heating INFINITI M35 2006 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3493 of 5621

GI-30

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2006 January2006 M35/M45

UNDER SEATING AREAS

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under seating areas, inspect wire routing for possible damage or

pinching.

Heat Sensitive

The customer's concern may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60

C (140F). If incident occurs

while heating the unit, either replace or properly insulate the compo-

nent.

Freezing

The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water freezing

somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked outside

overnight. In the morning, do a quick and thorough diagnosis of

those electrical components which could be affected.

The second method is to put the suspect component into a freezer

long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

Water Intrusion

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This can be simulated by soaking the car

or running it through a car wash.

Do not spray water directly on any electrical components.

Electrical Load

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

SGI842

SGI843

SGI844

SGI845

Page 4746 of 5621

![INFINITI M35 2006 Factory Owners Guide PRECAUTIONS

LU-3

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Liquid GasketNBS004PR

LIQUID GASKET APPLICATION PROCEDURE

1. Remove INFINITI M35 2006 Factory Owners Guide PRECAUTIONS

LU-3

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Liquid GasketNBS004PR

LIQUID GASKET APPLICATION PROCEDURE

1. Remove](/img/42/57023/w960_57023-4745.png)

PRECAUTIONS

LU-3

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Liquid GasketNBS004PR

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

Remove liquid gasket completely from the liquid gasket application surface, mounting bolts, and bolt

holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

3. Apply liquid gasket to the liquid gasket application surface.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-48, "

RECOMMENDED CHEMICAL

PRODUCTS AND SEALANTS" .

Within five minutes of liquid gasket application, install the mating component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten mounting bolts or nuts after the installation.

After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

Page 4765 of 5621

![INFINITI M35 2006 Factory Owners Guide LU-22

[VK45DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Liquid GasketNBS004Q7

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adherin INFINITI M35 2006 Factory Owners Guide LU-22

[VK45DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Liquid GasketNBS004Q7

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adherin](/img/42/57023/w960_57023-4764.png)

LU-22

[VK45DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Liquid GasketNBS004Q7

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

Remove liquid gasket completely from the liquid gasket application surface, mounting bolts, and bolt

holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to tube presser [SST: WS39930000

(—)].

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

Within five minutes of liquid gasket application, install the mat-

ing component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten mounting bolts or nuts after the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.EMA0622D

Page 5294 of 5621

CLIMATE CONTROLLED SEAT

SE-113

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

CLIMATE CONTROLLED SEATPFP:870U6

Component Parts and Harness Connector LocationNIS0027H

System DescriptionNIS0027I

The climate controlled seat system is controlled by climate controlled seat control unit.

Heating and cooling are possible for a thermal electric device (heat conversion machine).

NOTE:

The climate controlled seat system is downed when the temperature sensor set as the seat cushion and

the seat back's thermal electric device machine detects 20

C (68 F)or more of mutual differences of tem-

perature.

In this case, by turning off ignition switch, system down is canceled and it can be reused by turning on

ignition switch again.

The climate controlled seat blower keep low speed for approximately 60 seconds after turning the climate

controlled seat switch.

CAUTION:

The thermal electric device has the character in which, as for an opposite side. one side becomes

high temperature at the time of low temperature.

PIIB5891E

1. Fuse block (J/B) 2. Climate controlled seat relay E16 3.a: Climate controlled seat switch

driver side B20

b: Climate controlled seat switch

passenger side B19

4.a: Seat cushion thermal electric

device B285 (driver side)

B295 (passenger side)

b: Climate controlled seat control

unit B283, B284 (driver side)

B293, B294 (passenger side)

c: Climate controlled seat blower

motor B282 (driver side)

B292 (passenger side)5.Seatback thermal electric device

B220 (driver side)

B258 (passenger side)

Page 5324 of 5621

HEATED SEAT

SE-143

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

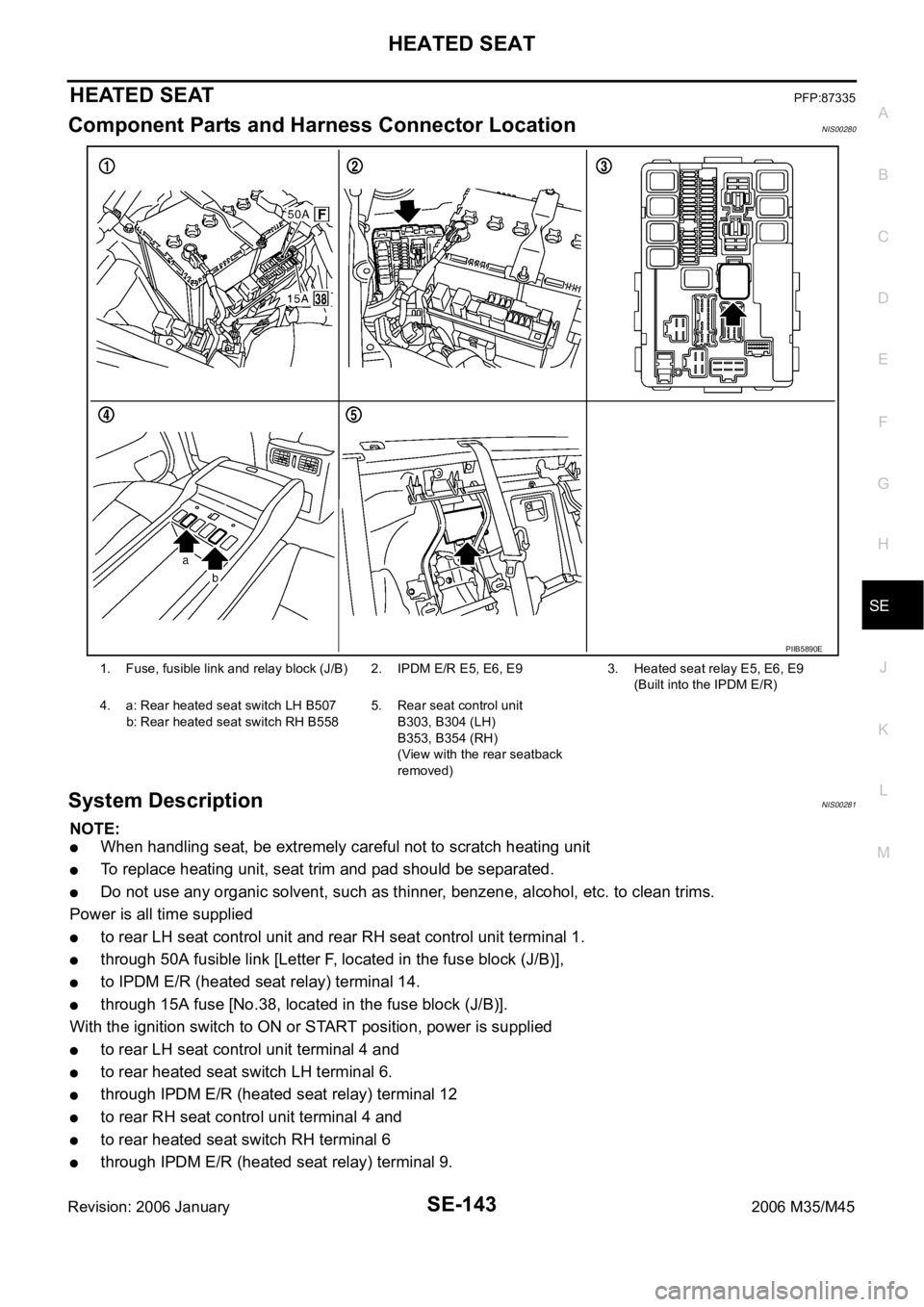

HEATED SEATPFP:87335

Component Parts and Harness Connector LocationNIS00280

System Description NIS00281

NOTE:

When handling seat, be extremely careful not to scratch heating unit

To replace heating unit, seat trim and pad should be separated.

Do not use any organic solvent, such as thinner, benzene, alcohol, etc. to clean trims.

Power is all time supplied

to rear LH seat control unit and rear RH seat control unit terminal 1.

through 50A fusible link [Letter F, located in the fuse block (J/B)],

to IPDM E/R (heated seat relay) terminal 14.

through 15A fuse [No.38, located in the fuse block (J/B)].

With the ignition switch to ON or START position, power is supplied

to rear LH seat control unit terminal 4 and

to rear heated seat switch LH terminal 6.

through IPDM E/R (heated seat relay) terminal 12

to rear RH seat control unit terminal 4 and

to rear heated seat switch RH terminal 6

through IPDM E/R (heated seat relay) terminal 9.

1. Fuse, fusible link and relay block (J/B) 2. IPDM E/R E5, E6, E93. Heated seat relay E5, E6, E9

(Built into the IPDM E/R)

4. a: Rear heated seat switch LH B507

b: Rear heated seat switch RH B5585. Rear seat control unit

B303, B304 (LH)

B353, B354 (RH)

(View with the rear seatback

removed)

PIIB5890E