ECO mode INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 49 of 5621

![INFINITI M35 2006 Factory User Guide ACS-40

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

14ECM CIRCUIT

[C1A14]

ECM malfunction.

Accelerator pedal position sensor

malfunction.

ICC sensor integrated INFINITI M35 2006 Factory User Guide ACS-40

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

14ECM CIRCUIT

[C1A14]

ECM malfunction.

Accelerator pedal position sensor

malfunction.

ICC sensor integrated](/img/42/57023/w960_57023-48.png)

ACS-40

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

14ECM CIRCUIT

[C1A14]

ECM malfunction.

Accelerator pedal position sensor

malfunction.

ICC sensor integrated unit mal-

function.ACS-55

15GEAR POSITION

[C1A15]

TCM malfunction.

A/T turbine revolution sensor mal-

function.

A/T vehicle speed sensor mal-

function.ACS-56

16RADAR STAIN

[C1A16]ICC sensor integrated unit body

window has contamination.ACS-57

18LASER AIMING INCMP

[C1A18]Laser beam aiming of ICC sensor

integrated unit is not adjusted.ACS-57

21UNIT HIGH TEMP

[C1A21]Temperature around ICC sensor

integrated unit is excessively high.ACS-57

24NP RANGE

[C1A24]

Park/neutral position switch mal-

function.

TCM malfunction.ACS-58

25 SHIFT RANGE IND

[C1A25]TCM malfunction.ACS-58

26ECD MODE MALF

[C1A26]

ABS actuator and electric unit

(control unit) malfunction.

ICC sensor integrated unit mal-

function.ACS-59

27ECD PWR SUPLY CIR

[C1A27]

ABS actuator and electric unit

(control unit) power supply voltage

is excessively low.

ABS actuator and electric unit

(control unit) malfunction.ACS-59

55NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.No malfunction item has been

detected. —

100CAN COMM CIRCUIT

[U1000]

ICC sensor integrated unit detects

CAN communication malfunction.ACS-60

11 0CONTROL UNIT (CAN)

[U1010]

ICC sensor integrated unit detects

malfunction by CAN initial diagno-

sis.ACS-60

DTC

No.CONSULT-II

screen termsICC

system

warning

lampFail-safe

Malfunctions detected where...Refer-

ence

page Vehicle-

to-

vehicle

d i s t a n c e

control

modeConven-

tional

(fixed

speed)

cruise

control

modeBrake

assist

(with

preview

function)

Page 87 of 5621

AT-8

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions NCS001JE

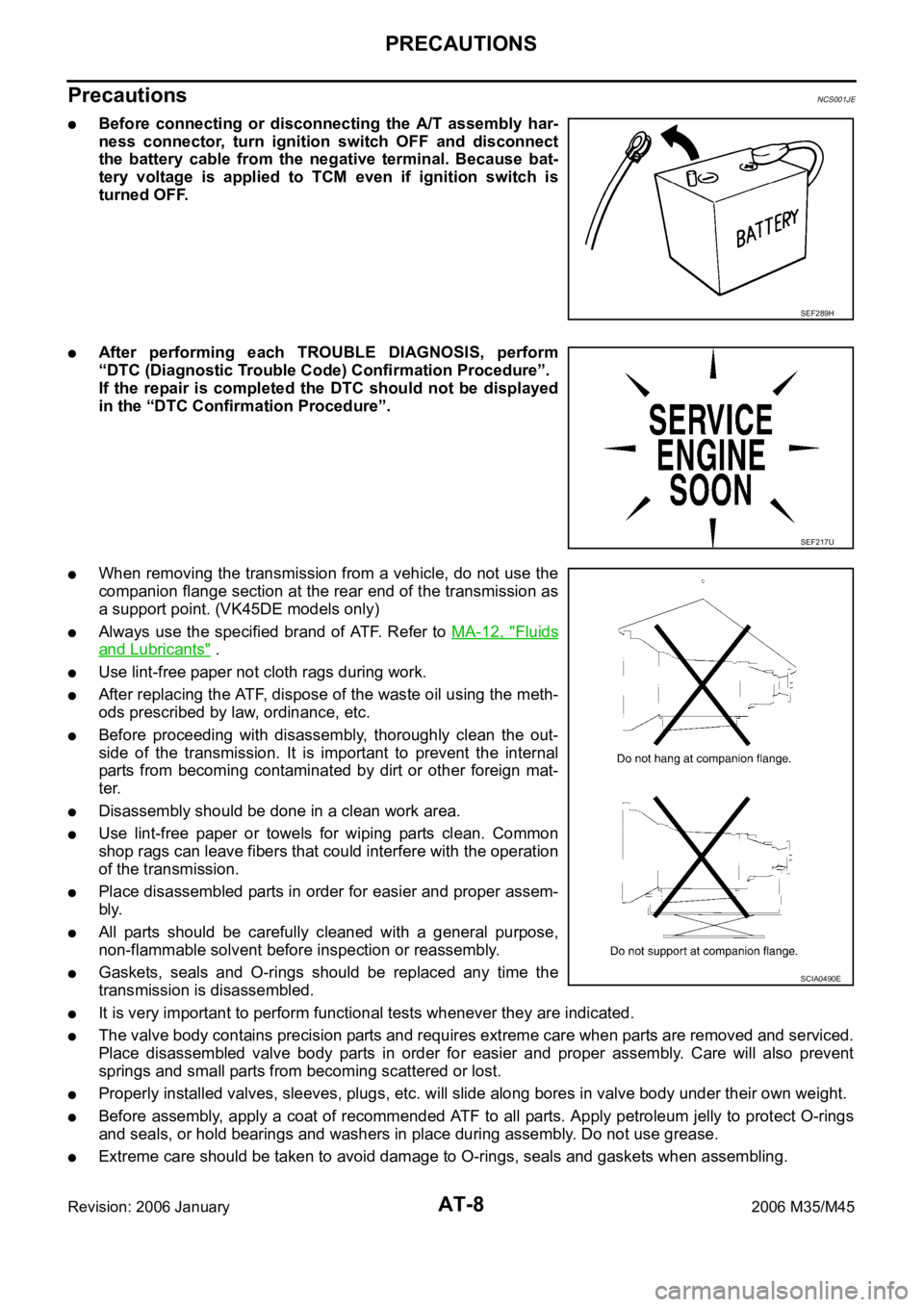

Before connecting or disconnecting the A/T assembly har-

ness connector, turn ignition switch OFF and disconnect

the battery cable from the negative terminal. Because bat-

tery voltage is applied to TCM even if ignition switch is

turned OFF.

After performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) Confirmation Procedure”.

If the repair is completed the DTC should not be displayed

in the “DTC Confirmation Procedure”.

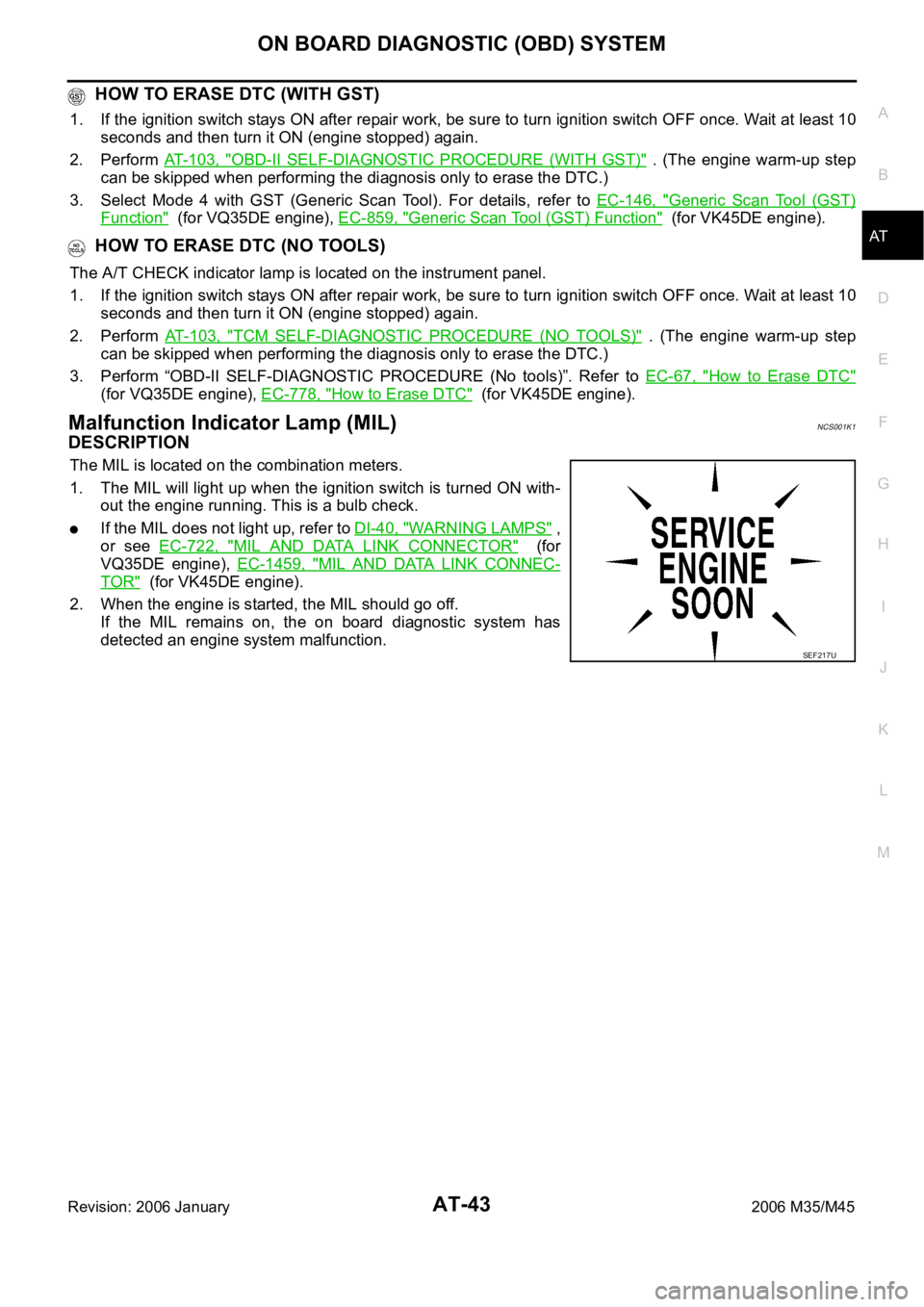

When removing the transmission from a vehicle, do not use the

companion flange section at the rear end of the transmission as

a support point. (VK45DE models only)

Always use the specified brand of ATF. Refer to MA-12, "Fluids

and Lubricants" .

Use lint-free paper not cloth rags during work.

After replacing the ATF, dispose of the waste oil using the meth-

ods prescribed by law, ordinance, etc.

Before proceeding with disassembly, thoroughly clean the out-

side of the transmission. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign mat-

ter.

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation

of the transmission.

Place disassembled parts in order for easier and proper assem-

bly.

All parts should be carefully cleaned with a general purpose,

non-flammable solvent before inspection or reassembly.

Gaskets, seals and O-rings should be replaced any time the

transmission is disassembled.

It is very important to perform functional tests whenever they are indicated.

The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

SEF289H

SEF217U

SCIA0490E

Page 119 of 5621

AT-40

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Revision: 2006 January2006 M35/M45

ON BOARD DIAGNOSTIC (OBD) SYSTEMPFP:00028

IntroductionNCS001JX

The A/T system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (OBD-II) performed by the TCM in combination

with the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC in

the ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the A/T CHECK indicator lamp. The malfunction is

stored in the TCM memory. The detected items are overlapped with OBD-II self-diagnostic items. For detail,

refer to AT- 9 2 , "

Display Items List" .

OBD-II Function for A/T SystemNCS001JY

The ECM provides emission-related on board diagnostic (OBD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-related parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indicator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in “One or Two Trip Detection Logic” when a malfunction is sensed in rela-

tion to A/T system parts.

One or Two Trip Detection Logic of OBD-IINCS001JZ

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “Trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)NCS001K0

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-II or GST) CONSULT-II or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-II also displays the malfunctioning component or system.)

1st trip DTC No. is the same as DTC No.

Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring

or occurred in the past and returned to normal.

CONSULT-II can identify them as shown below, therefore, CONSULT-II (if available) is recom-

mended.

A sample of CONSULT-II display for DTC and 1st trip DTC is shown

on the next page. DTC or 1st trip DTC of a malfunction is displayed

in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with CON-

SULT-II. Time data indicates how many times the vehicle was driven

after the last detection of a DTC.

BCIA0030E

Page 122 of 5621

ON BOARD DIAGNOSTIC (OBD) SYSTEM

AT-43

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform AT-103, "

OBD-II SELF-DIAGNOSTIC PROCEDURE (WITH GST)" . (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Select Mode 4 with GST (Generic Scan Tool). For details, refer to EC-146, "

Generic Scan Tool (GST)

Function" (for VQ35DE engine), EC-859, "Generic Scan Tool (GST) Function" (for VK45DE engine).

HOW TO ERASE DTC (NO TOOLS)

The A/T CHECK indicator lamp is located on the instrument panel.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform AT-103, "

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)" . (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Perform “OBD-II SELF-DIAGNOSTIC PROCEDURE (No tools)”. Refer to EC-67, "

How to Erase DTC"

(for VQ35DE engine), EC-778, "How to Erase DTC" (for VK45DE engine).

Malfunction Indicator Lamp (MIL)NCS001K1

DESCRIPTION

The MIL is located on the combination meters.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-40, "WARNING LAMPS" ,

or see EC-722, "

MIL AND DATA LINK CONNECTOR" (for

VQ35DE engine), EC-1459, "

MIL AND DATA LINK CONNEC-

TOR" (for VK45DE engine).

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

SEF217U

Page 123 of 5621

AT-44

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSISPFP:00004

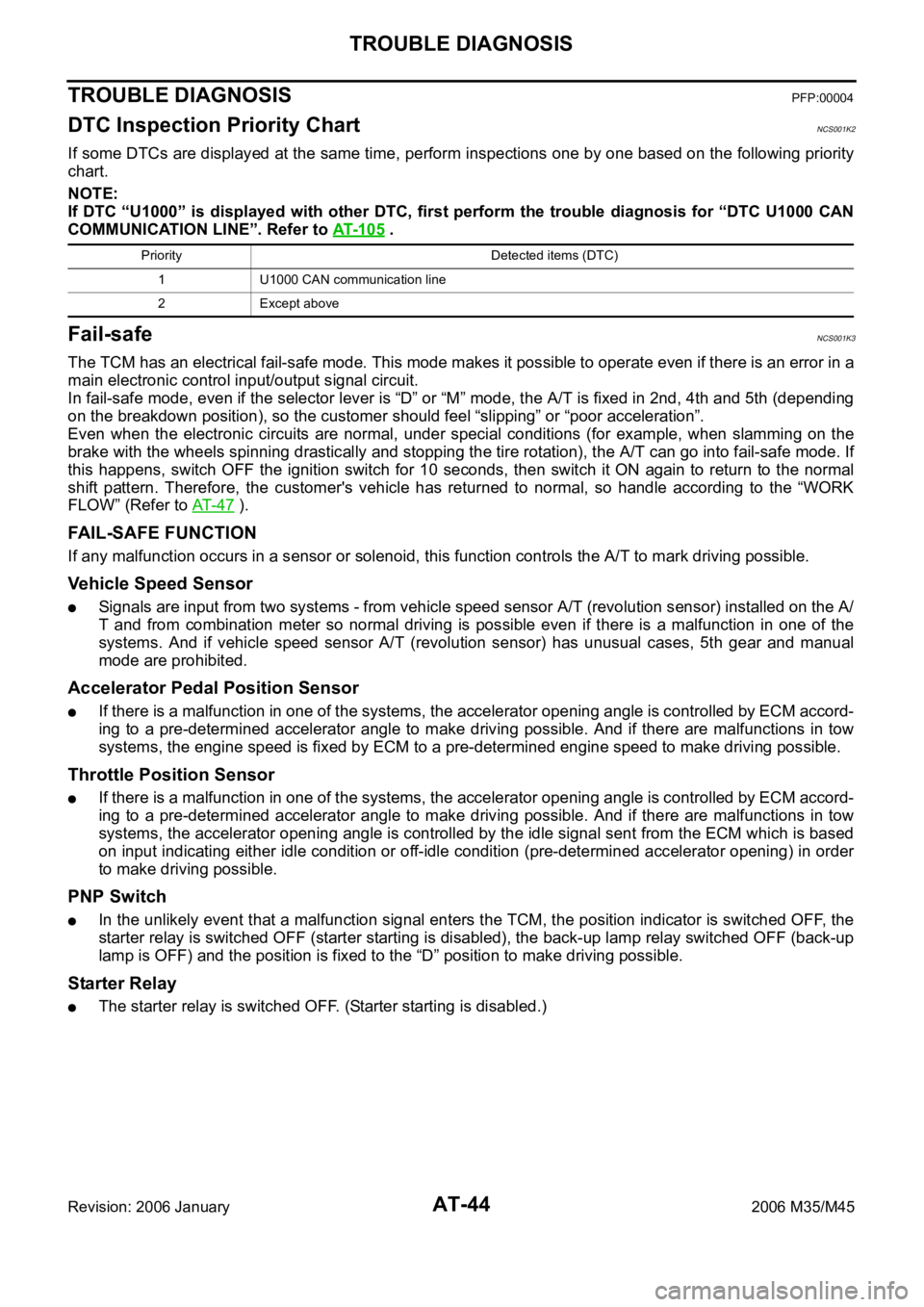

DTC Inspection Priority ChartNCS001K2

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000” is displayed with other DTC, first perform the trouble diagnosis for “DTC U1000 CAN

COMMUNICATION LINE”. Refer to AT- 1 0 5

.

Fail-safeNCS001K3

The TCM has an electrical fail-safe mode. This mode makes it possible to operate even if there is an error in a

main electronic control input/output signal circuit.

In fail-safe mode, even if the selector lever is “D” or “M” mode, the A/T is fixed in 2nd, 4th and 5th (depending

on the breakdown position), so the customer should feel “slipping” or “poor acceleration”.

Even when the electronic circuits are normal, under special conditions (for example, when slamming on the

brake with the wheels spinning drastically and stopping the tire rotation), the A/T can go into fail-safe mode. If

this happens, switch OFF the ignition switch for 10 seconds, then switch it ON again to return to the normal

shift pattern. Therefore, the customer's vehicle has returned to normal, so handle according to the “WORK

FLOW” (Refer to AT- 4 7

).

FAIL-SAFE FUNCTION

If any malfunction occurs in a sensor or solenoid, this function controls the A/T to mark driving possible.

Vehicle Speed Sensor

Signals are input from two systems - from vehicle speed sensor A/T (revolution sensor) installed on the A/

T and from combination meter so normal driving is possible even if there is a malfunction in one of the

systems. And if vehicle speed sensor A/T (revolution sensor) has unusual cases, 5th gear and manual

mode are prohibited.

Accelerator Pedal Position Sensor

If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM accord-

ing to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow

systems, the engine speed is fixed by ECM to a pre-determined engine speed to make driving possible.

Throttle Position Sensor

If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM accord-

ing to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow

systems, the accelerator opening angle is controlled by the idle signal sent from the ECM which is based

on input indicating either idle condition or off-idle condition (pre-determined accelerator opening) in order

to make driving possible.

PNP Switch

In the unlikely event that a malfunction signal enters the TCM, the position indicator is switched OFF, the

starter relay is switched OFF (starter starting is disabled), the back-up lamp relay switched OFF (back-up

lamp is OFF) and the position is fixed to the “D” position to make driving possible.

Starter Relay

The starter relay is switched OFF. (Starter starting is disabled.)

Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 136 of 5621

TROUBLE DIAGNOSIS

AT-57

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

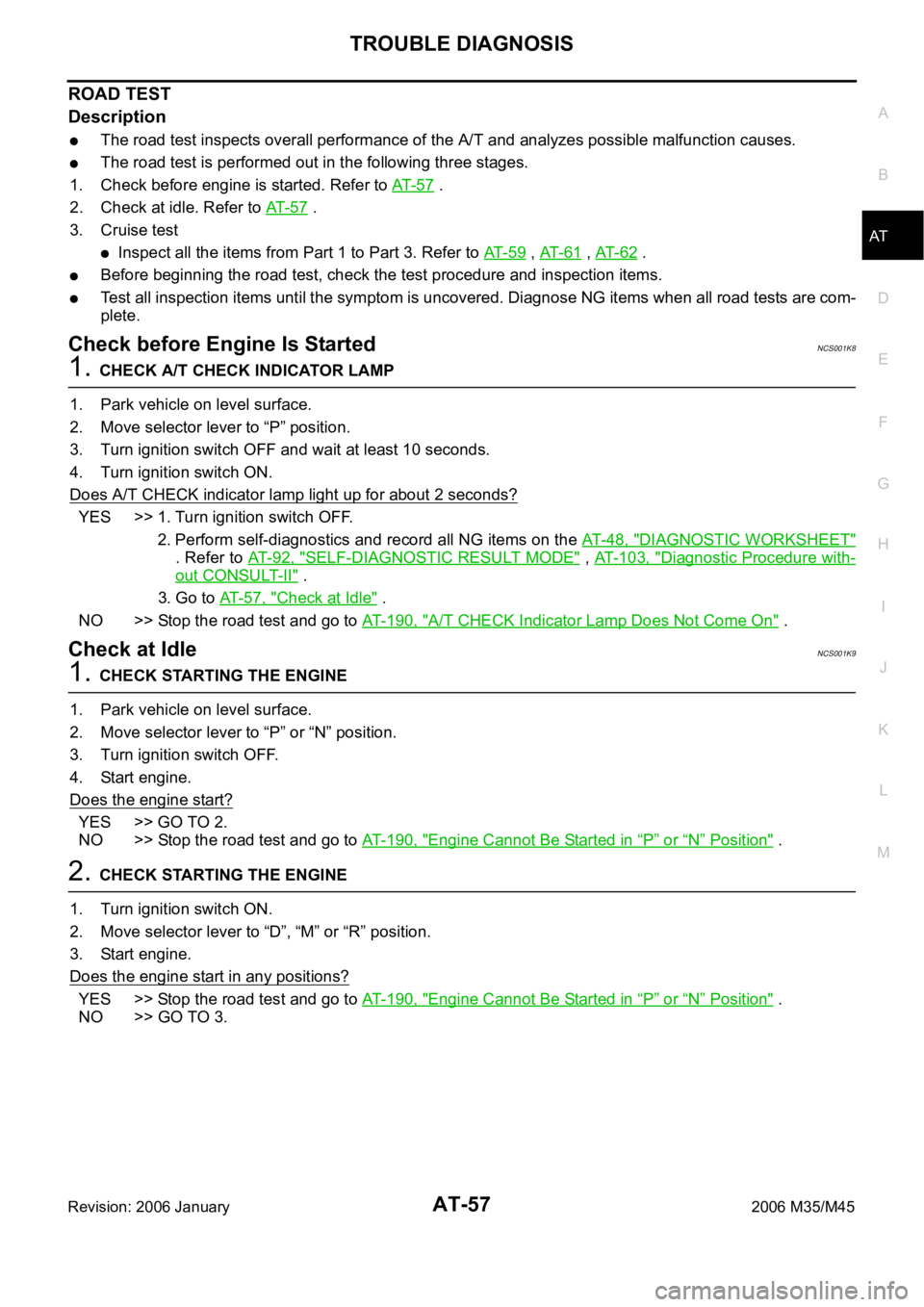

ROAD TEST

Description

The road test inspects overall performance of the A/T and analyzes possible malfunction causes.

The road test is performed out in the following three stages.

1. Check before engine is started. Refer to AT- 5 7

.

2. Check at idle. Refer to AT- 5 7

.

3. Cruise test

Inspect all the items from Part 1 to Part 3. Refer to AT- 5 9 , AT- 6 1 , AT- 6 2 .

Before beginning the road test, check the test procedure and inspection items.

Test all inspection items until the symptom is uncovered. Diagnose NG items when all road tests are com-

plete.

Check before Engine Is StartedNCS001K8

1. CHECK A/T CHECK INDICATOR LAMP

1. Park vehicle on level surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON.

Does A/T CHECK indicator lamp light up for about 2 seconds?

YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnostics and record all NG items on the AT- 4 8 , "

DIAGNOSTIC WORKSHEET"

. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "Diagnostic Procedure with-

out CONSULT-II" .

3. Go to AT- 5 7 , "

Check at Idle" .

NO >> Stop the road test and go to AT- 1 9 0 , "

A/T CHECK Indicator Lamp Does Not Come On" .

Check at IdleNCS001K9

1. CHECK STARTING THE ENGINE

1. Park vehicle on level surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Start engine.

Does the engine start?

YES >> GO TO 2.

NO >> Stop the road test and go to AT- 1 9 0 , "

Engine Cannot Be Started in “P” or “N” Position" .

2. CHECK STARTING THE ENGINE

1. Turn ignition switch ON.

2. Move selector lever to “D”, “M” or “R” position.

3. Start engine.

Does the engine start in any positions?

YES >> Stop the road test and go to AT- 1 9 0 , "Engine Cannot Be Started in “P” or “N” Position" .

NO >> GO TO 3.

Page 175 of 5621

AT-96

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

How to Erase Self-diagnostic Results

1. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE”

screen.

2. Touch ”ERASE”. (The self-diagnostic results will be erased.)

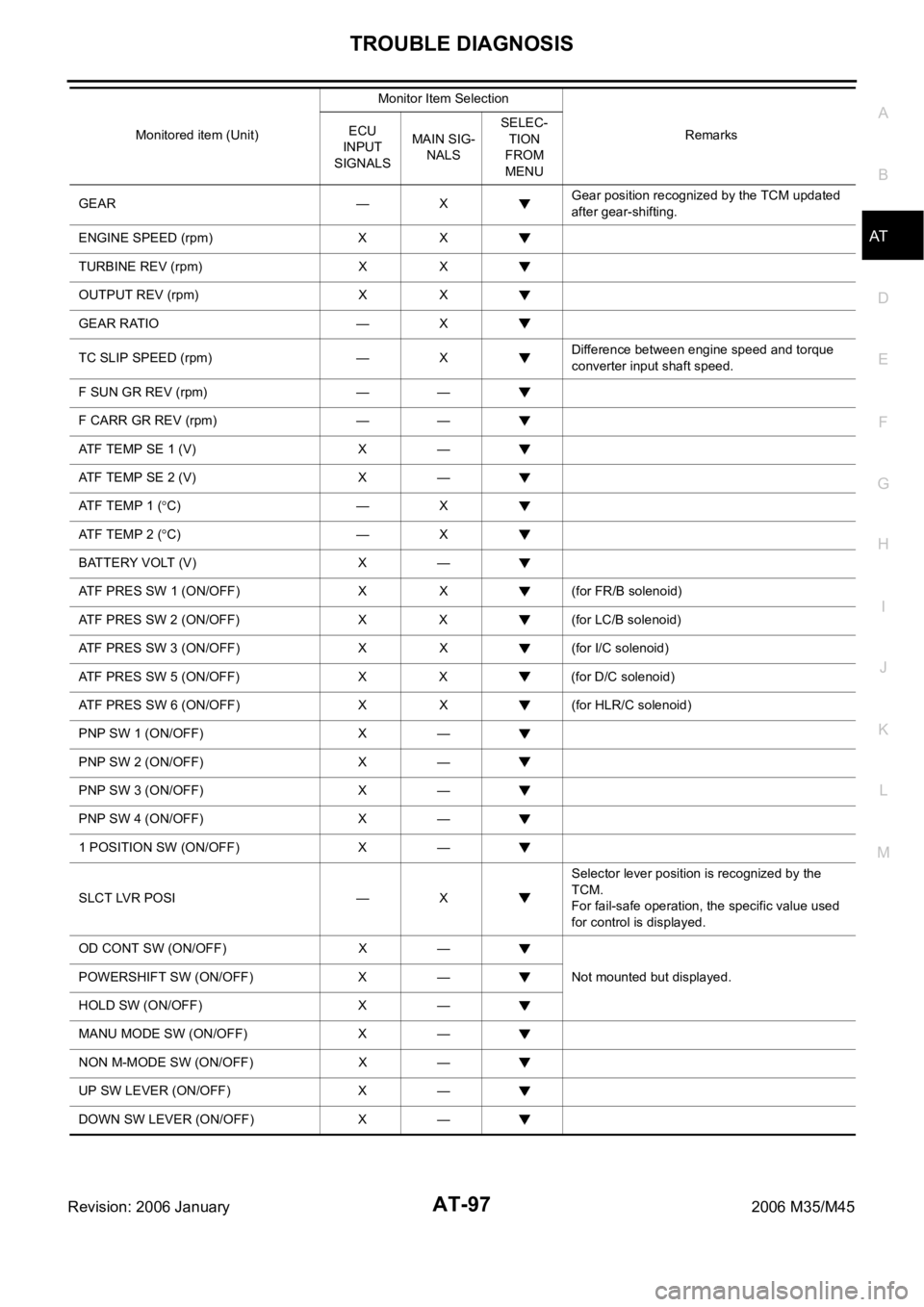

DATA MONITOR MODE

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

NOTE:

When malfunctions detected, CONSULT-II performs “REAL-

TIME DIAGNOSIS”. Also, any malfunction detected while in

this mode will be displayed at real time.

Display Items List

X: Standard, —: Not applicable, : Option

BCIA0031E

PCIA0061E

BCIA0031E

Monitored item (Unit)Monitor Item Selection

Remarks ECU

INPUT

SIGNALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

VHCL/S SEꞏA/T (km/h) X X Revolution sensor

VHCL/S SEꞏMTR (km/h) X —

ACCELE POSI (0.0/8) X — Accelerator pedal position signal

THROTTLE POSI (0.0/8) X XDegree of opening for accelerator recognized by

the TCM.

For fail-safe operation, the specific value used

for control is displayed.

CLSD THL POS (ON/OFF) X —

Signal input with CAN communications.

W/O THL POS (ON/OFF) X —

BRAKE SW (ON/OFF) X — Stop lamp switch

Page 176 of 5621

TROUBLE DIAGNOSIS

AT-97

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

GEAR — XGear position recognized by the TCM updated

after gear-shifting.

ENGINE SPEED (rpm) X X

TURBINE REV (rpm) X X

OUTPUT REV (rpm) X X

GEAR RATIO — X

TC SLIP SPEED (rpm) — XDifference between engine speed and torque

converter input shaft speed.

F SUN GR REV (rpm) — —

F CARR GR REV (rpm) — —

ATF TEMP SE 1 (V) X —

ATF TEMP SE 2 (V) X —

ATF TEMP 1 (

C) — X

ATF TEMP 2 (

C) — X

BATTERY VOLT (V) X —

ATF PRES SW 1 (ON/OFF) X X (for FR/B solenoid)

ATF PRES SW 2 (ON/OFF) X X (for LC/B solenoid)

ATF PRES SW 3 (ON/OFF) X X (for I/C solenoid)

ATF PRES SW 5 (ON/OFF) X X (for D/C solenoid)

ATF PRES SW 6 (ON/OFF) X X (for HLR/C solenoid)

PNP SW 1 (ON/OFF) X —

PNP SW 2 (ON/OFF) X —

PNP SW 3 (ON/OFF) X —

PNP SW 4 (ON/OFF) X —

1 POSITION SW (ON/OFF) X —

SLCT LVR POSI — XSelector lever position is recognized by the

TCM.

For fail-safe operation, the specific value used

for control is displayed.

OD CONT SW (ON/OFF) X —

Not mounted but displayed. POWERSHIFT SW (ON/OFF) X —

HOLD SW (ON/OFF) X —

MANU MODE SW (ON/OFF) X —

NON M-MODE SW (ON/OFF) X —

UP SW LEVER (ON/OFF) X —

DOWN SW LEVER (ON/OFF) X —Monitored item (Unit)Monitor Item Selection

Remarks ECU

INPUT

SIGNALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

Page 178 of 5621

TROUBLE DIAGNOSIS

AT-99

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

ATF WARN LAMP (ON/OFF) — — Not mounted but displayed.

BACK-UP LAMP (ON/OFF) — —

STARTER RELAY (ON/OFF) — —

PNP SW3 MON (ON/OFF) — —

C/V CLB ID1 — —

C/V CLB ID2 — —

C/V CLB ID3 — —

UNIT CLB ID1 — —

UNIT CLB ID2 — —

UNIT CLB ID3 — —

TRGT GR RATIO — —

TRGT PRES TCC (kPa) — —

TRGT PRES L/P (kPa) — —

TRGT PRES I/C (kPa) — —

TRGT PRE FR/B (kPa) — —

TRGT PRES D/C (kPa) — —

TRG PRE HLR/C (kPa) — —

SHIFT PATTERN — —

DRV CST JUDGE — —

START RLY MON — —

NEXT GR POSI — —

SHIFT MODE — —

MANU GR POSI — —

VEHICLE SPEED (km/h) — X Vehicle speed recognized by the TCM.

Voltage (V) — —Displays the value measured by the voltage

probe.

Frequency (Hz) — —

The value measured by the pulse probe is dis-

played. DUTY-HI (high) (%) — —

DUTY-LOW (low) (%) — —

PLS WIDTH-HI (ms) — —

PLS WIDTH-LOW (ms) — —Monitored item (Unit)Monitor Item Selection

Remarks ECU

INPUT

SIGNALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

Page 182 of 5621

TROUBLE DIAGNOSIS

AT-103

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Diagnostic Procedure without CONSULT-IINCS001KI

OBD-II SELF-DIAGNOSTIC PROCEDURE (WITH GST)

Refer to EC-146, "Generic Scan Tool (GST) Function" (for VQ35DE engine), EC-859, "Generic Scan Tool

(GST) Function" (for VK45DE engine).

OBD-II SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

Refer to EC-69, "Malfunction Indicator Lamp (MIL)" (for VQ35DE engine), EC-780, "Malfunction Indicator

Lamp (MIL)" (for VK45DE engine).

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

Description

As a method for locating the suspect circuit, when the self-diagnostics start signal is input, the memory for the

malfunction location is output and the A/T CHECK indicator lamp flashes to display the corresponding DTC.

Operation Procedure

1. CHECK A/T CHECK INDICATOR LAMP

1. Start the engine with selector lever in “P” position. Warm engine to normal operating temperature.

2. Turn ignition switch ON and OFF at least twice, then leave it in the OFF position.

3. Wait 10 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does A/T CHECK indicator lamp come on for about 2 seconds?

YES >> GO TO 2.

NO >> GO TO AT-190, "

A/T CHECK Indicator Lamp Does Not Come On" .

2. JUDGEMENT PROCEDURE

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Release accelerator pedal. (Set the closed throttle position signal ON.)

5. Depress brake pedal. (Stop lamp switch signal ON.)

6. Turn ignition switch ON.

7. Wait 3 seconds.

8. Move the selector lever to the manual shift gate side. (Manual mode signal ON.)

9. Release brake pedal. (Stop lamp switch signal OFF.)

10. Move the selector lever to “D” position. (Manual mode signal OFF.)

11. Depress brake pedal. (Stop lamp switch signal ON.)

12. Release brake pedal. (Stop lamp switch signal OFF.)

13. Depress accelerator pedal fully and release it.

>> GO TO 3.

3. CHECK SELF-DIAGNOSIS CODE

Check A/T CHECK indicator lamp.

Refer to AT-104, "

Judgement Self-diagnosis Code" .

If the system does not go into self-diagnostics. Refer to AT- 11 3 , "

DTC P0705 PARK/NEUTRAL POSITION

SWITCH" , AT- 1 8 4 , "CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIRCUIT" ,

AT- 1 6 7 , "

DTC P1815 MANUAL MODE SWITCH" , AT-185, "BRAKE SIGNAL CIRCUIT" .

>>DIAGNOSIS END