air condition INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5120 of 5621

PRE-CRASH SEAT BELT

SB-21

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Seat Belt Buckle Switch (Passenger Side) Circuit CheckNHS0008C

1. CHECK PRE-CRASH SEAT BELT CONTROL UNIT INPUT SIGNAL

With CONSULT-II

Select “SB SW RH SIG” on DATA MONITOR screen, and then make

sure that ON/OFF display changes synchronized with the insertion

operation to the seat belt buckle.

Without CONSULT-II

1. Turn the ignition switch ON.

2. Check voltage between seat belt buckle switch (passenger side)

harness connector and ground.

OK or NG

OK >> Seat belt buckle switch (passenger side) circuit is OK.

NG >> GO TO 2.

2. CHECK SEAT BELT BUCKLE SWITCH (PASSENGER SIDE) HARNESS

1. Turn ignition switch OFF.

2. Disconnect pre-crash seat belt control unit and seat belt buckle switch (passenger side) connector.

3. Check continuity between pre-crash seat belt control unit har-

ness connector and seat belt buckle switch (passenger side)

harness connector.

4. Check continuity between pre-crash seat belt control unit har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.SB SW RH SIG

When passenger seat belt is not fastened :OFF

When passenger seat belt is fastened :ON

PHIA0764E

Terminal

ConditionVoltage (V)

(Approx.) (+)

(–) Seat belt buckle

switch connector

(passenger side) Te r m i n a l

B253 1 GroundWhen seat belt is

unfastened0

When seat belt is

fastened5

PHIA1129E

AB

Continuity Pre-crash seat

belt control unit

connectorTerminalSeat belt buckle

switch (passenger

side) connectorTerminal

B142 8 B253 1 Yes

A

GroundContinuity

Pre-crash seat belt

control unit connectorTerminal

B142 8 No

PHIA1133E

Page 5121 of 5621

SB-22

PRE-CRASH SEAT BELT

Revision: 2006 January2006 M35/M45

3. CHECK RH SEAT BELT SWITCH

Check continuity between seat belt buckle switch (passenger side)

while performing the insertion operation to the seat belt buckle.

OK or NG

OK >> GO TO 4.

NG >> Replace seat belt buckle (passenger side).

4. CHECK RH SEAT BELT SWITCH GROUND CIRCUIT HARNNES

Check continuity between seat belt buckle switch (passenger side)

harness connector and ground.

OK or NG

OK >> Check harness connection.

If it is OK, replace pre-crash seat belt control unit.

If it is NG, repair or replace malfunction part.

NG >> Repair or replace harness.

Brake Pedal Stroke Sensor Circuit Check [B2453]NHS0008D

1. INSPECTION WITH CONSULT-II

With CONSULT-II

Select “SELF-DIAG RESULTS”, and then make sure that “BR

STROKE SEN CIRC” is displayed.

Without CONSULT-II

When CONSULT-II is not used, omit this inspection, and then GO TO 2.

Displayed B2453?

Yes >> GO TO 3.

No >> GO TO 2.

Seat belt buckle

switch connector

(passenger side)Terminal Condition Continuity

B253 1 2When seat belt is unfastened Yes

When seat belt is fastened No

PHIA1131E

Te r m i n a l

Continuity

Seat belt buckle switch

connector (passenger side) Terminal

Ground

B253 2 Yes

PHIA1132E

CONSULT-II display CONSULT-II display code

NO DTC –

BR STROKE SEN CIRC B2453

PHIA0769E

Page 5124 of 5621

PRE-CRASH SEAT BELT

SB-25

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

5. CHECK BRAKE PEDAL STROKE SENSOR

Check continuity between brake pedal stroke sensor while perform-

ing brake operation.

OK or NG

OK >> Check harness connection.

If it is OK, replace pre-crash seat belt control unit.

If it is NG, repair or replace malfunction part.

NG >> Replace brake pedal stroke sensor.

Pre-Crash Seat Belt Motor LH Circuit Check [B2452]NHS0008E

1. CHECK LH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

Select “SELF-DIAG RESULTS” of CONSULT-II, and then make sure

that “SB MOTOR LH CIRC” is displayed.

Without CONSULT-II

When CONSULT-II is not used, omit this inspection, and then GO TO 2.

Displayed B2452?

Ye s > > G O T O 2 .

No >> Pre-crash seat belt motor LH circuit is OK.

Brake pedal stroke

sensor connectorTerminal ConditionResistance

(K)

(Approx.)

E125 21

Brake released

depressed1.0 0.2

30.2

1.0

PHIA1137E

CONSULT-II display CONSULT-II display code

NO DTC –

SB MOTOR LH CIRC B2452

PHIA0768E

Page 5127 of 5621

SB-28

PRE-CRASH SEAT BELT

Revision: 2006 January2006 M35/M45

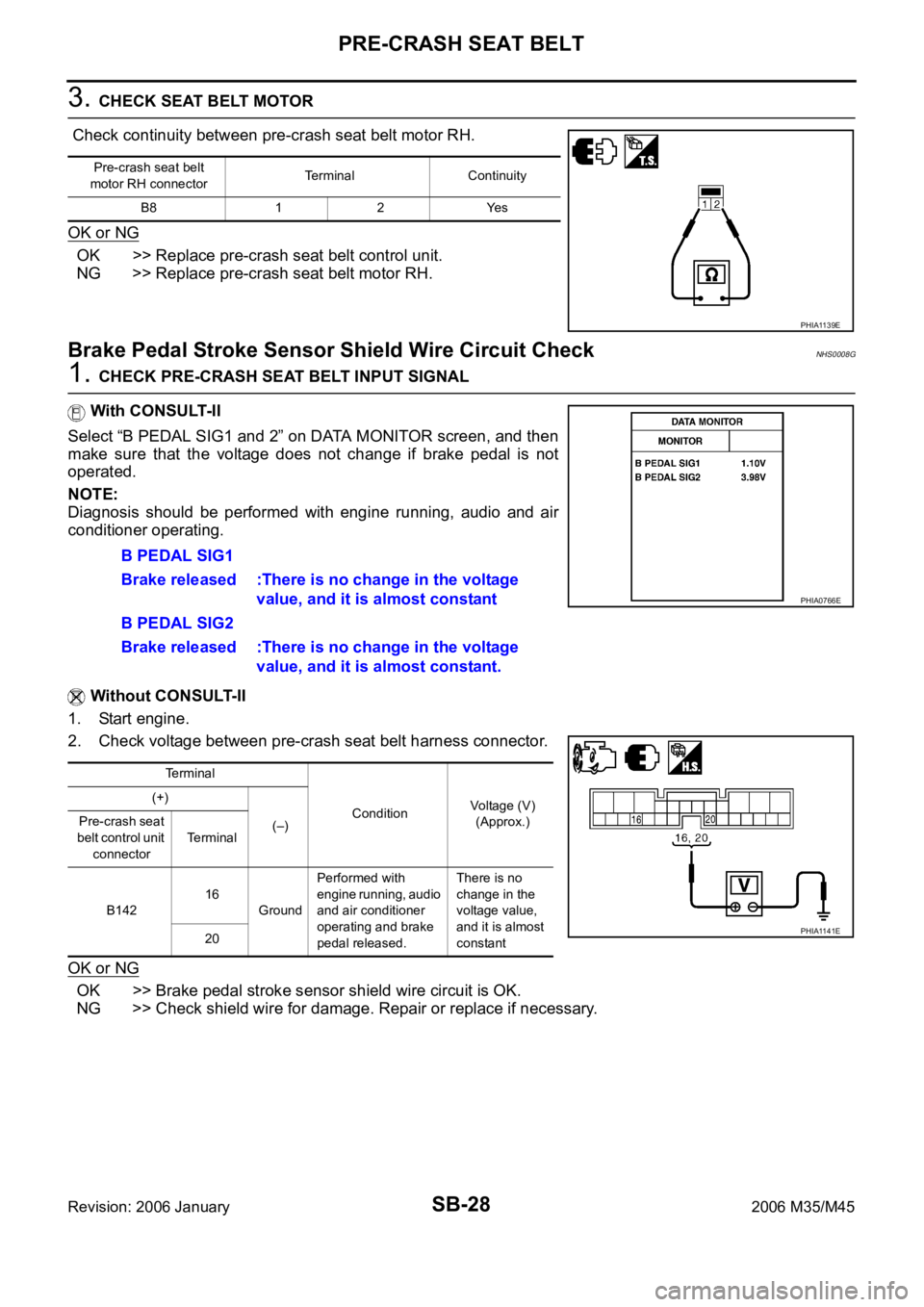

3. CHECK SEAT BELT MOTOR

Check continuity between pre-crash seat belt motor RH.

OK or NG

OK >> Replace pre-crash seat belt control unit.

NG >> Replace pre-crash seat belt motor RH.

Brake Pedal Stroke Sensor Shield Wire Circuit CheckNHS0008G

1. CHECK PRE-CRASH SEAT BELT INPUT SIGNAL

With CONSULT-II

Select “B PEDAL SIG1 and 2” on DATA MONITOR screen, and then

make sure that the voltage does not change if brake pedal is not

operated.

NOTE:

Diagnosis should be performed with engine running, audio and air

conditioner operating.

Without CONSULT-II

1. Start engine.

2. Check voltage between pre-crash seat belt harness connector.

OK or NG

OK >> Brake pedal stroke sensor shield wire circuit is OK.

NG >> Check shield wire for damage. Repair or replace if necessary.

Pre-crash seat belt

motor RH connectorTerminal Continuity

B8 1 2 Yes

PHIA1139E

B PEDAL SIG1

Brake released :There is no change in the voltage

value, and it is almost constant

B PEDAL SIG2

Brake released :There is no change in the voltage

value, and it is almost constant.

Terminal

ConditionVoltage (V)

(Approx.) (+)

(–) Pre-crash seat

belt control unit

connectorTerminal

B14216

GroundPerformed with

engine running, audio

and air conditioner

operating and brake

pedal released.There is no

change in the

voltage value,

and it is almost

constant 20

PHIA0766E

PHIA1141E

Page 5139 of 5621

SC-2

PRECAUTIONS

Revision: 2006 January2006 M35/M45

PRECAUTIONS PFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NKS003NB

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Power Generation Voltage Variable Control SystemNKS003NC

CAUTION:

For this model, the battery current sensor that is installed to the battery cable at the negative terminal

measures the charging/discharging current of the battery, and performs various controls. If the electri-

cal component or the ground wire is connected directly to the battery terminal, the current other than

that being measured with the battery current sensor is charging to or discharging from the battery.

This condition causes the malfunction of the control, and then the battery discharge may occur. Do

not connect the electrical component or the ground wire directly to the battery terminal.

Page 5170 of 5621

CHARGING SYSTEM

SC-33

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

2. CHECK “L” TERMINAL CIRCUIT (OPEN)

1. Disconnect alternator connector.

2. Apply ground to alternator harness connector terminal.

3. Check condition the charge warning lamp with the ignition

switch in the ON position.

OK or NG

OK >> Go to SC-31, "WORK FLOW" .

NG >> Check the following.

Harness for open between combination meter and alternator

Harness for open between combination meter and fuse

Charge warning lamp (Combination meter)

DIAGNOSTIC PROCEDURE 2

Check “L” Terminal Circuit (Short)

1. CHECK “L” TERMINAL CIRCUIT (SHORT)

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

Charge warning lamp should illuminate?

YES >> Check the following.

Harness for short between combination meter and alternator

Charge warning lamp (Combination meter)

NO >> Go to SC-31, "

WORK FLOW" .

DIAGNOSTIC PROCEDURE 3

Check “S” Terminal Circuit

1. CHECK “S” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “S” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “S” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test. Refer to SC-28, "

Trouble Diagnoses with Battery/Starting/Charging System Tester

(Charging)" .

Alternator

connectorTerminal

GroundCondition

Ignition switch

positionCharge warning

lamp

F20 (VQ35DE)

E209 (VK45DE)3 ON illuminate

PKIB8807E

Page 5172 of 5621

CHARGING SYSTEM

SC-35

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

Power Generation Voltage Variable Control System Operation InspectionNKS003NQ

CAUTION:

For this model, the battery current sensor that is installed to the battery cable at the negative ter-

minal measures the charging/discharging current of the battery, and performs various controls. If

the electrical component or the ground wire is connected directly to the battery terminal, the cur-

rent other than that being measured with the battery current sensor is charging to or discharging

from the battery. This condition causes the malfunction of the control, and then the battery dis-

charge may occur. Never connect the electrical component or the ground wire directly to the bat-

tery terminal.

When performing this inspection, always use the charged battery that completed the battery

inspection. (When the charging rate of the battery is low, the response speed of the voltage

change will become slow. This is a cause of an incorrect inspection.)

INSPECTION PROCEDURE

1. CHECK ECM (CONSULT-II)

Perform ECM self-diagnosis with CONSULT-II. Refer to EC-133, "

CONSULT-II Function (ENGINE)"

(VQ35DE) or EC-846, "CONSULT-II Function (ENGINE)" (VK45DE).

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2. CHECK OPERATION OF POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

1. Connect CONSULT-II and start the engine.

2. The selector lever is in “P” or “N” position and all of the electric

loads and A/C, etc. are turned OFF.

3. Select “ALTERNATOR DUTY” at “ACTIVE TEST” of “ENGINE”,

and then check the value of “BATTERY VOLT” monitor when

DUTY value of “ALTERNATOR DUTY” is set to 40.0 %.

4. Check the value of “BATTERY VOLT” monitor when DUTY value

of “ALTERNATOR DUTY” is set to 80.0%.

OK or NG

OK >> INSPECTION END

NG >> GO TO 3. (The charging condition of the battery should

be normal.)

3. CHECK IPDM E/R (CONSULT-II)

Perform IPDM E/R self-diagnosis with CONSULT-II. Refer to PG-20, "

CONSULT-II Function (IPDM E/R)" .

Self

-diagnostic results content

No malfunction detected>> GO TO 4.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts. “BATTERY VOLT”

2 seconds after setting the

DUTY value of “ALTERNA-

TOR DUTY” to 40.0 %: 12 - 13.6 V

PKIB4503E

“BATTERY VOLT”

20 seconds after setting

the DUTY value of “ALTER-

NATOR DUTY” to 80.0 %: +0.5 V or more against

the value of “BATTERY

VOLT” monitor when

DUTY value is 40.0 %

PKIB4504E

Page 5173 of 5621

SC-36

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

4. CHECK HARNESS BETWEEN ALTERNATOR AND IPDM E/R

1. Turn ignition switch OFF.

2. Disconnect alternator connector and IPDM E/R connector.

3. Check continuity between alternator harness connector (A) and

IPDM E/R harness connector (B).

4. Check continuity between alternator harness connector (A) and

ground.

OK or NG

OK >> Replace IPDM E/R.

NG >> Repair harness or connector between IPDM E/R and alternator.

AB

Continuity

Connector Terminal Connector Terminal

F20 (VQ35DE)

E209 (VK45DE)5 E8 33 Yes

A

GroundCondition

Connector Terminal

F20 (VQ35DE)

E209 (VK45DE)5No

PKIB8811E

Page 5186 of 5621

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-5

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

SQUEAK AND RATTLE TROUBLE DIAGNOSESPFP:00000

Work FlowNIS0025N

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to SE-9, "

Diagnostic Worksheet" . This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

Tick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperature, may have a great effect on noise level.

SBT842

Page 5187 of 5621

SE-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

placing a piece of paper between components that you suspect are causing the noise.

looking for loose components and contact marks.

Refer to SE-7, "

Generic Squeak and Rattle Troubleshooting" .

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Nissan Squeak and Rattle Kit (J-43980) is available through your authorized Nissan Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100

135 mm (3.945.31 in)/76884-71L01: 6085 mm (2.363.35 in)/76884-

71L02: 15

25 mm (0.590.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50

50 mm (1.971.97 in)/73982-50Y00:

10 mm (0.39 in) thick, 50

50 mm (1.971.97 in)