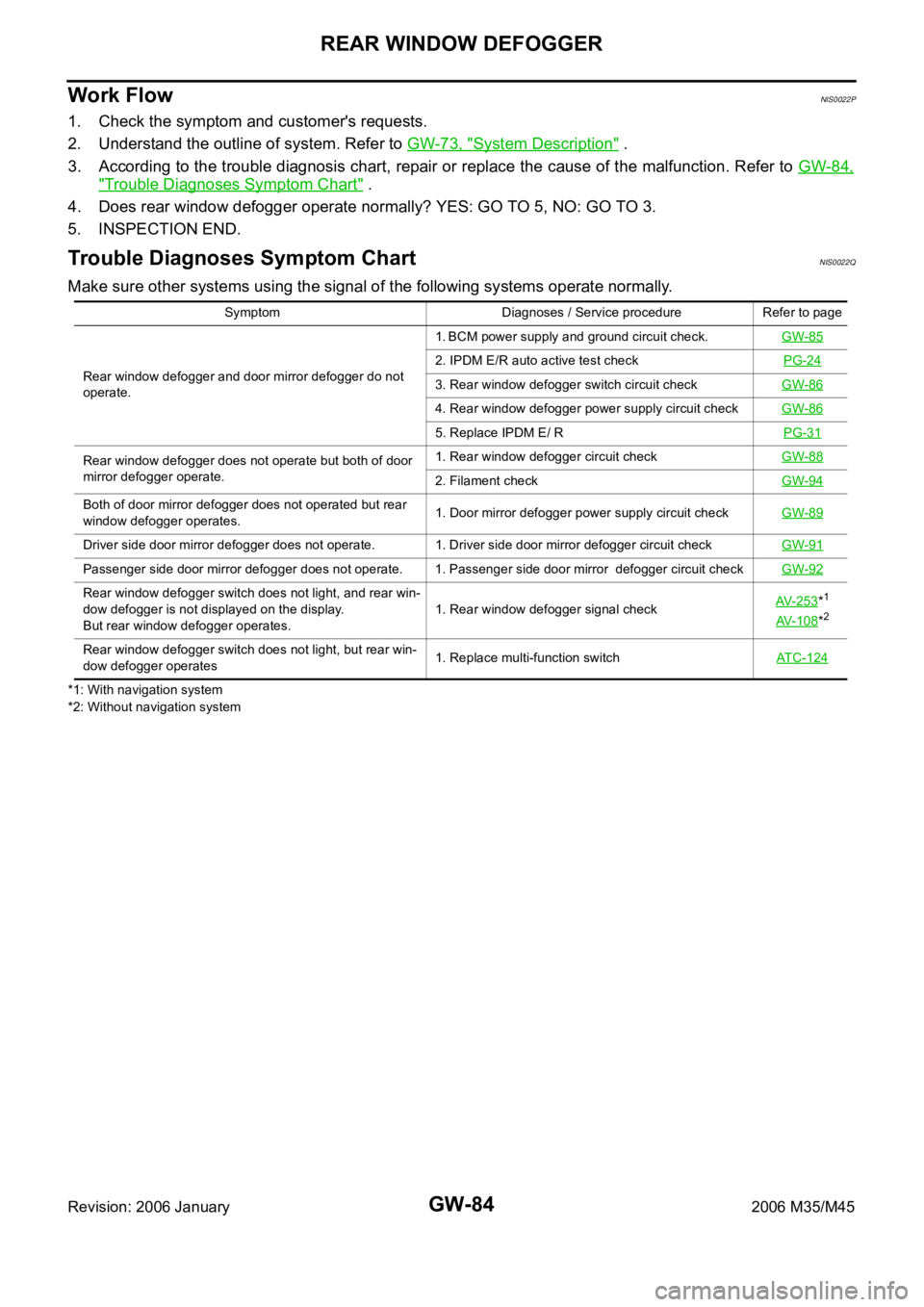

Work FlowNIS0022P

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to GW-73, "

System Description" .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to GW-84,

"Trouble Diagnoses Symptom Chart" .

4. Does rear window defogger operate normally? YES: GO TO 5, NO: GO TO 3.

5. INSPECTION END.

Trouble Diagnoses Symptom ChartNIS0022Q

Make sure other systems using the signal of the following systems operate normally.

*1: With navigation system

*2: Without navigation systemSymptom Diagnoses / Service procedure Refer to page

Rear window defogger and door mirror defogger do not

operate. 1. BCM power supply and ground circuit check.GW-85

2. IPDM E/R auto active test checkPG-24

3. Rear window defogger switch circuit checkGW-86

4. Rear window defogger power supply circuit checkGW-86

5. Replace IPDM E/ RPG-31

Rear window defogger does not operate but both of door

mirror defogger operate.1. Rear window defogger circuit checkGW-88

2. Filament checkGW-94

Both of door mirror defogger does not operated but rear

window defogger operates. 1. Door mirror defogger power supply circuit checkGW-89

Driver side door mirror defogger does not operate. 1. Driver side door mirror defogger circuit checkGW-91

Passenger side door mirror defogger does not operate. 1. Passenger side door mirror defogger circuit checkGW-92

Rear window defogger switch does not light, and rear win-

dow defogger is not displayed on the display.

But rear window defogger operates. 1. Rear window defogger signal checkAV-253*1

AV-108*2

Rear window defogger switch does not light, but rear win-

dow defogger operates1. Replace multi-function switchATC-124

Page 3604 of 5621

REAR WINDOW DEFOGGER

GW-85

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

BCM Power Supply and Ground Circuit CheckNIS0022R

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-II, when perform the each trouble

diagnosis. Refer to BCS-15, "

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)" .

1. CHECK FUSE

Check 15A fuse [No.1, located in the fuse block (J/B)]

Check 10A fuse [No.21, located in the fuse block (J/B)]

Check 50A fusible link (letter F located in the fuse and fusible link box).

NOTE:

Refer to GW-73, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate cause of malfunction before installing new fuse. Refer to

PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between BCM connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Check BCM power supply circuit for open or short.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM connector and ground.

OK or NG

OK >> Power supply and ground circuit are OK.

NG >> Check BCM ground circuit for open or short.

Terminals

Condition of

ignition switchVoltage (V)

(Approx.) (+)

(–)

BCM connector Terminal

M1 38

GroundON

Battery voltage

M242

OFF

55

PIIB5934E

BCM connector Terminal

GroundContinuity

M2 52 Yes

PIIB5935E