turn signal INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4582 of 5621

![INFINITI M35 2006 Factory Service Manual ACTIVE AFS

LT-155

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

SWIVEL

ACTUATOR

[RH]

[B2503]Any of several statuses below

Large difference between swivel motor drive signal (swivel

a INFINITI M35 2006 Factory Service Manual ACTIVE AFS

LT-155

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

SWIVEL

ACTUATOR

[RH]

[B2503]Any of several statuses below

Large difference between swivel motor drive signal (swivel

a](/img/42/57023/w960_57023-4581.png)

ACTIVE AFS

LT-155

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

SWIVEL

ACTUATOR

[RH]

[B2503]Any of several statuses below

Large difference between swivel motor drive signal (swivel

angle command signal) transmitted by AFS control unit and

swivel position sensor signal (swivel angle feed back signal)

by swivel position sensor exists for 2 seconds or longer. Or

swivel position sensor signal does not change for 2 seconds

or longer even when AFS control unit transmit swivel motor

drive signal.

CAUTION:

Detects when swivel operating (excludes initialization).

Short or open circuit exists for 2 seconds or longer on one of

swivel motor circuits (AFS control unit terminals 11, 13, 32 or

34).

CAUTION:

Detects when swivel operating (excludes initialization).

Voltage of swivel position sensor power supply (AFS control

unit terminal 4) had more than 6 V or had less than 4 V for 2

seconds or longer.

Voltage of swivel position sensor signal (AFS control unit ter-

minal 9) had more than 4.75 V or had less than 0.25 V for 2

seconds or longer.1. Stop the swivel motor RH and

LH when the malfunction

occurred.

2. Reduce approx. 2 V of the aim-

ing motor drive signal value from

that of when error is detected.

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.LT-162, "

DTC

B2503

SWIVEL

ACTUATOR

RH"

SWIVEL

ACTUATOR

[LH]

[B2504]Any of several statuses below

Large difference between swivel motor drive signal (swivel

angle command signal) transmitted by AFS control unit and

swivel position sensor signal (swivel angle feed back signal)

by swivel position sensor exists for 2 seconds or longer. Or

swivel position sensor signal does not change for 2 seconds

or longer even when AFS control unit transmit swivel motor

drive signal.

CAUTION:

Detects when swivel operating (excludes initialization).

Short or open circuit exists for 2 seconds or longer on one of

swivel motor circuits (AFS control unit terminals 15, 17, 36 or

38).

CAUTION:

Detects when swivel operating (excludes initialization).

Voltage of swivel position sensor power supply (AFS control

unit terminal 24) had more than 6 V or had less than 4 V for 2

seconds or longer.

Voltage of swivel position sensor signal (AFS control unit ter-

minal 29) had more than 4.75 V or had less than 0.25 V for 2

seconds or longer.1. Stop the swivel motor RH and

LH when the malfunction

occurred.

2. Reduce approx. 2 V of the aim-

ing motor drive signal value from

that of when error is detected.

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.LT-168, "

DTC

B2504

SWIVEL

ACTUATOR

LH"

HI SEN

UNUSUAL

[RR]

[B2514]Any of several statuses belowVoltage of height sensor power supply (AFS control unit termi-

nal 6) had more than 6 V or had less than 4 V for 2 seconds or

longer.

Voltage of height sensor signal (AFS control unit terminal 28)

had more than 4.75 V or had less than 0.25 V for 2 seconds or

longer.1. Normal operation

2. Stop aiming motors when the

malfunction occurred.

3. Remains OFF.

4. Turn ignition switch OFF.LT-174, "

DTC

B2514 HI SEN

UNUSUAL

RR"

Details of

error

indication

detected by

CONSULT-

IIConditions of error detectionFail-safe

1. Swivel operation

2. Auto aiming operation

3. AFS OFF indicator operation

4. CancellationReference

Page 4583 of 5621

![INFINITI M35 2006 Factory Service Manual LT-156

ACTIVE AFS

Revision: 2006 January2006 M35/M45

ST ANG

SEN SIG

[B2515]Any of several statuses belowCannot receive steering angle sensor signal.

Receives steering angle sensor error.

Receives ste INFINITI M35 2006 Factory Service Manual LT-156

ACTIVE AFS

Revision: 2006 January2006 M35/M45

ST ANG

SEN SIG

[B2515]Any of several statuses belowCannot receive steering angle sensor signal.

Receives steering angle sensor error.

Receives ste](/img/42/57023/w960_57023-4582.png)

LT-156

ACTIVE AFS

Revision: 2006 January2006 M35/M45

ST ANG

SEN SIG

[B2515]Any of several statuses belowCannot receive steering angle sensor signal.

Receives steering angle sensor error.

Receives steering angle sensor signal except 943 to +943.1. Back to the initial position.

2. Normal operation

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.BRC-23, "

Self-

Diagnosis" in

BRC section.

If above sys-

tem is normal,

replace AFS

control unit.

SHIFT SIG

[P, R]

[B2516]Cannot receive A/T position indicator signal.1. Back to the initial position.

2. Normal operation

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.AT- 9 2 , "

SELF-

DIAGNOSTIC

RESULT

MODE" in A/T

section.

If above sys-

tem is normal,

replace AFS

control unit.

VEHICLE

SPEED SIG

[B2517]Cannot receive vehicle speed signal.1. Back to the initial position.

2. Stop when the malfunction

occurred.

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.DI-32, "

SELF-

DIAG

RESULTS" in

DI section.

If above sys-

tem is normal,

replace AFS

control unit.

HEAD

LAMP SIG

[B2518]Cannot receive low beam status signal.1. Back to the initial position.

2. Stop aiming motors when the

malfunction occurred.

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.PG-21,

"SELF-DIAG

RESULTS" in

PG section.

If above sys-

tem is normal,

replace AFS

control unit.

LEVEL-

IZER CALIB

[B2519]Cannot recognize height sensor signal value at unloaded vehicle

position.1. Normal operation

2. Stop aiming motors when the

malfunction occurred.

3. Remains OFF.

4. When levelizer adjustment is

completedLT- 1 5 3 ,

"WORK SUP-

PORT (LEV-

ELIZER

ADJUST-

MENT)"

ST ANGLE

SEN CALIB

[B2520]Cannot recognize steering angle sensor neutral point (straight-

ahead position).1. Back to the initial position.

2. Normal operation

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. When steering angle sensor

adjustment is completedBRC-6,

"Adjustment of

Steering Angle

Sensor Neu-

tral Position"

in BRC sec-

tion. Details of

error

indication

detected by

CONSULT-

IIConditions of error detectionFail-safe

1. Swivel operation

2. Auto aiming operation

3. AFS OFF indicator operation

4. CancellationReference

Page 4584 of 5621

![INFINITI M35 2006 Factory Service Manual ACTIVE AFS

LT-157

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

CAUTION:

If DTC relating to CAN communication [U1000] and other components are displayed at the same

time, INFINITI M35 2006 Factory Service Manual ACTIVE AFS

LT-157

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

CAUTION:

If DTC relating to CAN communication [U1000] and other components are displayed at the same

time,](/img/42/57023/w960_57023-4583.png)

ACTIVE AFS

LT-157

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

CAUTION:

If DTC relating to CAN communication [U1000] and other components are displayed at the same

time, diagnose CAN communication first.

Make sure of the normal operation after the parts (except AFS control unit) replacement according

to the self-diagnosis results. Delete the malfunction history.

Display Results

0: There is malfunction now.

1 – 39: Displays when it is normal at present and finds malfunction in the past. It increases in order

of 0

12...3839 after returning to the normal condition whenever IGN OFFON. If it is over 39,

it is fixed to 39 until the self-diagnostic results are erased. It returns to 0 when malfunction is

detected again in the process.

ECU CIRC

[B2521]Any of several statuses below

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) or ground of swivel position sensor (RH) power

supply (AFS control unit terminal 4).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) of swivel position sensor (RH) signal (AFS con-

trol unit terminal 9).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) or ground of swivel position sensor (LH) power

supply (AFS control unit terminal 24).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) of swivel position sensor (LH) signal (AFS con-

trol unit terminal 29).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) or ground of height sensor power supply (AFS

control unit terminal 6).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) of height sensor signal (AFS control unit termi-

nal 28).

AFS control unit (RAM/ROM) malfunctions.1. Stop the swivel motor RH and

LH when the malfunction

occurred.

2. Stop aiming motors when the

malfunction occurred.

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.LT-178, "

DTC

B2521 ECU

CIRC"

ECM SIG

[B2522]Cannot receive engine speed signal.1. Back to the initial position.

2. Stop when the malfunction

occurred.

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.EC-137,

"SELF-DIAG

RESULTS

MODE" in EC

section.

If above sys-

tem is normal,

replace AFS

control unit.

AFS SIG

[B2523]Cannot transmit AFS off indicator signal.1. Back to the initial position.

2. Normal operation

3. Flashes at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.Replace

AFS control

unit LT-191

Details of

error

indication

detected by

CONSULT-

IIConditions of error detectionFail-safe

1. Swivel operation

2. Auto aiming operation

3. AFS OFF indicator operation

4. CancellationReference

Page 4585 of 5621

LT-158

ACTIVE AFS

Revision: 2006 January2006 M35/M45

DATA MONITOR

Operation Procedure

1. Touch “ADAPTIVE” on the “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on the “SELECT DIAG MODE” screen.

3. Touch “ALL SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR ITEM” screen.

4. When “SELECTION FROM MENU” is selected, touch items to be monitored. When “ALL SIGNALS” is

selected, all items will be monitored.

5. Touch “START”.

6. Touch “RECORD” while monitoring and status of the item being

monitored can be recorded. To stop recording, touch “STOP”.

Data Monitor item

ALL SIGNALS Monitors all items.

SELECTION FROM MENU Selects items and monitors them.

SKIB4793E

Monitors itemMeasuring condition

Description

Operation or conditionReference

value

STR ANGLE SIG “

” Steering wheelStraight-ahead Approx. 0Displays steering angle based on

steering angle sensor signals.

TurnedApprox. 550

to 550

VHCL SPD “ km/h ” —Displays vehicle speed based on

vehicle speed sensor signals.

SLCT LVR POSI “ P – 1 ” —Displays A/T selector lever position

based on AT position indicator sig-

nals.

HEAD LAMP “ ON/OFF ” Lighting switch 2ND ON Displays low beam headlamps on/off

status based on low beam status sig-

nal. Out of 2ND OFF

AFS SW “ ON/OFF ” AFS switchON ON

Displays AFS switch ON/OFF position

based on AFS switch signals.

OFF OFF

HI SEN OTP RR “ V ”Vehicle height

(With 18-inch wheel)Unloaded vehi-

cle positionApprox. 2.5 V

Displays vehicle height value based

on height sensor signals. Maximum

laden conditionApprox. 1.0 V

Vehicle height

(With 19-inch wheel)Unloaded vehi-

cle positionApprox. 2.5 V

Maximum

laden conditionApprox. 1.3 V

Page 4589 of 5621

LT-162

ACTIVE AFS

Revision: 2006 January2006 M35/M45

DTC B2503 SWIVEL ACTUATOR RHNKS003QO

1. CHECK SWIVEL POSITION SENSOR SIGNAL

1. Turn ignition switch ON.

2. Check voltage between AFS control unit harness connector

F110 terminal 9 and Ground.

OK or NG

OK >> GO TO 2.

NG >>

If voltage is less than approx. 0.25V, GO TO 3.

If voltage is more than approx. 4.75V, GO TO 6.

2. CHECK SWIVEL POSITION SENSOR POWER SUPPLY

Check voltage between AFS control unit harness connector F110

terminal 4 and Ground.

OK or NG

OK >> GO TO 12.

NG >> Replace AFS control unit. Refer to LT- 1 9 1 , "

Removal

and Installation of AFS Control Unit" .

3. CHECK SWIVEL POSITION SENSOR POWER SUPPLY

Check voltage between AFS control unit harness connector F110

terminal 4 and Ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 8.9 – Ground : Approx. 0.25 – 4.75 V

PKIC0646E

4 – Ground : Approx. 4 – 6 V

PKIC0645E

4 – Ground : Approx. 4 – 6 V

PKIC0645E

Page 4590 of 5621

ACTIVE AFS

LT-163

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

4. CHECK SWIVEL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH connector.

3. Turn ignition switch ON.

4. Check voltage between front combination lamp RH harness

connector E48 terminal 15 and Ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5. CHECK SWIVEL POSITION SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect AFS control unit connector.

3. Check continuity between AFS control unit harness connector

(A) F110 terminal 9 and front combination lamp RH harness

connector (B) E48 terminal 14.

OK or NG

OK >> Replace front combination lamp RH (swivel position

sensor malfunction). Refer to LT- 1 9 0 , "

Removal and

Installation of Front Combination Lamp" .

NG >> Repair harness or connector.

6. CHECK SWIVEL POSITION SENSOR GROUND

Check voltage between AFS control unit harness connector F110

terminal 2 and Ground.

OK or NG

OK >> GO TO 7.

NG >> Check connector for connection, bend and loose fit. If it

is normal, replace AFS control unit. Refer to LT- 1 9 1 ,

"Removal and Installation of AFS Control Unit" . 15 – Ground : Approx. 4 – 6 V

PKIC0647E

9 – 14 : Continuity should exist.

PKIC0648E

2 – Ground : Approx. 0 V

PKIC0649E

Page 4592 of 5621

ACTIVE AFS

LT-165

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

10. CHECK SWIVEL POSITION SENSOR SIGNAL CIRCUIT (SHORT CIRCUIT)

1. Turn ignition switch OFF.

2. Disconnect AFS control unit connector.

3. Check continuity between AFS control unit harness connector

F110 terminal 9 and ground.

OK or NG

OK >> Replace front combination lamp RH (swivel position

sensor malfunction). Refer to LT- 1 9 0 , "

Removal and

Installation of Front Combination Lamp" .

NG >> Repair harness or connector.

11 . CHECK SWIVEL POSITION SENSOR POWER SUPPLY CIRCUIT (SHORT CIRCUIT)

1. Turn ignition switch OFF.

2. Disconnect AFS control unit connector.

3. Check continuity between AFS control unit harness connector

F110 terminal 4 and ground.

OK or NG

OK >> Replace AFS control unit. Refer to LT- 1 9 1 , "Removal

and Installation of AFS Control Unit" .

NG >> Repair harness or connector.9 – Ground : Continuity should not exist.

SKIB4968E

4 – Ground : Continuity should not exist.

PKIC0652E

Page 4595 of 5621

LT-168

ACTIVE AFS

Revision: 2006 January2006 M35/M45

DTC B2504 SWIVEL ACTUATOR LHNKS003QP

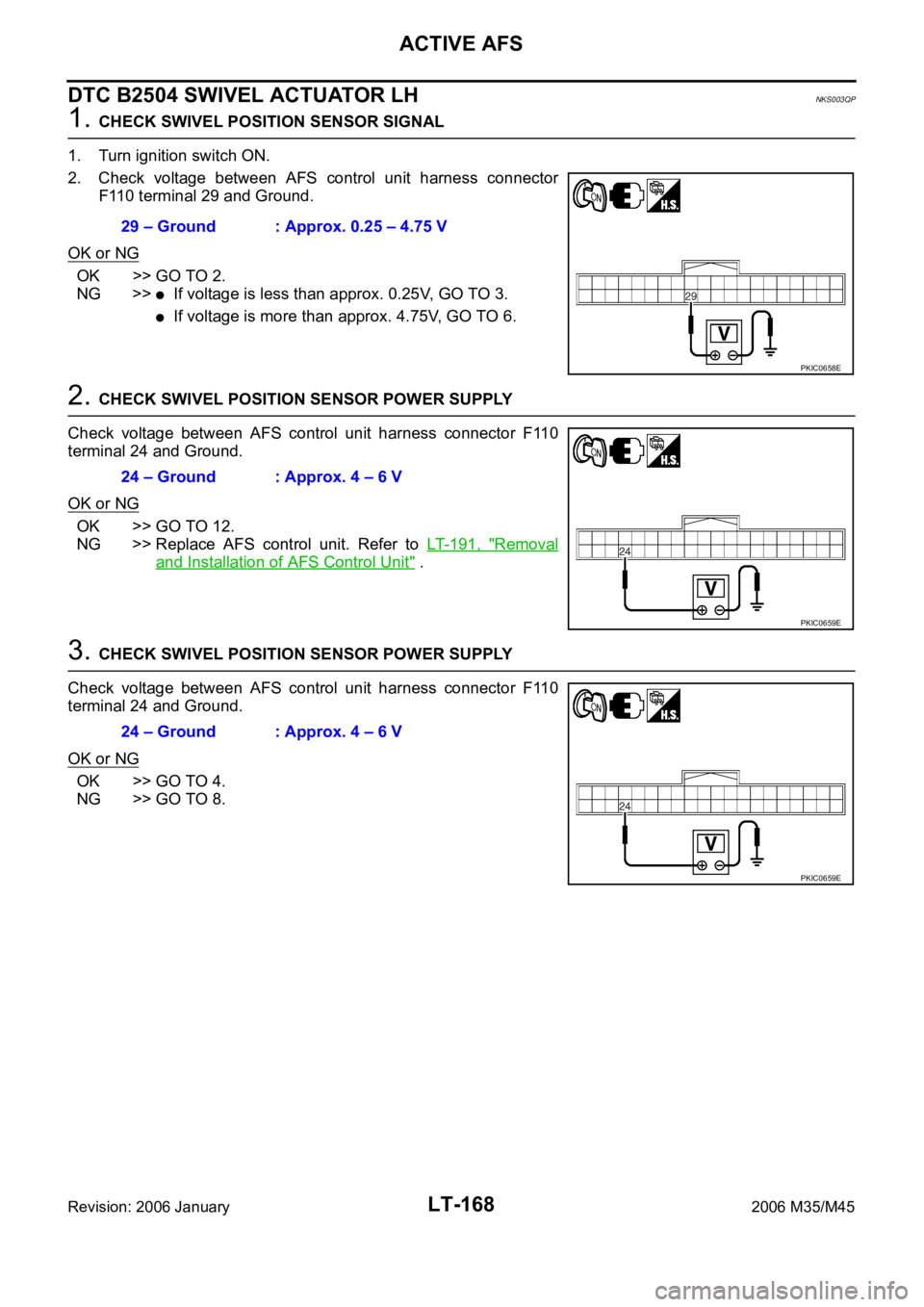

1. CHECK SWIVEL POSITION SENSOR SIGNAL

1. Turn ignition switch ON.

2. Check voltage between AFS control unit harness connector

F110 terminal 29 and Ground.

OK or NG

OK >> GO TO 2.

NG >>

If voltage is less than approx. 0.25V, GO TO 3.

If voltage is more than approx. 4.75V, GO TO 6.

2. CHECK SWIVEL POSITION SENSOR POWER SUPPLY

Check voltage between AFS control unit harness connector F110

terminal 24 and Ground.

OK or NG

OK >> GO TO 12.

NG >> Replace AFS control unit. Refer to LT- 1 9 1 , "

Removal

and Installation of AFS Control Unit" .

3. CHECK SWIVEL POSITION SENSOR POWER SUPPLY

Check voltage between AFS control unit harness connector F110

terminal 24 and Ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 8.29 – Ground : Approx. 0.25 – 4.75 V

PKIC0658E

24 – Ground : Approx. 4 – 6 V

PKIC0659E

24 – Ground : Approx. 4 – 6 V

PKIC0659E

Page 4596 of 5621

ACTIVE AFS

LT-169

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

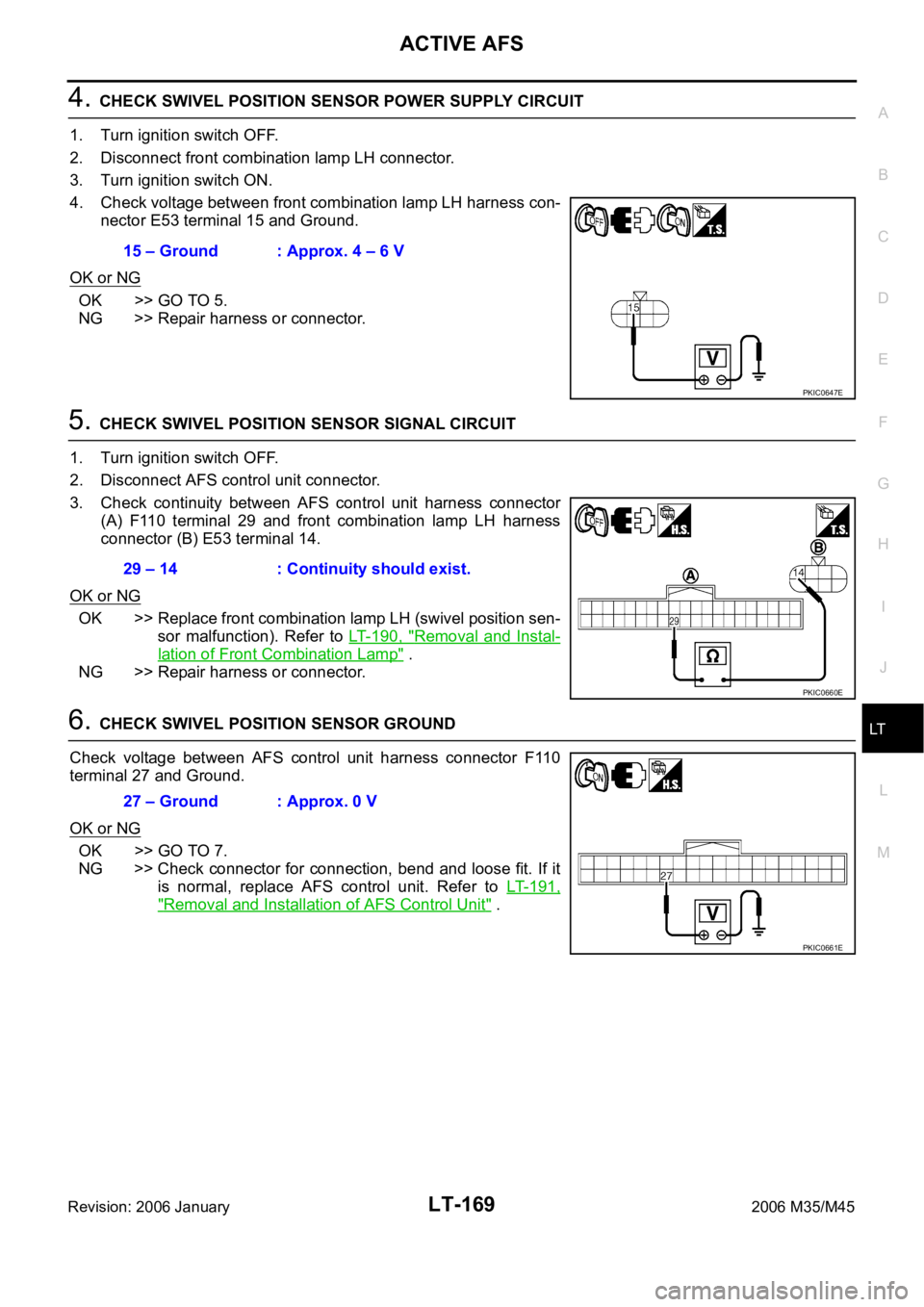

4. CHECK SWIVEL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front combination lamp LH connector.

3. Turn ignition switch ON.

4. Check voltage between front combination lamp LH harness con-

nector E53 terminal 15 and Ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5. CHECK SWIVEL POSITION SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect AFS control unit connector.

3. Check continuity between AFS control unit harness connector

(A) F110 terminal 29 and front combination lamp LH harness

connector (B) E53 terminal 14.

OK or NG

OK >> Replace front combination lamp LH (swivel position sen-

sor malfunction). Refer to LT- 1 9 0 , "

Removal and Instal-

lation of Front Combination Lamp" .

NG >> Repair harness or connector.

6. CHECK SWIVEL POSITION SENSOR GROUND

Check voltage between AFS control unit harness connector F110

terminal 27 and Ground.

OK or NG

OK >> GO TO 7.

NG >> Check connector for connection, bend and loose fit. If it

is normal, replace AFS control unit. Refer to LT- 1 9 1 ,

"Removal and Installation of AFS Control Unit" . 15 – Ground : Approx. 4 – 6 V

PKIC0647E

29 – 14 : Continuity should exist.

PKIC0660E

27 – Ground : Approx. 0 V

PKIC0661E

Page 4598 of 5621

ACTIVE AFS

LT-171

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

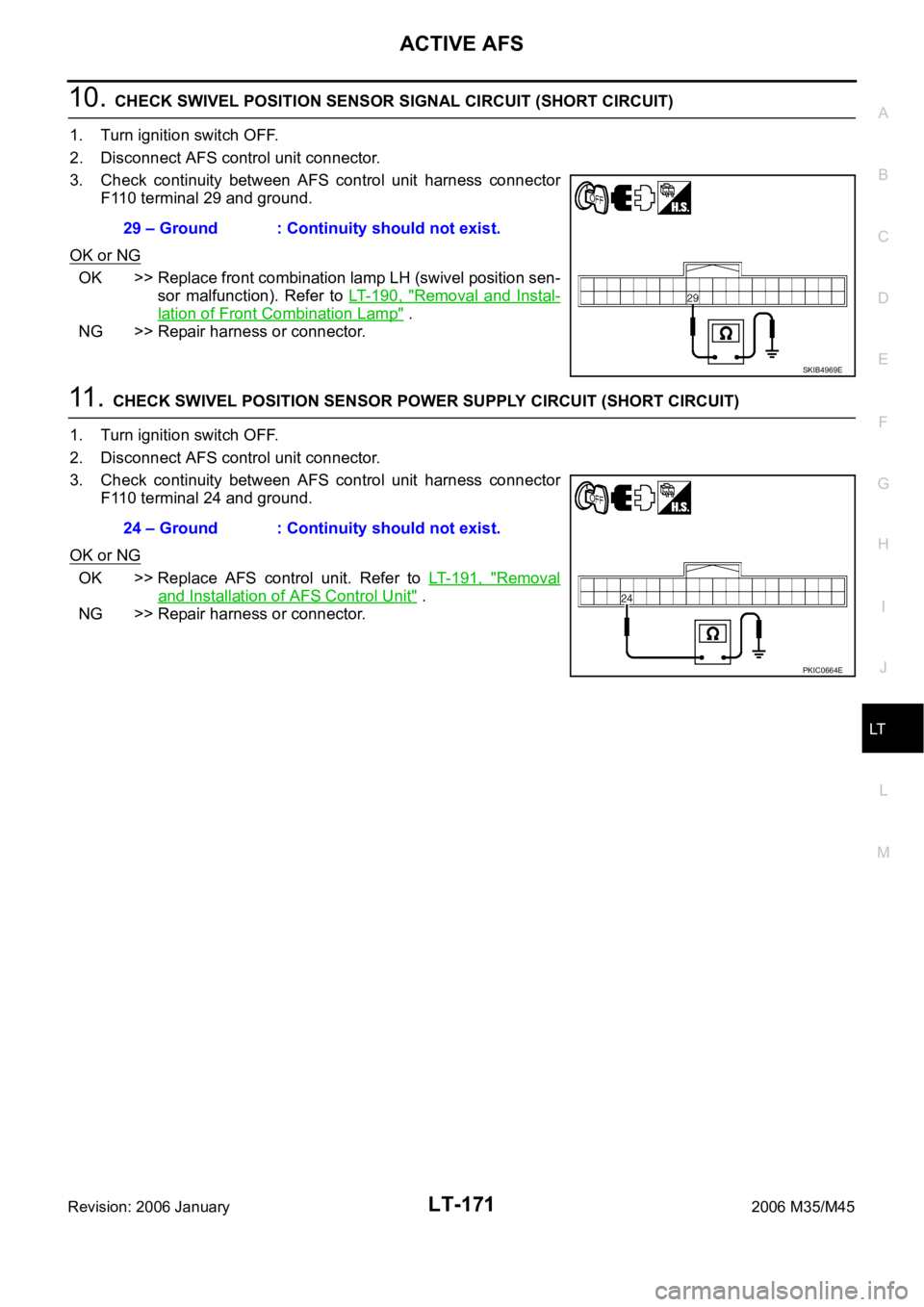

10. CHECK SWIVEL POSITION SENSOR SIGNAL CIRCUIT (SHORT CIRCUIT)

1. Turn ignition switch OFF.

2. Disconnect AFS control unit connector.

3. Check continuity between AFS control unit harness connector

F110 terminal 29 and ground.

OK or NG

OK >> Replace front combination lamp LH (swivel position sen-

sor malfunction). Refer to LT- 1 9 0 , "

Removal and Instal-

lation of Front Combination Lamp" .

NG >> Repair harness or connector.

11 . CHECK SWIVEL POSITION SENSOR POWER SUPPLY CIRCUIT (SHORT CIRCUIT)

1. Turn ignition switch OFF.

2. Disconnect AFS control unit connector.

3. Check continuity between AFS control unit harness connector

F110 terminal 24 and ground.

OK or NG

OK >> Replace AFS control unit. Refer to LT- 1 9 1 , "Removal

and Installation of AFS Control Unit" .

NG >> Repair harness or connector.29 – Ground : Continuity should not exist.

SKIB4969E

24 – Ground : Continuity should not exist.

PKIC0664E