light INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4601 of 5621

LT-174

ACTIVE AFS

Revision: 2006 January2006 M35/M45

DTC B2514 HI SEN UNUSUAL RRNKS003QQ

1. CHECK HEIGHT SENSOR SIGNAL

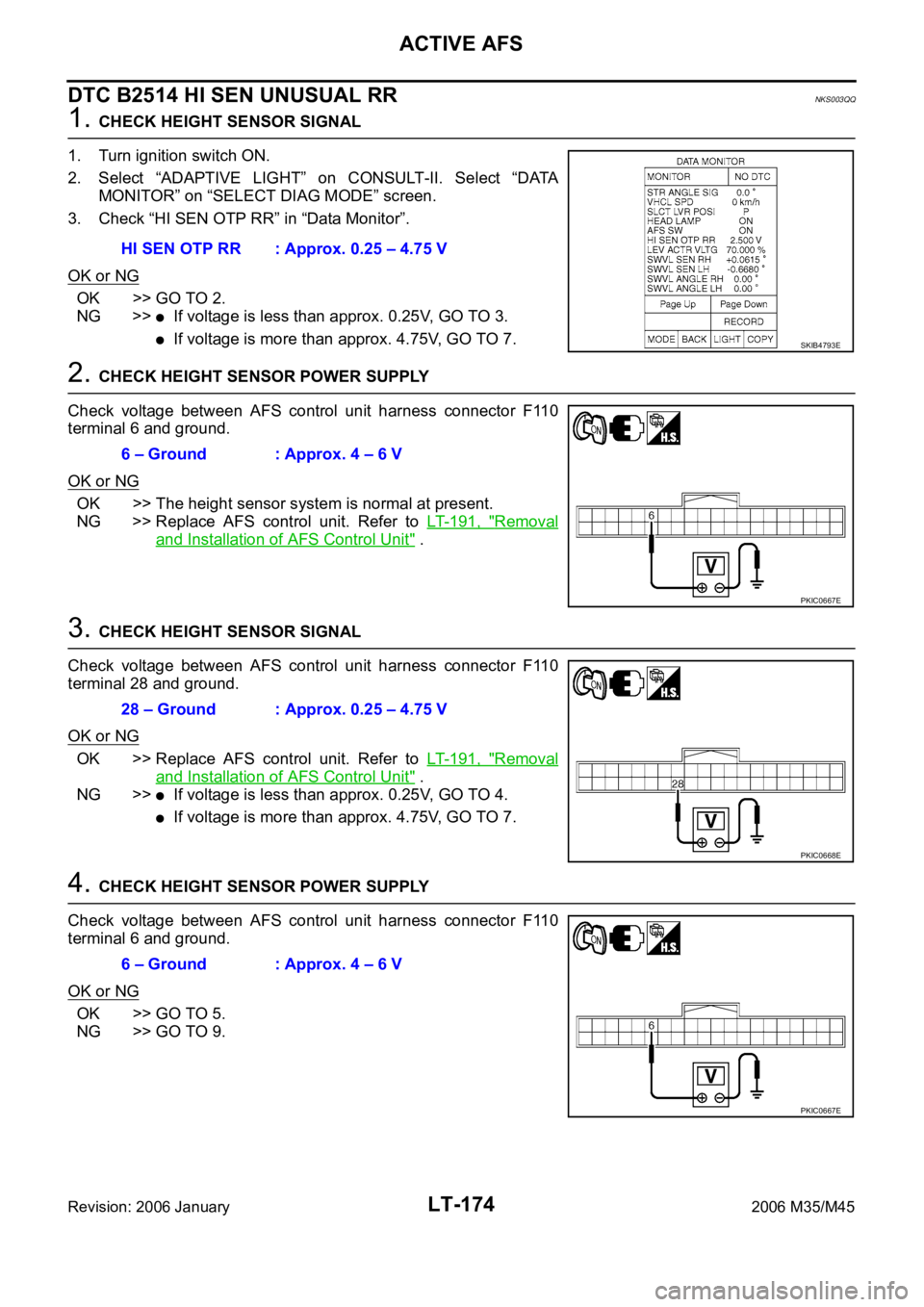

1. Turn ignition switch ON.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “DATA

MONITOR” on “SELECT DIAG MODE” screen.

3. Check “HI SEN OTP RR” in “Data Monitor”.

OK or NG

OK >> GO TO 2.

NG >>

If voltage is less than approx. 0.25V, GO TO 3.

If voltage is more than approx. 4.75V, GO TO 7.

2. CHECK HEIGHT SENSOR POWER SUPPLY

Check voltage between AFS control unit harness connector F110

terminal 6 and ground.

OK or NG

OK >> The height sensor system is normal at present.

NG >> Replace AFS control unit. Refer to LT- 1 9 1 , "

Removal

and Installation of AFS Control Unit" .

3. CHECK HEIGHT SENSOR SIGNAL

Check voltage between AFS control unit harness connector F110

terminal 28 and ground.

OK or NG

OK >> Replace AFS control unit. Refer to LT- 1 9 1 , "Removal

and Installation of AFS Control Unit" .

NG >>

If voltage is less than approx. 0.25V, GO TO 4.

If voltage is more than approx. 4.75V, GO TO 7.

4. CHECK HEIGHT SENSOR POWER SUPPLY

Check voltage between AFS control unit harness connector F110

terminal 6 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 9.HI SEN OTP RR : Approx. 0.25 – 4.75 V

SKIB4793E

6 – Ground : Approx. 4 – 6 V

PKIC0667E

28 – Ground : Approx. 0.25 – 4.75 V

PKIC0668E

6 – Ground : Approx. 4 – 6 V

PKIC0667E

Page 4603 of 5621

LT-176

ACTIVE AFS

Revision: 2006 January2006 M35/M45

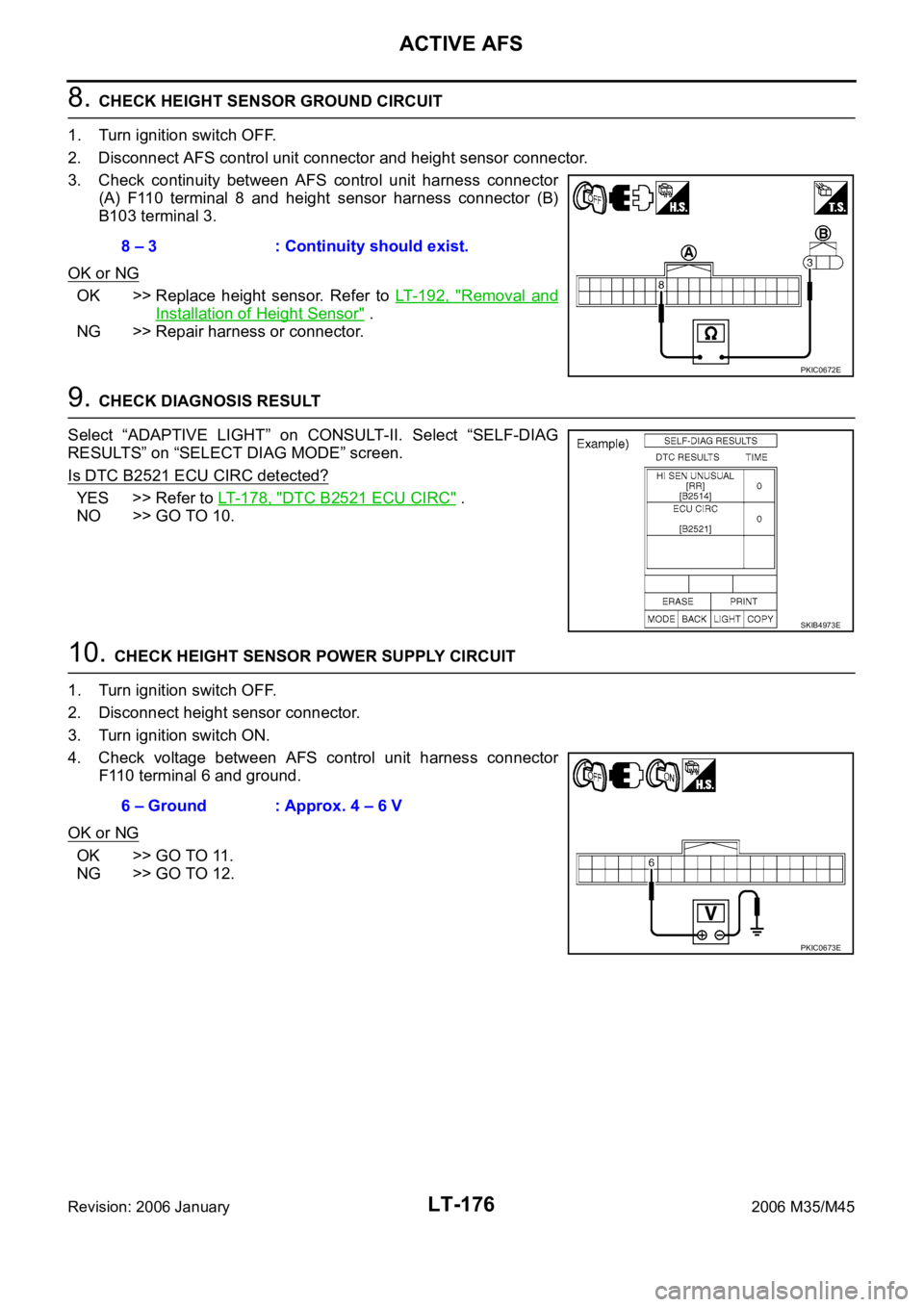

8. CHECK HEIGHT SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect AFS control unit connector and height sensor connector.

3. Check continuity between AFS control unit harness connector

(A) F110 terminal 8 and height sensor harness connector (B)

B103 terminal 3.

OK or NG

OK >> Replace height sensor. Refer to LT- 1 9 2 , "Removal and

Installation of Height Sensor" .

NG >> Repair harness or connector.

9. CHECK DIAGNOSIS RESULT

Select “ADAPTIVE LIGHT” on CONSULT-II. Select “SELF-DIAG

RESULTS” on “SELECT DIAG MODE” screen.

Is DTC B2521 ECU CIRC detected?

YES >> Refer to LT- 1 7 8 , "DTC B2521 ECU CIRC" .

NO >> GO TO 10.

10. CHECK HEIGHT SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect height sensor connector.

3. Turn ignition switch ON.

4. Check voltage between AFS control unit harness connector

F110 terminal 6 and ground.

OK or NG

OK >> GO TO 11.

NG >> GO TO 12.8 – 3 : Continuity should exist.

PKIC0672E

SKIB4973E

6 – Ground : Approx. 4 – 6 V

PKIC0673E

Page 4608 of 5621

ACTIVE AFS

LT-181

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

AFS Operation Check (Function Test)NKS003QS

1. CHECK SWIVEL ACTUATOR

1. Start engine and turn lighting switch to 2ND position.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “ACTIVE

TEST” on “SELECT DIAG MODE” screen.

3. Select “LOW BEAM TEST RIGHT” or “LOW BEAM TEST LEFT”

on “SELECT TEST ITEM” screen.

4. Touch “ORIGIN–FAST/SLOW” and “PEAK–FAST/SLOW”

screen.

5. Make sure of swivel operation.

OK or NG

OK >> GO TO 2.

NG >>

When interference or poor fitment is found, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, replace headlamp. Refer to LT- 1 9 0 , "Removal and Installation of

Front Combination Lamp" .

When the operation range is irregular, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, GO TO 3.

2. CHECK STEERING ANGLE SENSOR

Check “STR ANGLE SIG” in “Data Monitor” when driving straight

and steering turn 90

to right or left.

OK or NG

OK >> GO TO 3.

NG >>

When steering is out of range while driving straight, perform steering angle sensor adjustment.

Refer to BRC-6, "

Adjustment of Steering Angle Sensor Neutral Position" in “ON-VEHICLE

SERVICE”.

When the function is normal while driving straight but the displayed value is different from

actual steering position with turning to right or left, replace steering angle sensor. Refer to LT-

190, "Removal and Installation of Steering Angle Sensor" .

SKIB4794E

TEST ITEM ORIGIN PEAKLight axis range at 10 m (394.7 in) off

(Reference value)

LOW BEAM TEST RIGHT Swivel angle 0

Swivel angle 7 to 13Approx. 1.200 to 2.300 mm (48 to 90 in)

LOW BEAM TEST LEFT Swivel angle 0

Swivel angle 17 to 23Approx. 3.000 to 4.200 mm (120 to 167 in)

Steering conditionSTR ANGLE SIG

(Data monitor)

Driving straight

5.0 to + 5.0

Turn 90 to right Approx. + 90

Tu rn 90 to left Approx. 90

SKIB4793E

Page 4609 of 5621

LT-182

ACTIVE AFS

Revision: 2006 January2006 M35/M45

3. CHECK SWIVEL ACTUATOR AND AFS CONTROL UNIT

Check “SWVL SEN RH/LH” and “SWVL ANGLE RH/LH” in “Data

Monitor” with steering turning to right or left under swivel operative

condition.

NOTE:

The angle can be slightly different between the displayed value on “SWVL SEN” and

that on “SWVL ANGLE” even when AFS operation is normal.

OK or NG

OK >> AFS function is normal.

NG >>

When the difference is 4.5 or more between the displayed value on “SWVL ANGLE” and that

on “SWVL SEN”, replace headlamp.

When the displayed angle on “SWVL ANGLE” is irregular, replace AFS control unit.

TEST ITEM Turn 180 or more to left Turn 180 or more to right

SWVL SEN RH

SWVL ANGLE RHApprox. 0 7 to 13

SWVL SEN LH

SWVL ANGLE LH 17 to 23Approx. 0

SKIB4793E

Page 4610 of 5621

ACTIVE AFS

LT-183

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

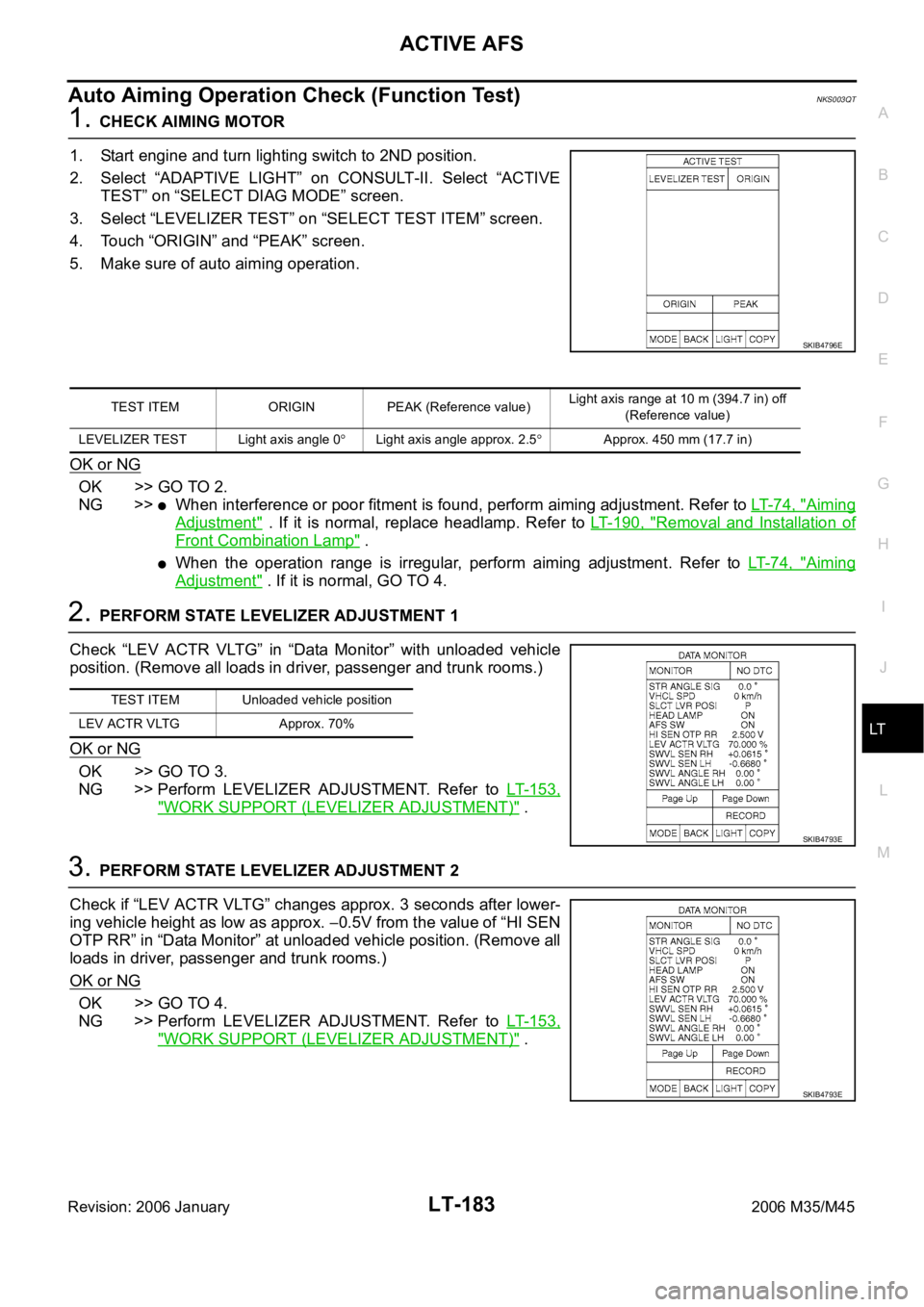

Auto Aiming Operation Check (Function Test)NKS003QT

1. CHECK AIMING MOTOR

1. Start engine and turn lighting switch to 2ND position.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “ACTIVE

TEST” on “SELECT DIAG MODE” screen.

3. Select “LEVELIZER TEST” on “SELECT TEST ITEM” screen.

4. Touch “ORIGIN” and “PEAK” screen.

5. Make sure of auto aiming operation.

OK or NG

OK >> GO TO 2.

NG >>

When interference or poor fitment is found, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, replace headlamp. Refer to LT- 1 9 0 , "Removal and Installation of

Front Combination Lamp" .

When the operation range is irregular, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, GO TO 4.

2. PERFORM STATE LEVELIZER ADJUSTMENT 1

Check “LEV ACTR VLTG” in “Data Monitor” with unloaded vehicle

position. (Remove all loads in driver, passenger and trunk rooms.)

OK or NG

OK >> GO TO 3.

NG >> Perform LEVELIZER ADJUSTMENT. Refer to LT- 1 5 3 ,

"WORK SUPPORT (LEVELIZER ADJUSTMENT)" .

3. PERFORM STATE LEVELIZER ADJUSTMENT 2

Check if “LEV ACTR VLTG” changes approx. 3 seconds after lower-

ing vehicle height as low as approx.

0.5V from the value of “HI SEN

OTP RR” in “Data Monitor” at unloaded vehicle position. (Remove all

loads in driver, passenger and trunk rooms.)

OK or NG

OK >> GO TO 4.

NG >> Perform LEVELIZER ADJUSTMENT. Refer to LT- 1 5 3 ,

"WORK SUPPORT (LEVELIZER ADJUSTMENT)" .

SKIB4796E

TEST ITEM ORIGIN PEAK (Reference value)Light axis range at 10 m (394.7 in) off

(Reference value)

LEVELIZER TEST Light axis angle 0

Light axis angle approx. 2.5Approx. 450 mm (17.7 in)

TEST ITEM Unloaded vehicle position

LEV ACTR VLTG Approx. 70%

SKIB4793E

SKIB4793E

Page 4611 of 5621

LT-184

ACTIVE AFS

Revision: 2006 January2006 M35/M45

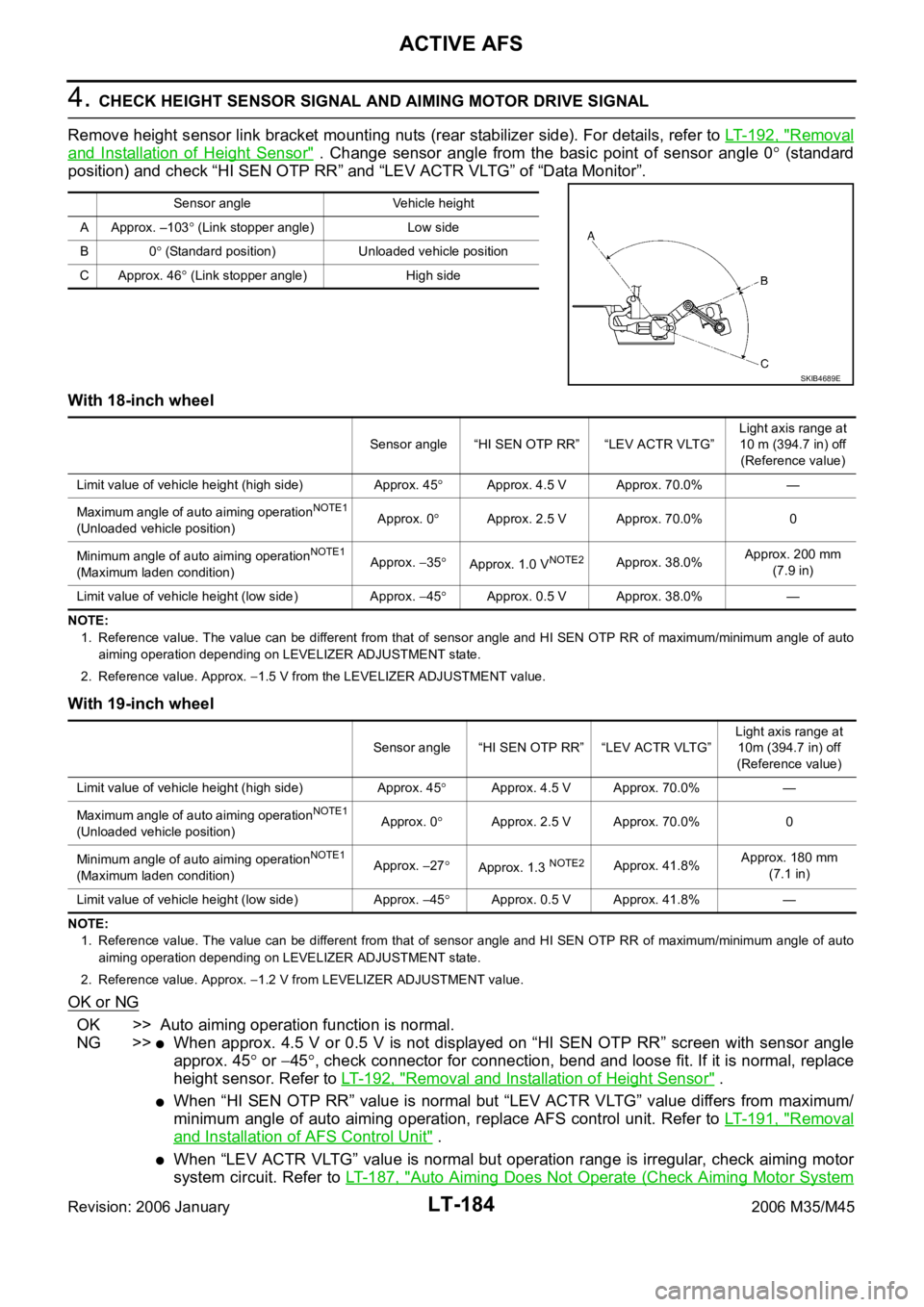

4. CHECK HEIGHT SENSOR SIGNAL AND AIMING MOTOR DRIVE SIGNAL

Remove height sensor link bracket mounting nuts (rear stabilizer side). For details, refer to LT- 1 9 2 , "

Removal

and Installation of Height Sensor" . Change sensor angle from the basic point of sensor angle 0 (standard

position) and check “HI SEN OTP RR” and “LEV ACTR VLTG” of “Data Monitor”.

With 18-inch wheel

NOTE:

1. Reference value. The value can be different from that of sensor angle and HI SEN OTP RR of maximum/minimum angle of auto

aiming operation depending on LEVELIZER ADJUSTMENT state.

2. Reference value. Approx.

1.5 V from the LEVELIZER ADJUSTMENT value.

With 19-inch wheel

NOTE:

1. Reference value. The value can be different from that of sensor angle and HI SEN OTP RR of maximum/minimum angle of auto

aiming operation depending on LEVELIZER ADJUSTMENT state.

2. Reference value. Approx.

1.2 V from LEVELIZER ADJUSTMENT value.

OK or NG

OK >> Auto aiming operation function is normal.

NG >>

When approx. 4.5 V or 0.5 V is not displayed on “HI SEN OTP RR” screen with sensor angle

approx. 45

or 45, check connector for connection, bend and loose fit. If it is normal, replace

height sensor. Refer to LT- 1 9 2 , "

Removal and Installation of Height Sensor" .

When “HI SEN OTP RR” value is normal but “LEV ACTR VLTG” value differs from maximum/

minimum angle of auto aiming operation, replace AFS control unit. Refer to LT- 1 9 1 , "

Removal

and Installation of AFS Control Unit" .

When “LEV ACTR VLTG” value is normal but operation range is irregular, check aiming motor

system circuit. Refer to LT- 1 8 7 , "

Auto Aiming Does Not Operate (Check Aiming Motor System

Sensor angle Vehicle height

A Approx. –103

(Link stopper angle) Low side

B0

(Standard position) Unloaded vehicle position

C Approx. 46

(Link stopper angle) High side

SKIB4689E

Sensor angle “HI SEN OTP RR” “LEV ACTR VLTG”Light axis range at

10 m (394.7 in) off

(Reference value)

Limit value of vehicle height (high side) Approx. 45

Approx. 4.5 V Approx. 70.0% —

Maximum angle of auto aiming operation

NOTE1

(Unloaded vehicle position)Approx. 0Approx. 2.5 V Approx. 70.0% 0

Minimum angle of auto aiming operation

NOTE1

(Maximum laden condition)Approx. 35Approx. 1.0 VNOTE2Approx. 38.0%Approx. 200 mm

(7.9 in)

Limit value of vehicle height (low side) Approx.

45Approx. 0.5 V Approx. 38.0% —

Sensor angle “HI SEN OTP RR” “LEV ACTR VLTG”Light axis range at

10m (394.7 in) off

(Reference value)

Limit value of vehicle height (high side) Approx. 45

Approx. 4.5 V Approx. 70.0% —

Maximum angle of auto aiming operation

NOTE1

(Unloaded vehicle position)Approx. 0Approx. 2.5 V Approx. 70.0% 0

Minimum angle of auto aiming operation

NOTE1

(Maximum laden condition)Approx. 27Approx. 1.3 NOTE2Approx. 41.8%Approx. 180 mm

(7.1 in)

Limit value of vehicle height (low side) Approx.

45Approx. 0.5 V Approx. 41.8% —

Page 4612 of 5621

ACTIVE AFS

LT-185

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Circuit)" .

AFS Switch Does Not OperateNKS003QU

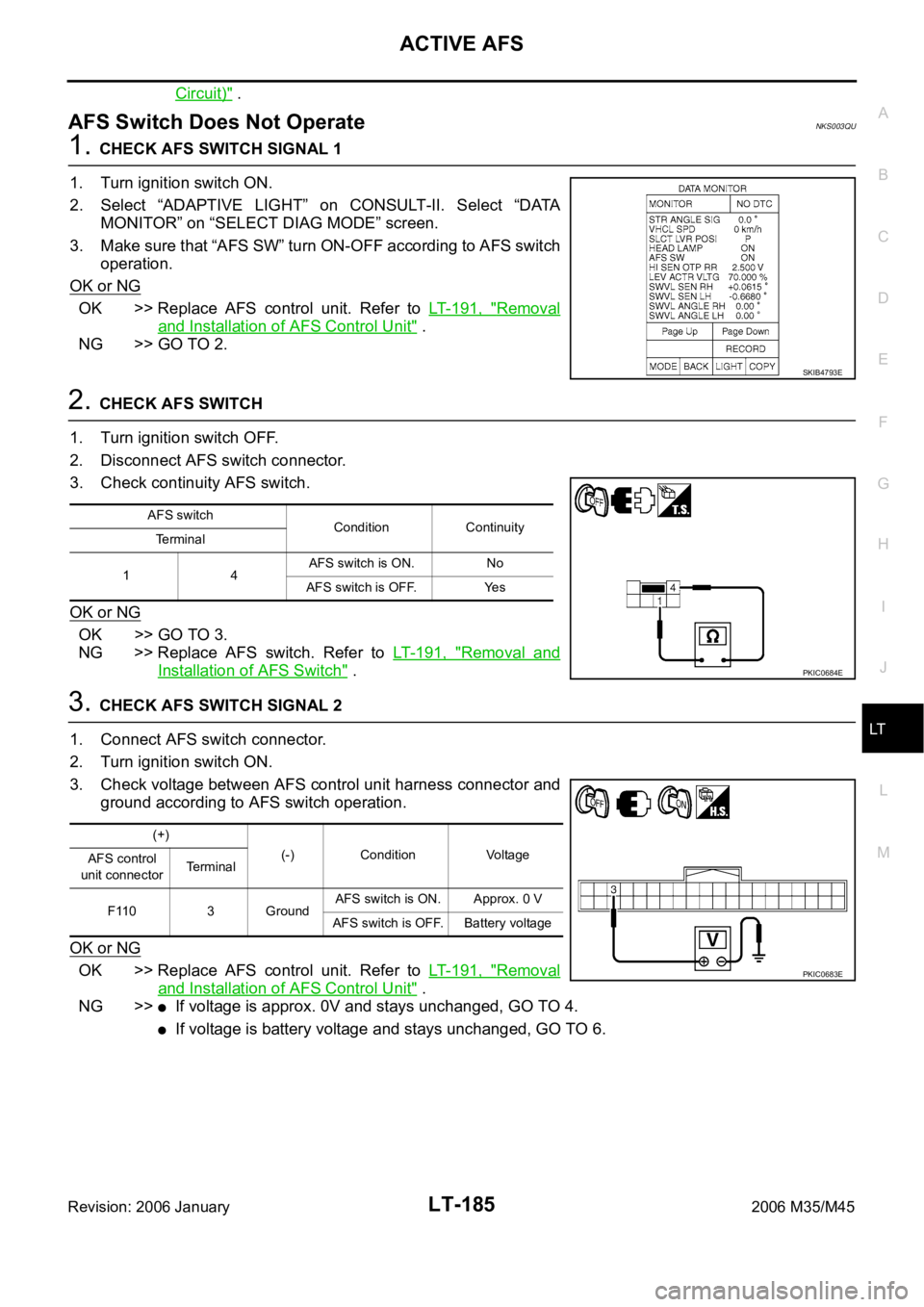

1. CHECK AFS SWITCH SIGNAL 1

1. Turn ignition switch ON.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “DATA

MONITOR” on “SELECT DIAG MODE” screen.

3. Make sure that “AFS SW” turn ON-OFF according to AFS switch

operation.

OK or NG

OK >> Replace AFS control unit. Refer to LT- 1 9 1 , "Removal

and Installation of AFS Control Unit" .

NG >> GO TO 2.

2. CHECK AFS SWITCH

1. Turn ignition switch OFF.

2. Disconnect AFS switch connector.

3. Check continuity AFS switch.

OK or NG

OK >> GO TO 3.

NG >> Replace AFS switch. Refer to LT- 1 9 1 , "

Removal and

Installation of AFS Switch" .

3. CHECK AFS SWITCH SIGNAL 2

1. Connect AFS switch connector.

2. Turn ignition switch ON.

3. Check voltage between AFS control unit harness connector and

ground according to AFS switch operation.

OK or NG

OK >> Replace AFS control unit. Refer to LT- 1 9 1 , "Removal

and Installation of AFS Control Unit" .

NG >>

If voltage is approx. 0V and stays unchanged, GO TO 4.

If voltage is battery voltage and stays unchanged, GO TO 6.

SKIB4793E

AFS switch

Condition Continuity

Te r m i n a l

14AFS switch is ON. No

AFS switch is OFF. Yes

PKIC0684E

(+)

(-) Condition Voltage

AFS control

unit connectorTerminal

F110 3 GroundAFS switch is ON. Approx. 0 V

AFS switch is OFF. Battery voltage

PKIC0683E

Page 4614 of 5621

ACTIVE AFS

LT-187

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

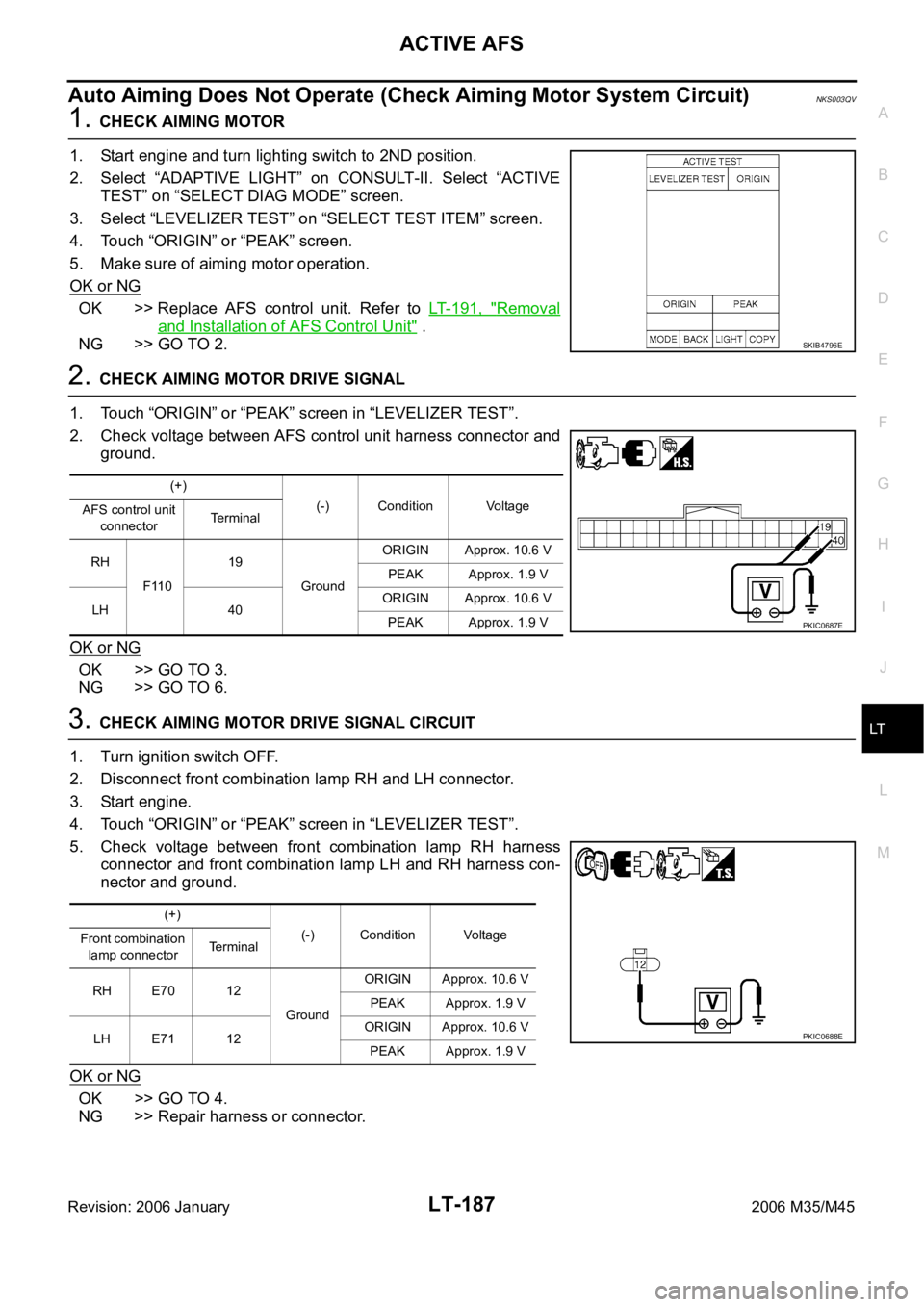

Auto Aiming Does Not Operate (Check Aiming Motor System Circuit)NKS003QV

1. CHECK AIMING MOTOR

1. Start engine and turn lighting switch to 2ND position.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “ACTIVE

TEST” on “SELECT DIAG MODE” screen.

3. Select “LEVELIZER TEST” on “SELECT TEST ITEM” screen.

4. Touch “ORIGIN” or “PEAK” screen.

5. Make sure of aiming motor operation.

OK or NG

OK >> Replace AFS control unit. Refer to LT- 1 9 1 , "Removal

and Installation of AFS Control Unit" .

NG >> GO TO 2.

2. CHECK AIMING MOTOR DRIVE SIGNAL

1. Touch “ORIGIN” or “PEAK” screen in “LEVELIZER TEST”.

2. Check voltage between AFS control unit harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 6.

3. CHECK AIMING MOTOR DRIVE SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connector.

3. Start engine.

4. Touch “ORIGIN” or “PEAK” screen in “LEVELIZER TEST”.

5. Check voltage between front combination lamp RH harness

connector and front combination lamp LH and RH harness con-

nector and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

SKIB4796E

(+)

(-) Condition Voltage

AFS control unit

connectorTerminal

RH

F11019

GroundORIGIN Approx. 10.6 V

PEAK Approx. 1.9 V

LH 40ORIGIN Approx. 10.6 V

PEAK Approx. 1.9 V

PKIC0687E

(+)

(-) Condition Voltage

Front combination

lamp connectorTerminal

RH E70 12

GroundORIGIN Approx. 10.6 V

PEAK Approx. 1.9 V

LH E71 12ORIGIN Approx. 10.6 V

PEAK Approx. 1.9 V

PKIC0688E

Page 4617 of 5621

LT-190

ACTIVE AFS

Revision: 2006 January2006 M35/M45

AFS OFF Indicator Does Not OperateNKS003QW

1. CHECK DIAGNOSIS RESULT (AFS CONTROL UNIT)

Select “ADAPTIVE LIGHT” on CONSULT-II. Select “SELF-DIAG

RESULTS” on “SELECT DIAG MODE” screen.

Is DTC detected?

YES >> Refer to LT- 1 5 4 , "SELF-DIAG RESULTS" .

NO >> GO TO 2.

2. CHECK DIAGNOSIS RESULT (UNIFIED METER AND A/C AMP.)

Select “METER A/C AMP” on CONSULT-II. Select “SELF-DIAG

RESULTS” on “SELECT DIAG MODE” screen.

Is DTC detected?

YES >> Refer to DI-32, "SELF-DIAG RESULTS" in DI section.

NO >> GO TO 3.

3. CHECK AFS OFF INDICATOR SIGNAL (UNIFIED METER AND A/C AMP.)

Check “AFS OFF IND” in “Data Monitor” according to AFS switch

operation.

OK or NG

OK >> Replace combination meter.

NG >> Replace unified meter and A/C amp.

Removal and Installation of Steering Angle SensorNKS003QX

Refer to BRC-63, "STEERING ANGLE SENSOR" .

Removal and Installation of Front Combination LampNKS003QY

Refer to LT-41, "Removal and Installation" .

PKIA6866E

PKIA6866E

Condition “AFS OFF IND”

AFS switch is OFF. ON

AFS switch is ON. OFF

SKIB4971E

Page 4620 of 5621

FRONT FOG LAMP

LT-193

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

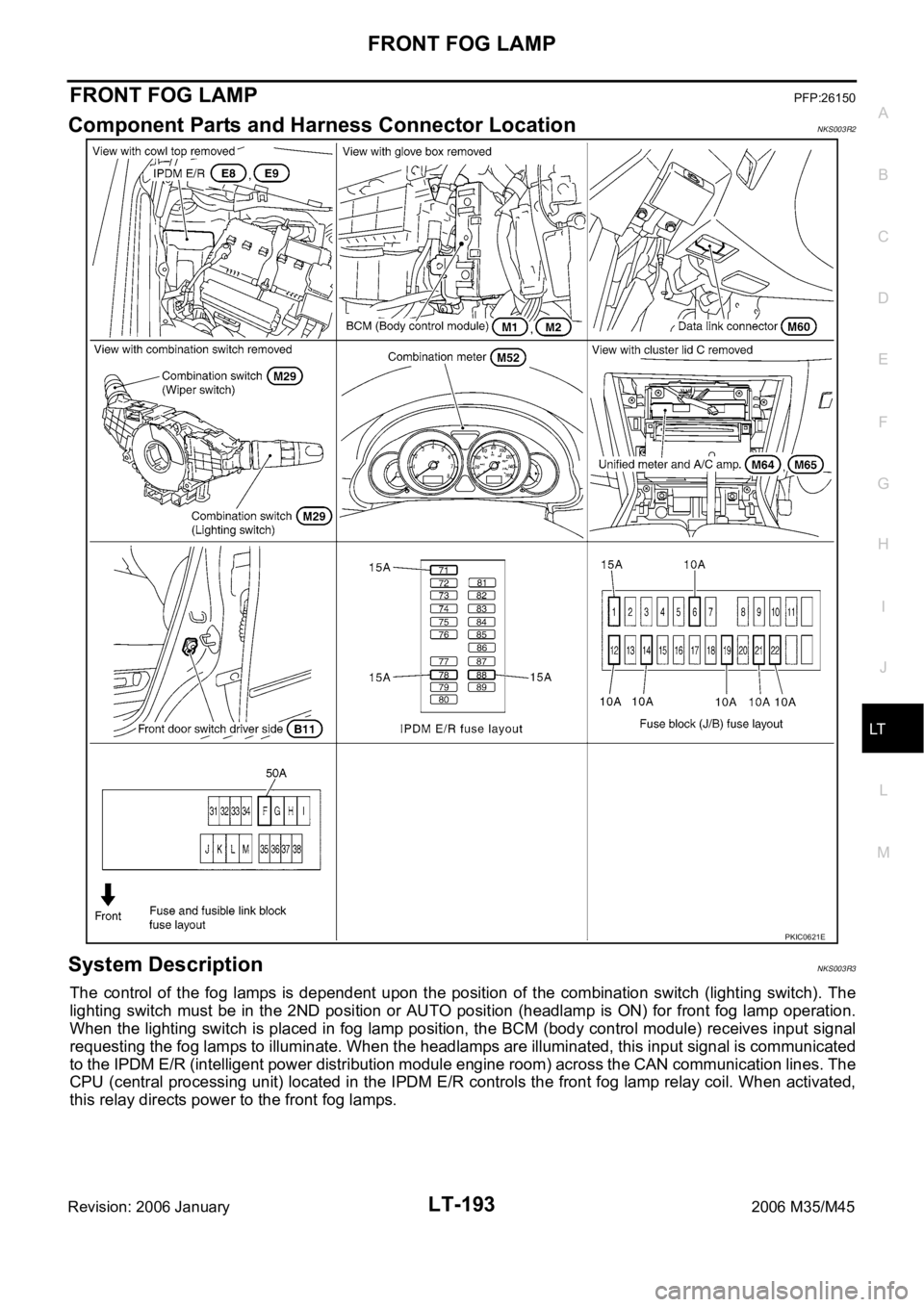

FRONT FOG LAMPPFP:26150

Component Parts and Harness Connector LocationNKS003R2

System DescriptionNKS003R3

The control of the fog lamps is dependent upon the position of the combination switch (lighting switch). The

lighting switch must be in the 2ND position or AUTO position (headlamp is ON) for front fog lamp operation.

When the lighting switch is placed in fog lamp position, the BCM (body control module) receives input signal

requesting the fog lamps to illuminate. When the headlamps are illuminated, this input signal is communicated

to the IPDM E/R (intelligent power distribution module engine room) across the CAN communication lines. The

CPU (central processing unit) located in the IPDM E/R controls the front fog lamp relay coil. When activated,

this relay directs power to the front fog lamps.

PKIC0621E