heater INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 450 of 5621

ATC-3

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45 INSPECTION FLOW ......................................... . 111

Memory Function .................................................. 112

INSPECTION FLOW .......................................... 112

Ambient Sensor Circuit ......................................... 113

COMPONENT DESCRIPTION .......................... 113

AMBIENT TEMPERATURE INPUT PROCESS .. 113

DIAGNOSIS PROCEDURE FOR AMBIENT

SENSOR ............................................................ 113

COMPONENT INSPECTION ............................. 115

In-Vehicle Sensor Circuit ....................................... 116

COMPONENT DESCRIPTION .......................... 116

DIAGNOSIS PROCEDURE FOR IN-VEHICLE

SENSOR ............................................................ 117

COMPONENT INSPECTION ............................. 118

Sunload Sensor Circuit ......................................... 119

COMPONENT DESCRIPTION .......................... 119

SUNLOAD INPUT PROCESS ........................... 119

DIAGNOSIS PROCEDURE FOR SUNLOAD

SENSOR ............................................................ 119

COMPONENT INSPECTION ............................121

Intake Sensor Circuit ............................................122

COMPONENT DESCRIPTION .........................122

DIAGNOSIS PROCEDURE FOR INTAKE SEN-

SOR ..................................................................122

COMPONENT INSPECTION ............................123

CONTROLLER .......................................................124

Removal and Installation of Multifunction Switch . 124

REMOVAL ........................................................

.124

INSTALLATION .................................................124

AUTO AMP .............................................................125

Removal and Installation of Unified Meter and A/C

Auto Amp. ............................................................125

REMOVAL ........................................................

.125

INSTALLATION .................................................125

AMBIENT SENSOR ................................................126

Removal and Installation ......................................126

REMOVAL ........................................................

.126

INSTALLATION .................................................126

IN-VEHICLE SENSOR ............................................127

Removal and Installation ......................................127

REMOVAL ........................................................

.127

INSTALLATION .................................................127

SUNLOAD SENSOR ..............................................128

Removal and Installation ......................................128

REMOVAL ........................................................

.128

INSTALLATION .................................................128

INTAKE SENSOR .................................................. .129

Removal and Installation ......................................129

REMOVAL ........................................................

.129

INSTALLATION .................................................129

BLOWER UNIT .......................................................130

Removal and Installation ......................................130

REMOVAL ........................................................

.130

INSTALLATION .................................................130

Disassembly and Assembly .................................131

BLOWER MOTOR ..................................................132

Removal and Installation ......................................132

REMOVAL ........................................................

.132

INSTALLATION .................................................132INTAKE DOOR MOTOR .........................................133

Removal and Installation ......................................133

REMOVAL ........................................................

.133

INSTALLATION .................................................133

IN-CABIN MICROFILTER .......................................134

Removal and Installation ......................................134

FUNCTION .......................................................

.134

REPLACEMENT TIMING ..................................134

REPLACEMENT PROCEDURES .....................134

HEATER & COOLING UNIT ASSEMBLY ...............135

Removal and Installation ......................................135

REMOVAL ........................................................

.135

INSTALLATION .................................................136

Disassembly and Assembly ..................................138

MODE DOOR MOTOR ............................................140

Removal and Installation ......................................140

REMOVAL ........................................................

.140

INSTALLATION .................................................140

AIR MIX DOOR MOTOR .........................................141

Removal and Installation ......................................141

REMOVAL ........................................................

.141

INSTALLATION .................................................141

UPPER VENTILATOR DOOR MOTOR ..................142

Removal and Installation ......................................142

REMOVAL ........................................................

.142

INSTALLATION .................................................142

HEATER CORE .......................................................143

Removal and Installation ......................................143

REMOVAL ........................................................

.143

INSTALLATION .................................................143

DUCTS AND GRILLES ...........................................144

Removal and Installation ......................................144

COMPONENT LAYOUT ....................................144

REMOVAL ........................................................

.146

INSTALLATION .................................................150

REFRIGERANT LINES ...........................................151

HFC-134a (R-134a) Service Procedure ...............151

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................151

Components ....................................................

.....153

VQ35DE ............................................................153

VK45DE .............................................................154

Removal and Installation of Compressor ..............155

REMOVAL ........................................................

.155

INSTALLATION .................................................157

Check Disc to Pulley Clearance ...........................157

Removal and Installation of Low-Pressure Flexible

Hose and Pipe ......................................................158

REMOVAL ........................................................

.158

INSTALLATION .................................................158

Removal and Installation of High-Pressure Flexible

Hose .....................................................................159

REMOVAL ........................................................

.159

INSTALLATION .................................................160

Removal and Installation of High-Pressure Pipe 1

(Engine Compartment) .........................................160

REMOVAL ........................................................

.160

INSTALLATION .................................................161

Removal and Installation of Low-Pressure Pipe 1

Page 526 of 5621

TROUBLE DIAGNOSIS

ATC-79

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

Mode Door Control Specification

COMPONENT DESCRIPTION

Mode Door Motor

The mode door motors are attached to the heater & cooling unit

assembly. It rotates so that air is discharged from the outlet set by

the unified meter and A/C amp. Motor rotation is conveyed to a link

which activates the mode door.

DIAGNOSIS PROCEDURE FOR MODE DOOR MOTOR

SYMPTOM: Mode door motor does not operate normally.

Perform diagnosis procedure. Refer to AT C - 7 0 , "

DIAGNOSIS PROCEDURE FOR LAN CIRCUIT" .

RJIA1778E

RJIA4057E

RJIA4058E

Page 529 of 5621

ATC-82

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Upper Ventilator Door Control Specification

COMPONENT DESCRIPTION

Upper Ventilator Door Motor

The upper ventilator door motor is attached to the heater & cooling

unit assembly. It rotates so that air is discharged from the outlet set

by the unified meter and A/C amp. Motor rotation is conveyed to a

rod which activates the upper ventilator door.

DIAGNOSIS PROCEDURE FOR UPPER VENTILATOR DOOR MOTOR

SYMPTOM: Upper ventilator door motor does not operate normally.

Perform diagnosis procedure. Refer to AT C - 7 0 , "

DIAGNOSIS PROCEDURE FOR LAN CIRCUIT" .

RJIA4061E

RJIA4062E

Page 532 of 5621

TROUBLE DIAGNOSIS

ATC-85

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

COMPONENT DESCRIPTION

Air Mix Door Motor

The air mix door motors are attached to the heater & cooling unit

assembly. It rotates so that the air mix door is opened or closed to a

position set by the unified meter and A/C amp. Motor rotation is then

conveyed through a shaft and the air mix door position feedback is

then sent to the unified meter and A/C amp. by PBR built-in air mix

door motor.

DIAGNOSIS PROCEDURE FOR AIR MIX DOOR MOTOR

SYMPTOM: Discharge air temperature does not change.

Perform diagnosis procedure. Refer to AT C - 7 0 , "

DIAGNOSIS PROCEDURE FOR LAN CIRCUIT" .

Air Mix Door Motor PBR CircuitNJS000GR

SYMPTOM:

Discharge air temperature does not change.

PBR circuit is open or shorted.

DIAGNOSIS PROCEDURE FOR AIR MIX DOOR MOTOR PBR

Perform diagnosis procedure. Refer to AT C - 7 0 , "DIAGNOSIS PROCEDURE FOR LAN CIRCUIT" .

RJIA4064E

RJIA4065E

Page 544 of 5621

TROUBLE DIAGNOSIS

ATC-97

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

5. CHECK BCM INPUT (COMPRESSOR ON) SIGNAL

Check compressor ON/OFF signal. Refer to AT C - 4 0 , "

CONSULT-II

Function (ECM)" .

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

6. CHECK REFRIGERANT PRESSURE SENSOR

WITH CONSULT-II

1. Start the engine.

2. Check voltage of refrigerant pressure sensor. Refer to EC-149, "

CONSULT-II Reference Value in Data

Monitor" (VQ35DE) or EC-862, "CONSULT-II Reference Value in Data Monitor" (VK45DE).

WITHOUT CONSULT-II

1. Start the engine.

2. Check voltage between ECM harness connector F108 terminal

70 and ground.

OK or NG

OK >>WITH CONSULT-II: GO TO 7.

WITHOUT CONSULT-II: Repair harness or connector.

NG >> Refer to EC-692, "

REFRIGERANT PRESSURE SENSOR" (VQ35DE) or EC-1434, "REFRIGER-

ANT PRESSURE SENSOR" (VK45DE).

7. CHECK ECM INPUT (FAN ON) SIGNAL

Check FAN ON/OFF signal. Refer to AT C - 4 0 , "

CONSULT-II Function

(ECM)" .

OK or NG

OK >> GO TO 8.

NG >> Repair harness or connector.A/C SW ON : AIR COND SIG ON

A/C SW OFF : AIR COND SIG OFF

RJIA3646E

Terminals

Condition Voltage (+)

(

)

ECM

connectorTerminal

No.

F108 70 GroundA/C switch: ON

(Blower motor operates.)Approx. 1.0 -

4.0 V

PBIB1188E

FAN SW ON : HEATER FAN SW ON

FAN SW OFF : HEATER FAN SW OFF

RJIA3646E

Page 563 of 5621

ATC-116

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

In-Vehicle Sensor CircuitNJS000H1

COMPONENT DESCRIPTION

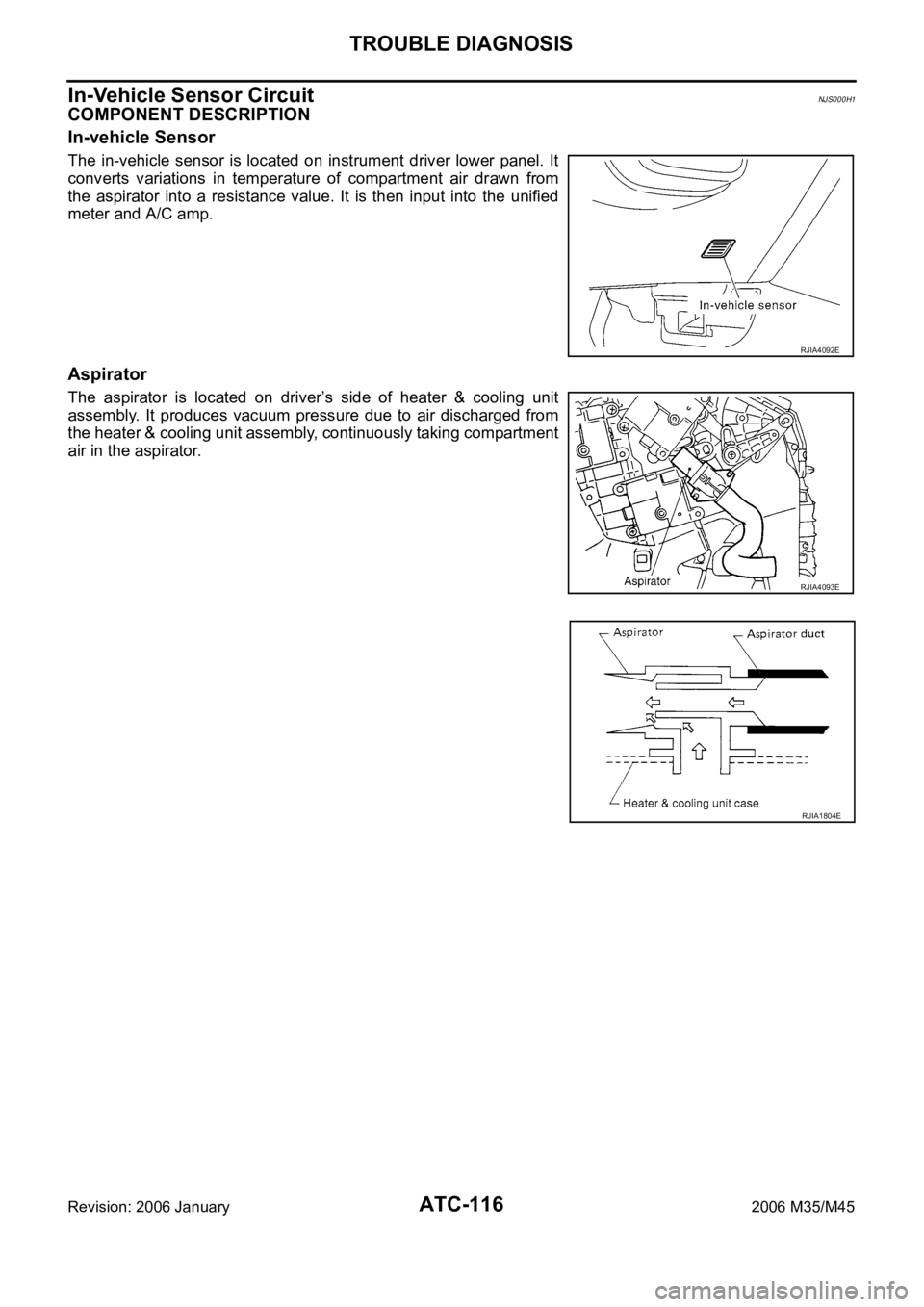

In-vehicle Sensor

The in-vehicle sensor is located on instrument driver lower panel. It

converts variations in temperature of compartment air drawn from

the aspirator into a resistance value. It is then input into the unified

meter and A/C amp.

Aspirator

The aspirator is located on driver’s side of heater & cooling unit

assembly. It produces vacuum pressure due to air discharged from

the heater & cooling unit assembly, continuously taking compartment

air in the aspirator.

RJIA4092E

RJIA4093E

RJIA1804E

Page 569 of 5621

ATC-122

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Intake Sensor CircuitNJS000H3

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit assembly. It

converts temperature of air after it passes through the evaporator

into a resistance value which is then input to the unified meter and A/

C amp.

DIAGNOSIS PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. (24 or 24 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M82

terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector M82

terminal 2 and unified meter and A/C amp. harness connector

M65 terminal 59.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

RJIA4103E

RJIA4104E

1 – Ground : Approx. 5 V

RJIA4215E

2 – 59 : Continuity should exist.

RJIA4106E

Page 582 of 5621

HEATER & COOLING UNIT ASSEMBLY

ATC-135

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

HEATER & COOLING UNIT ASSEMBLYPFP:27110

Removal and InstallationNJS000HF

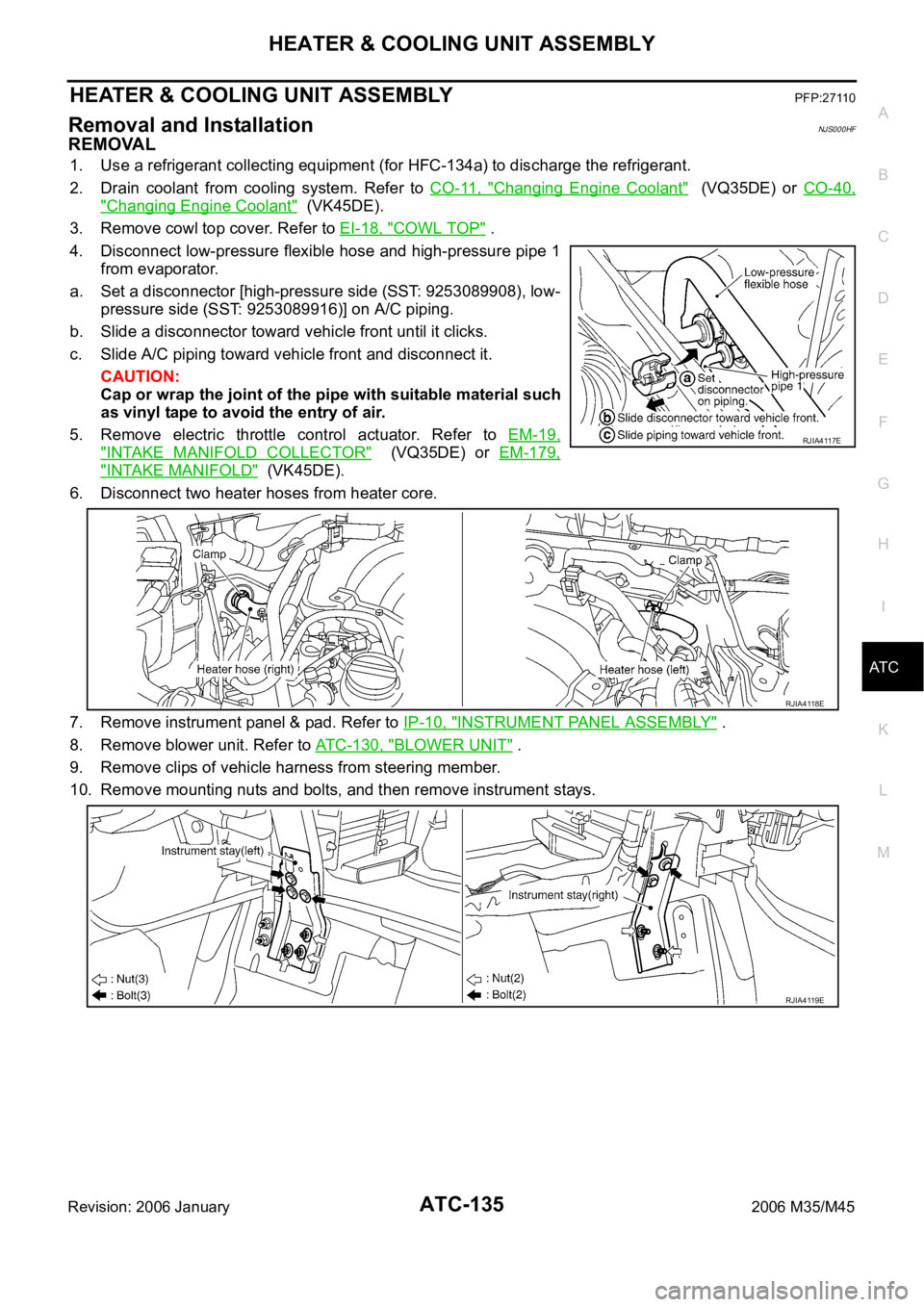

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Drain coolant from cooling system. Refer to CO-11, "

Changing Engine Coolant" (VQ35DE) or CO-40,

"Changing Engine Coolant" (VK45DE).

3. Remove cowl top cover. Refer to EI-18, "

COWL TOP" .

4. Disconnect low-pressure flexible hose and high-pressure pipe 1

from evaporator.

a. Set a disconnector [high-pressure side (SST: 9253089908), low-

pressure side (SST: 9253089916)] on A/C piping.

b. Slide a disconnector toward vehicle front until it clicks.

c. Slide A/C piping toward vehicle front and disconnect it.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

5. Remove electric throttle control actuator. Refer to EM-19,

"INTAKE MANIFOLD COLLECTOR" (VQ35DE) or EM-179,

"INTAKE MANIFOLD" (VK45DE).

6. Disconnect two heater hoses from heater core.

7. Remove instrument panel & pad. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

8. Remove blower unit. Refer to ATC-130, "

BLOWER UNIT" .

9. Remove clips of vehicle harness from steering member.

10. Remove mounting nuts and bolts, and then remove instrument stays.

RJIA4117E

RJIA4118E

RJIA4119E

Page 583 of 5621

ATC-136

HEATER & COOLING UNIT ASSEMBLY

Revision: 2006 January2006 M35/M45

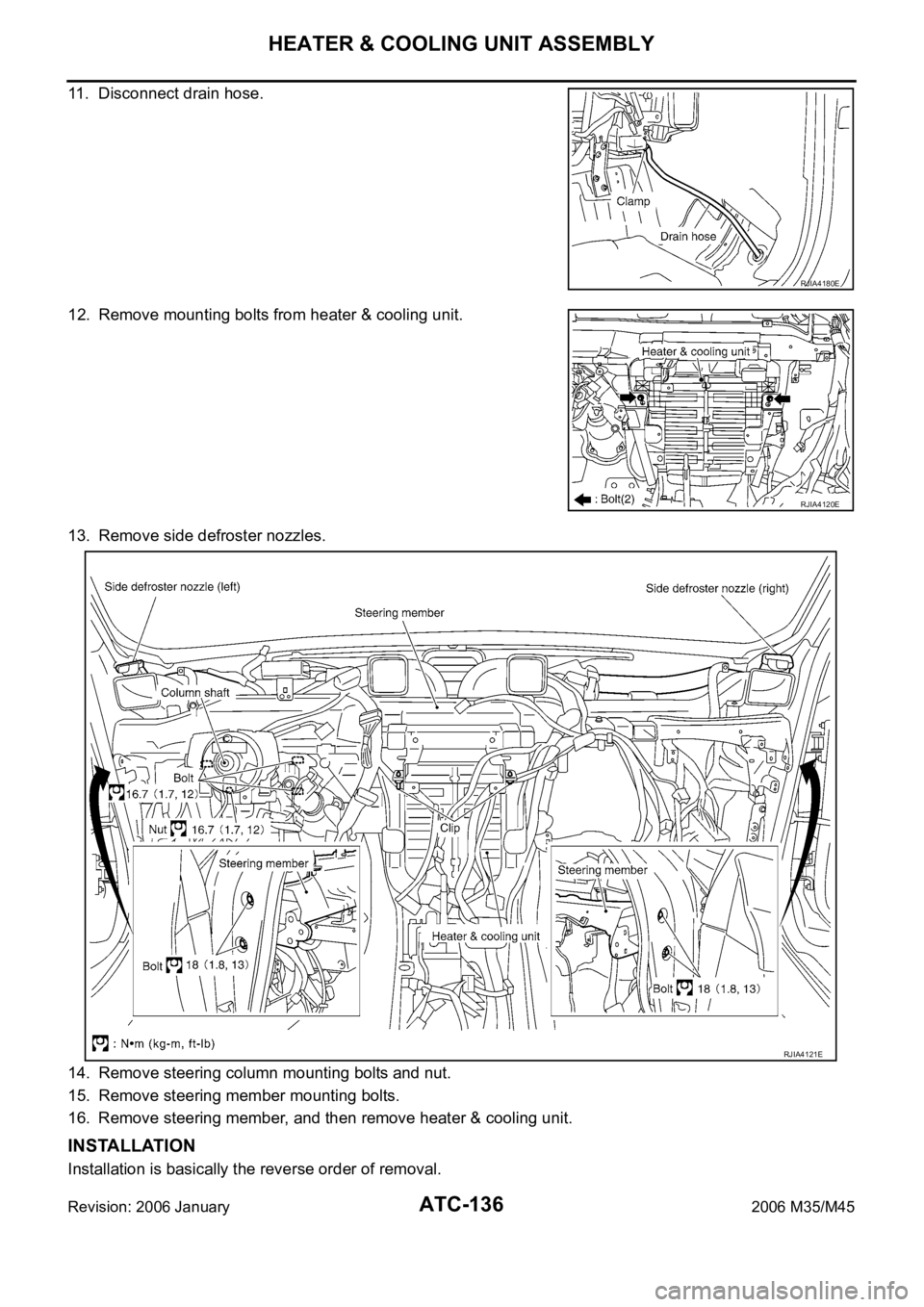

11. Disconnect drain hose.

12. Remove mounting bolts from heater & cooling unit.

13. Remove side defroster nozzles.

14. Remove steering column mounting bolts and nut.

15. Remove steering member mounting bolts.

16. Remove steering member, and then remove heater & cooling unit.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA4180E

RJIA4120E

RJIA4121E

Page 584 of 5621

HEATER & COOLING UNIT ASSEMBLY

ATC-137

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

CAUTION:

Replace O-rings of A/C piping with new ones, and then apply compressor oil to it when installing

it.

Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

When recharging refrigerant, check for leaks.

NOTE:

When filling radiator with coolant, refer to CO-11, "Changing Engine Coolant" (VQ35DE) or CO-40,

"Changing Engine Coolant" (VK45DE).

Recharge the refrigerant.

Heater & cooling unit assembly mounting bolt

: 6.9 Nꞏm (0.7 kg-m, 61 in-lb)

Instrument stay mounting nut and bolt

: 12 Nꞏm (1.25 kg-m, 9 ft-lb)