pressure INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 110 of 5621

A/T CONTROL SYSTEM

AT-31

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

TCM FunctionNCS001JP

The function of the TCM is to:

Receive input signals sent from various switches and sensors.

Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLINE

The A/T senses vehicle operating conditions through various sensors or signals. It always controls the opti-

mum shift position and reduces shifting and lock-up shocks.

CONTROL SYSTEM DIAGRAM

SENSORS (or SIGNAL)TCMACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Manual mode switch signal

Stop lamp switch signal

Turbine revolution sensor

ATF pressure switchShift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

Duet-EA control

CAN systemInput clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch

solenoid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Back-up lamp relay

Sta r te r re l a y

SCIA5325E

Page 111 of 5621

AT-32

A/T CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

CAN CommunicationNCS001JQ

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. Refer to LAN-34, "

CAN

Communication Unit" .

Input/Output Signal of TCMNCS001JR

*1: Spare for vehicle speed sensorꞏA/T (revolution sensor)

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: Used as a condition for starting self-diagnostics; if self-diagnostics are not started, it is judged that there is some kind of error.

*5: Input by CAN communications.

*6: Output by CAN communications.Control itemLine

pressure

controlVehicle

speed

controlShift

controlLock-up

controlEngine

brake

controlFail-safe

function

(*3)Self-diag-

nostics

function

InputAccelerator pedal position signal

(*5)XXXXXXX

Vehicle speed sensor A/T

(revolution sensor)XXXXXXX

Vehicle speed sensor MTR

(*1) (*5)X

Closed throttle position signal

(*5)X(*2) X X X X(*4)

Wide open throttle position signal

(*5)XX(*4)

Turbine revolution sensor 1 X X X X X

Turbine revolution sensor 2

(for 4th speed only)X XXXX

Engine speed signals

(*5)XXXXXXX

Stop lamp switch signal

(*5)XXX X(*4)

A/T fluid temperature sensors 1, 2XXXX XX

ASCD or ICC

sensor inte-

grated unitOperation signal

(*5)XXX

Overdrive cancel

signal

(*5)X

Out-

putDirect clutch solenoid

(ATF pressure switch 5)XX XX

Input clutch solenoid

(ATF pressure switch 3)XX XX

High and low reverse clutch solenoid

(ATF pressure switch 6)XX XX

Front brake solenoid

(ATF pressure switch 1)XX XX

Low coast brake solenoid

(ATF pressure switch 2)XX XXX

Line pressure solenoidXXXXXXX

TCC solenoid X X X

Self-diagnostics table

(*6)X

Starter relayXX

Page 112 of 5621

A/T CONTROL SYSTEM

AT-33

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Line Pressure ControlNCS001JS

When an input torque signal equivalent to the engine drive force is sent from the ECM to the TCM, the

TCM controls the line pressure solenoid.

This line pressure solenoid controls the pressure regulator valve as the signal pressure and adjusts the

pressure of the operating oil discharged from the oil pump to the line pressure most appropriate to the

driving state.

LINE PRESSURE CONTROL IS BASED ON THE TCM LINE PRESSURE CHARACTERISTIC

PATTERN

The TCM has stored in memory a number of patterns for the optimum line pressure characteristic for the

driving state.

In order to obtain the most appropriate line pressure characteristic to meet the current driving state, the

TCM controls the line pressure solenoid current value and thus controls the line pressure.

Normal Control

Each clutch is adjusted to the necessary pressure to match the

engine drive force.

Back-up Control (Engine Brake)

When the select operation is performed during driving and the A/T is

shifted down, the line pressure is set according to the vehicle speed.

PCIA0007E

PCIA0008E

PCIA0009E

Page 113 of 5621

AT-34

A/T CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

During Shift Change

The necessary and adequate line pressure for shift change is set.

For this reason, line pressure pattern setting corresponds to input

torque and gearshift selection. Also, line pressure characteristic is

according to engine speed, during engine brake operation.

At Low Fluid Temperature

When the A/T fluid temperature drops below the prescribed tempera-

ture, in order to speed up the action of each friction element, the line

pressure is set higher than the normal line pressure characteristic.

Shift ControlNCS001JT

The clutch pressure control solenoid is controlled by the signals from the switches and sensors. Thus, the

clutch pressure is adjusted to be appropriate to the engine load state and vehicle driving state. It becomes

possible to finely control the clutch hydraulic pressure with high precision and a smoother shift change charac-

teristic is attained.

PCIA0010E

PCIA0011E

PCIA0012E

Page 114 of 5621

A/T CONTROL SYSTEM

AT-35

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

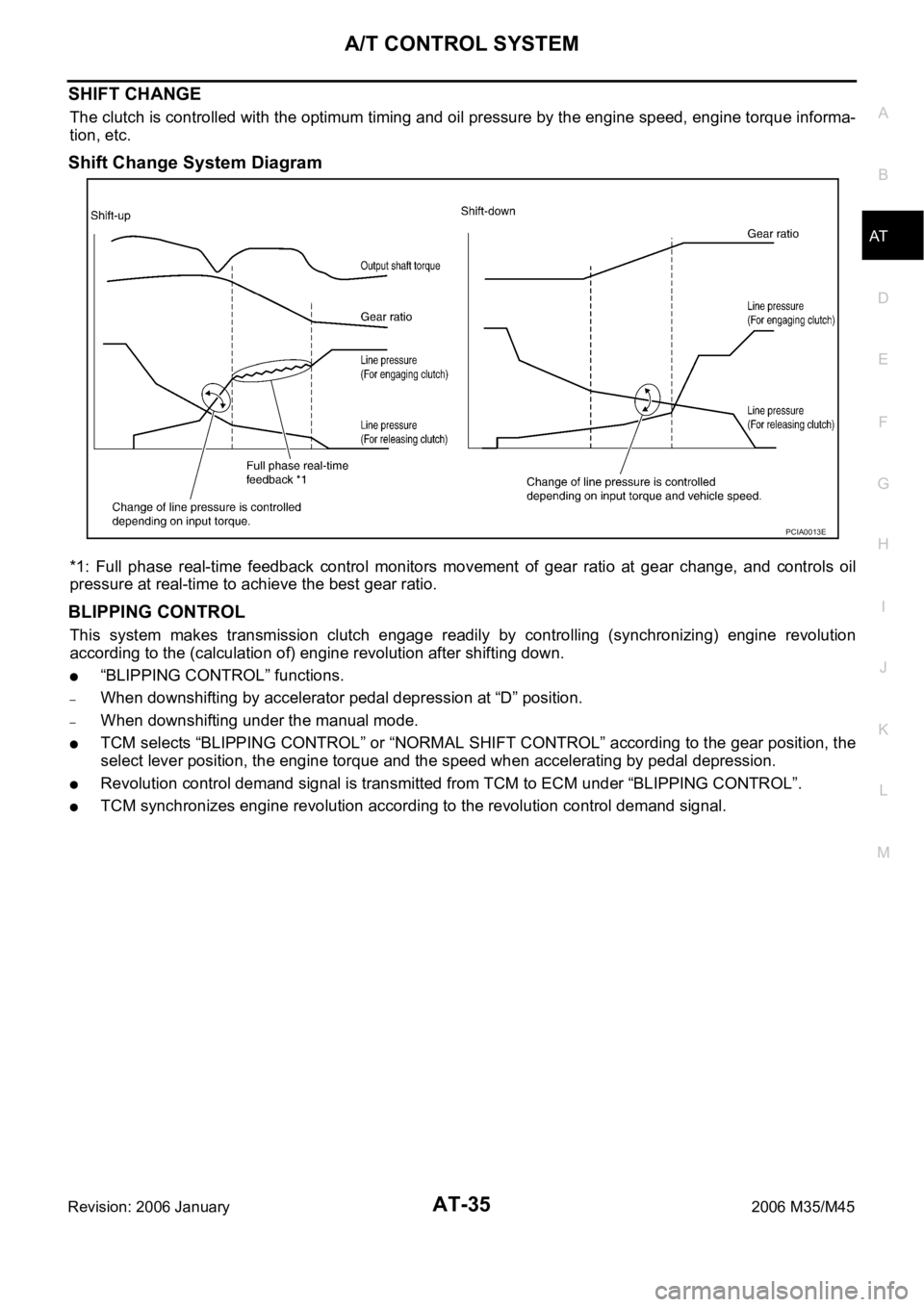

SHIFT CHANGE

The clutch is controlled with the optimum timing and oil pressure by the engine speed, engine torque informa-

tion, etc.

Shift Change System Diagram

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

pressure at real-time to achieve the best gear ratio.

BLIPPING CONTROL

This system makes transmission clutch engage readily by controlling (synchronizing) engine revolution

according to the (calculation of) engine revolution after shifting down.

“BLIPPING CONTROL” functions.

–When downshifting by accelerator pedal depression at “D” position.

–When downshifting under the manual mode.

TCM selects “BLIPPING CONTROL” or “NORMAL SHIFT CONTROL” according to the gear position, the

select lever position, the engine torque and the speed when accelerating by pedal depression.

Revolution control demand signal is transmitted from TCM to ECM under “BLIPPING CONTROL”.

TCM synchronizes engine revolution according to the revolution control demand signal.

PCIA0013E

Page 116 of 5621

A/T CONTROL SYSTEM

AT-37

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

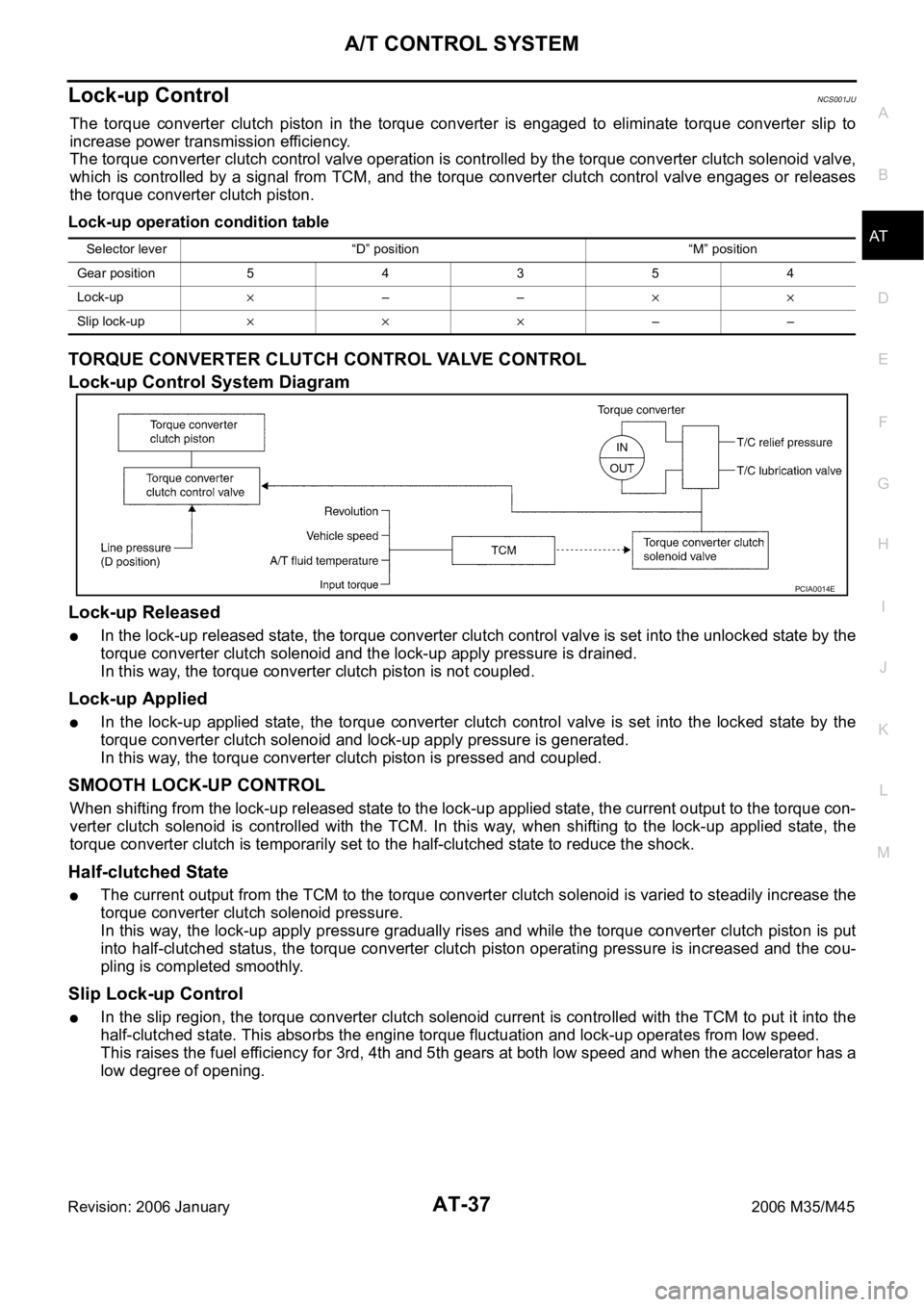

Lock-up ControlNCS001JU

The torque converter clutch piston in the torque converter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is controlled by the torque converter clutch solenoid valve,

which is controlled by a signal from TCM, and the torque converter clutch control valve engages or releases

the torque converter clutch piston.

Lock-up operation condition table

TORQUE CONVERTER CLUTCH CONTROL VALVE CONTROL

Lock-up Control System Diagram

Lock-up Released

In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied

In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the

torque converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

SMOOTH LOCK-UP CONTROL

When shifting from the lock-up released state to the lock-up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In this way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

The current output from the TCM to the torque converter clutch solenoid is varied to steadily increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put

into half-clutched status, the torque converter clutch piston operating pressure is increased and the cou-

pling is completed smoothly.

Slip Lock-up Control

In the slip region, the torque converter clutch solenoid current is controlled with the TCM to put it into the

half-clutched state. This absorbs the engine torque fluctuation and lock-up operates from low speed.

This raises the fuel efficiency for 3rd, 4th and 5th gears at both low speed and when the accelerator has a

low degree of opening.

Selector lever “D” position “M” position

Gear position 5 4 3 5 4

Lock-up

––

Slip lock-up––

PCIA0014E

Page 117 of 5621

AT-38

A/T CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

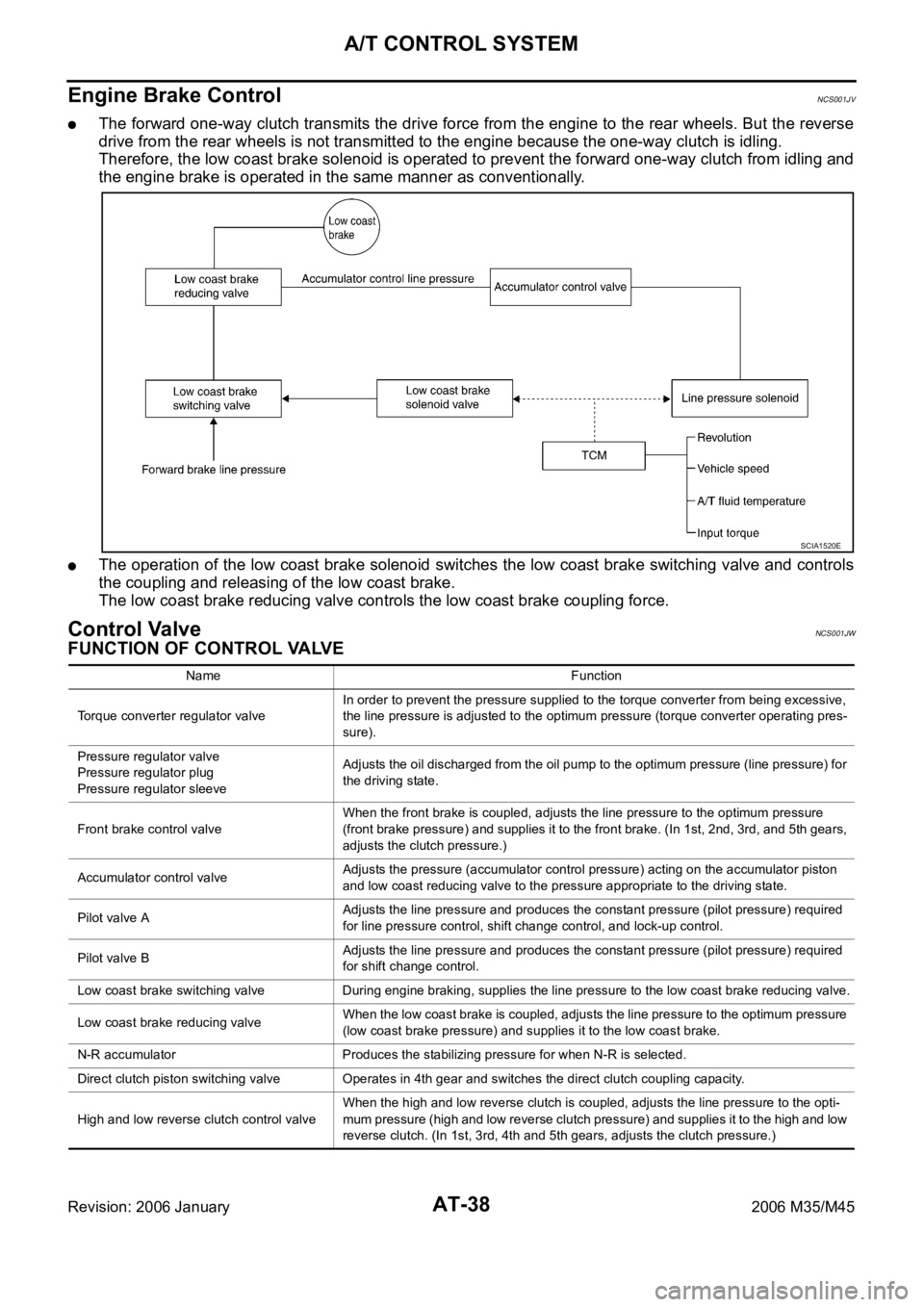

Engine Brake ControlNCS001JV

The forward one-way clutch transmits the drive force from the engine to the rear wheels. But the reverse

drive from the rear wheels is not transmitted to the engine because the one-way clutch is idling.

Therefore, the low coast brake solenoid is operated to prevent the forward one-way clutch from idling and

the engine brake is operated in the same manner as conventionally.

The operation of the low coast brake solenoid switches the low coast brake switching valve and controls

the coupling and releasing of the low coast brake.

The low coast brake reducing valve controls the low coast brake coupling force.

Control ValveNCS001JW

FUNCTION OF CONTROL VALVE

SCIA1520E

Name Function

Torque converter regulator valveIn order to prevent the pressure supplied to the torque converter from being excessive,

the line pressure is adjusted to the optimum pressure (torque converter operating pres-

sure).

Pressure regulator valve

Pressure regulator plug

Pressure regulator sleeveAdjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valveWhen the front brake is coupled, adjusts the line pressure to the optimum pressure

(front brake pressure) and supplies it to the front brake. (In 1st, 2nd, 3rd, and 5th gears,

adjusts the clutch pressure.)

Accumulator control valveAdjusts the pressure (accumulator control pressure) acting on the accumulator piston

and low coast reducing valve to the pressure appropriate to the driving state.

Pilot valve AAdjusts the line pressure and produces the constant pressure (pilot pressure) required

for line pressure control, shift change control, and lock-up control.

Pilot valve BAdjusts the line pressure and produces the constant pressure (pilot pressure) required

for shift change control.

Low coast brake switching valve During engine braking, supplies the line pressure to the low coast brake reducing valve.

Low coast brake reducing valveWhen the low coast brake is coupled, adjusts the line pressure to the optimum pressure

(low coast brake pressure) and supplies it to the low coast brake.

N-R accumulator Produces the stabilizing pressure for when N-R is selected.

Direct clutch piston switching valve Operates in 4th gear and switches the direct clutch coupling capacity.

High and low reverse clutch control valveWhen the high and low reverse clutch is coupled, adjusts the line pressure to the opti-

mum pressure (high and low reverse clutch pressure) and supplies it to the high and low

reverse clutch. (In 1st, 3rd, 4th and 5th gears, adjusts the clutch pressure.)

Page 118 of 5621

A/T CONTROL SYSTEM

AT-39

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

FUNCTION OF PRESSURE SWITCH

Input clutch control valveWhen the input clutch is coupled, adjusts the line pressure to the optimum pressure

(input clutch pressure) and supplies it to the input clutch. (In 4th and 5th gears, adjusts

the clutch pressure.)

Direct clutch control valveWhen the direct clutch is coupled, adjusts the line pressure to the optimum pressure

(direct clutch pressure) and supplies it to the direct clutch. (In 2nd, 3rd, and 4th gears,

adjusts the clutch pressure.)

TCC control valve

TCC control plug

TCC control sleeveSwitches the lock-up to operating or released. Also, by performing the lock-up operation

transiently, lock-up smoothly.

Torque converter lubrication valveOperates during lock-up to switch the torque converter, cooling, and lubrication system

oil passage.

Cool bypass valve Allows excess oil to bypass cooler circuit without being fed into it.

Line pressure relief valve Discharges excess oil from line pressure circuit.

N-D accumulator Produces the stabilizing pressure for when N-D is selected.

Manual valveSends line pressure to each circuit according to the select position. Th e circuits to which

the line pressure is not sent drain. Name Function

Name Function

ATF pressure switch 1 (FR/B)Detects any malfunction in the front brake hydraulic pressure. When it detects any mal-

function, it puts the system into fail-safe mode.

ATF pressure switch 2 (LC/B)Detects any malfunction in the low coast brake hydraulic pressure. When it detects any

malfunction, it puts the system into fail-safe mode.

ATF pressure switch 3 (I/C)Detects any malfunction in the input clutch hydraulic pressure. When it detects any mal-

function, it puts the system into fail-safe mode.

ATF pressure switch 5 (D/C)Detects any malfunction in the direct clutch hydraulic pressure. When it detects any mal-

function, it puts the system into fail-safe mode.

ATF pressure switch 6 (HLR/C)Detects any malfunction in the high and low reverse clutch hydraulic pressure. When it

detects any malfunction, it puts the system into fail-safe mode.

Page 124 of 5621

TROUBLE DIAGNOSIS

AT-45

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

A/T Interlock

If there is an A/T interlock judgment malfunction, the A/T is fixed in 2nd gear to make driving possible.

NOTE:

When the vehicle is driven fixed in 2nd gear, a turbine revolution sensor malfunction is displayed,

but this is not a turbine revolution sensor malfunction.

When the coupling pattern below is detected, the fail-safe action corresponding to the pattern is per-

formed.

A/T INTERLOCK COUPLING PATTERN TABLE

: NG X: OK

A/T 1st Engine Braking

When there is an A/T first gear engine brake judgment malfunction, the low coast brake solenoid is

switched OFF to avoid the engine brake operation.

Line Pressure Solenoid

The solenoid is switched OFF and the line pressure is set to the maximum hydraulic pressure to make

driving possible.

Torque Converter Clutch Solenoid

The solenoid is switched OFF to release the lock-up.

Low Coast Brake Solenoid

When a malfunction (electrical or functional) occurs, in order to make driving possible. If the solenoid is

ON, the A/T is held in 2nd gear. If the solenoid is OFF, the A/T is held in 4th gear. (Engine brake is not

applied in 1st and 2nd gear.)

Input Clutch Solenoid

If a malfunction (electrical or functional) occurs with the solenoid either ON or OFF, the A/T is held in 4th

gear to make driving possible.

Direct Clutch Solenoid

If a malfunction (electrical or functional) occurs with the solenoid either ON or OFF, the A/T is held in 4th

gear to make driving possible.

Front Brake Solenoid

If a malfunction (electrical or functional) occurs with the solenoid ON, in order to make driving possible.

The A/T is held in 5th gear. If the solenoid is OFF, the A/T is 4th gear.

High and Low Reverse Clutch Solenoid

If a (electrical or functional) malfunction occurs with the solenoid either ON or OFF, the A/T is held in 4th

gear to make driving possible.

Turbine Revolution Sensor 1 or 2

The control is the same as if there were no turbine revolution sensors, 5th gear and manual mode are pro-

hibited.

Gear positionATF pressure switch output

Fail-safe

functionClutch pressure output pattern after fail-safe func-

tion

SW3

(I/C)SW6

(HLR/

C)SW5

(D/C)SW1

(FR/B)SW2

(LC/B)I/C HLR/C D/C FR/B LC/B L/U

A/T inter-

lock cou-

pling pattern3rd – X X –

Held in

2nd gearOFF OFF ON OFF OFF OFF

4th – X X –

Held in

2nd gearOFF OFF ON OFF OFF OFF

5th X X – X

Held in

2nd gearOFF OFF ON OFF OFF OFF

Page 127 of 5621

AT-48

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

WHAT..... Vehicle and A/T model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Diagnostic Worksheet Chart

Customer name MR/MS Model and Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequency

Continuous Intermittent ( times a day)

Symptoms

Vehicle does not move. ( Any position Particular position)

No up-shift ( 1st 2nd 2nd 3rd 3rd 4th 4th 5th)

No down-shift ( 5th 4th 4th 3rd 3rd 2nd 2nd 1st)

Lock-up malfunction

Shift point too high or too low.

Shift shock or slip ( N D N R Lock-up Any drive position)

Noise or vibration

No kick down

No pattern select

Others

()

A/T CHECK indicator lamp

Continuously lit Not lit

Malfunction indicator lamp (MIL)

Continuously lit Not lit

1 Read the item on cautions concerning fail-safe and understand the customer's complaint.AT- 4 4

2

A/T fluid inspectionAT- 5 3

Leak (Repair leak location.)

State

Amount

3

Stall test and line pressure testAT- 5 3, AT-

55 Stall test

Torque converter one-way clutch

Front brake

High and low reverse clutch

Low coast brake

Forward brake

Reverse brake

Forward one-way clutch

1st one-way clutch

3rd one-way clutch

Engine

Line pressure low

Except for input clutch and direct

clutch, clutches and brakes OK

Line pressure inspection - Suspected part: