high beam INFINITI M35 2006 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4492 of 5621

HEADLAMP (FOR USA) - XENON TYPE -

LT-65

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Headlamp High Beam Does Not Illuminate (One Side)NKS003OX

1. CHECK BULB

Check bulb of lamp which does not illuminate.

OK or NG

OK >> GO TO 2.

NG >> Replace headlamp bulb.

2. CHECK HEADLAMP INPUT SIGNAL

With CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH or LH connector.

3. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “HI” screen.

6. When headlamp high beam is operating, check voltage between

front combination lamp RH or LH harness connector and

ground. (Headlamp high beam repeats ON-OFF every 1 sec-

ond.)

Without CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH or LH connector.

3. Start auto active test. Refer to PG-24, "

Auto Active Test" .

4. When headlamp high beam is operating, check voltage between front combination lamp RH or LH har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

Terminal

Vo l ta g e (+)

(-)

Front combination lamp

connectorTerminal

RH E47 6

Ground Battery voltage

LH E54 6

Terminal

Vo l ta g e (+)

(-)

Front combination lamp

connectorTerminal

RH E47 6

Ground Battery voltage

LH E54 6

SKIB4749E

Page 4493 of 5621

LT-66

HEADLAMP (FOR USA) - XENON TYPE -

Revision: 2006 January2006 M35/M45

3. CHECK HEADLAMP GROUND

1. Turn ignition switch OFF.

2. Check continuity between front headlamp RH or LH harness

connector and ground.

OK or NG

OK >> Check connecting condition headlamp harness connec-

tor.

NG >> Repair harness or connector.

4. CHECK CIRCUIT BETWEEN IPDM E/R AND FRONT COMBINATION LAMP

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front combination lamp RH or LH connector.

3. Check harness continuity between IPDM E/R harness connector

(A) and front combination lamp RH or LH harness connector (B).

4. Check harness continuity between IPDM E/R harness connector

(A) and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-31, "Removal and Installation of IPDM E/R" .

NG >> Repair harness or connector.

High Beam Indicator Lamp Does Not IlluminateNKS003OY

1. CHECK BULB

Check bulb of high beam indicator lamp.

OK or NG

OK >> Replace combination meter.

NG >> Replace indicator bulb.

Front combination lamp

connectorTerminal

GroundContinuity

RH E47 2

Ye s

LH E54 2

SKIB4750E

CircuitAB

Continuity

Connector Terminal Connector Terminal

RH

E727 E47 6

Ye s

LH 28 E54 6

A

GroundContinuity

Connector Terminal

RH

E727

No

LH 28

SKIB4753E

Page 4501 of 5621

LT-74

HEADLAMP (FOR USA) - XENON TYPE -

Revision: 2006 January2006 M35/M45

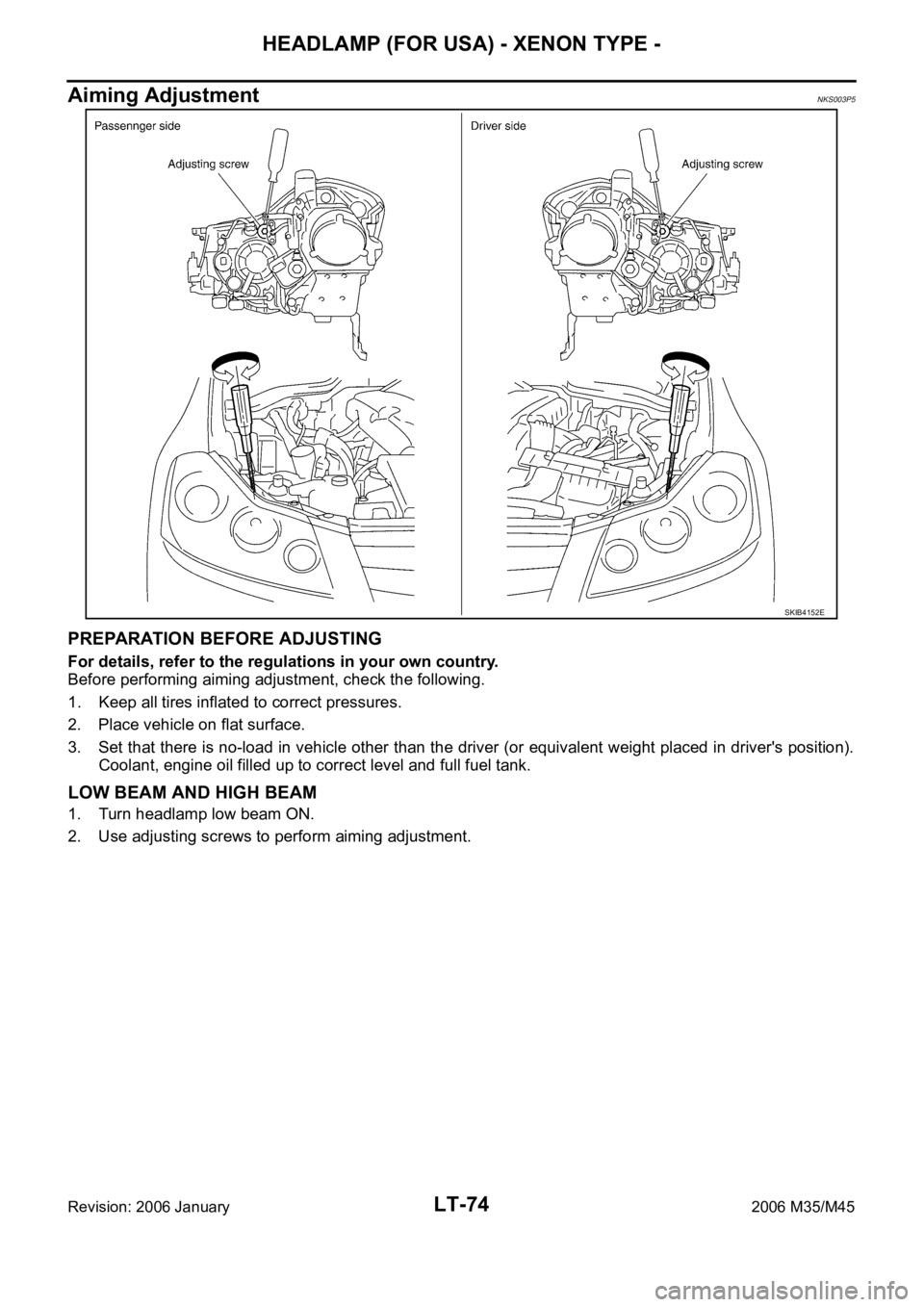

Aiming AdjustmentNKS003P5

PREPARATION BEFORE ADJUSTING

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on flat surface.

3. Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screws to perform aiming adjustment.

SKIB4152E

Page 4502 of 5621

HEADLAMP (FOR USA) - XENON TYPE -

LT-75

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check aiming.

Use the aiming chart shown in the figure.

Basic illumination area for adjustment should be within the range shown on the aiming chart.

Adjust headlamp accordingly.

Bulb ReplacementNKS003P6

HEADLAMP (INNER) HIGH BEAM

1. Turn lighting switch OFF.

2. Disconnect negative battery cable or remove circuit fuse.

3. Remove air cleaner case when replacing bulb LH. Refer to EM-17, "

Removal and Installation" (VQ35) or

EM-177, "

Removal and Installation" (VK45).

4. Remove washer tank inlet when replacing bulb RH. Refer to WW-47, "

Removal and Installation of Washer

Ta n k" .

5. Turn plastic cap counterclockwise and unlock it.

6. Turn bulb socket counterclockwise and unlock it.

7. Disconnect connector, and remove bulb.

SKIB4153E

Headlamp (inner) high beam : 12V - 60W (HB3)

Page 4508 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-81

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

HEADLAMP OPERATION

Low Beam Operation

With the lighting switch in 2ND position, the BCM receives input signal requesting the headlamps to illuminate.

This input signal is communicated to IPDM E/R across the CAN communication lines. The CPU located in the

IPDM E/R controls the headlamp low relay coil, which when energized, directs power

through 15A fuse (No. 76, located in IPDM E/R)

through IPDM E/R terminal 20

to front combination lamp RH terminal 8,

through 15A fuse (No. 86, located in IPDM E/R)

through IPDM E/R terminal 30

to front combination lamp LH terminal 8.

Ground is supplied

to front combination lamp RH terminal 4

to front combination lamp LH terminal 4

through grounds E22 and E43.

With power and ground supplied, low beam headlamps illuminate.

High Beam Operation (When Daytime Light Does Not Operate)/Flash-to-Pass Operation

With the lighting switch in 2ND position and placed in HIGH BEAM or PASSING position, the BCM receives

input signal requesting headlamp high beams to illuminate. High beam request signal is communicated to the

IPDM E/R across the CAN communication lines. The CPU located in the IPDM E/R controls headlamp high

relay coil and low relay coil, which when energized, directs power

through 10A fuse (No. 72, located in IPDM E/R)

through IPDM E/R terminal 27

through front combination lamp RH terminals 6 and 2

to daytime light relay terminal 3,

through 10A fuse (No. 74, located in IPDM E/R)

through IPDM E/R terminal 28

to front combination lamp LH terminal 6,

through 15A fuse (No. 76, located in IPDM E/R)

through IPDM E/R terminal 20

to front combination lamp RH terminal 8,

through 15A fuse (No. 86, located in IPDM E/R)

through IPDM E/R terminal 30

to front combination lamp LH terminal 8.

Ground is supplied

to daytime light relay terminal 4

to front combination lamp RH terminal 4

to front combination lamp LH terminal 2

to front combination lamp LH terminal 4

through grounds E22 and E43.

With the power and ground supplied, the headlamp high beam and low headlamp illuminate.

High beam indicator illuminates when combination meter receives input signal requesting high beam indicator

to illuminate. This is communicated to BCM across the CAN communication lines.

Page 4509 of 5621

LT-82

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

DAYTIME LIGHT OPERATION

With the engine running, the lighting switch in the OFF or AUTO position (headlamp is not illuminate) and

parking brake released, the IPDM E/R receives input request signal from BCM to turn on daytime light. This

input is communicated across the CAN communication lines. The CPU of the IPDM E/R controls the daytime

light relay coil. When energized, this relay directs power

through daytime light relay terminals 5 and 3

through front combination lamp RH terminal 2

through front combination lamp RH terminal 6

through IPDM E/R terminal 27

through 10A fuse (No. 72, located in IPDM E/R)

through 10A fuse (No. 74, located in IPDM E/R)

through IPDM E/R terminal 28

to front combination lamp LH terminal 6.

Ground is supplied

to combination lamp LH terminal 2

through grounds E22 and E43.

With power and grounds supplied, the daytime lights illuminate. The high beam headlamps are now wired in

series and illuminate at a reduced intensity.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "COMBINATION SWITCH READING FUNCTION" .

AUTO LIGHT OPERATION

For auto light operation, refer to LT- 11 6 , "System Description" .

CAN Communication System DescriptionNKS003PB

Refer to LAN-34, "CAN COMMUNICATION" .

Page 4522 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-95

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

4. Touch “HEAD LAMP” on “SELECT TEST ITEM” screen.

DATA MONITOR

Operation Procedure

1. Touch “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch either “ALL SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR ITEM” screen.

4. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. When “ALL SIG-

NALS” is selected, all the items will be monitored.

5. Touch “START”.

6. Touch “RECORD” while monitoring, then the status of the monitored item can be recorded. To stop

recording, touch “STOP”.

Display Item List

PKIA5226E

ALL SIGNALS Monitors all the signals.

SELECTION FROM MENU Selects items and monitor them.

Monitor item Contents

IGN ON SW “ON/OFF” Displays “IGN position (ON)/OFF, ACC position (OFF)” judged from the ignition switch signal.

ACC ON SW “ON/OFF” Displays “ACC (ON)/OFF, Ignition OFF (OFF)” status judged from ignition switch signal.

KEY ON SW “ON/OFF”Displays “Intelligent Key inserted into key slot (ON)/Intelligent Key removed from key slot

(OFF)” status judged from the key switch signal.

TURN SIGNAL R “ON/OFF” Displays status (turn right: ON/others: OFF) as judged from lighting switch signal.

TURN SIGNAL L “ON/OFF” Displays status (turn left: ON/others: OFF) as judged from lighting switch signal.

HI BEAM SW “ON/OFF”Displays status (high beam switch: ON/others: OFF) of high beam switch judged from lighting

switch signal.

HEAD LAMP SW 1 “ON/OFF”Displays status (headlamp switch 1: ON/others: OFF) of headlamp switch 1 judged from light-

ing switch signal.

HEAD LAMP SW 2 “ON/OFF”Displays status (headlamp switch 2: ON/others: OFF) of headlamp switch 2 judged from light-

ing switch signal.

TAIL LAMP SW “ON/OFF”Displays status (lighting switch 1ST or 2ND position: ON/others: OFF) of lighting switch

judged from lighting switch signal.

AUTO LIGHT SW “ON/OFF”Displays status of the lighting switch as judged from the lighting switch signal. (AUTO position:

ON/other than AUTO position: OFF)

PASSING SW “ON/OFF”Displays status (flash-to-passing switch: ON/others: OFF) of flash-to-passing switch judged

from lighting switch signal.

FR FOG SW “ON/OFF”Displays status (front fog lamp switch: ON/others: OFF) of front fog lamp switch judged from

lighting switch signal.

DOOR SW - DR “ON/OFF”Displays status of the driver door as judged from the driver door switch signal. (door is open:

ON/door is closed: OFF)

DOOR SW - AS “ON/OFF”Displays status of the passenger door as judged from the passenger door switch signal. (door

is open: ON/door is closed: OFF)

DOOR SW - RR “ON/OFF”Displays status of the rear door as judged from the rear door switch (RH) signal. (door is

open: ON/door is closed: OFF)

Page 4525 of 5621

LT-98

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

4. Select the desired part to be diagnosed on the “SELECT DIAG

MODE” screen.

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECTION DIAG MODE ” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR

ITEM” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. In “ALL SIG-

NALS”, all items are monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be correct.

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

BCIA0031E

ALL SIGNALS Monitors all items.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Selects items and monitors them.

Item nameCONSULT-II

screen displayDisplay

or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Position lights request TAIL&CLR REQ ON/OFF

Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF

Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF

Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF

Signal status input from BCM

Daytime running light request DTRL REQ ON/OFF

–Signal status input from BCM

Test itemCONSULT-II

screen displayDescription

Tail lamp relay output TAIL LAMP Allows tail lamp relay to operate by switching operation ON-OFF at your option.

Headlamp relay (HI, LO) output

LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON, LO

ON) at your option (Headlamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output Allows fog lamp relay to operate by switching operation ON-OFF at your option.

Page 4529 of 5621

LT-102

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

Headlamp High Beam Does Not Illuminate (Both Sides)NKS003PL

1. CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-II

Select “BCM” on CONSULT-II, With “HEAD LAMP” data monitor,

make sure “HI BEAM SW” turns ON-OFF linked with operation of

lighting switch.

Without CONSULT-II

Refer to LT- 2 4 0 , "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer to LT-

240, "Combination Switch Inspection" .

2. HEADLAMP ACTIVE TEST

With CONSULT-II

1. Select “IPDM E/R” on CONSULT-II, and select “ACTIVE TEST”

on “SELECT DIAG MODE” screen.

2. Select “LAMPS” on “SELECT TEST ITEM” screen.

3. Touch “HI” screen.

4. Make sure headlamp high beam operation.

Without CONSULT-II

1. Start auto active test. Refer to PG-24, "

Auto Active Test" .

2. Make sure headlamp high beam operation.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3. CHECK IPDM E/R

1. Select “IPDM E/R” on CONSULT-II, and select “DATA MONI-

TOR” on “SELECT DIAG MODE” screen.

2. Make sure “HL LO REQ” and “HL HI REQ” turns ON when light-

ing switch is in HIGH BEAM position.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-31, "Removal and

Installation of IPDM E/R" .

NG >> Replace BCM. Refer to BCS-17, "

Removal and Installa-

tion of BCM" . When lighting switch is

HIGH BEAM position: HI BEAM SW ON

PKIA6324E

Headlamp high beam should operate

(Headlamp high beam repeats ON-OFF every 1 second).

Headlamp high beam should operate.

SKIA5774E

When lighting switch is

HIGH BEAM position: HL LO REQ ON

: HL HI REQ ON

SKIA5775E

Page 4530 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-103

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

4. CHECK HEADLAMP INPUT SIGNAL

With CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connector.

3. Select “IPDM E/R” on CONSULT-II, select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “HI” screen.

6. When headlamp high beam is operating, check voltage between

front combination lamp (RH and LH) harness connector and

ground. (Headlamp high beam repeats ON-OFF every 1 sec-

ond.)

Without CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connector.

3. Start auto active test. Refer to PG-24, "

Auto Active Test" .

4. When headlamp high beam is operating, check voltage between front combination lamp (RH and LH) har-

ness connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 8.

5. CHECK HEADLAMP (LH SIDE) GROUND

1. Turn ignition switch OFF.

2. Check continuity between front headlamp LH harness connector

E54 terminal 2 and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

Terminal

Vo l ta g e (+)

(-)

Front combination lamp

connectorTerminal

RH E47 6

Ground Battery voltage

LH E54 6

Terminal

Vo l ta g e (+)

(-)

Front combination lamp

connectorTerminal

RH E47 6

Ground Battery voltage

LH E54 6

SKIB4749E

2 – Ground : Continuity should exist.

SKIB4750E