pressure INFINITI M35 2006 Factory Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 272 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-193

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Large Shock (“N” to “D” Position)NCS001Q3

SYMPTOM:

A noticeable shock occurs when the selector lever is shifted from “N” to “D” position.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)" .

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 2.

2. ENGINE IDLE SPEED

Check engine idle speed. Refer to EC-82, "

Idle Speed and Ignition Timing Check" (for VQ35DE engine), EC-

793, "Idle Speed and Ignition Timing Check" (for VK45DE engine).

OK or NG

OK >> GO TO 3.

NG >> Adjust engine idle speed. Refer to EC-82, "

Idle Speed and Ignition Timing Check" (for VQ35DE

engine), EC-793, "

Idle Speed and Ignition Timing Check" (for VK45DE engine).

3. CHECK CONTROL LINKAGE

Check control linkage.

Refer to AT-228, "Checking of A/T Position" .

OK or NG

OK >> GO TO 4.

NG >> Adjust control linkage. Refer to AT-227, "

Adjustment of A/T Position" .

4. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 5.

NG >> Refill ATF.

5. CHECK LINE PRESSURE

Check line pressure at idle with selector lever in “D” position. Refer to AT-55, "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 8.

NG - 1 >> Line pressure high: GO TO 6.

NG - 2 >> Line pressure low: GO TO 7.

6. DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT- 2 3 6 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2" .

2. Disassemble A/T. Refer to AT-298, "

DISASSEMBLY" .

3. Check the following.

–Oil pump assembly. Refer to AT-318, "Oil Pump" .

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

Page 274 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-195

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Vehicle Does Not Creep Backward in “R” PositionNCS001Q4

SYMPTOM:

The vehicle does not creep in “R” position. Or an extreme lack of acceleration is observed.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)" .

Is any malfunction detected by self-diagnosis results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 2.

2. CHECK CONTROL LINKAGE

Check control linkage.

Refer to AT-228, "Checking of A/T Position" .

OK or NG

OK >> GO TO 3.

NG >> Adjust control linkage. Refer to AT-227, "

Adjustment of A/T Position" .

3. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4. CHECK STALL TEST

Check stall revolution with selector lever in “M” and “R” positions.

Refer to AT- 5 3 , "

STALL TEST" .

OK or NG

OK >> GO TO 6.

OK in “M” position, NG in “R” position>>GO TO 5

NG in both “M” and “R” positions>>GO TO 8.

5. DETECT MALFUNCTIONING ITEM

1. Disassemble A/T. Refer to AT-298, "

DISASSEMBLY" .

2. Check the following.

–Reverse brake. Refer to AT-298, "DISASSEMBLY" .

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

6. CHECK LINE PRESSURE

Check line pressure with the engine idling. Refer to AT- 5 5 , "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 9.

NG - 1 >> Line pressure high: GO TO 7.

NG - 2 >> Line pressure low: GO TO 8.

Page 276 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-197

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

13. DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT- 6 4 ,

"Symptom Chart" (Symptom No.43).

OK or NG

OK >> GO TO 11.

NG >> Repair or replace damaged parts.

Vehicle Does Not Creep Forward in “D” PositionNCS001Q5

SYMPTOM:

Vehicle does not creep forward when selecting “D” position.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)" .

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 2.

2. CHECK CONTROL LINKAGE

Check control linkage.

Refer to AT-228, "Checking of A/T Position" .

OK or NG

OK >> GO TO 3.

NG >> Adjust control linkage. Refer to AT-227, "

Adjustment of A/T Position" .

3. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4. CHECK STALL TEST

Check stall revolution with selector lever in “D” position. Refer to AT-53, "

STALL TEST" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 7.

5. CHECK LINE PRESSURE

Check line pressure at idle with selector lever in “D” position. Refer to AT-55, "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 8.

NG - 1 >> Line pressure high: GO TO 6.

NG - 2 >> Line pressure low: GO TO 7.

Page 278 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-199

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

12. DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT- 6 4 ,

"Symptom Chart" (Symptom No.43).

OK or NG

OK >> GO TO 10.

NG >> Repair or replace damaged parts.

Vehicle Cannot Be Started from D1NCS001Q6

SYMPTOM:

Vehicle cannot be started from D1 on cruise test - Part 1.

DIAGNOSTIC PROCEDURE

1. CONFIRM THE SYMPTOM

Check if vehicle creeps in “R” position.

OK or NG

OK >> GO TO 2.

NG >> Refer to AT-195, "

Vehicle Does Not Creep Backward in “R” Position" .

2. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)"

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 3.

3. CHECK ACCELERATOR PEDAL POSITION (APP) SENSOR

Check accelerator pedal position (APP) sensor. Refer to AT- 11 3 , "

DTC P0705 PARK/NEUTRAL POSITION

SWITCH"

OK or NG

OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position (APP) sensor.

4. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 5.

NG >> Refill ATF.

5. CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT- 5 5 , "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 8.

NG - 1 >> Line pressure high: GO TO 6.

NG - 2 >> Line pressure low: GO TO 7.

Page 280 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-201

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

12. DETECT MALFUNCTIONING ITEM

Check malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT- 6 4 ,

"Symptom Chart" (Symptom No.23).

OK or NG

OK >> GO TO 10.

NG >> Repair or replace damaged parts.

A/T Does Not Shift: D1 D2NCS001Q7

SYMPTOM:

The vehicle does not shift-up from the D1 to D2 gear at the specified speed.

DIAGNOSTIC PROCEDURE

1. CONFIRM THE SYMPTOM

Check if vehicle creep forward in “D” position and vehicle can be started from D

1.

OK or NG

OK >> GO TO 2.

NG >> Refer to AT- 1 9 7 , "

Vehicle Does Not Creep Forward in “D” Position" , AT- 1 9 9 , "Vehicle Cannot Be

Started from D1" .

2. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)"

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 3.

3. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4. CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT- 5 5 , "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 7.

NG - 1 >> Line pressure high: GO TO 5.

NG - 2 >> Line pressure low: GO TO 6.

5. DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT- 2 3 6 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2" .

2. Disassemble A/T. Refer to AT-298, "

DISASSEMBLY" .

3. Check the following.

–Oil pump assembly. Refer to AT-318, "Oil Pump" .

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Page 282 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-203

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

A/T Does Not Shift: D2 D3NCS001Q8

SYMPTOM:

The vehicle does not shift-up from D2 to D3 gear at the specified speed.

DIAGNOSTIC PROCEDURE

1. CONFIRM THE SYMPTOM

Check if vehicle creep forward in “D” position and vehicle can be started from D

1.

OK or NG

OK >> GO TO 2.

NG >> Refer to AT- 1 9 7 , "

Vehicle Does Not Creep Forward in “D” Position" , AT- 1 9 9 , "Vehicle Cannot Be

Started from D1" .

2. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)"

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 3.

3. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4. CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT- 5 5 , "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 7.

NG - 1 >> Line pressure high: GO TO 5.

NG - 2 >> Line pressure low: GO TO 6.

5. DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT- 2 3 6 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2" .

2. Disassemble A/T. Refer to AT-298, "

DISASSEMBLY" .

3. Check the following.

–Oil pump assembly. Refer to AT-318, "Oil Pump" .

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Page 284 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-205

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

A/T Does Not Shift: D3 D4NCS001Q9

SYMPTOM:

The vehicle does not shift-up from the D3 to D4 gear at the specified speed.

DIAGNOSTIC PROCEDURE

1. CONFIRM THE SYMPTOM

Check if vehicle creep forward in “D” position and vehicle can be started from D

1.

OK or NG

OK >> GO TO 2.

NG >> Refer to AT- 1 9 7 , "

Vehicle Does Not Creep Forward in “D” Position" , AT- 1 9 9 , "Vehicle Cannot Be

Started from D1" .

2. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)"

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 3.

3. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4. CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT- 5 5 , "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 7.

NG - 1 >> Line pressure high: GO TO 5.

NG - 2 >> Line pressure low: GO TO 6.

5. DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT- 2 3 6 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2" .

2. Disassemble A/T. Refer to AT-298, "

DISASSEMBLY" .

3. Check the following.

–Oil pump assembly. Refer to AT-318, "Oil Pump" .

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Page 286 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-207

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

A/T Does Not Shift: D4 D5NCS001QA

SYMPTOM:

The vehicle does not shift-up from the D4 to D5 gear at the specified speed.

The vehicle does not shift-up from the D4 to D5 gear unless A/T is warmed up.

DIAGNOSTIC PROCEDURE

1. CONFIRM THE SYMPTOM

Check if vehicle creep forward in “D” position and vehicle can be started from D

1.

OK or NG

OK >> GO TO 2.

NG >> Refer to AT- 1 9 7 , "

Vehicle Does Not Creep Forward in “D” Position" , AT- 1 9 9 , "Vehicle Cannot Be

Started from D1" .

2. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)"

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 3.

3. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4. CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT- 5 5 , "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 7.

NG - 1 >> Line pressure high: GO TO 5.

NG - 2 >> Line pressure low: GO TO 6.

5. DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT- 2 3 6 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2" .

2. Disassemble A/T. Refer to AT-298, "

DISASSEMBLY" .

3. Check the following.

–Oil pump assembly. Refer to AT-318, "Oil Pump" .

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Page 288 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-209

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

A/T Does Not Lock-UpNCS001QB

SYMPTOM:

A/T does not lock-up at the specified speed.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)" .

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer to AT- 9 2 , "SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 4 ,

"Judgement Self-diagnosis Code" .

NO >> GO TO 2.

2. CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 1 3 , "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3. CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT- 5 5 , "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 6.

NG - 1 >> Line pressure high: GO TO 4.

NG - 2 >> Line pressure low: GO TO 5.

4. DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT- 2 3 6 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2" .

2. Disassemble A/T. Refer to AT-298, "

DISASSEMBLY" .

3. Check the following.

–Oil pump assembly. Refer to AT-318, "Oil Pump" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5. DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT- 2 3 6 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2" .

2. Disassemble A/T. Refer to AT-298, "

DISASSEMBLY" .

3. Check the following.

–Oil pump assembly. Refer to AT-318, "Oil Pump" .

–Power train system. Refer to AT-298, "DISASSEMBLY" .

–Transmission case. Refer to AT- 2 9 8 , "DISASSEMBLY" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

Page 316 of 5621

ON-VEHICLE SERVICE

AT-237

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

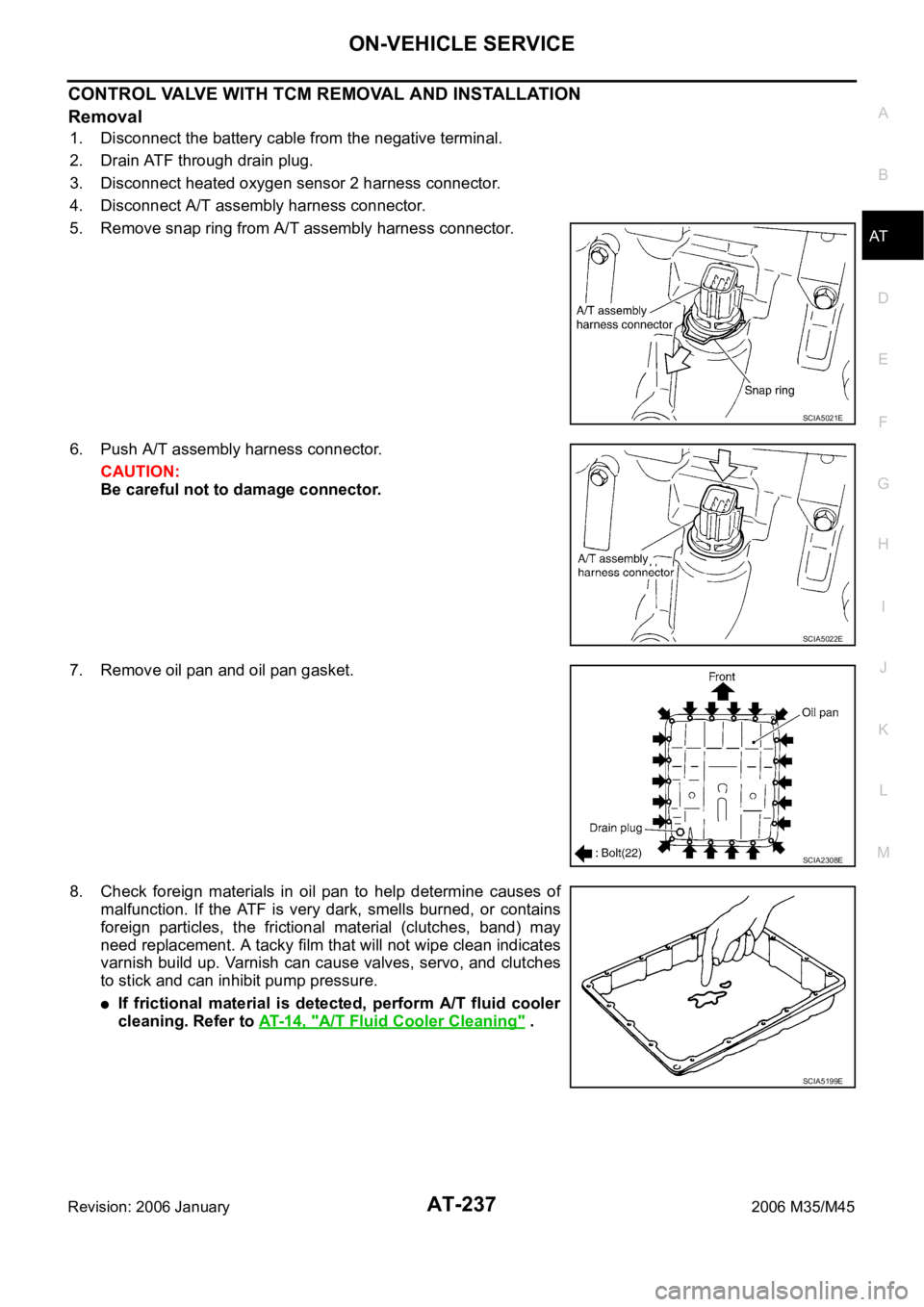

CONTROL VALVE WITH TCM REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery cable from the negative terminal.

2. Drain ATF through drain plug.

3. Disconnect heated oxygen sensor 2 harness connector.

4. Disconnect A/T assembly harness connector.

5. Remove snap ring from A/T assembly harness connector.

6. Push A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

7. Remove oil pan and oil pan gasket.

8. Check foreign materials in oil pan to help determine causes of

malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can cause valves, servo, and clutches

to stick and can inhibit pump pressure.

If frictional material is detected, perform A/T fluid cooler

cleaning. Refer to AT- 1 4 , "

A/T Fluid Cooler Cleaning" .

SCIA5021E

SCIA5022E

SCIA2308E

SCIA5199E