fuel system INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5153 of 5621

SC-16

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

DIAGNOSTIC PROCEDURE 2

Check “S” Connector Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1. CHECK “S” CONNECTOR CIRCUIT

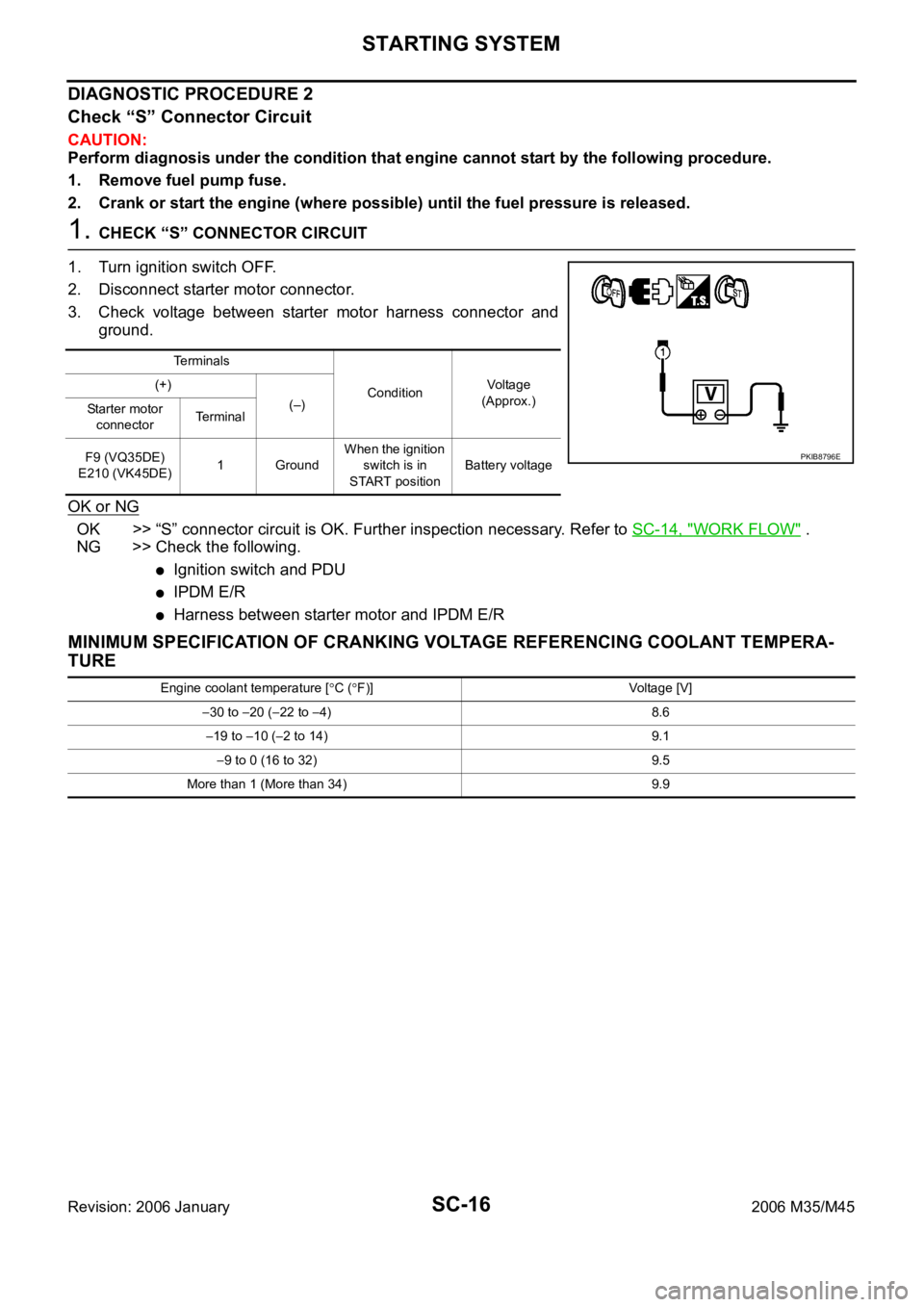

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Check voltage between starter motor harness connector and

ground.

OK or NG

OK >> “S” connector circuit is OK. Further inspection necessary. Refer to SC-14, "WORK FLOW" .

NG >> Check the following.

Ignition switch and PDU

IPDM E/R

Harness between starter motor and IPDM E/R

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Te r m i n a l s

ConditionVoltage

(Approx.) (+)

(–)

Starter motor

connectorTe r m i n a l

F9 (VQ35DE)

E210 (VK45DE)1 GroundWhen the ignition

switch is in

START positionBattery voltage

PKIB8796E

Engine coolant temperature [C (F)] Voltage [V]

30 to 20 (22 to 4) 8.6

19 to 10 (2 to 14) 9.1

9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Page 5161 of 5621

SC-24

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

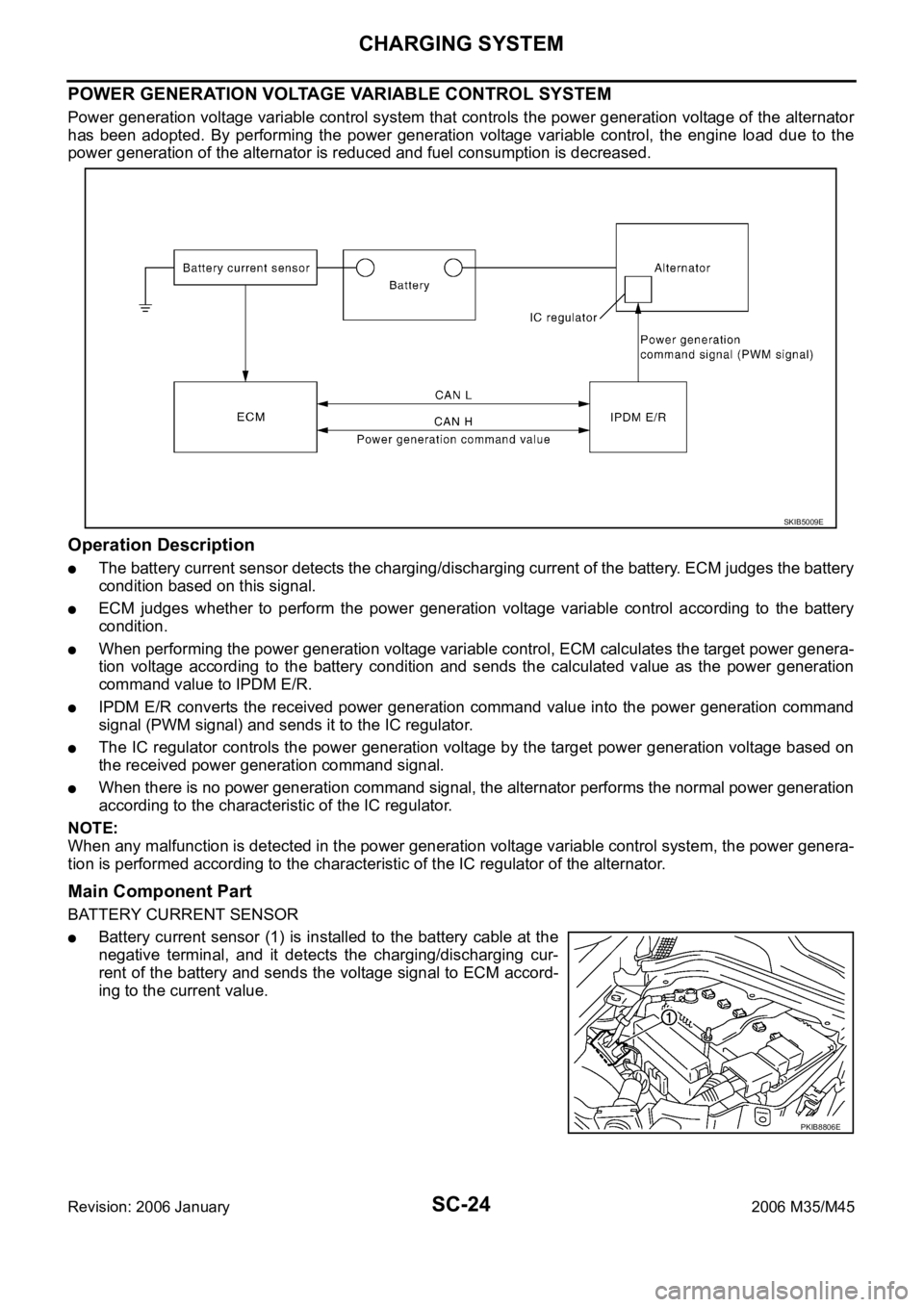

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Power generation voltage variable control system that controls the power generation voltage of the alternator

has been adopted. By performing the power generation voltage variable control, the engine load due to the

power generation of the alternator is reduced and fuel consumption is decreased.

Operation Description

The battery current sensor detects the charging/discharging current of the battery. ECM judges the battery

condition based on this signal.

ECM judges whether to perform the power generation voltage variable control according to the battery

condition.

When performing the power generation voltage variable control, ECM calculates the target power genera-

tion voltage according to the battery condition and sends the calculated value as the power generation

command value to IPDM E/R.

IPDM E/R converts the received power generation command value into the power generation command

signal (PWM signal) and sends it to the IC regulator.

The IC regulator controls the power generation voltage by the target power generation voltage based on

the received power generation command signal.

When there is no power generation command signal, the alternator performs the normal power generation

according to the characteristic of the IC regulator.

NOTE:

When any malfunction is detected in the power generation voltage variable control system, the power genera-

tion is performed according to the characteristic of the IC regulator of the alternator.

Main Component Part

BATTERY CURRENT SENSOR

Battery current sensor (1) is installed to the battery cable at the

negative terminal, and it detects the charging/discharging cur-

rent of the battery and sends the voltage signal to ECM accord-

ing to the current value.

SKIB5009E

PKIB8806E

Page 5475 of 5621

TF-10

AWD SYSTEM

Revision: 2006 January2006 M35/M45

AWD SYSTEMPFP:41650

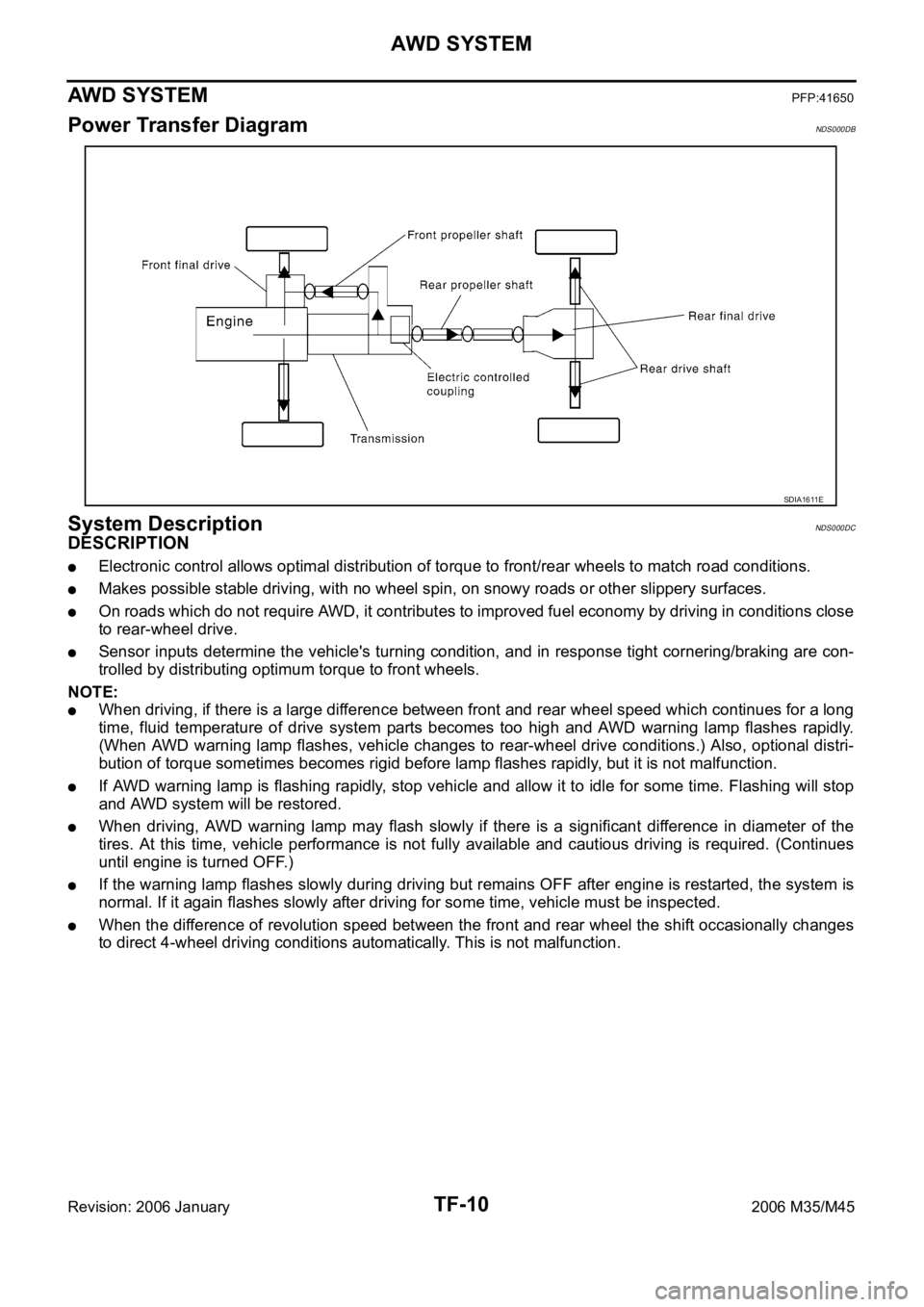

Power Transfer DiagramNDS000DB

System DescriptionNDS000DC

DESCRIPTION

Electronic control allows optimal distribution of torque to front/rear wheels to match road conditions.

Makes possible stable driving, with no wheel spin, on snowy roads or other slippery surfaces.

On roads which do not require AWD, it contributes to improved fuel economy by driving in conditions close

to rear-wheel drive.

Sensor inputs determine the vehicle's turning condition, and in response tight cornering/braking are con-

trolled by distributing optimum torque to front wheels.

NOTE:

When driving, if there is a large difference between front and rear wheel speed which continues for a long

time, fluid temperature of drive system parts becomes too high and AWD warning lamp flashes rapidly.

(When AWD warning lamp flashes, vehicle changes to rear-wheel drive conditions.) Also, optional distri-

bution of torque sometimes becomes rigid before lamp flashes rapidly, but it is not malfunction.

If AWD warning lamp is flashing rapidly, stop vehicle and allow it to idle for some time. Flashing will stop

and AWD system will be restored.

When driving, AWD warning lamp may flash slowly if there is a significant difference in diameter of the

tires. At this time, vehicle performance is not fully available and cautious driving is required. (Continues

until engine is turned OFF.)

If the warning lamp flashes slowly during driving but remains OFF after engine is restarted, the system is

normal. If it again flashes slowly after driving for some time, vehicle must be inspected.

When the difference of revolution speed between the front and rear wheel the shift occasionally changes

to direct 4-wheel driving conditions automatically. This is not malfunction.

SDIA1611E