check engine light INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4587 of 5621

LT-160

ACTIVE AFS

Revision: 2006 January2006 M35/M45

ACTIVE TEST

Operation Procedure

1. Start the engine. (Swivel actuator is initialized.)

2. Touch “ADAPTIVE LIGHT” on “SELECT SYSTEM” screen.

3. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Touch “LOW BEAM TEST RIGHT”, “LOW BEAM TEST LEFT”, or “LEVELIZER TEST” on “SELECT TEST

ITEM” screen.

CAUTION:

Can be tested only when swivel actuator initialization is completed. If initialization is not com-

pleted, “RETRY COMMAND” is displayed and cannot be tested.

LOW BEAM TEST RIGHT

Low beam headlamp (right) can be operated to swivel angle

0

by touching “ORIGIN”, and to maximum angle by “PEAK”.

LOW BEAM TEST LEFT

Low beam headlamp (left) can be operated to swivel angle 0

by touching “ORIGIN”, and to maximum angle by “PEAK”.

LEVELIZER TEST

Aiming motor drive signal can be changed to approx. 85%

(ratio to IGN power supply) by touching “ORIGIN”, and to

approx. 15% by “PEAK”. That angles headlamp LO up and

down.

5. During the operation check, touching “BACK” deactivates the operation.

Test Item Swivel Speed Mode

ORIGIN/PEAK - FAST Three times fast as SLOW Normal operation

ORIGIN/PEAK - SLOW — Initialization

SKIB4794E

Test Item Swivel Speed Mode

ORIGIN/PEAK - FAST Three times fast as SLOW Normal operation

ORIGIN/PEAK - SLOW — Initialization

SKIB4795E

Test ItemAiming Motor Drive Signal

Light Axis

(Reference Value) Ratio to IGN

power supplyVoltage

ORIGIN Approx. 85% Approx. 10.6 V 0

PEAK Approx. 15% Approx. 1.9 VApprox. 2.5

(Relatively lower than

that of origin)SKIB4796E

Page 4588 of 5621

ACTIVE AFS

LT-161

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Symptom ChartNKS003QN

CAUTION:

The low beam headlamps performs small movements when AFS control unit detects the engine start.

This is normal with initialization of swivel actuator by AFS control unit.

SymptomAFS OFF

indicatorCausal system Reference

AFS operates, but cannot judge normal/

abnormal.

(AFS function test)NormalCheck swivel operation.LT-181, "AFS

Operation

Check (Func-

tion Test)"

Check steering angle sensor neutral point (straight-ahead

position).

Auto aiming operates, but cannot judge

normal/abnormal.

(Auto aiming function test)NormalCheck auto aiming operation.LT-183, "Auto

Aiming Opera-

tion Check

(Function

Te s t )"

Check height sensor signal value recognized by AFS con-

trol unit at unloaded vehicle position.

Check height sensor signal and aiming motor drive signal.

Neither AFS operates nor auto aiming

operates.BlinkingCheck AFS control unit self-diagnostic results. LT-154,

"SELF-DIAG

RESULTS"

Check AFS control unit power supply and ground circuit.

NOTE:

Check only when “ADAPTIVE LIGHT” is not displayed on

CONSULT-II “SELECT SYSTEM” screen.LT-151, "Pre-

liminary

Check"

AFS does not operate.

(Auto aiming operation is normal.)Blinking Check AFS control unit self-diagnostic results. LT-154,

"SELF-DIAG

RESULTS"

Illuminated Check AFS switch system circuit.LT-185, "

AFS

Switch Does

Not Operate"

Auto aiming does not operate.

(AFS operation is normal.)NormalCheck AFS control unit self-diagnostic results. LT-154,

"SELF-DIAG

RESULTS"

Check aiming motor system circuit.LT-187, "

Auto

Aiming Does

Not Operate

(Check Aiming

Motor System

Circuit)"

Auto aiming operates in the reverse way.

(Lowering vehicle height angles light

axis up.)Normal Replace AFS control unit.LT-191, "Removal and

Installation of

AFS Control

Unit"

AFS OFF indicator does not illuminate.

(AFS operation and auto aiming opera-

tion are normal.)Not

illuminatedCheck circuit between unified meter and A/C amp. and

combination meter.LT-190, "

AFS

OFF Indicator

Does Not

Operate"AFS OFF indicator blinks.

(AFS operation and auto aiming opera-

tion are normal.)BlinkingCheck receive state of AFS off indicator signal from uni-

fied meter and A/C amp.

AFS cannot be cancelled.

(AFS switch does not operate.)Normal Check AFS switch system circuit.LT-185, "AFS

Switch Does

Not Operate"

Page 4608 of 5621

ACTIVE AFS

LT-181

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

AFS Operation Check (Function Test)NKS003QS

1. CHECK SWIVEL ACTUATOR

1. Start engine and turn lighting switch to 2ND position.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “ACTIVE

TEST” on “SELECT DIAG MODE” screen.

3. Select “LOW BEAM TEST RIGHT” or “LOW BEAM TEST LEFT”

on “SELECT TEST ITEM” screen.

4. Touch “ORIGIN–FAST/SLOW” and “PEAK–FAST/SLOW”

screen.

5. Make sure of swivel operation.

OK or NG

OK >> GO TO 2.

NG >>

When interference or poor fitment is found, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, replace headlamp. Refer to LT- 1 9 0 , "Removal and Installation of

Front Combination Lamp" .

When the operation range is irregular, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, GO TO 3.

2. CHECK STEERING ANGLE SENSOR

Check “STR ANGLE SIG” in “Data Monitor” when driving straight

and steering turn 90

to right or left.

OK or NG

OK >> GO TO 3.

NG >>

When steering is out of range while driving straight, perform steering angle sensor adjustment.

Refer to BRC-6, "

Adjustment of Steering Angle Sensor Neutral Position" in “ON-VEHICLE

SERVICE”.

When the function is normal while driving straight but the displayed value is different from

actual steering position with turning to right or left, replace steering angle sensor. Refer to LT-

190, "Removal and Installation of Steering Angle Sensor" .

SKIB4794E

TEST ITEM ORIGIN PEAKLight axis range at 10 m (394.7 in) off

(Reference value)

LOW BEAM TEST RIGHT Swivel angle 0

Swivel angle 7 to 13Approx. 1.200 to 2.300 mm (48 to 90 in)

LOW BEAM TEST LEFT Swivel angle 0

Swivel angle 17 to 23Approx. 3.000 to 4.200 mm (120 to 167 in)

Steering conditionSTR ANGLE SIG

(Data monitor)

Driving straight

5.0 to + 5.0

Turn 90 to right Approx. + 90

Tu rn 90 to left Approx. 90

SKIB4793E

Page 4610 of 5621

ACTIVE AFS

LT-183

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

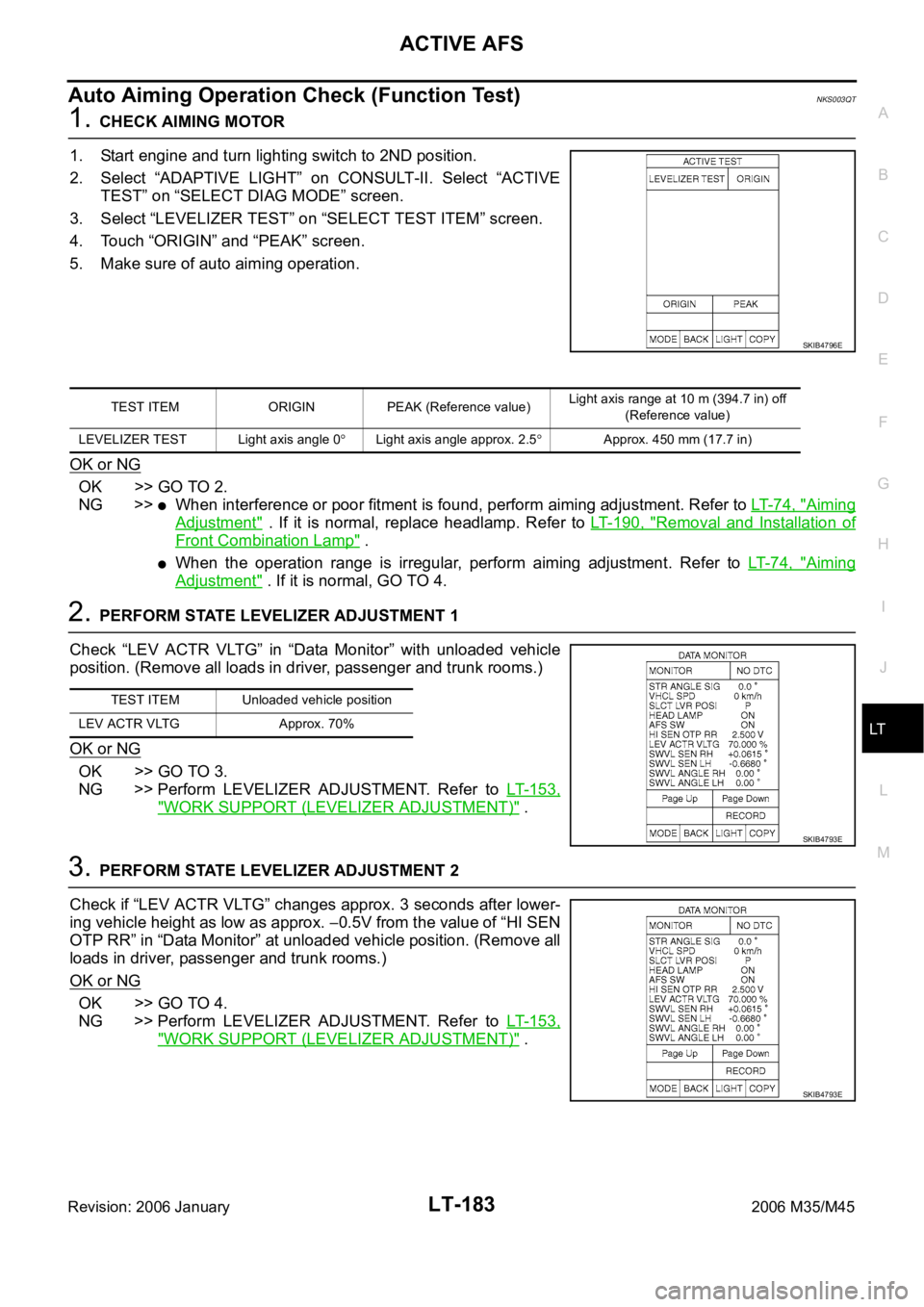

Auto Aiming Operation Check (Function Test)NKS003QT

1. CHECK AIMING MOTOR

1. Start engine and turn lighting switch to 2ND position.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “ACTIVE

TEST” on “SELECT DIAG MODE” screen.

3. Select “LEVELIZER TEST” on “SELECT TEST ITEM” screen.

4. Touch “ORIGIN” and “PEAK” screen.

5. Make sure of auto aiming operation.

OK or NG

OK >> GO TO 2.

NG >>

When interference or poor fitment is found, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, replace headlamp. Refer to LT- 1 9 0 , "Removal and Installation of

Front Combination Lamp" .

When the operation range is irregular, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, GO TO 4.

2. PERFORM STATE LEVELIZER ADJUSTMENT 1

Check “LEV ACTR VLTG” in “Data Monitor” with unloaded vehicle

position. (Remove all loads in driver, passenger and trunk rooms.)

OK or NG

OK >> GO TO 3.

NG >> Perform LEVELIZER ADJUSTMENT. Refer to LT- 1 5 3 ,

"WORK SUPPORT (LEVELIZER ADJUSTMENT)" .

3. PERFORM STATE LEVELIZER ADJUSTMENT 2

Check if “LEV ACTR VLTG” changes approx. 3 seconds after lower-

ing vehicle height as low as approx.

0.5V from the value of “HI SEN

OTP RR” in “Data Monitor” at unloaded vehicle position. (Remove all

loads in driver, passenger and trunk rooms.)

OK or NG

OK >> GO TO 4.

NG >> Perform LEVELIZER ADJUSTMENT. Refer to LT- 1 5 3 ,

"WORK SUPPORT (LEVELIZER ADJUSTMENT)" .

SKIB4796E

TEST ITEM ORIGIN PEAK (Reference value)Light axis range at 10 m (394.7 in) off

(Reference value)

LEVELIZER TEST Light axis angle 0

Light axis angle approx. 2.5Approx. 450 mm (17.7 in)

TEST ITEM Unloaded vehicle position

LEV ACTR VLTG Approx. 70%

SKIB4793E

SKIB4793E

Page 4614 of 5621

ACTIVE AFS

LT-187

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

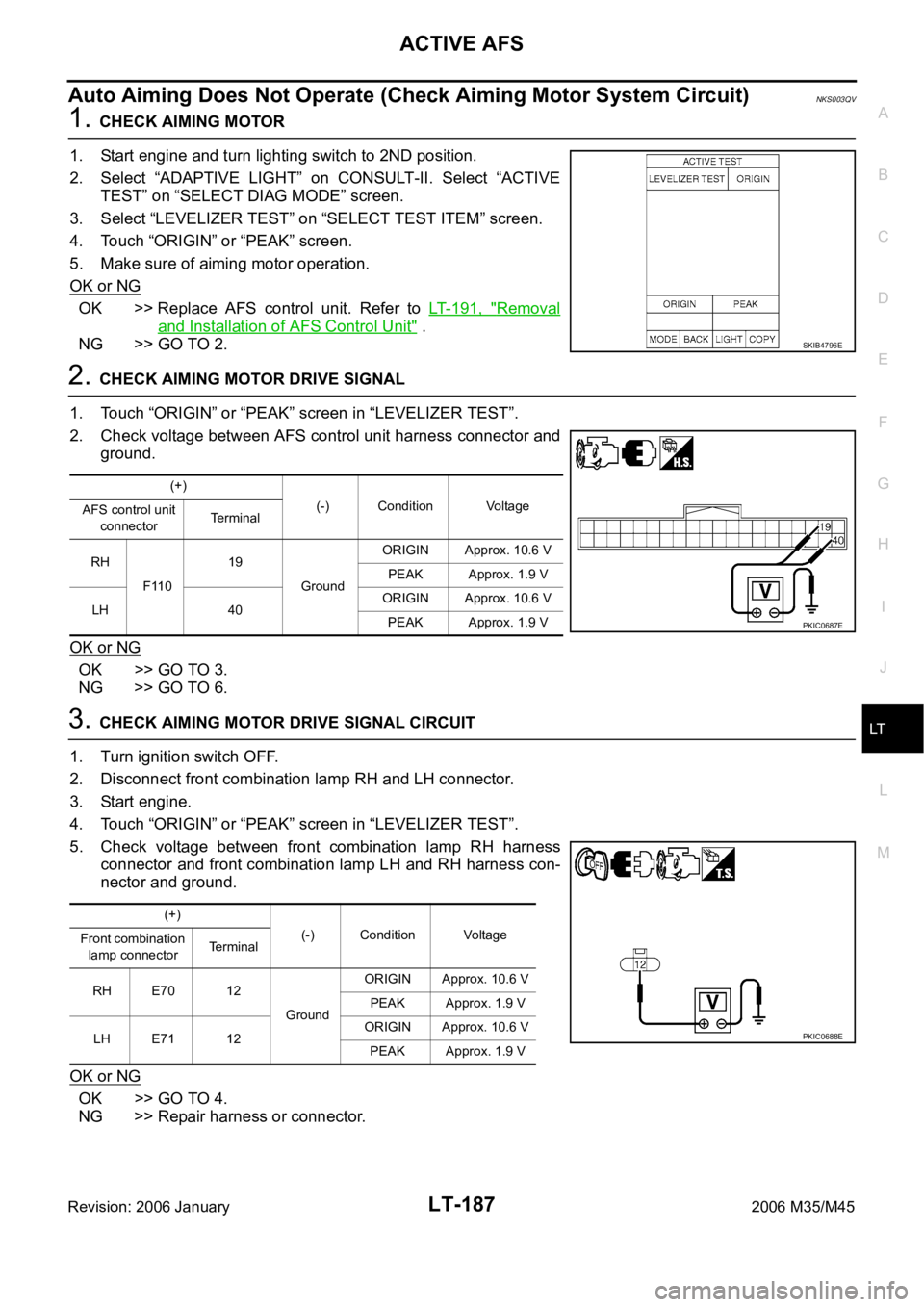

Auto Aiming Does Not Operate (Check Aiming Motor System Circuit)NKS003QV

1. CHECK AIMING MOTOR

1. Start engine and turn lighting switch to 2ND position.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “ACTIVE

TEST” on “SELECT DIAG MODE” screen.

3. Select “LEVELIZER TEST” on “SELECT TEST ITEM” screen.

4. Touch “ORIGIN” or “PEAK” screen.

5. Make sure of aiming motor operation.

OK or NG

OK >> Replace AFS control unit. Refer to LT- 1 9 1 , "Removal

and Installation of AFS Control Unit" .

NG >> GO TO 2.

2. CHECK AIMING MOTOR DRIVE SIGNAL

1. Touch “ORIGIN” or “PEAK” screen in “LEVELIZER TEST”.

2. Check voltage between AFS control unit harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 6.

3. CHECK AIMING MOTOR DRIVE SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connector.

3. Start engine.

4. Touch “ORIGIN” or “PEAK” screen in “LEVELIZER TEST”.

5. Check voltage between front combination lamp RH harness

connector and front combination lamp LH and RH harness con-

nector and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

SKIB4796E

(+)

(-) Condition Voltage

AFS control unit

connectorTerminal

RH

F11019

GroundORIGIN Approx. 10.6 V

PEAK Approx. 1.9 V

LH 40ORIGIN Approx. 10.6 V

PEAK Approx. 1.9 V

PKIC0687E

(+)

(-) Condition Voltage

Front combination

lamp connectorTerminal

RH E70 12

GroundORIGIN Approx. 10.6 V

PEAK Approx. 1.9 V

LH E71 12ORIGIN Approx. 10.6 V

PEAK Approx. 1.9 V

PKIC0688E

Page 4963 of 5621

PS-10

STEERING WHEEL

Revision: 2006 January2006 M35/M45

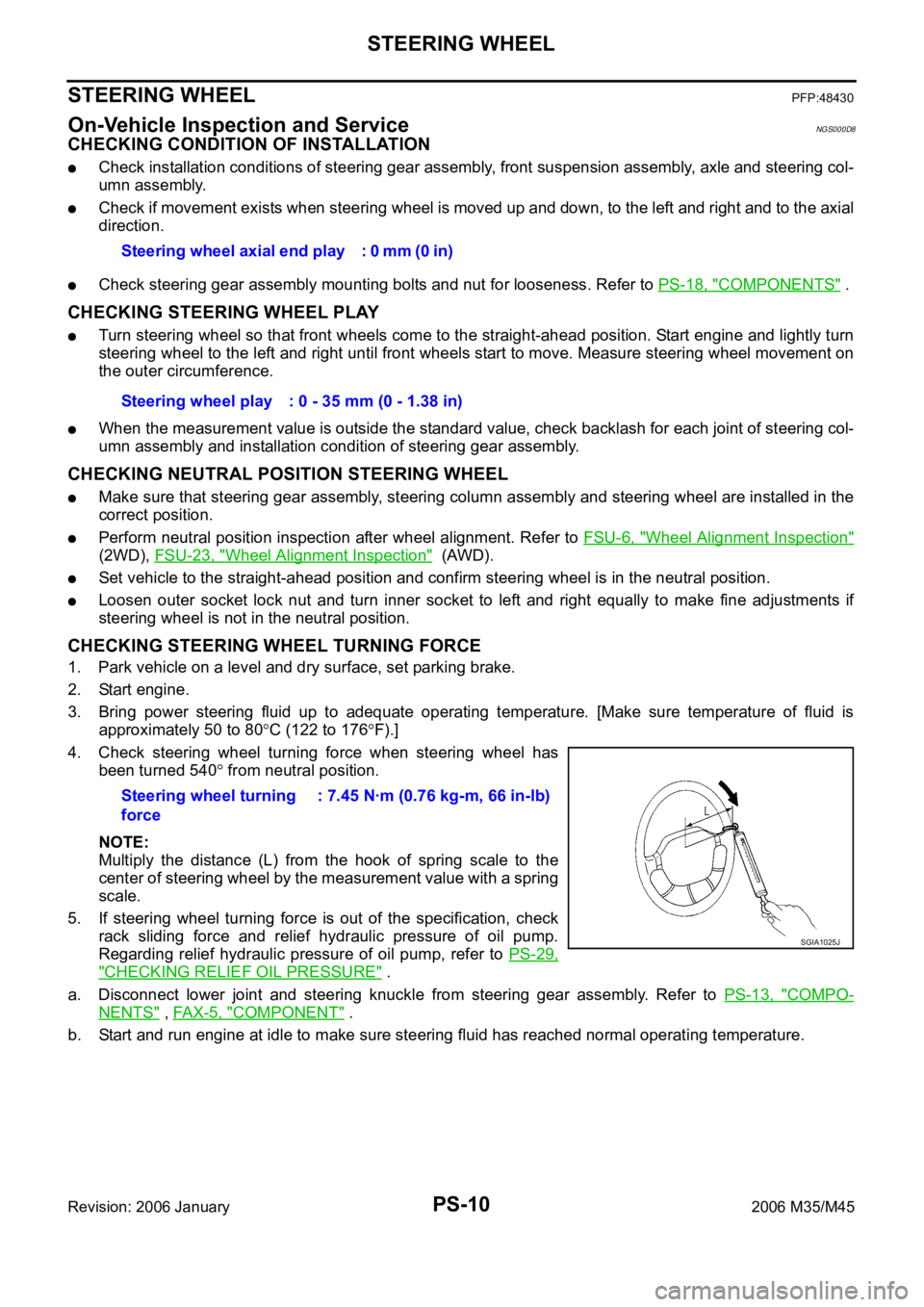

STEERING WHEELPFP:48430

On-Vehicle Inspection and ServiceNGS000D8

CHECKING CONDITION OF INSTALLATION

Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

Check steering gear assembly mounting bolts and nut for looseness. Refer to PS-18, "COMPONENTS" .

CHECKING STEERING WHEEL PLAY

Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on

the outer circumference.

When the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

Perform neutral position inspection after wheel alignment. Refer to FSU-6, "Wheel Alignment Inspection"

(2WD), FSU-23, "Wheel Alignment Inspection" (AWD).

Set vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if

steering wheel is not in the neutral position.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 50 to 80

C (122 to 176F).]

4. Check steering wheel turning force when steering wheel has

been turned 540

from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring scale to the

center of steering wheel by the measurement value with a spring

scale.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer to PS-29,

"CHECKING RELIEF OIL PRESSURE" .

a. Disconnect lower joint and steering knuckle from steering gear assembly. Refer to PS-13, "

COMPO-

NENTS" , FAX-5, "COMPONENT" .

b. Start and run engine at idle to make sure steering fluid has reached normal operating temperature. Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel turning

force: 7.45 Nꞏm (0.76 kg-m, 66 in-lb)

SGIA1025J

Page 5425 of 5621

![INFINITI M35 2006 Factory Repair Manual STC-10

[EPS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. CHECK POWER STEERING CONTROL UNIT POWER SUPPLY CIRCUIT

Turn ignition switch ON, and then check voltage between power

steer INFINITI M35 2006 Factory Repair Manual STC-10

[EPS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. CHECK POWER STEERING CONTROL UNIT POWER SUPPLY CIRCUIT

Turn ignition switch ON, and then check voltage between power

steer](/img/42/57023/w960_57023-5424.png)

STC-10

[EPS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. CHECK POWER STEERING CONTROL UNIT POWER SUPPLY CIRCUIT

Turn ignition switch ON, and then check voltage between power

steering control unit harness connector M8 and ground.

OK or NG

OK >> Power supply and ground circuit are normal.

NG >> Power supply circuit open or shorted. Repair or replace

any inoperative parts.

Symptom: The Steering Force Does Not Change Smoothly According to the

Vehicle Speed

NGS000E4

Heavy steering force with the static steering/light steering force during high-speed driving

1. POWER STEERING SOLENOID VALVE SIGNAL INSPECTION 1

1. Start engine.

2. Change the vehicle speed from 0 to 100 km/h (0 to 62 MPH)

slowly, and then check voltage between power steering control

unit harness connector M8 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 7.

2. POWER STEERING SOLENOID VALVE SIGNAL INSPECTION 2

1. Activate fail-safe function by running the engine speed at 1,500 rpm or higher for 10 seconds with the

vehicle stopped.

2. Change the engine speed to the idling, to approximately 1,600

rpm, and to approximately 3,000 rpm slowly, and then check

voltage between power steering control unit harness connector

M8 and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 8.

3. CHECK POWER STEERING SOLENOID VALVE CONNECTOR

Turn ignition switch OFF, disconnect power steering solenoid valve harness connector, and check terminal for

deformation, disconnection, looseness, etc.

OK or NG

OK >> GO TO 4.

NG >> Harness or connector open or shorted. Repair or replace any inoperative parts. Terminal 1 – ground : Battery voltage (Approx. 12 V)

SGIA1232E

Terminal 7 – ground : The voltage has changed from

approximately 4.4 - 6.6 V to

approximately 2.4 - 3.6 V

SGIA1233E

Terminal 7 – ground : The voltage has changed from

approximately 5.5 V to approxi-

mately 2.1 V step-by-step.

SGIA1233E

Page 5461 of 5621

![INFINITI M35 2006 Factory Repair Manual STC-46

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Diagnosis Chart by Symptom 1NGS000F1

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform RAS self-diagnosis.

With CONSULT-II: STC-28, "SELF-D INFINITI M35 2006 Factory Repair Manual STC-46

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Diagnosis Chart by Symptom 1NGS000F1

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform RAS self-diagnosis.

With CONSULT-II: STC-28, "SELF-D](/img/42/57023/w960_57023-5460.png)

STC-46

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Diagnosis Chart by Symptom 1NGS000F1

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform RAS self-diagnosis.

With CONSULT-II: STC-28, "SELF-DIAG RESULT MODE"

Without CONSULT-II: STC-31, "Diagnosis Procedure with Self-Diagnosis Function (Without CONSULT-

II)"

Are malfunctioning items displayed in self-diagnosis results?

YES >> Repair or replace any malfunctioning items.

NO >> GO TO 2.

2. CHECK RAS STATIC/DYNAMIC CHARACTERISTICS

Check RAS static/dynamic characteristics. Refer to STC-48, "

Check RAS Static/Dynamic Characteristics" .

Is the malfunction corrected?

YES >> INSPECTION END

NO >> Perform the following check, and then check the symptom again.

Adjust neutral position of steering angle sensor. Refer to BRC-6, "Adjustment of Steering Angle

Sensor Neutral Position" .

Steering angle sensor mounting condition. Refer to BRC-63, "Removal and Installation" .

Diagnosis Chart by Symptom 2NGS000F2

The steering force does not change smoothly according to the vehicle speed (Heavy steering force with the

vehicle stopped/Light handle operation during high-speed driving)

1. CHECK (1): POWER STEERING SOLENOID VALVE SIGNAL

1. Start engine.

2. Change the vehicle speed from 0 to 100 km/h (0 to 62 MPH)

slowly, and then check voltage RAS control unit harness con-

nector B127.

OK or NG

OK >> GO TO 2.

NG >> GO TO 7.

2. CHECK (2): POWER STEERING SOLENOID VALVE SIGNAL

1. Activate fail-safe function by running engine speed at 1,500 rpm or higher for 10 seconds with the vehicle

stopped.

2. Change the engine speed to the idling speed, approx. 1,600

rpm, and approximately 3,000 rpm slowly, and then check volt-

age RAS control unit harness connector B127.

OK or NG

OK >> GO TO 3.

NG >> GO TO 7.Terminal 36 – 34 : The voltage has changed from

approximately 4.4 - 6.6 V to approxi-

mately 2.4 - 3.6 V.

SGIA1281E

Terminal 36 – 34 : The voltage is changed from

approximately 5.5 V to approximately

2.1 V step-by-step.

SGIA1281E

Page 5485 of 5621

TF-20

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Trouble Diagnosis Chart for SymptomsNDS000DK

If AWD warning lamp turns ON, perform self-diagnosis. Refer to TF-22, "SELF-DIAG RESULT MODE" .

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunction.

AWD Control Unit Input/Output Signal Reference ValuesNDS000DL

AWD CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check item Reference page

AWD warning lamp does not turn ON when

the ignition switch is turned to ON.

(AWD warning lamp check)Ignition switch: ONCAN communication line

TF-33

Unified meter and A/C amp.

Unified meter control unit

AWD warning lamp does not turn OFF sev-

eral seconds after engine started.Engine runningCAN communication line

TF-33

Power supply and ground for AWD con-

trol unit

Unified meter and A/C amp.

Unified meter control unit

AWD solenoid

AWD actuator relay (integrated in AWD

control unit)

Wheel sensor

Heavy tight-corner braking symptom occurs

when the vehicle is driven and the steering

wheel is turned fully to either side after the

engine is started. (See NOTE.)

While driving

Steering wheel is

turned fully to either

sidesCAN communication line

TF-35Accelerator pedal position signal

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (clutch sticking etc.)

Vehicle does not enter AWD mode even

though AWD warning lamp turned to OFF.While drivingCAN communication line

TF-36

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (Mechanical engage-

ment of clutch is not possible.)

While driving, AWD warning lamp flashes

rapidly. (When flashing in approx. 1 minute

and then turning OFF.)

Rapid flashing: 2 times/secondWhile drivingProtection function is activated due to

heavy load to electric controlled cou-

pling. (AWD system is not malfunction-

ing. Also, optional distribution of torque

sometimes becomes rigid before lamp

flashes rapidly, but it is not malfunction.)TF-37

While driving, AWD warning lamp flashes

slowly. (When continuing to flash until turn-

ing ignition switch OFF)

Slow flashing: 1 time/2 secondsWhile driving

Vehicle speed: 20 km/h

(12 MPH) or moreTire size is different between front and

rear of vehicle.TF-37

Monitor item [Unit] Content Condition Display value

FR RH SENSOR [km/h] or [mph]Wheel speed (Front wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

FR LH SENSOR [km/h] or [mph]Wheel speed (Front wheel

left)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

Page 5500 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-35

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

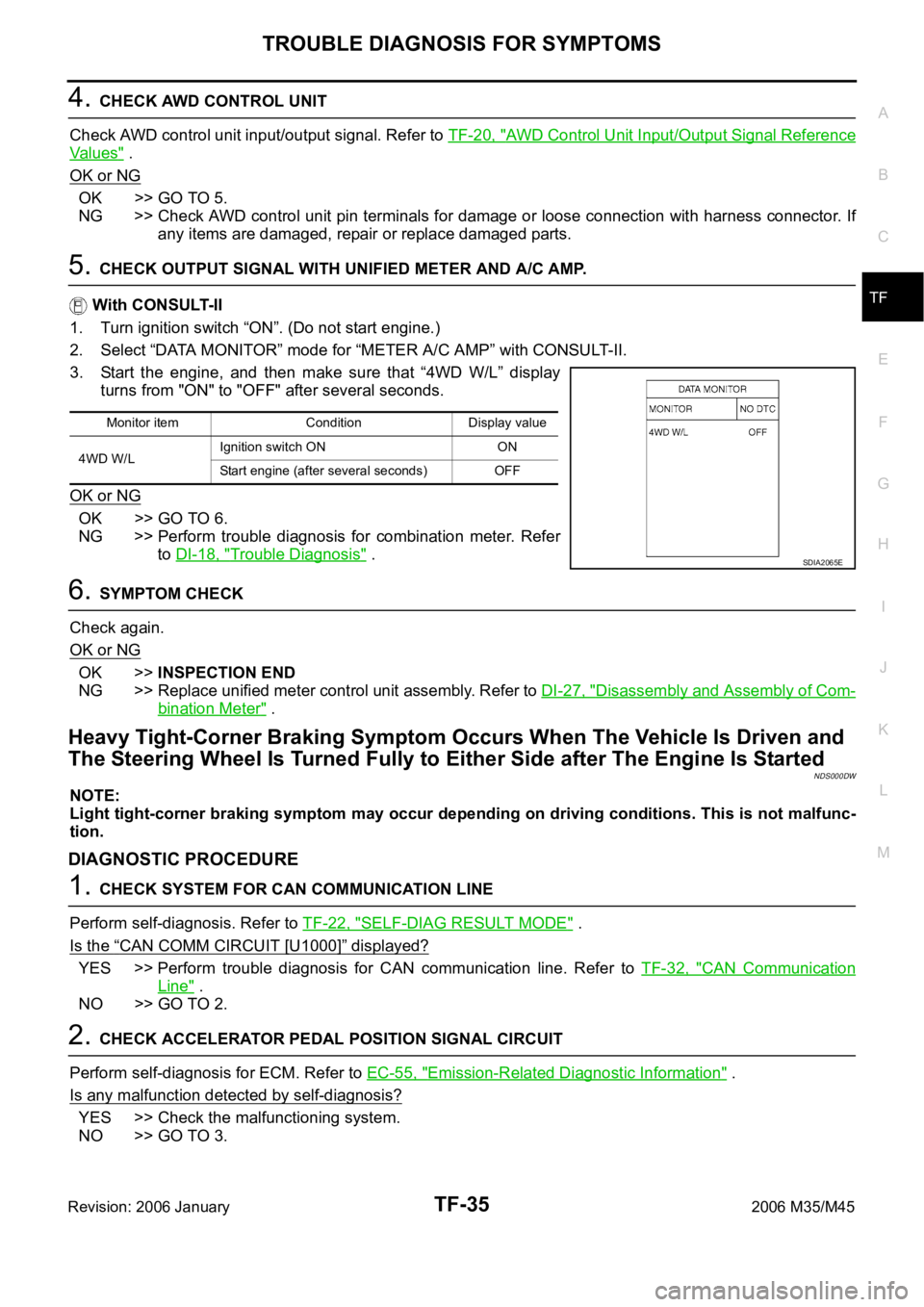

4. CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e s" .

OK or NG

OK >> GO TO 5.

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

5. CHECK OUTPUT SIGNAL WITH UNIFIED METER AND A/C AMP.

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “METER A/C AMP” with CONSULT-II.

3. Start the engine, and then make sure that “4WD W/L” display

turns from "ON" to "OFF" after several seconds.

OK or NG

OK >> GO TO 6.

NG >> Perform trouble diagnosis for combination meter. Refer

to DI-18, "

Trouble Diagnosis" .

6. SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> Replace unified meter control unit assembly. Refer to DI-27, "

Disassembly and Assembly of Com-

bination Meter" .

Heavy Tight-Corner Braking Symptom Occurs When The Vehicle Is Driven and

The Steering Wheel Is Turned Fully to Either Side after The Engine Is Started

NDS000DW

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunc-

tion.

DIAGNOSTIC PROCEDURE

1. CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-22, "

SELF-DIAG RESULT MODE" .

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-32, "CAN Communication

Line" .

NO >> GO TO 2.

2. CHECK ACCELERATOR PEDAL POSITION SIGNAL CIRCUIT

Perform self-diagnosis for ECM. Refer to EC-55, "

Emission-Related Diagnostic Information" .

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 3.

Monitor item Condition Display value

4WD W/LIgnition switch ON ON

Start engine (after several seconds) OFF

SDIA2065E