stall INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1310 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-35

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

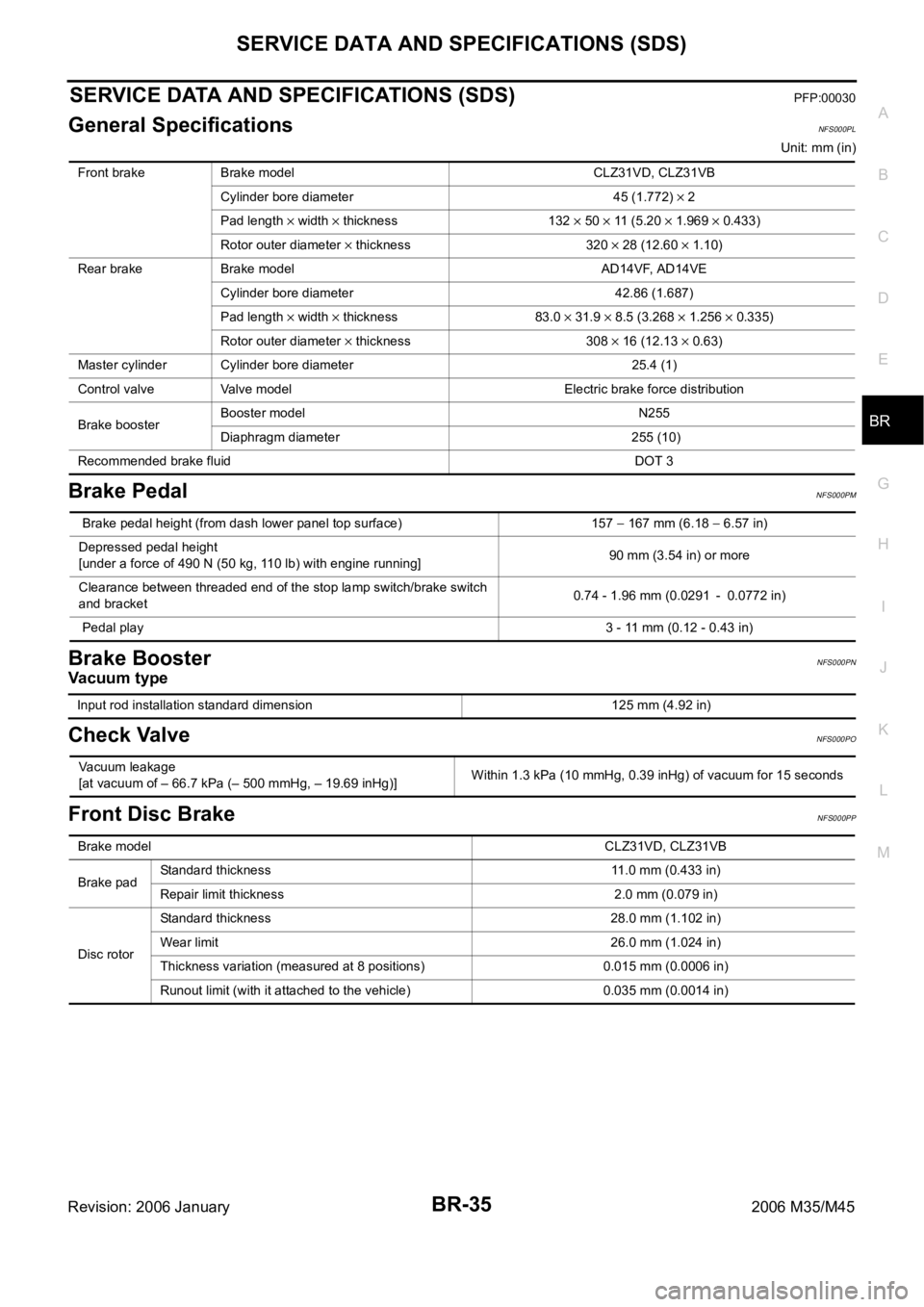

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsNFS000PL

Unit: mm (in)

Brake PedalNFS000PM

Brake BoosterNFS000PN

Va c u u m t y p e

Check ValveNFS000PO

Front Disc BrakeNFS000PP

Front brake Brake model CLZ31VD, CLZ31VB

Cylinder bore diameter 45 (1.772)

2

Pad length

width thickness 132 50 11 (5.20 1.969 0.433)

Rotor outer diameter

thickness 320 28 (12.60 1.10)

Rear brake Brake model AD14VF, AD14VE

Cylinder bore diameter 42.86 (1.687)

Pad length

width thickness 83.0 31.9 8.5 (3.268 1.256 0.335)

Rotor outer diameter

thickness 308 16 (12.13 0.63)

Master cylinder Cylinder bore diameter 25.4 (1)

Control valve Valve model Electric brake force distribution

Brake boosterBooster model N255

Diaphragm diameter 255 (10)

Recommended brake fluid DOT 3

Brake pedal height (from dash lower panel top surface) 157 167 mm (6.18 6.57 in)

Depressed pedal height

[under a force of 490 N (50 kg, 110 lb) with engine running]90 mm (3.54 in) or more

Clearance between threaded end of the stop lamp switch/brake switch

and bracket 0.74 - 1.96 mm (0.0291 - 0.0772 in)

Pedal play3 - 11 mm (0.12 - 0.43 in)

Input rod installation standard dimension 125 mm (4.92 in)

Vacuum leakage

[at vacuum of – 66.7 kPa (– 500 mmHg, – 19.69 inHg)]Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds

Brake modelCLZ31VD, CLZ31VB

Brake padStandard thickness 11.0 mm (0.433 in)

Repair limit thickness 2.0 mm (0.079 in)

Disc rotorStandard thickness 28.0 mm (1.102 in)

Wear limit 26.0 mm (1.024 in)

Thickness variation (measured at 8 positions) 0.015 mm (0.0006 in)

Runout limit (with it attached to the vehicle) 0.035 mm (0.0014 in)

Page 1313 of 5621

BRC-2Revision: 2006 January2006 M35/M45 Inspection 12: Brake Fluid Level Switch Circuit ...... 48

Inspection 13: RAS Control Unit Circuit (With RAS) ... 49

Inspection 14: ICC Sensor Integrated Unit Circuit

(With ICC) ............................................................... 50

Inspection 15: AWD Control Unit Circuit (AWD

Model) ..................................................................... 50

Inspection 16: CAN Communication Circuit ............ 51

Inspection 17: VDC OFF Switch Circuit .................. 51

Inspection 18: Parking Brake Switch Circuit ........... 52

Inspection 19: Warning Lamp and Indicator Lamp

Circuit ..................................................................... 53

Symptom 1 Excessive ABS Function Operation Fre-

quency .................................................................... 53

Symptom 2 Unexpected Pedal Reaction ................ 54

Symptom 3 The Braking Distance Is Long ............. 55

Symptom 4 ABS Function Does Not Operate ........ 55

Symptom 5 Pedal Vibration or ABS Operation

Sound Occurs ......................................................... 55

Symptom 6 Vehicle Jerks During VDC/TCS/ABS

Control .................................................................... 56WHEEL SENSOR ................................................... ... 57

Removal and Installation ......................................... 57

COMPONENT ...................................................... 57

REMOVAL ............................................................ 57

INSTALLATION .................................................... 57

SENSOR ROTOR ...................................................

... 59

Removal and Installation ......................................... 59

REMOVAL ............................................................ 59

INSTALLATION .................................................... 59

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY) ... 60

Removal and Installation ......................................... 60

COMPONENT ...................................................... 60

REMOVAL ............................................................ 60

INSTALLATION .................................................... 61

G-SENSOR ................................................................ 62

Removal and Installation ......................................... 62

REMOVAL ............................................................ 62

INSTALLATION .................................................... 62

STEERING ANGLE SENSOR ................................... 63

Removal and Installation ......................................... 63

REMOVAL ............................................................ 63

INSTALLATION .................................................... 63

Page 1314 of 5621

![INFINITI M35 2006 Factory Service Manual PRECAUTIONS

BRC-3

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

[VDC/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and � INFINITI M35 2006 Factory Service Manual PRECAUTIONS

BRC-3

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

[VDC/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and �](/img/42/57023/w960_57023-1313.png)

PRECAUTIONS

BRC-3

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

[VDC/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NFS000PY

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Procedures without Cowl Top CoverNFS000PZ

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions for Brake SystemNFS000Q0

Recommended fluid is brake fluid “DOT 3”.

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted surface of body. If brake fluid is splashed on painted sur-

faces of body immediately wipe off then with cloth and then wash it away with water.

Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

Use a flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten brake tube flare nuts.

When installing brake tubes, be sure to check torque.

Brake system is an important safety part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction

is detected, replace part with a new one.

Before working, turn ignition switch OFF and disconnect con-

nectors of ABS actuator and electric unit (control unit) or the bat-

tery cable from the negative terminal.

WAR NING :

Clean brake pads and shoes with a waste cloth, then wipe with

a dust collector.

PIIB3706J

SBR686C

Page 1315 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-4

[VDC/TCS/ABS]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Brake ControlNFS000Q1

Just after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operatin INFINITI M35 2006 Factory Service Manual BRC-4

[VDC/TCS/ABS]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Brake ControlNFS000Q1

Just after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operatin](/img/42/57023/w960_57023-1314.png)

BRC-4

[VDC/TCS/ABS]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Brake ControlNFS000Q1

Just after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operating noise may

be heard from engine compartment. This is normal condition.

When an error is indicated by ABS or another warning lamp, collect all necessary information from cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting

diagnostic servicing. Besides electrical system inspection, check brake booster operation, brake fluid

level, and oil leaks.

If tire size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

ABS might be out of order or malfunctions by putting a radio (wiring inclusive), an antenna and a lead-in

wire near the control unit.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

VDC system may not operate normally or a VDC OFF indicator lamp or SLIP indicator lamp may light.

–When replacing the following parts with parts other than genuine parts or making modifications: Suspen-

sion-related parts (shock absorber, spring, bushing, etc.), tires, wheels (other than specified sizes), brake-

related parts (pad, rotor, caliper, etc.), engine-related parts (muffler, ECM, etc.) and body reinforcement-

related parts (roll bar, tower bar, etc.).

–When driving with worn or deteriorated suspension, tires and brake-related parts.

Page 1316 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

BRC-5

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service ToolsNFS000Q2

The actual shapes of Kent-Moore tools may differ from t INFINITI M35 2006 Factory Service Manual PREPARATION

BRC-5

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service ToolsNFS000Q2

The actual shapes of Kent-Moore tools may differ from t](/img/42/57023/w960_57023-1315.png)

PREPARATION

BRC-5

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service ToolsNFS000Q2

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsNFS000Q3

Tool number

(Kent-Moore No.)

Tool nameDescription

ST30720000

(J-25405)

Drift

a: 77 mm (3.03 in) dia.

b: 55 mm (2.17 in) dia.

Installing rear sensor rotor ST27863000

(—)

Drift

a: 75 mm (2.95 in) dia.

b: 62 mm (2.44 in) dia.

kV40104710

(—)

a: 76 mm (2.99 in) dia.

b: 68.5 mm (2.697 in) dia.

ZZA0701D

ZZA0832D

ZZA0832D

To o l n a m eDescription

1. Flare nut crowfoot

a: 10 mm (0.39 in) /12mm (0.47 in)

2. Torque wrenchInstalling brake tube

S-NT360

Page 1317 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to INFINITI M35 2006 Factory Service Manual BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to](/img/42/57023/w960_57023-1316.png)

BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to the list below, make sure to adjust neutral position of steering angle sen-

sor before running vehicle.

: Required

–: Not required

CAUTION:

To adjust neutral position of steering angle sensor, make sure to use CONSULT-II.

(Adjustment cannot be done without CONSULT-II.)

1. Stop vehicle with front wheels in straight-ahead position.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector on vehicle.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

3. Turn ignition switch ON and touch the CONSULT-II screen in the order of “ABS”, “WORK SUPPORT” and

“ST ANG SEN ADJUSTMENT”.

4. Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle

sensor.

5. After approximately 10 seconds, touch “END”. (After approxi-

mately 60 seconds, it ends automatically.)

6. Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to perform above operation.

7. Run vehicle with front wheels in straight-ahead position, then

stop.

8. Select “DATA MONITOR”, “ECU INPUT SIGNALS”, and “STR ANGLE SIG” on CONSULT-II screen. Then

make sure “STR ANGLE SIG” is within 0

2.5. If value is more than specification, repeat steps 1 to 7.

9. Erase memory of ABS actuator and electric unit (control unit) and ECM. ABS actuator and electric unit

(control unit): Refer to BRC-23, "

ERASE MEMORY" . ECM: Refer to EC-100, "TROUBLE DIAGNOSIS"

(VQ35DE), EC-811, "TROUBLE DIAGNOSIS" (VK45DE).

10. Turn ignition switch OFF.

Situation Adjustment of Steering Angle Sensor Neutral Position

Removing/Installing ABS actuator and electric unit (control unit)

Replacing ABS actuator and electric unit (control unit)

Removing/Installing steering angle sensor

Removing/Installing steering components

Removing/Installing suspension components

Change tires to new ones–

Tire rotation–

Adjusting wheel alignment

SFIA0793E

Page 1365 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-54

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to front: FAX-5, &# INFINITI M35 2006 Factory Service Manual BRC-54

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to front: FAX-5, &#](/img/42/57023/w960_57023-1364.png)

BRC-54

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to front: FAX-5, "

WHEEL BEAR-

ING INSPECTION" , Rear: RAX-5, "WHEEL BEARING INSPECTION" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace malfunctioning components.

3. CHECK WHEEL SENSOR AND SENSOR ROTOR

Check the following.

Wheel sensor installation for damage.

Sensor rotor installation for damage.

Wheel sensor connector connection.

Wheel sensor harness inspection.

OK or NG

OK >> GO TO 4.

NG >>

Replace wheel sensor or sensor rotor.

Repair harness.

4. CHECK ABS WARNING LAMP DISPLAY

Make sure that the ABS warning lamp is turned off after the ignition switch is turned ON or when driving.

OK or NG

OK >> Normal

NG >> Perform self-diagnosis. Refer to BRC-23, "

Self-Diagnosis" .

Symptom 2 Unexpected Pedal ReactionNFS000R5

1. CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Refer to BR-6, "

Inspection and Adjustment" .

Is the stroke too big?

YES >>Bleed air from brake tube and hose. Refer to BR-11, "Bleeding Brake System" .

Check brake pedal, brake booster, and master cylinder for mount play, looseness, brake sys-

tem fluid leakage, etc. Refer to brake pedal: BR-7, "

COMPONENTS" , brake booster and mas-

ter cylinder: BR-19, "

COMPONENTS" .

NO >> GO TO 2.

2. CHECK FUNCTION

Disconnect ABS actuator and electric unit (control unit) connector to deactivate ABS. Check if braking force is

normal in this condition.Connect connector after inspection.

OK or NG

OK >> GO TO procedure 3 “CHECK WHEEL SENSOR AND SENSOR ROTOR” of symptom 1. Refer to

BRC-53, "

Symptom 1 Excessive ABS Function Operation Frequency" .

NG >> Check brake system.

Page 1368 of 5621

![INFINITI M35 2006 Factory Service Manual WHEEL SENSOR

BRC-57

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

WHEEL SENSORPFP:47910

Removal and InstallationNFS000RA

COMPONENT

NOTE:

The above figure (front side) sho INFINITI M35 2006 Factory Service Manual WHEEL SENSOR

BRC-57

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

WHEEL SENSORPFP:47910

Removal and InstallationNFS000RA

COMPONENT

NOTE:

The above figure (front side) sho](/img/42/57023/w960_57023-1367.png)

WHEEL SENSOR

BRC-57

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

WHEEL SENSORPFP:47910

Removal and InstallationNFS000RA

COMPONENT

NOTE:

The above figure (front side) shows left side. Right side is the mirror image.

REMOVAL

Pay attention to the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pull-

ing on sensor harness.

Take care to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before

removing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor

function.

INSTALLATION

Pay attention to the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-57, "

COMPONENT" .

1. Front LH wheel sensor 2. Front LH wheel sensor connector 3. Clamp

4. Bracket 5. Rear RH wheel sensor connector 6. Rear LH wheel sensor connector

7. Rear LH wheel sensor 8. Rear RH wheel sensor

A. Front side B. Rear side : Front

Refer to GI section GI-11, "

Components" for symbol marks in the figure.

SFIA2723J

Page 1369 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-58

[VDC/TCS/ABS]

WHEEL SENSOR

Revision: 2006 January2006 M35/M45

When installing, make sure there is no foreign material such as iron chips on and in the mounting hole of

the wheel sensor. Make su INFINITI M35 2006 Factory Service Manual BRC-58

[VDC/TCS/ABS]

WHEEL SENSOR

Revision: 2006 January2006 M35/M45

When installing, make sure there is no foreign material such as iron chips on and in the mounting hole of

the wheel sensor. Make su](/img/42/57023/w960_57023-1368.png)

BRC-58

[VDC/TCS/ABS]

WHEEL SENSOR

Revision: 2006 January2006 M35/M45

When installing, make sure there is no foreign material such as iron chips on and in the mounting hole of

the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove any foreign

material and clean the mount.

When installing wheel sensor, be sure to press rubber grommets in until they lock at locations shown

above in the figure. When installed, harness must not be twisted.

Page 1370 of 5621

![INFINITI M35 2006 Factory Service Manual SENSOR ROTOR

BRC-59

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

SENSOR ROTORPFP:47970

Removal and InstallationNFS000RB

REMOVAL

CAUTION:

Do not reuse sensor rotor.

Front INFINITI M35 2006 Factory Service Manual SENSOR ROTOR

BRC-59

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

SENSOR ROTORPFP:47970

Removal and InstallationNFS000RB

REMOVAL

CAUTION:

Do not reuse sensor rotor.

Front](/img/42/57023/w960_57023-1369.png)

SENSOR ROTOR

BRC-59

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

SENSOR ROTORPFP:47970

Removal and InstallationNFS000RB

REMOVAL

CAUTION:

Do not reuse sensor rotor.

Front

Sensor rotor cannot be disassembled. Remove the sensor rotor together with hub bearing assembly.

Refer to FAX-5, "

REMOVAL" .

Rear

Follow the procedure below to remove rear sensor rotor.

–Remove side flange. Refer to RFD-14, "SIDE OIL SEAL" .

–Using a bearing replacer (suitable tool) and puller (suitable tool), remove sensor rotor from side flange.

INSTALLATION

Front

Sensor rotor cannot be disassembled. Remove the sensor rotor together with hub bearing assembly.

Refer to FAX-7, "

INSTALLATION" .

Rear

Follow the procedure below to install rear sensor rotor.

–Using a drift (SST), press rear sensor rotor onto side flange.

–Install side flange. Refer to RFD-14, "SIDE OIL SEAL" .

SFIA2040J