display INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3628 of 5621

REVERSE INTERLOCK DOOR MIRROR SYSTEM

GW-109

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

Check Changeover Switch CircuitNIS0023B

1. CHECK CHANGEOVER SWITCH SIGNAL

With CONSULT-II

Check the operation on (MIR CHNG SW-R” or “MIR CHNG SW-L) in the DATA MONITOR.

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between automatic drive positioner control unit connector and ground.

OK

orNG

OK >> Changeover switch circuit is OK.

NG >> GO TO 2.

Monitor item

[OPERATION or UNIT]Contents

MIR CHNG SW–R“ON/

OFF”ON/OFF status judged from the changeover

switch (switching to RIGHT) signal is displayed.

MIR CHNG SW–L“ON/

OFF”ON/OFF status judged from the changeover

switch (switching to LEFT) signal is displayed.

PIIA0191E

Terminals

Change over switch

conditionVoltage (V)

(Approx.) (+)

(-) Automatic

drive posi-

tioner con-

trol unit

connectorTerminal

M62

GroundRIGHT 0

Other than above 5

18LEFT 0

Other than above 5

PIIB6015E

Page 3630 of 5621

REVERSE INTERLOCK DOOR MIRROR SYSTEM

GW-111

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

5. CHECK AUTOMATIC DRIVE POSITIONER CONTROL UNIT OUTPUT SIGNAL

1. Connect automatic drive positioner control unit connector.

2. Turn ignition switch ON.

3. Check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> Check the condition of harness and connector.

NG >> Replace automatic drive positioner control unit.

Check Mirror Switch Circuit CheckNIS0023C

1. CHECK MIRROR SWITCH SIGNAL

With CONSULT-II

Check the operation on “(MIR CON SW–UP/DN) and (MIR CON SW–RH/LH) in the DATA MONITOR.

Without CONSULT-II

1. Turn ignition switch to ON position.

2. Check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> Mirror switch circuit is OK.

NG >> GO TO 2.

Terminals

Voltage (V)

(Approx.) (+)

(-) Automatic drive

positioner control

unit connectorTerminal

M62

Ground 5

18

PIIB6015E

Monitor item

[OPERATION or UNIT]Contents

MIR CON SW–UP“ON/

OFF”ON/OFF status judged from the mirror switch

(UP) signal is displayed.

MIR CON SW–DN“ON/

OFF”ON/OFF status judged from the mirror switch

(DOWN) signal is displayed.

MIR CON SW–RH“ON/

OFF”ON/OFF status judged from the mirror switch

(RIGHT) signal is displayed.

MIR CON SW–LH“ON/

OFF”ON/OFF status judged from the mirror switch

(LEFT) signal s displayed.

PIIA0199E

Te r m i n a l s

Mirror switch

ConditionVoltage (V)

(Approx.) (+)

(–) Automatic drive

positioner control

unit connectorTerminal

M63

GroundUP 0

Other than above 5

4LEFT 0

Other than above 5

19DOWN 0

Other than above 5

20RIGHT 0

Other than above 5

PIIB6019E

Page 3635 of 5621

GW-116

REVERSE INTERLOCK DOOR MIRROR SYSTEM

Revision: 2006 January2006 M35/M45

Check Mirror Sensor Circuit Check NIS0023E

1. CHECK MIRROR SENSOR INSPECTION

With CONSULT-II

Check the voltage on (MIR/SE LH R–L, MIR/SE LH U–D, MIR/SE RH R–L, MIR/SE RH U–D) in the DATA

MONITOR.

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> Mirror sensor LH circuit is OK.

NG >> GO TO 3.

2. CHECK MIRROR SENSOR POWER SUPPLY 1

Check voltage between door mirror connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

Monitor item

[OPERATION or UNIT]Contents

MIR/SE LH R–L “V”Voltage output from door mirror LH horizontal sensor

(LH/RH) is displayed.

MIR/SE LH U–D “V”Voltage output from door mirror LH vertical sensor

(UP/DOWN) is displayed.

MIR/SE RH R–L “V”Voltage output from door mirror RH horizontal sensor

(LH/RH) is displayed.

MIR/SE RH U–D “V”Voltage output from door mirror RH vertical sensor

(UP/DOWN) is displayed.

PIIA0197E

Terminals

Mirror face positionVoltage (V)

(Approx.) (+)

(-) Automatic drive

positioner control

unit connectorTerminal

M6Door

mirror

RH side5

GroundClose to perk 4.2

Close to valley 0.5

21Close to left edge 3.5

Close to right edge 0.5

Door

mirror

LH side6Close to perk 4.2

Close to valley 0.5

22Close to left edge 0.5

Close to right edge 3.5

PIIB6027E

Terminals

Voltage (V)

(Approx.) (+)

(-)

Door mirror

connectorTe r m i n a l

D2 (LH)

D39 (RH)11 Ground Battery voltage

PIIB6032E

Page 3644 of 5621

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Camshaft(VQ35DE) ........................................... EM-84

CAN .................................................................... DI-77

CAN - Wiring diagram ......... EC-174, EC-887, AT-106,

LAN-50

, LAN-91, LAN-132, LAN-179, LAN-226,

LAN-277

, LAN-323, LAN-369, LAN-419, LAN-469,

LAN-523

, LAN-566, LAN-609, LAN-658, LAN-707

CAN (Controller Area Network) ... SB-5, BL-26, BL-60,

BL-224

, GW-19, GW-75, GW-97, SE-16

CAN communication ........... EC-173, EC-176, EC-748,

EC-886

, EC-889, AT-32, AT-105, TF-13, TF-32, WT-12,

SB-5

, BL-26, BL-60, BL-224, GW-19, GW-75, GW-97,

SE-16

, WW-11

Canister-See EVAP canister ............... EC-42, EC-752

Center bearing assembly (propeller shaft) ........ PR-12

Center bearing disassembly (propeller shaft) .... PR-11

CHARGE - Wiring diagram ................................ SC-25

Charging system ................................................ SC-23

Chassis and body maintenance ........................ MA-29

CHIME - Wiring diagram ..................................... DI-64

CIGAR - Wiring diagram .................................. WW-49

Cigarette lighter ............................................... WW-49

Circuit breaker ................................................... PG-17

Clock ................................................................. DI-108

CLOCK - Wiring diagram .................................. DI-108

Closed loop control .............................. EC-32, EC-742

Closed loop control (Bank 1) ........... EC-509, EC-1236

Closed loop control (Bank 2) ........... EC-509, EC-1236

Collision diagnosis ........................................... SRS-50

Combination lamp, front, removal and installation ........

LT-76

Combination lamp, rear, removal and installation ........

LT-266

Combination meter ............................................... DI-5

COMPAS - Wiring diagram ............................... DI-106

Compass .......................................................... DI-105

Component Location (auto A/C) ...................... ATC-42

Compression pressure(VK45DE) .................... EM-233

Compression pressure(VQ35DE) .................... EM-101

Compressor special service tool ...................... ATC-16

Condenser ..................................................... ATC-165

Connecting rod bearing clearance(VK45DE) .. EM-273

Connecting rod bushing clearance .................. EM-142

Connecting rod bushing clearance(VK45DE) .. EM-268

Connecting rod(VK45DE) ................................ EM-268

Connecting rod(VQ35DE) ................................ EM-140

CONSULT-II Reference value (A/T) .................. AT-90

Control units (terminal arrangement) ............... PG-104

Control valve (A/T) ............................................. AT-38

Controller Area Network (CAN) ... SB-5, BL-26, BL-60,

BL-224

, GW-19, GW-75, GW-97, SE-16

Converter housing installation ............ AT-274, AT-277

COOL/F - Wiring diagram ................ EC-515, EC-1242

Coolant replacement(VQ35DE) ......................... MA-15

Cooling circuit (engine)(VK45DE) ...................... CO-38

Cooling circuit (engine)(VQ35DE) ....................... CO-9

Cooling fan motor ............ EC-524, EC-1249, EC-1250

Cooling fan(VK45DE) ........................................ CO-51

Cooling fan(VQ35DE) ........................................ CO-22

Cowl top ............................................................... EI-18

Cowl top cover .................................................... EI-18

Crankcase ventilation system - See Positive crankcase

ventilation ............................................. EC-51

, EC-761

Crankshaft position sensor (POS) ... EC-376, EC-1099

Crankshaft(VK45DE) ...................................... EM-250

Crankshaft(VQ35DE) ...................................... EM-140

Crash zone sensor .......................................... SRS-45

CUR/SE - Wiring diagram .. EC-539, EC-545, EC-551,

EC-557

, EC-1265, EC-1271, EC-1277, EC-1283

Cylinder block boring(VK45DE) ...................... EM-271

Cylinder block(VK45DE) ................................. EM-249

Cylinder block(VQ35DE) ................................. EM-123

Cylinder head bolt tightening(VK45DE) .......... EM-235

Cylinder head bolt tightening(VQ35DE) .......... EM-104

Cylinder head(VK45DE) ................................. EM-233

Cylinder head(VQ35DE) ................................. EM-101

D

D/LOCK - Wiring diagram .................................. BL-28

Daytime light system ........................................... LT-79

Daytime running light - See Daytime light system LT-79

DEF - Wiring diagram ............................ SB-7, SE-118

Diagnosis sensor unit ..................................... SRS-48

Diagnostic trouble code (DTC) for OBD system EC-16,

EC-58

, EC-726, EC-769

Direct clutch solenoid valve ............... AT-155, AT-157

Display and amp.assembly ............... ATC-53, ATC-66

Door glass ........................................... GW-63, GW-67

Door glass Fitting Adjustment(Front) ................ GW-66

Door glass Fitting Adjustment(Rear) ................. GW-70

Door lock .......................................................... BL-196

Door mirror ...................................................... GW-120

Door trim ............................................................. EI-34

Door, front ........................................... BL-190, GW-63

Door, rear ............................................ BL-190, GW-67

Drive belt inspection ......................................... MA-22

Drive belt inspection(VQ35DE) ......................... MA-14

Drive belt(VK45DE) ........................................ EM-174

Drive belt(VQ35DE) .......................................... EM-15

Drive shaft ......................................................... MA-38

Drive shaft (rear) ............................................... RAX-8

Driver air bag .................................................. SRS-38

DTRL - Wiring diagram ....................................... LT-84

Duct and grilles .............................................. ATC-144

E

ECM power supply EC-166

, EC-492, EC-879, EC-1211

ECM/PW - Wiring diagram ............... EC-493, EC-1212

ECTS - Wiring diagram ...................... EC-228, EC-950

Electric sunroof .................................................. RF-10

Electric throttle control actuator ........ EC-613, EC-624,

EC-1344

, EC-1356

Electric throttle control actuator (VK45DE) ..... EM-179

Electric throttle control actuator (VQ35DE) ....... EM-19

Electrical load signal circuit .............. EC-697, EC-1439

Electrical unit ................................................... PG-104

Electrical units location ...................................... PG-96

Page 3660 of 5621

INSTRUMENT PANEL ASSEMBLY

IP-11

C

D

E

F

G

H

J

K

L

MA

B

IP

Revision: 2006 January2006 M35/M45

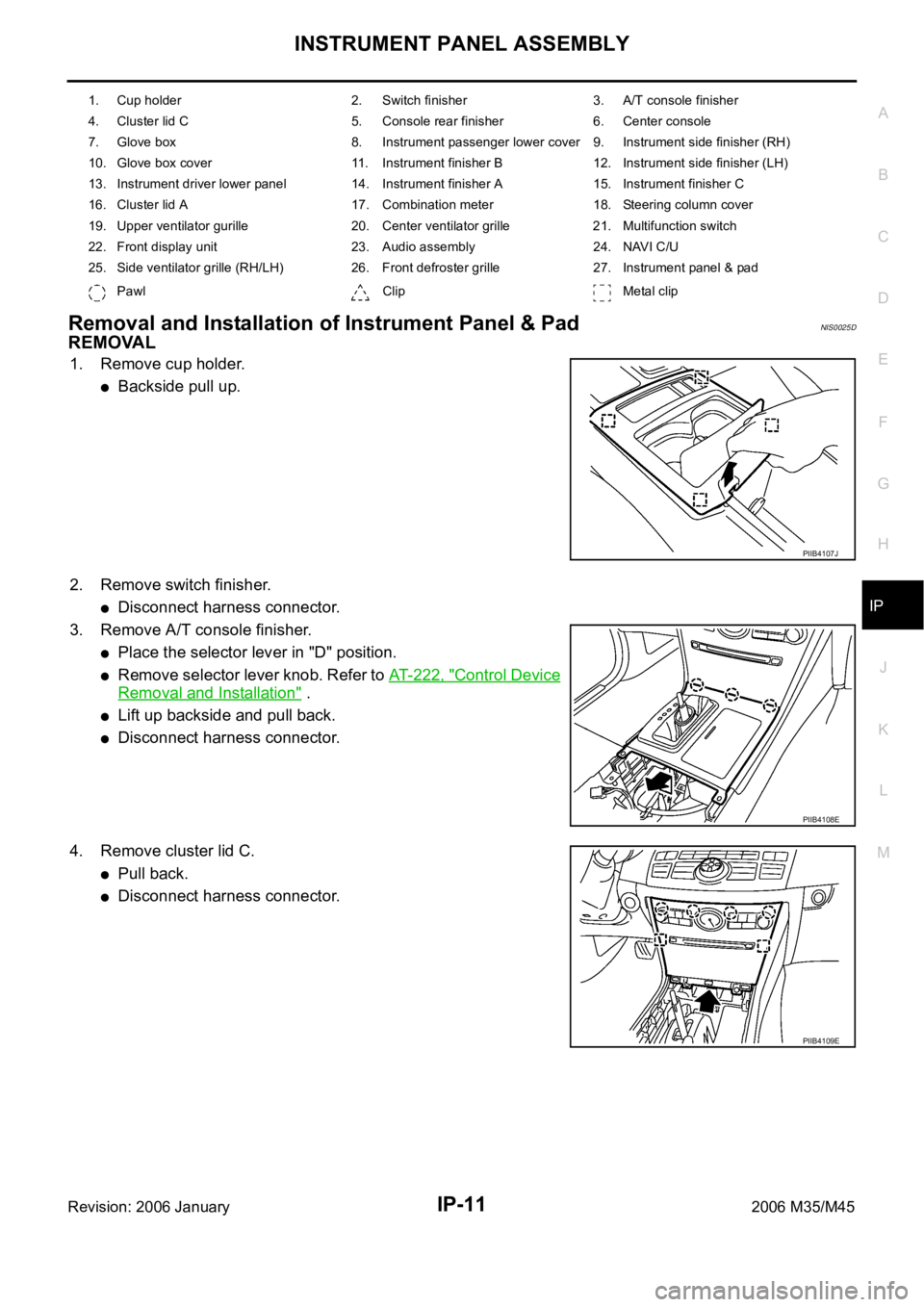

Removal and Installation of Instrument Panel & PadNIS0025D

REMOVAL

1. Remove cup holder.

Backside pull up.

2. Remove switch finisher.

Disconnect harness connector.

3. Remove A/T console finisher.

Place the selector lever in "D" position.

Remove selector lever knob. Refer to AT- 2 2 2 , "Control Device

Removal and Installation" .

Lift up backside and pull back.

Disconnect harness connector.

4. Remove cluster lid C.

Pull back.

Disconnect harness connector.

1. Cup holder 2. Switch finisher 3. A/T console finisher

4. Cluster lid C 5. Console rear finisher 6. Center console

7. Glove box 8. Instrument passenger lower cover 9. Instrument side finisher (RH)

10. Glove box cover 11. Instrument finisher B 12. Instrument side finisher (LH)

13. Instrument driver lower panel 14. Instrument finisher A 15. Instrument finisher C

16. Cluster lid A 17. Combination meter 18. Steering column cover

19. Upper ventilator gurille 20. Center ventilator grille 21. Multifunction switch

22. Front display unit 23. Audio assembly 24. NAVI C/U

25. Side ventilator grille (RH/LH) 26. Front defroster grille 27. Instrument panel & pad

Pawl Clip Metal clip

PIIB4107J

PIIB4108E

PIIB4109E

Page 3663 of 5621

IP-14

INSTRUMENT PANEL ASSEMBLY

Revision: 2006 January2006 M35/M45

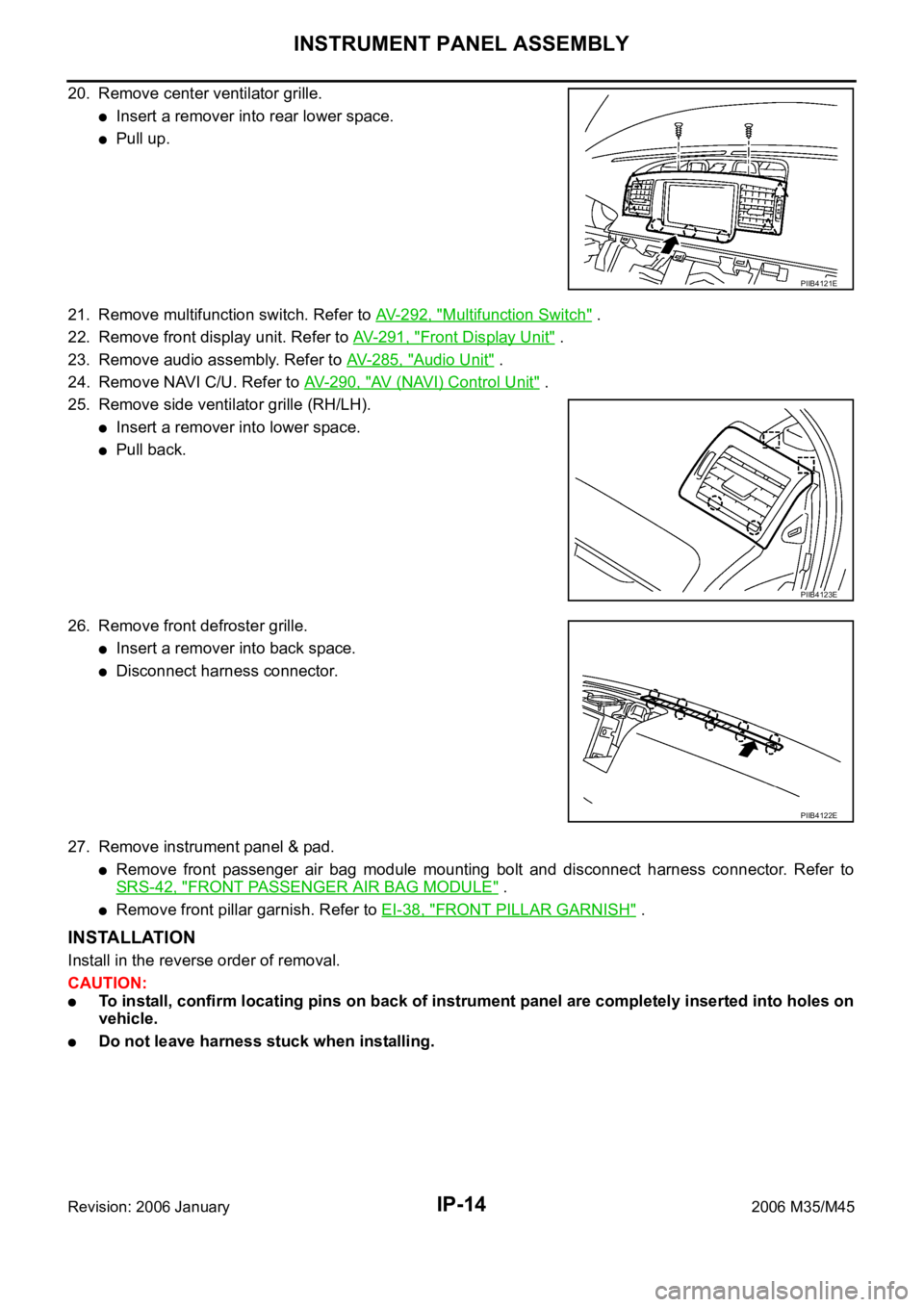

20. Remove center ventilator grille.

Insert a remover into rear lower space.

Pull up.

21. Remove multifunction switch. Refer to AV-292, "

Multifunction Switch" .

22. Remove front display unit. Refer to AV-291, "

Front Display Unit" .

23. Remove audio assembly. Refer to AV- 2 8 5 , "

Audio Unit" .

24. Remove NAVI C/U. Refer to AV- 2 9 0 , "

AV (NAVI) Control Unit" .

25. Remove side ventilator grille (RH/LH).

Insert a remover into lower space.

Pull back.

26. Remove front defroster grille.

Insert a remover into back space.

Disconnect harness connector.

27. Remove instrument panel & pad.

Remove front passenger air bag module mounting bolt and disconnect harness connector. Refer to

SRS-42, "

FRONT PASSENGER AIR BAG MODULE" .

Remove front pillar garnish. Refer to EI-38, "FRONT PILLAR GARNISH" .

INSTALLATION

Install in the reverse order of removal.

CAUTION:

To install, confirm locating pins on back of instrument panel are completely inserted into holes on

vehicle.

Do not leave harness stuck when installing.

PIIB4121E

PIIB4123E

PIIB4122E

Page 3670 of 5621

LAN-1

LAN SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION LAN

A

B

LAN

Revision: 2006 January2006 M35/M45

LAN SYSTEM

CAN

PRECAUTIONS .......................................................... 7

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 7

Precautions When Using CONSULT-II ..................... 7

CHECK POINTS FOR USING CONSULT-II ......... 7

Precautions For Trouble Diagnosis .......................... 7

CAN SYSTEM ....................................................... 7

Precautions For Harness Repair .............................. 8

CAN SYSTEM ....................................................... 8

TROUBLE DIAGNOSES WORK FLOW .................... 9

When Displaying CAN Communication System

Errors ....................................................................... 9

WHEN A MALFUNCTION IS DETECTED BY

CAN COMMUNICATION SYSTEM ....................... 9

WHEN A MALFUNCTION IS DETECTED

EXCEPT CAN COMMUNICATION SYSTEM ........ 9

TROUBLE DIAGNOSIS FLOW CHART ............. 10

Diagnosis Procedure ............................................... 11

SELECTING CAN SYSTEM TYPE (HOW TO

USE SPECIFICATION TABLE) ............................ 11

ACQUISITION OF DATA BY CONSULT-II .......... 12

HOW TO USE CHECK SHEET TABLE .............. 14

CAN Diagnostic Support Monitor ........................... 20

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ECM ............................... 20

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR TCM ............................... 21

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR AWD CONTROL UNIT ... 21

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR AFS CONTROL UNIT .... 22

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR BCM ............................... 23

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR LDW CAMERA UNIT ..... 24

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR LOW TIRE PRESSURE WARNING CONTROL UNIT ............................... 25

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR INTELLIGENT KEY UNIT ... 26

DESCRIPTION OF “CAN DIAG SUPPORT

M N T R ” S C R E E N F O R U N I F I E D M E T E R A N D A /

C AMP. ................................................................. 27

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR AV(NAVI) CONTROL

UNIT .................................................................... 28

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR RAS CONTROL UNIT .... 29

DESCRIPTION OF “CAN DIAG SUPPORT

M N T R ” S C R E E N F O R P R E - C R A S H S E A T B E L T

CONTROL UNIT ................................................. 30

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR DRIVER SEAT CON-

TROL UNIT ...................................................... ... 31

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT) ................... 31

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ICC SENSOR INTE-

GRATED UNIT .................................................... 32

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR IPDM E/R ....................... 33

CAN COMMUNICATION ........................................... 34

System Description ................................................. 34

CAN Communication Unit ....................................... 34

SYSTEM DIAGRAM ............................................ 34

INPUT/OUTPUT SIGNAL CHART ...................... 40

CAN SYSTEM (TYPE 1) ........................................... 48

Component Parts and Harness Connector Location ... 48

Schematic ............................................................... 49

Wiring Diagram — CAN — ..................................... 50

Check Sheet ........................................................... 53

CHECK SHEET RESULTS (EXAMPLE) ............. 56

Inspection Between TCM and Data Link Connector

Circuit ..................................................................

... 72

Inspection Between Data Link Connector and Driver

Seat Control Unit Circuit ......................................

... 73

Page 3678 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN](/img/42/57023/w960_57023-3677.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN A MALFUNCTION IS DETECTED BY CAN COMMUNICATION SYSTEM

CAN communication line is open. (CAN H, CAN L, or both)

CAN communication line is shorted. (Ground, between CAN lines, or other harnesses)

The areas related to CAN communication of unit is malfunctioning.

WHEN A MALFUNCTION IS DETECTED EXCEPT CAN COMMUNICATION SYSTEM

Removal and installation of parts: When the units that perform CAN communication or the sensors related

to CAN communication are removed and installed, malfunction may be detected (or DTC other than CAN

communication may be detected).

Fuse blown out (removed): CAN communication of the unit may be stopped at such time.

Low voltage: If the voltage decreases because of battery discharge when IGN is ON, malfunction may be

detected by self-diagnosis according to the units.

Page 3683 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-14

[CAN]

TROUBLE DIAGNOSES WORK FLOW

Revision: 2006 January2006 M35/M45

HOW TO USE CHECK SHEET TABLE

1. Unit names displayed on CONSULT-II

2. “No indication”: Put a check mark to it if the un INFINITI M35 2006 Factory Service Manual LAN-14

[CAN]

TROUBLE DIAGNOSES WORK FLOW

Revision: 2006 January2006 M35/M45

HOW TO USE CHECK SHEET TABLE

1. Unit names displayed on CONSULT-II

2. “No indication”: Put a check mark to it if the un](/img/42/57023/w960_57023-3682.png)

LAN-14

[CAN]

TROUBLE DIAGNOSES WORK FLOW

Revision: 2006 January2006 M35/M45

HOW TO USE CHECK SHEET TABLE

1. Unit names displayed on CONSULT-II

2. “No indication”: Put a check mark to it if the unit name described in step 1 is not displayed on “SELECT

SYSTEM” screen of CONSULT-II. (Unit communicating with CONSULT-II via CAN communication line)

“–”: Column not used (Unit communicating with CONSULT-II excluding CAN communication line)

3. “NG”: Display “NG” when malfunction is detected in the initial diagnosis of the diagnosed unit. Replace the

unit if “NG” is displayed.

“–”: Column not used (Initial diagnosis is not performed.)

4. “UNKWN”: Display “UNKWN” when the diagnosed unit does not transmit the data normally. Put a check

mark to it if “UNKWN” is displayed on CONSULT-II.

“–”: Column not used (Transmit diagnosis is not performed.)

5. “UNKWN”: Display “UNKWN” when the diagnosed unit does not receive the data normally. Put a check

mark to it if “UNKWN” is displayed on CONSULT-II.

“–”: Column not used (It is not necessary for CAN communication trouble diagnosis.)

NOTE:

CAN communication diagnosis checks if CAN communication works normally. (Contents of data are not diag-

nosed.)

When the initial conditions are reproduced. Refer to LAN-15, "Example of Filling in Check Sheet When Ini-

tial Conditions Are Reproduced" .

When the initial conditions are not reproduced. Refer to LAN-18, "Example of Filling in Check Sheet When

Initial Conditions Are Not Reproduced" .

PKIC0264E

Page 3684 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-15

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

Example of Filling in Check Sheet When Initial Conditions Are Reproduced

1. Put a check mark to � INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-15

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

Example of Filling in Check Sheet When Initial Conditions Are Reproduced

1. Put a check mark to �](/img/42/57023/w960_57023-3683.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-15

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

Example of Filling in Check Sheet When Initial Conditions Are Reproduced

1. Put a check mark to “No indication” if some of unit names listed on the column of diagnosis system selec-

tion screen of a check sheet table are not displayed on “SELECT SYSTEM” screen attached to the check

sheet.

NOTE:

Put a check mark to “No indication” of BCM and AUTO DRIVE POS. because BCM and AUTO DRIVE

POS. is not displayed on “SELECT SYSTEM” screen.

2. Confirm the unit name that “UNKWN” is displayed from the copy of “CAN DIAG SUPPORT MNTR” screen

of “ENGINE” attached to the check sheet, and then put a check mark to the check sheet table.

NOTE:

In “CAN DIAG SUPPORT MNTR” screen, “UNKWN” is displayed on “VDC/TCS/ABS”, “METER/M&A” and

“IPDM E/R”. Put a check mark to it.

3. Confirm the unit name that “UNKWN” is displayed on the copy of “CAN DIAG SUPPORT MNTR” screen

of “A/T” and “AIR PRESSURE MONITOR” as well as “ENGINE”. And then, put a check mark to the check

sheet table.

NOTE:

For “A/T”, “UNKWN” is displayed on “VDC/TCS/ABS”, “METER/M&A”, “ICC/e4WD” and “AWD/4WD”.

But put a check mark to “VDC/TCS/ABS” and “METER/M&A” because “UNKWN” is listed on the col-

umn of reception diagnosis of the check sheet table.

For “AIR PRESSURE MONITOR”, “UNKWN” is displayed on “ECM”. Put a check mark to it.

PKIC0265E