engine oil INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3471 of 5621

GI-8

PRECAUTIONS

Revision: 2006 January2006 M35/M45

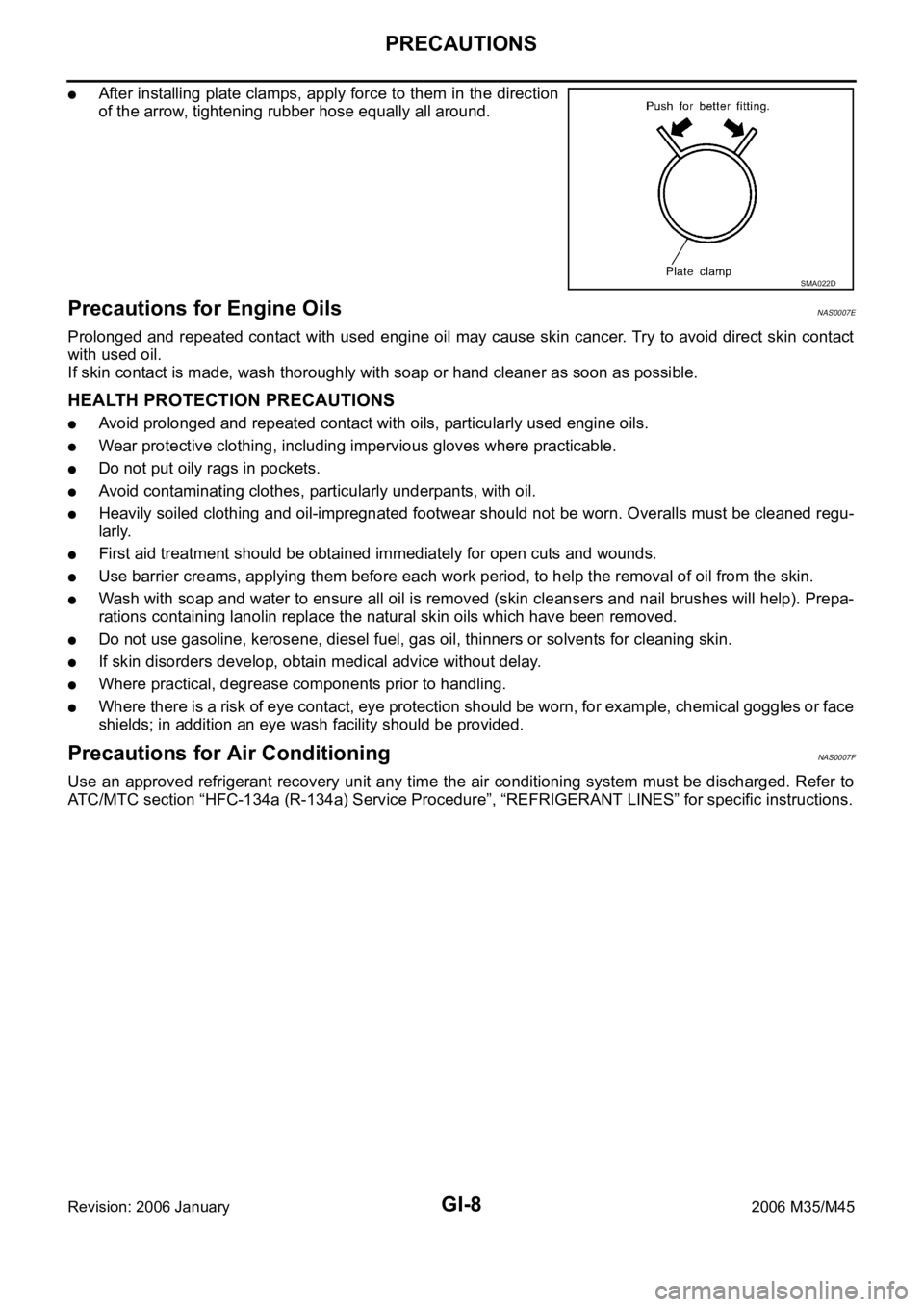

After installing plate clamps, apply force to them in the direction

of the arrow, tightening rubber hose equally all around.

Precautions for Engine OilsNAS0007E

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin contact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

Avoid prolonged and repeated contact with oils, particularly used engine oils.

Wear protective clothing, including impervious gloves where practicable.

Do not put oily rags in pockets.

Avoid contaminating clothes, particularly underpants, with oil.

Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regu-

larly.

First aid treatment should be obtained immediately for open cuts and wounds.

Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Prepa-

rations containing lanolin replace the natural skin oils which have been removed.

Do not use gasoline, kerosene, diesel fuel, gas oil, thinners or solvents for cleaning skin.

If skin disorders develop, obtain medical advice without delay.

Where practical, degrease components prior to handling.

Where there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face

shields; in addition an eye wash facility should be provided.

Precautions for Air Conditioning NAS0007F

Use an approved refrigerant recovery unit any time the air conditioning system must be discharged. Refer to

ATC/MTC section “HFC-134a (R-134a) Service Procedure”, “REFRIGERANT LINES” for specific instructions.

SMA022D

Page 3505 of 5621

GI-42

LIFTING POINT

Revision: 2006 January2006 M35/M45

LIFTING POINTPFP:00000

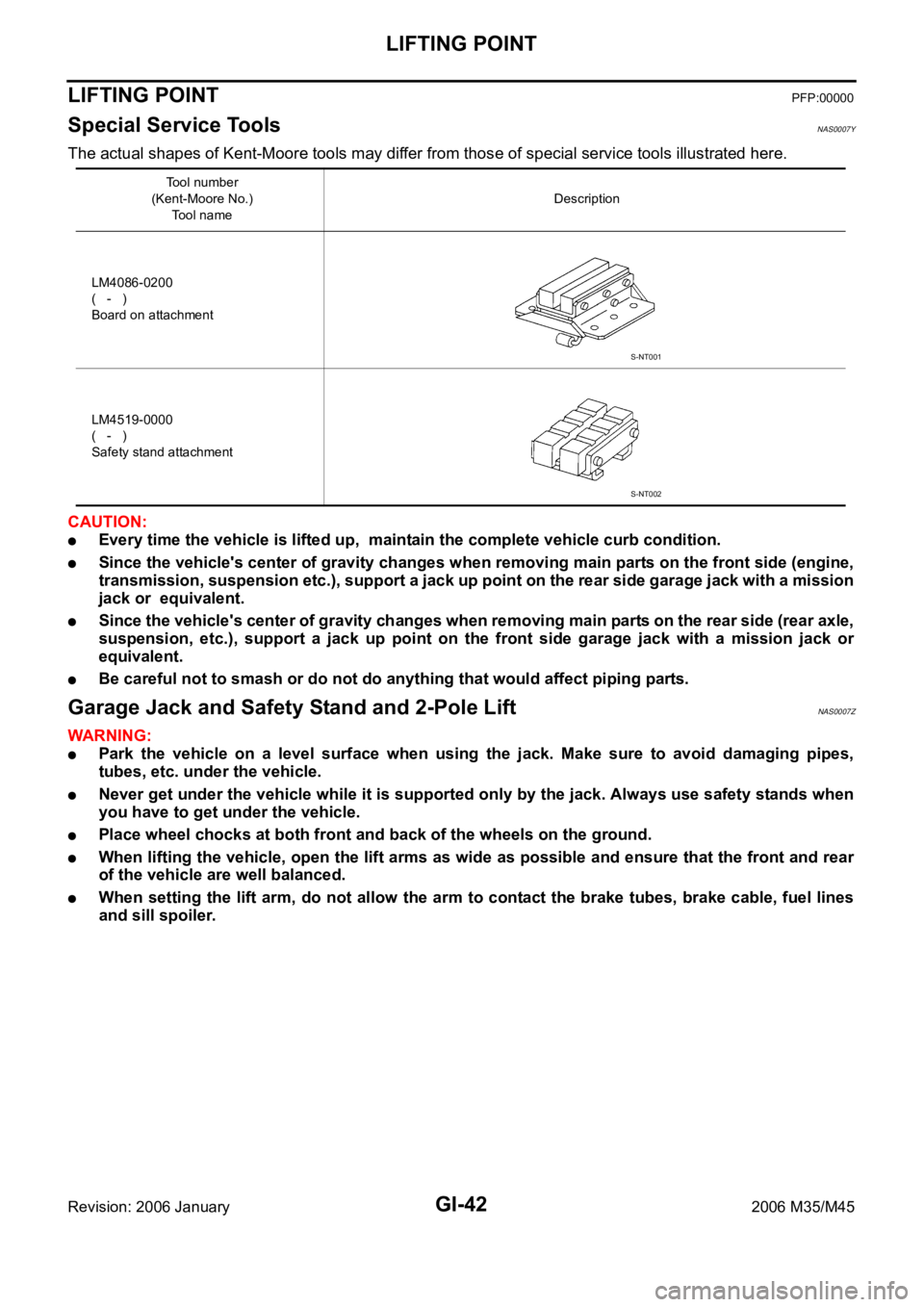

Special Service Tools NAS0007Y

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

CAUTION:

Every time the vehicle is lifted up, maintain the complete vehicle curb condition.

Since the vehicle's center of gravity changes when removing main parts on the front side (engine,

transmission, suspension etc.), support a jack up point on the rear side garage jack with a mission

jack or equivalent.

Since the vehicle's center of gravity changes when removing main parts on the rear side (rear axle,

suspension, etc.), support a jack up point on the front side garage jack with a mission jack or

equivalent.

Be careful not to smash or do not do anything that would affect piping parts.

Garage Jack and Safety Stand and 2-Pole LiftNAS0007Z

WAR NING :

Park the vehicle on a level surface when using the jack. Make sure to avoid damaging pipes,

tubes, etc. under the vehicle.

Never get under the vehicle while it is supported only by the jack. Always use safety stands when

you have to get under the vehicle.

Place wheel chocks at both front and back of the wheels on the ground.

When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear

of the vehicle are well balanced.

When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, fuel lines

and sill spoiler.

Tool number

(Kent-Moore No.)

Tool nameDescription

LM4086-0200

( - )

Board on attachment

LM4519-0000

( - )

Safety stand attachment

S-NT001

S-NT002

Page 3645 of 5621

IDX-4

ALPHABETICAL INDEX

Electronic ignition (EI) system ............. EC-33, EC-743

Engine control module (ECM) .......... EC-496, EC-1215

Engine control system diagram ........... EC-30, EC-740

Engine coolant temperature sensor (ECTS) ... EC-226,

EC-238

, EC-948, EC-961

Engine coolant(VK45DE) .................................. CO-40

Engine coolant(VQ35DE) ................................. CO-11

Engine oil filter replacement ............................. MA-26

Engine oil filter replacement(VQ35DE) ............. MA-19

Engine oil precautions .......................................... GI-8

Engine oil replacement(VQ35DE) ..................... MA-18

Engine oil(VK45DE) ........................................... LU-26

Engine oil(VQ35DE) ............................................ LU-7

Engine removal(VK45DE) ............................... EM-244

Engine removal(VQ35DE) .............................. EM-113

Engine room cover ............................................ EM-14

Engine room cover(VK45DE) ......................... EM-173

ETC1 - Wiring diagram .................... EC-614, EC-1345

ETC2 - Wiring diagram .................... EC-609, EC-1340

ETC3 - Wiring diagram .................... EC-620, EC-1352

EVAP canister ...................................... EC-42, EC-752

EVAP canister purge volume control solenoid valve ....

EC-412

, EC-420, EC-1132, EC-1140

EVAP canister vent control valve ...... EC-427, EC-434,

EC-1147

, EC-1154

EVAP control system (small leak) diagnosis .. EC-403,

EC-466

, EC-1124, EC-1185

EVAP control system pressure sensor ........... EC-440,

EC-443

, EC-450, EC-1160, EC-1163, EC-1170

EVAP control system purge flow monitoring diagnosis

EC-398

, EC-1119

EVAP vapor lines inspection ................. MA-21, MA-28

Evaporative emission (EVAP) system . EC-39, EC-749

Evaporator ..................................................... ATC-168

Exhaust manifold(VK45DE) ............................ EM-183

Exhaust system ................................................... EX-3

Exhaust system inspection ..................... EX-3, MA-29

Expansion valve ............................................. ATC-169

F

F/FOG - Wiring diagram ................................... LT-197

F/PUMP - Wiring diagram ................ EC-686, EC-1428

Final drive pre-inspection .................. FFD-16, RFD-19

Final drive removal and installation .. FFD-13, RFD-16

Floor trim ............................................................. EI-50

Flow charts ......................................................... GI-28

Fluid temperature sensor (A/T) ........................ AT-135

Fluorescent leak detector .............................. ATC-170

FPCM - Wiring diagram ................... EC-527, EC-1253

Freeze frame data ............................... EC-59, EC-770

Front brake solenoid valve ................. AT-151, AT-153

Front bumper ...................................................... EI-11

Front combination lamp removal and installation LT-76

Front door ............................. BL-190, BL-196, GW-63

Front passenger air bag .................................. SRS-42

Front seat belt .................................................... SB-30

Front seat belt pre-tensioner ..... SB-2, SRS-3, SRS-47

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-136

FTTS - Wiring diagram .... EC-345, EC-350, EC-1068,

EC-1073

Fuel cut control (at no load high engine speed) EC-34,

EC-744

Fuel filter replacement ......................................... FL-4

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) ......... EC-321, EC-332,

EC-1044

, EC-1055

Fuel injection system (Bank 2) ......... EC-321, EC-332,

EC-1044

, EC-1055

Fuel injector ................................................... EC-1420

Fuel injector and fuel tube(VK45DE) .............. EM-193

Fuel injector and fuel tube(VQ35DE) ................ EM-45

Fuel level sensor EC-475, EC-477, EC-479, EC-1194,

EC-1196

, EC-1198

Fuel line inspection .................................. FL-3, MA-25

Fuel line inspection(VQ35DE) .......................... MA-18

Fuel precautions ................................................... GI-6

Fuel pressure check ........................... EC-98, EC-809

Fuel pressure release ......................... EC-98, EC-809

Fuel pump ....................................... EC-685, EC-1427

Fuel pump and gauge .......................................... FL-4

Fuel pump control module .............. EC-525, EC-1251

Fuel pump dropping resistor ........... EC-525, EC-1251

Fuel system ......................................................... FL-3

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor .......... EC-343, EC-349,

EC-1066

, EC-1072

Fuel tank vacuum relief valve ............. EC-42, EC-752

FUELB1 - Wiring diagram EC-323, EC-334, EC-1046,

EC-1057

FUELB2 - Wiring diagram EC-325, EC-336, EC-1048,

EC-1059

Fuse .................................................................. PG-17

Fuse and fusible link box ................................ PG-112

Fusible link ........................................................ PG-17

G

Gauges ................................................................. DI-5

Generator ........................................................... SC-23

Generator - See Alternator ................................ SC-23

Glass ........................ GW-11, GW-61, GW-63, GW-67

Grille - See Exterior ............................................ EI-16

Ground distribution ........................................... PG-46

H

H/LAMP - Wiring diagram ....................... LT-13

, LT-48

Harness connector .......................................... PG-102

Harness layout .................................................. PG-63

Hazard warning lamp ....................................... LT-211

Headlamp removal and installation .................... LT-76

Headlining - See Roof trim .................................. EI-52

Heated oxygen sensor 2 (bank 1) .... EC-286, EC-297,

EC-310

, EC-1009, EC-1020, EC-1033

Heated oxygen sensor 2 (bank 2) .... EC-286, EC-297,

Page 3646 of 5621

IDX-5

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

EC-310, EC-1009, EC-1020, EC-1033

Heated oxygen sensor 2 heater (bank 1) ....... EC-189,

EC-911

Heated oxygen sensor 2 heater (bank 2) ....... EC-189,

EC-911

Heated seat ..................................................... SE-143

Heater and cooling unit (Heater core) ........... ATC-135

HFC134a (R134a) system precaution ............... ATC-6

HFC134a (R134a) system service procedure ATC-151

HFC134a (R134a) system service tools .......... ATC-17

HFC134a system service equipment precaution ..........

ATC-13

High and low reverse clutch solenoid valve .... AT-159,

AT-161

Hood ................................................................... BL-15

Horn ................................................................. WW-53

HORN - Wiring diagram ................................... WW-53

How to erase DTC for OBD system ..... EC-67, EC-778

HSEAT - Wiring diagram ................................. SE-146

I

IATS - Wiring diagram ....................... EC-223

, EC-945

ICC - Wiring diagram ....................................... ACS-21

ICC/BS - Wiring diagram ................. EC-578, EC-1304

ICC/SW - Wiring diagram ................ EC-563, EC-1289

ICCBOF - Wiring diagram ................ EC-700, EC-1442

Idle air volume learning ....................... EC-96, EC-807

Idle mixture ratio .................................. EC-84, EC-795

Idle speed .............................. EC-77, EC-788, EC-793

Idle speed control (ISC) .... EC-483, EC-485, EC-1202,

EC-1204

Ignition coil ....................................... EC-666, EC-1407

Ignition coil(VK45DE) ...................................... EM-190

Ignition coil(VQ35DE) ........................................ EM-42

Ignition control system ..................... EC-666, EC-1407

Ignition timing ........................ EC-77, EC-788, EC-793

IGNSYS - Wiring diagram ................ EC-667, EC-1408

Illumination ....................................................... LT-295

Illumination control ................. LT-291, LT-292, LT-293

In vehicle sensor ........................... ATC-116, ATC-127

INJECT - Wiring diagram ................. EC-680, EC-1421

Injector ............................................................. EC-679

Input clutch solenoid valve ................. AT-147, AT-149

Instrument panel .................................................. IP-10

Intake air temperature sensor ........... EC-221, EC-241,

EC-943

, EC-964

Intake door control linkage adjustment ............ ATC-88

Intake door motor ........................... ATC-86, ATC-133

Intake manifold collector(VQ35DE) ................... EM-19

Intake manifold(VK45DE) ................................ EM-179

Intake manifold(VQ35DE) .................................. EM-24

Intake sensor ................................ ATC-122, ATC-129

Intake valve timing control (Bank 1) .. EC-178, EC-891

Intake valve timing control (Bank 2) .. EC-178, EC-891

Intake valve timing control position sensor (Bank 1) ....

EC-1228

Intake valve timing control position sensor (Bank 2) ....

EC-1228

Intake valve timing control solenoid valve (Bank 1) ......

EC-197

, EC-920

Intake valve timing control solenoid valve (Bank 2) ......

EC-197

, EC-920

Integrated homelink transmitter ....................... BL-281

Intelligent cruise control (ICC) system .............. ACS-6

Interior ................................................................. EI-37

Interior lamp ...................................................... LT-267

IPDM (Intelligent power distribution module engine

room) ................................................................. PG-18

IVCB1 - Wiring diagram ..................... EC-198, EC-921

IVCB2 - Wiring diagram ..................... EC-200, EC-923

IVCSB1 - Wiring diagram ............................... EC-1229

IVCSB2 - Wiring diagram ............................... EC-1231

IVIS (Infiniti vehicle immobilizer system) precautions ...

GI-3

IVTB1 - Wiring diagram ................................... EC-894

IVTB2 - Wiring diagram ................................... EC-896

K

Knock sensor (KS) ........................... EC-371

, EC-1094

KS - Wiring diagram ......................... EC-372, EC-1095

L

LAN system circuit ........................................... ATC-70

Lane Departure Warning System ....................... DI-78

Laser beam aiming adjustment ....................... ACS-13

Latch (lower anchors and tether for children) system ...

SB-36

LDW .................................................................... DI-78

LDW - Wiring Diagram ........................................ DI-89

License lamp ..................................................... LT-249

Line pressure solenoid valve ........................... AT-130

Line pressure test (A/T) ..................................... AT-55

Liquid gasket application ......................... EM-7, LU-22

Liquid gasket application(VQ35DE) ........... LU-3, CO-3

Location of electrical units ................................. PG-96

Low coast brake solenoid valve ......... AT-163, AT-165

Low tire pressure warning system ...................... WT-9

Lubricant (R134a) A/C ..................................... ATC-26

Lubrication circuit (engine)(VK45DE) ................ LU-24

Lubrication circuit (engine)(VQ35DE) .................. LU-5

Lubrication oil A/C .......................................... ATC-174

M

MAFS - Wiring diagram ..... EC-208

, EC-216, EC-930,

EC-938

Magnet clutch .................................................. ATC-94

MAIN - Wiring diagram ........ EC-166, EC-879, AT-180

Maintenance (engine)(VQ35DE) ...................... MA-14

Major overhaul (Final drive) .............. FFD-15, RFD-18

Major overhaul (Transfer) .................................. TF-45

Malfunction indicator lamp (MIL) .......... EC-69, EC-780

Manual mode switch ........................................ AT-167

Mass air flow sensor (MAFS) ............ EC-205, EC-214,

EC-927

, EC-936

Page 3647 of 5621

IDX-6

ALPHABETICAL INDEX

Meter ..................................................................... DI-5

METER - Wiring diagram .................................... DI-13

MIL data link connectors circuit ....... EC-722, EC-1459

MIL/DL - Wiring diagram .................. EC-722, EC-1459

MIRROR - Wiring diagram ................................ GW-99

Mirror, door ..................................................... GW-120

Mirror, out side ................................................ GW-120

Misfire .............................................. EC-361, EC-1084

MMSW - Wiring diagram .................................. AT-168

Mode door control linkage adjustment ATC-79, ATC-82

Mode door motor .............. ATC-75, ATC-80, ATC-140

Molding - See Exterior .............................. EI-25, EI-29

Mud guard - See Exterior .................................... EI-22

Multiport fuel injection (MFI) system .... EC-31, EC-741

Multiport fuel injection precautions ....................... GI-7

N

NATS - Wiring diagram .................................... BL-256

NONDTC - Wiring diagram .............................. AT-187

NVH troubleshooting (EM) .............................. EM-171

NVH troubleshooting (EM)(VQ35DE) ............... EM-12

NVH troubleshooting (Final drive) ......... FFD-6, RFD-7

NVH troubleshooting (Propeller shaft) ................. PR-3

NVH troubleshooting (Transfer) ........................... TF-8

NVIS (Nissan vehicle immobilizer system) precautions

GI-3

O

O2H2B1 - Wiring diagram .................. EC-191

, EC-913

O2H2B2 - Wiring diagram .................. EC-193, EC-915

O2S2B1 - Wiring diagram .. EC-289, EC-300, EC-313,

EC-1012

, EC-1023, EC-1036

O2S2B2 - Wiring diagram .. EC-291, EC-302, EC-315,

EC-1014

, EC-1025, EC-1038

Oil cooler (engine)(VQ35DE) ............................. LU-14

Oil filter(VK45DE) .............................................. LU-29

Oil filter(VQ35DE) .............................................. LU-10

Oil pan (engine)(VK45DE) .............................. EM-187

Oil pan (engine)(VQ35DE) ................................ EM-29

Oil pressure (engine)(VK45DE) ......................... LU-26

Oil pressure (engine)(VQ35DE) ........................... LU-8

Oil pressure relief valve (engine)(VQ35DE) ........ LU-6

Oil pump (A/T) ................................................. AT-318

Oil pump (engine)(VK45DE) .............................. LU-30

Oil pump (engine)(VQ35DE) .............................. LU-18

Oil pump regulator valve (engine)(VK45DE) ..... LU-30

Oil pump regulator valve (engine)(VQ35DE) ..... LU-18

Oil seal replacement (engine)(VK45DE) ......... EM-229

Oil seal replacement (engine)(VQ35DE) .......... EM-98

Oil seal replacement (front of final drive) .......... FFD-9,

RFD-10

Oil seal replacement (side of final drive) ......... FFD-11,

RFD-14

On board diagnostic system ................ EC-54, EC-764

ORVR (On-board Refueling Vapor Recovery) .. EC-46,

EC-756

Out side mirror ................................................ GW-120

Overheat ......................................... EC-512, EC-1239

P

P/SCKT - Wiring diagram ................................ WW-51

Park/Neutral position switch ........... EC-504, EC-1223

Park/neutral position switch (A/T) .................... AT-113

Parking brake control ........................................... PB-3

Parking lamp .................................................... LT-249

PCV (positive crankcase ventilation) .. EC-51, EC-761

PGC/V - Wiring diagram .. EC-414, EC-422, EC-1134,

EC-1142

PHASE - Wiring diagram ............................... EC-1108

PHSB1 - Wiring diagram .................................. EC-385

PHSB2 - Wiring diagram .................................. EC-387

Pilot bushing replacement - See Pilot

converter(VQ35DE) ........................................ EM-124

Piston assembly(VK45DE) ............................. EM-260

Piston assembly(VQ35DE) ............................. EM-135

Piston pin inspection(VK45DE) ....................... EM-266

Piston pin inspection(VQ35DE) ...................... EM-140

Piston ring inspection(VK45DE) ..................... EM-267

Piston ring inspection(VQ35DE) ..................... EM-141

Piston to bore clearance(VK45DE) ................. EM-270

Piston to bore clearance(VQ35DE) ................ EM-144

PNP/SW - Wiring diagram . EC-506, EC-1225, AT-114

POS - Wiring diagram ..................... EC-378, EC-1101

POWER - Wiring diagram ................................... PG-5

Power door mirror .............................................. BL-24

Power socket ................................................... WW-51

Power steering fluid level ........................ PS-8, MA-37

Power steering gear ........................................... PS-18

Power steering hydraulic pressure .................... PS-29

Power steering oil pump .................................... PS-29

Power steering system bleeding .......................... PS-8

Power supply routing .......................................... PG-3

Power window .................................................. GW-13

PRE/SE - Wiring diagram EC-445, EC-452, EC-1165,

EC-1172

Precations for Leak detection dye .................. ATC-15

Precautions (General) ........................................... GI-4

Pressure switch 1 .............................. AT-153, AT-172

Pressure switch 2 ............................................ AT-165

Pressure switch 3 .............................. AT-149, AT-174

Pressure switch 5 .............................. AT-157, AT-176

Pressure switch 6 .............................. AT-161, AT-178

Pressure test (A/T) ............................................. AT-55

Propeller shaft ........................................... PR-4, PR-6

Propeller shaft on vehicle service ............. PR-4, PR-6

Propeller shaft vibration ............................ PR-4, PR-6

PS/SEN - Wiring diagram ............... EC-488, EC-1207

R

Radiator(VK45DE) ............................................ CO-43

Radiator(VQ35DE) ............................................ CO-14

Rear axle .......................................................... RAX-5

Rear bumper ....................................................... EI-14

Rear combination lamp removal and installation ..........

Page 4435 of 5621

LT-8

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -PFP:26010

Component Parts and Harness Connector LocationNKS003NY

System DescriptionNKS003NZ

The control of the headlamp system operation is dependent upon the position of the combination switch (light-

ing switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives

input signal requesting the headlamps (and tail lamps) illuminate. This input signal is communicated to the

IPDM E/R (intelligent power distribution module engine room) across the CAN communication lines. The CPU

(central processing unit) located in the IPDM E/R controls the headlamp high and headlamp low relay coils.

These relays, when energized, direct power to the respective headlamps, which then illuminate.

PKIC0617E

Page 4465 of 5621

LT-38

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

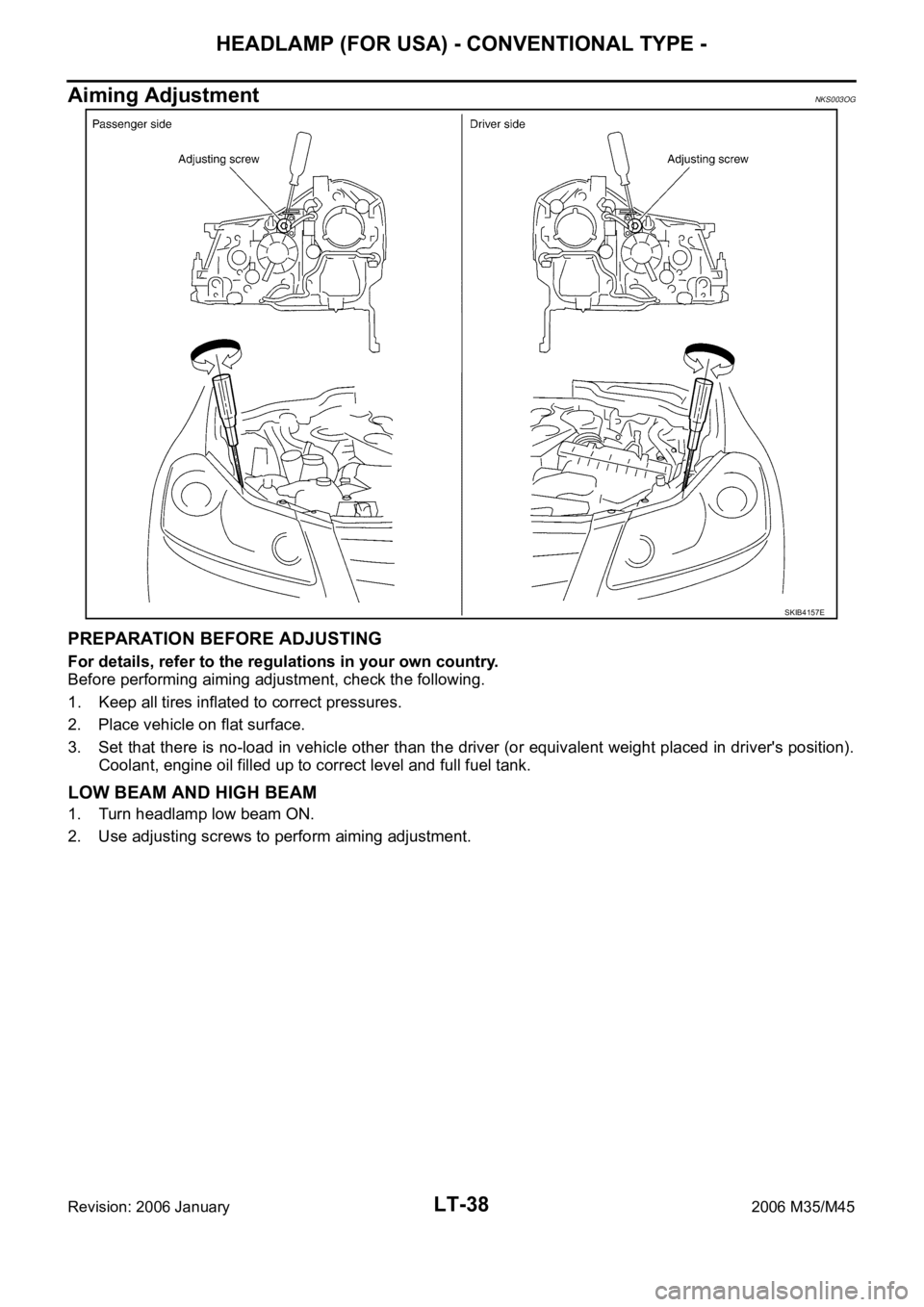

Aiming AdjustmentNKS003OG

PREPARATION BEFORE ADJUSTING

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on flat surface.

3. Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screws to perform aiming adjustment.

SKIB4157E

Page 4470 of 5621

HEADLAMP (FOR USA) - XENON TYPE -

LT-43

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

HEADLAMP (FOR USA) - XENON TYPE -PFP:26010

Component Parts and Harness Connector LocationNKS003OK

System DescriptionNKS003OL

The control of the headlamp system operation is dependent upon the position of the combination switch (light-

ing switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives

input signal requesting the headlamps (and tail lamps) illuminate. This input signal is communicated to the

IPDM E/R (intelligent power distribution module engine room) across the CAN communication lines. The CPU

(central processing unit) located in the IPDM E/R controls the headlamp high and headlamp low relay coils.

These relays, when energized, direct power to the respective headlamps, which then illuminate.

PKIC0617E

Page 4501 of 5621

LT-74

HEADLAMP (FOR USA) - XENON TYPE -

Revision: 2006 January2006 M35/M45

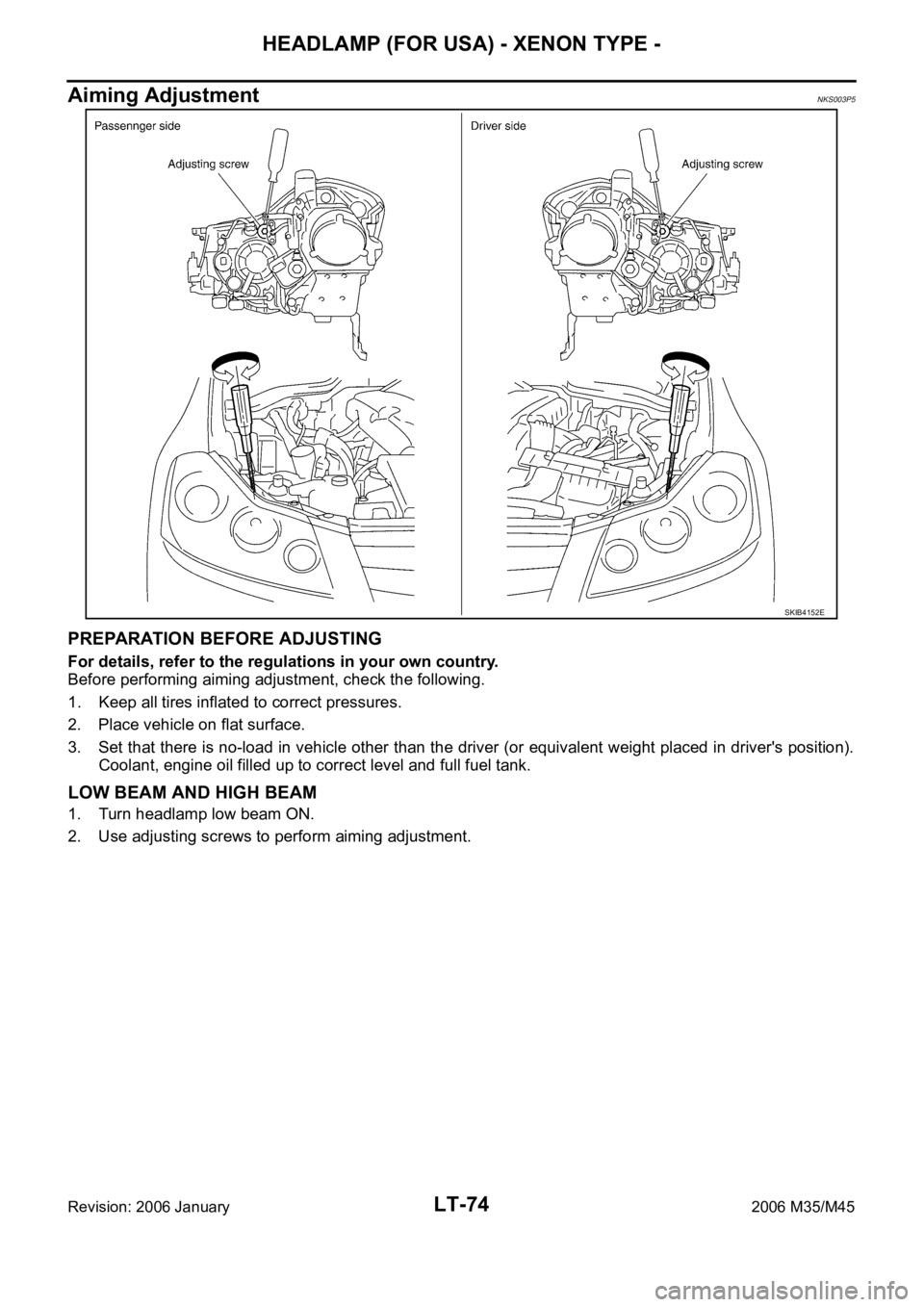

Aiming AdjustmentNKS003P5

PREPARATION BEFORE ADJUSTING

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on flat surface.

3. Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screws to perform aiming adjustment.

SKIB4152E

Page 4509 of 5621

LT-82

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

DAYTIME LIGHT OPERATION

With the engine running, the lighting switch in the OFF or AUTO position (headlamp is not illuminate) and

parking brake released, the IPDM E/R receives input request signal from BCM to turn on daytime light. This

input is communicated across the CAN communication lines. The CPU of the IPDM E/R controls the daytime

light relay coil. When energized, this relay directs power

through daytime light relay terminals 5 and 3

through front combination lamp RH terminal 2

through front combination lamp RH terminal 6

through IPDM E/R terminal 27

through 10A fuse (No. 72, located in IPDM E/R)

through 10A fuse (No. 74, located in IPDM E/R)

through IPDM E/R terminal 28

to front combination lamp LH terminal 6.

Ground is supplied

to combination lamp LH terminal 2

through grounds E22 and E43.

With power and grounds supplied, the daytime lights illuminate. The high beam headlamps are now wired in

series and illuminate at a reduced intensity.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "COMBINATION SWITCH READING FUNCTION" .

AUTO LIGHT OPERATION

For auto light operation, refer to LT- 11 6 , "System Description" .

CAN Communication System DescriptionNKS003PB

Refer to LAN-34, "CAN COMMUNICATION" .