manual transmission INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 114 of 5621

A/T CONTROL SYSTEM

AT-35

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

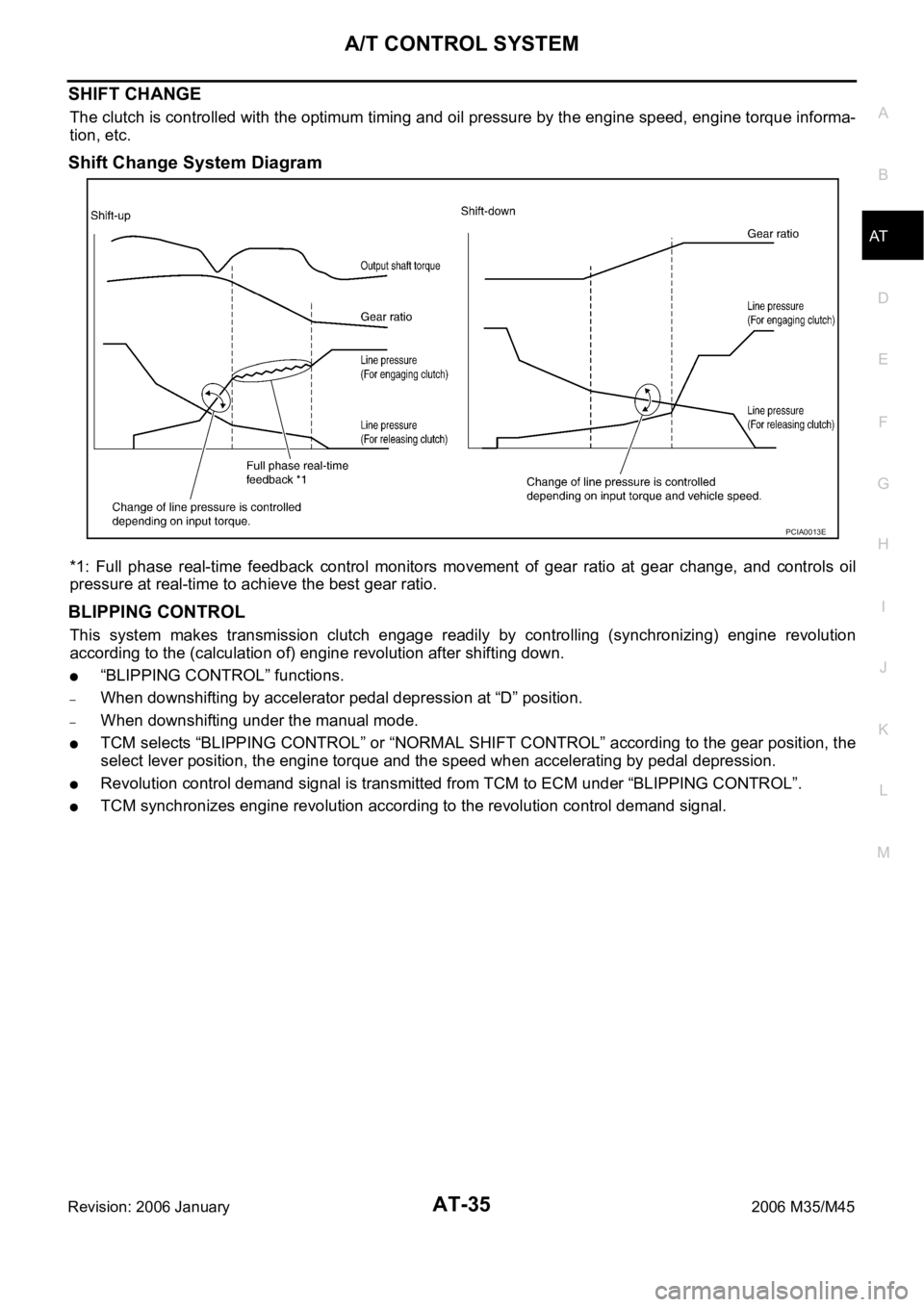

SHIFT CHANGE

The clutch is controlled with the optimum timing and oil pressure by the engine speed, engine torque informa-

tion, etc.

Shift Change System Diagram

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

pressure at real-time to achieve the best gear ratio.

BLIPPING CONTROL

This system makes transmission clutch engage readily by controlling (synchronizing) engine revolution

according to the (calculation of) engine revolution after shifting down.

“BLIPPING CONTROL” functions.

–When downshifting by accelerator pedal depression at “D” position.

–When downshifting under the manual mode.

TCM selects “BLIPPING CONTROL” or “NORMAL SHIFT CONTROL” according to the gear position, the

select lever position, the engine torque and the speed when accelerating by pedal depression.

Revolution control demand signal is transmitted from TCM to ECM under “BLIPPING CONTROL”.

TCM synchronizes engine revolution according to the revolution control demand signal.

PCIA0013E

Page 318 of 5621

ON-VEHICLE SERVICE

AT-239

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

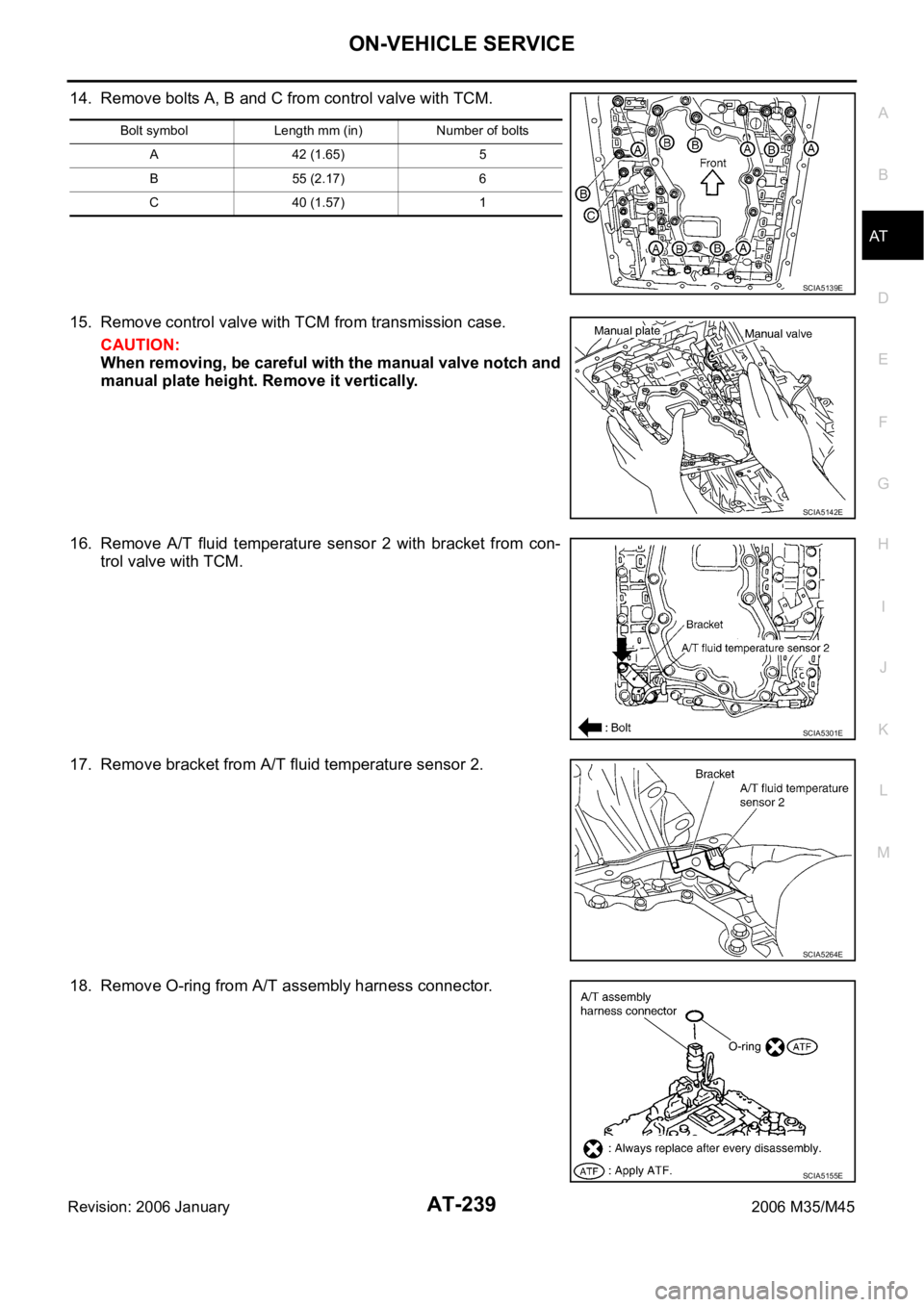

14. Remove bolts A, B and C from control valve with TCM.

15. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with the manual valve notch and

manual plate height. Remove it vertically.

16. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

17. Remove bracket from A/T fluid temperature sensor 2.

18. Remove O-ring from A/T assembly harness connector.

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5139E

SCIA5142E

SCIA5301E

SCIA5264E

SCIA5155E

Page 321 of 5621

AT-242

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

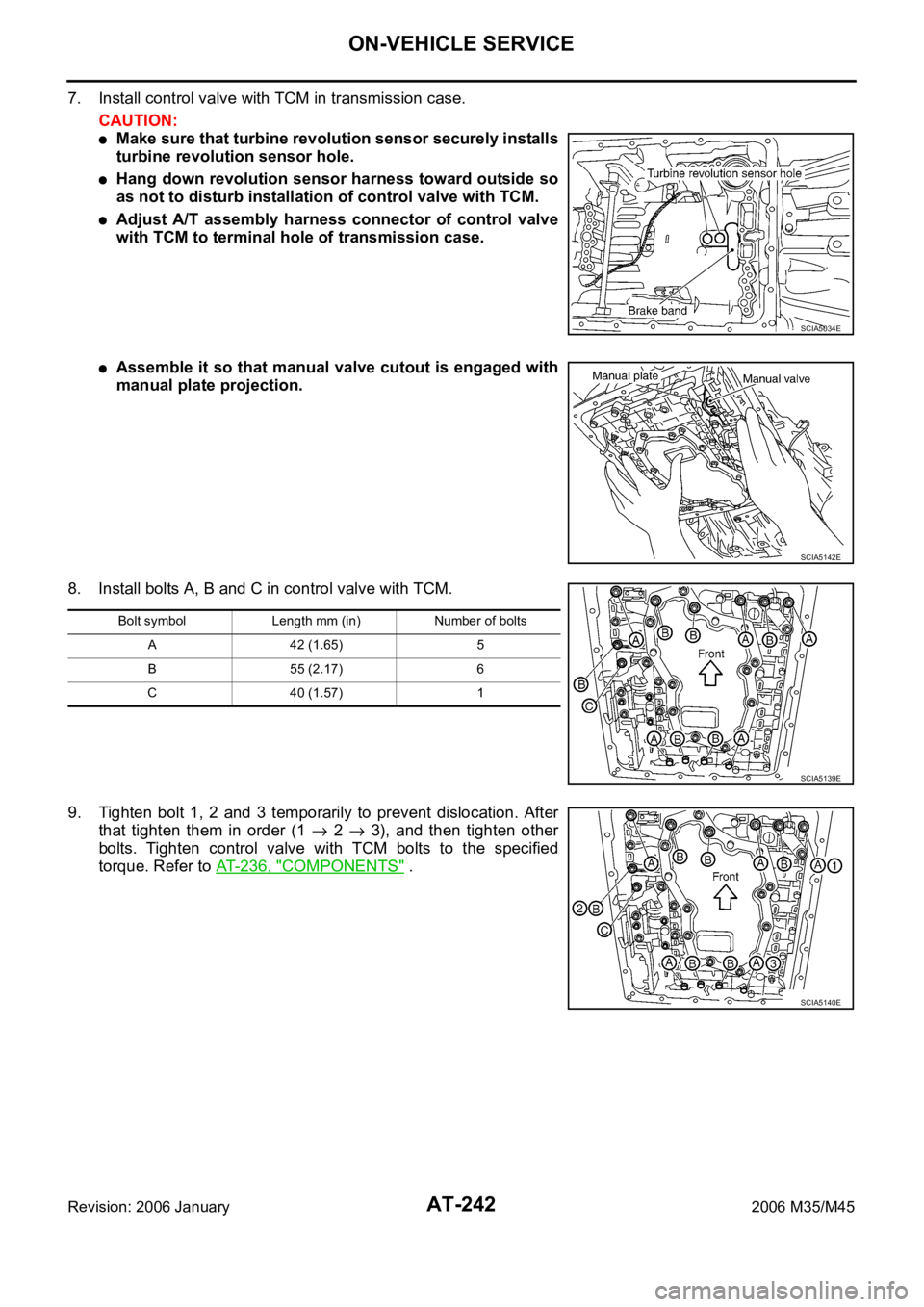

7. Install control valve with TCM in transmission case.

CAUTION:

Make sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

Hang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

Adjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

Assemble it so that manual valve cutout is engaged with

manual plate projection.

8. Install bolts A, B and C in control valve with TCM.

9. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1

2 3), and then tighten other

bolts. Tighten control valve with TCM bolts to the specified

torque. Refer to AT-236, "

COMPONENTS" .

SCIA5034E

SCIA5142E

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5139E

SCIA5140E

Page 366 of 5621

OVERHAUL

AT-287

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

7. Pawl shaft 8. Seal ring 9. Needle bearing

10. Revolution sensor 11. Parking gear 12. Output shaft

13. Bearing race 14. Needle bearing 15. Manual plate

16. Parking rod 17. Manual shaft oil seal 18. Manual shaft

19. O-ring 20. Band servo anchor end pin 21. Detent spring

22. Spacer 23. Seal ring 24. Snap ring

25. Return spring 26. O-ring 27. Servo assembly

28. Snap ring 29. Sub-harness 30. Control valve with TCM

31. Bracket 32. A/T fluid temperature sensor 2 33. Oil pan

34. Magnet 35. Drain plug 36. Drain plug gasket

37. Oil pan mounting bolt 38. Oil pan gasket 39. Terminal cord assembly

40. O-ring 41. Retaining pin 42. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-11, "

Components" .

However, refer to the following symbols for others.

*:Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-48, "Recommended Chemical Products and Sealants"

.

Page 368 of 5621

OVERHAUL

AT-289

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

1. Output shaft & companion flange

complement2. Parking actuator support 3. Parking pawl

4. Return spring 5. Pawl shaft 6. Self-sealing bolt

7. Seal ring 8. Needle bearing 9. Revolution sensor

10. Intermediate shaft 11. Manual plate 12. Parking rod

13. Manual shaft oil seal 14. Manual shaft 15. Retaining pin

16. O-ring 17. Band servo anchor end pin 18. Detent spring

19. Spacer 20. Return spring 21. Seal ring

22. O-ring 23. Servo assembly 24. Snap ring

25. Snap ring 26. Sub-harness 27. Control valve with TCM

28. Bracket 29. A/T fluid temperature sensor 2 30. Terminal cord assembly

31. O-ring 32. Oil pan 33. Magnet

34. Drain plug 35. Drain plug gasket 36. Oil pan mounting bolt

37. Oil pan gasket 38. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-11, "

Components" .

However, refer to the following symbols for others.

*:Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-48, "Recommended Chemical Products and Sealants" .

Page 370 of 5621

OVERHAUL

AT-291

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

7. Pawl shaft 8. Self-sealing bolt 9. Seal ring

10. Needle bearing 11. Gasket 12. Revolution sensor

13. Parking gear 14. Output shaft 15. Bearing race

16. Needle bearing 17. Manual plate 18. Parking rod

19. Manual shaft oil seal 20. Manual shaft 21. O-ring

22. Band servo anchor end pin 23. Detent spring 24. Spacer

25. Seal ring 26. Snap ring 27. Return spring

28. O-ring 29. Servo assembly 30. Snap ring

31. Sub-harness 32. Control valve with TCM 33. Bracket

34. A/T fluid temperature sensor 2 35. Oil pan 36. Magnet

37. Drain plug 38. Drain plug gasket 39. Oil pan mounting bolt

40. Oil pan gasket 41. Terminal cord assembly 42. O-ring

43. Retaining pin 44. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-11, "

Components" .

Page 384 of 5621

DISASSEMBLY

AT-305

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

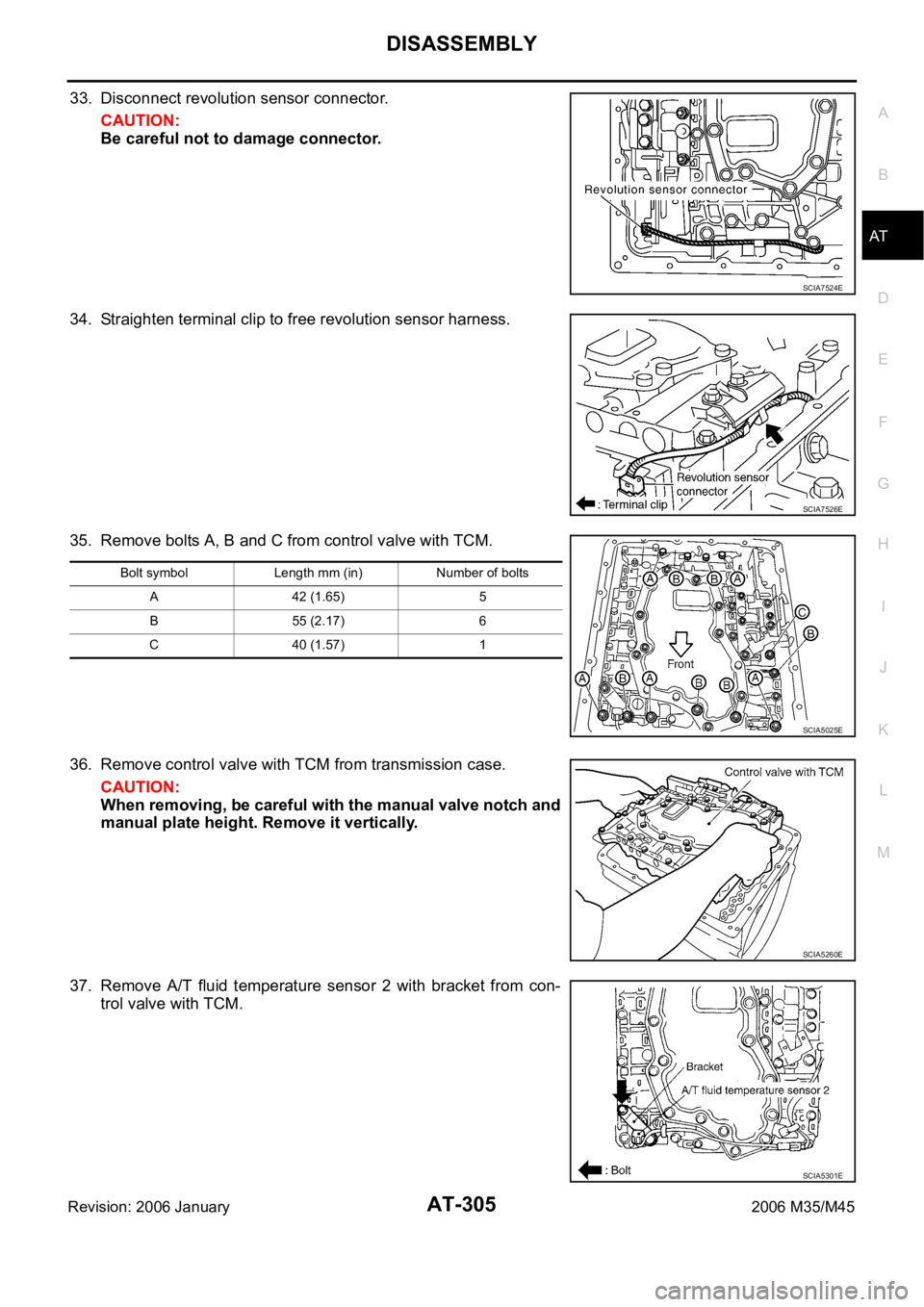

33. Disconnect revolution sensor connector.

CAUTION:

Be careful not to damage connector.

34. Straighten terminal clip to free revolution sensor harness.

35. Remove bolts A, B and C from control valve with TCM.

36. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with the manual valve notch and

manual plate height. Remove it vertically.

37. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

SCIA7524E

SCIA7526E

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5025E

SCIA5260E

SCIA5301E

Page 393 of 5621

AT-314

DISASSEMBLY

Revision: 2006 January2006 M35/M45

57. Remove manual shaft retaining pin with a pair of nippers.

58. Remove manual plate (with parking rod) from manual shaft.

59. Remove parking rod from manual plate.

60. Remove manual shaft from transmission case.

61. Remove manual shaft oil seals using a flat-bladed screwdriver.

CAUTION:

Be careful not to scratch transmission case.

SCIA2329E

SCIA5715E

SCIA5220E

SCIA5716E

SCIA2331E

Page 419 of 5621

![INFINITI M35 2006 Factory Service Manual AT-340

ASSEMBLY

Revision: 2006 January2006 M35/M45

ASSEMBLYPFP:00000

Assembly (1)NCS001RA

1. As shown in the figure, use a drift [22 mm (0.87 in) dia. commer-

cial service tool] to drive manual shaft INFINITI M35 2006 Factory Service Manual AT-340

ASSEMBLY

Revision: 2006 January2006 M35/M45

ASSEMBLYPFP:00000

Assembly (1)NCS001RA

1. As shown in the figure, use a drift [22 mm (0.87 in) dia. commer-

cial service tool] to drive manual shaft](/img/42/57023/w960_57023-418.png)

AT-340

ASSEMBLY

Revision: 2006 January2006 M35/M45

ASSEMBLYPFP:00000

Assembly (1)NCS001RA

1. As shown in the figure, use a drift [22 mm (0.87 in) dia. commer-

cial service tool] to drive manual shaft oil seals into the transmis-

sion case until it is flush.

CAUTION:

Apply ATF to manual shaft oil seals.

Do not reuse manual shaft oil seals.

2. Install detent spring and spacer in transmission case. Tighten

detent spring and spacer bolts to the specified torque. Refer to

AT-278, "

Components" .

3. Install manual shaft to transmission case.

4. Install parking rod to manual plate.

SCIA5259E

SCIA5248E

SCIA5716E

SCIA5220E

Page 420 of 5621

ASSEMBLY

AT-341

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

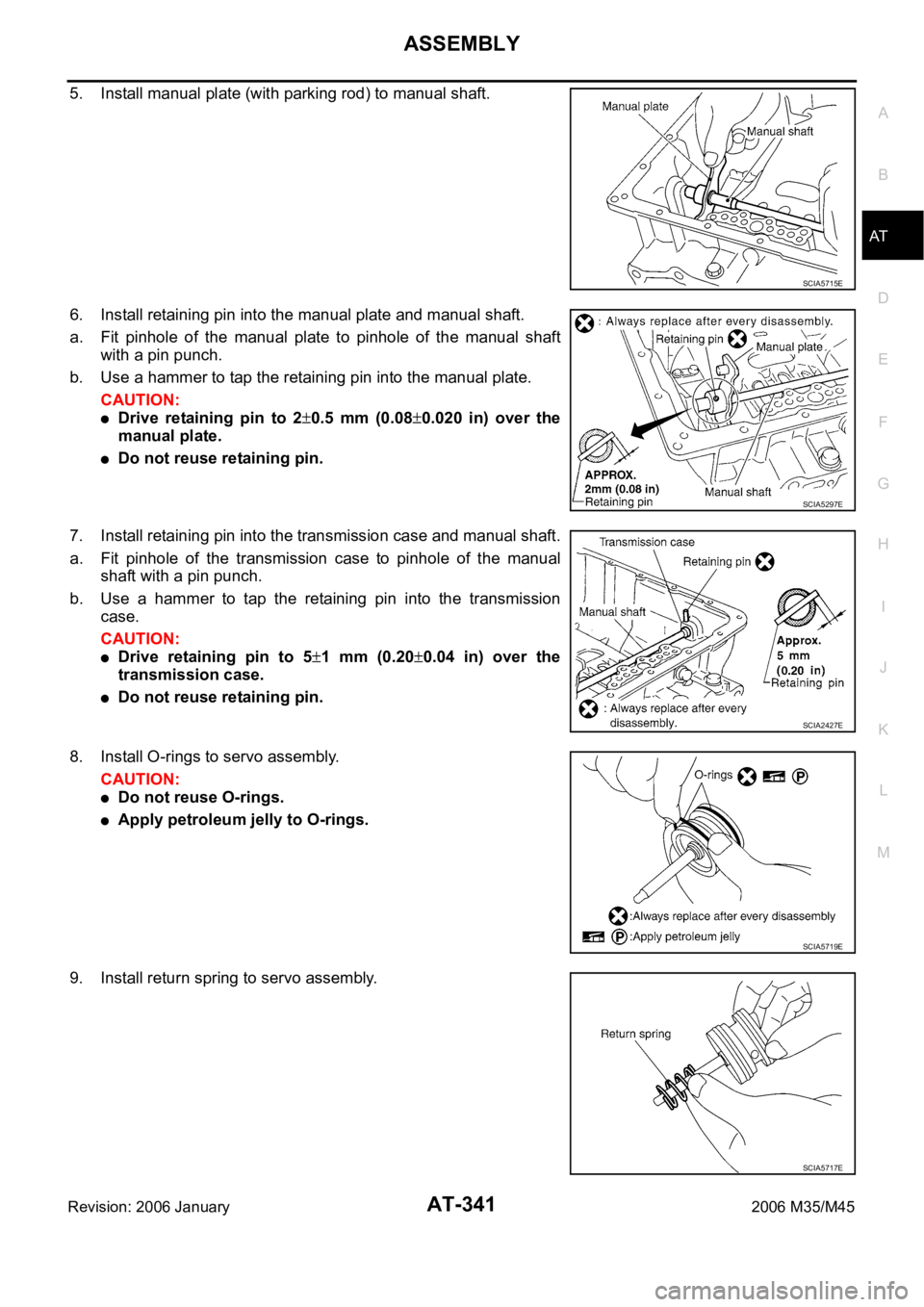

5. Install manual plate (with parking rod) to manual shaft.

6. Install retaining pin into the manual plate and manual shaft.

a. Fit pinhole of the manual plate to pinhole of the manual shaft

with a pin punch.

b. Use a hammer to tap the retaining pin into the manual plate.

CAUTION:

Drive retaining pin to 20.5 mm (0.080.020 in) over the

manual plate.

Do not reuse retaining pin.

7. Install retaining pin into the transmission case and manual shaft.

a. Fit pinhole of the transmission case to pinhole of the manual

shaft with a pin punch.

b. Use a hammer to tap the retaining pin into the transmission

case.

CAUTION:

Drive retaining pin to 51 mm (0.200.04 in) over the

transmission case.

Do not reuse retaining pin.

8. Install O-rings to servo assembly.

CAUTION:

Do not reuse O-rings.

Apply petroleum jelly to O-rings.

9. Install return spring to servo assembly.

SCIA5715E

SCIA5297E

SCIA2427E

SCIA5719E

SCIA5717E