ground INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3637 of 5621

GW-118

REVERSE INTERLOCK DOOR MIRROR SYSTEM

Revision: 2006 January2006 M35/M45

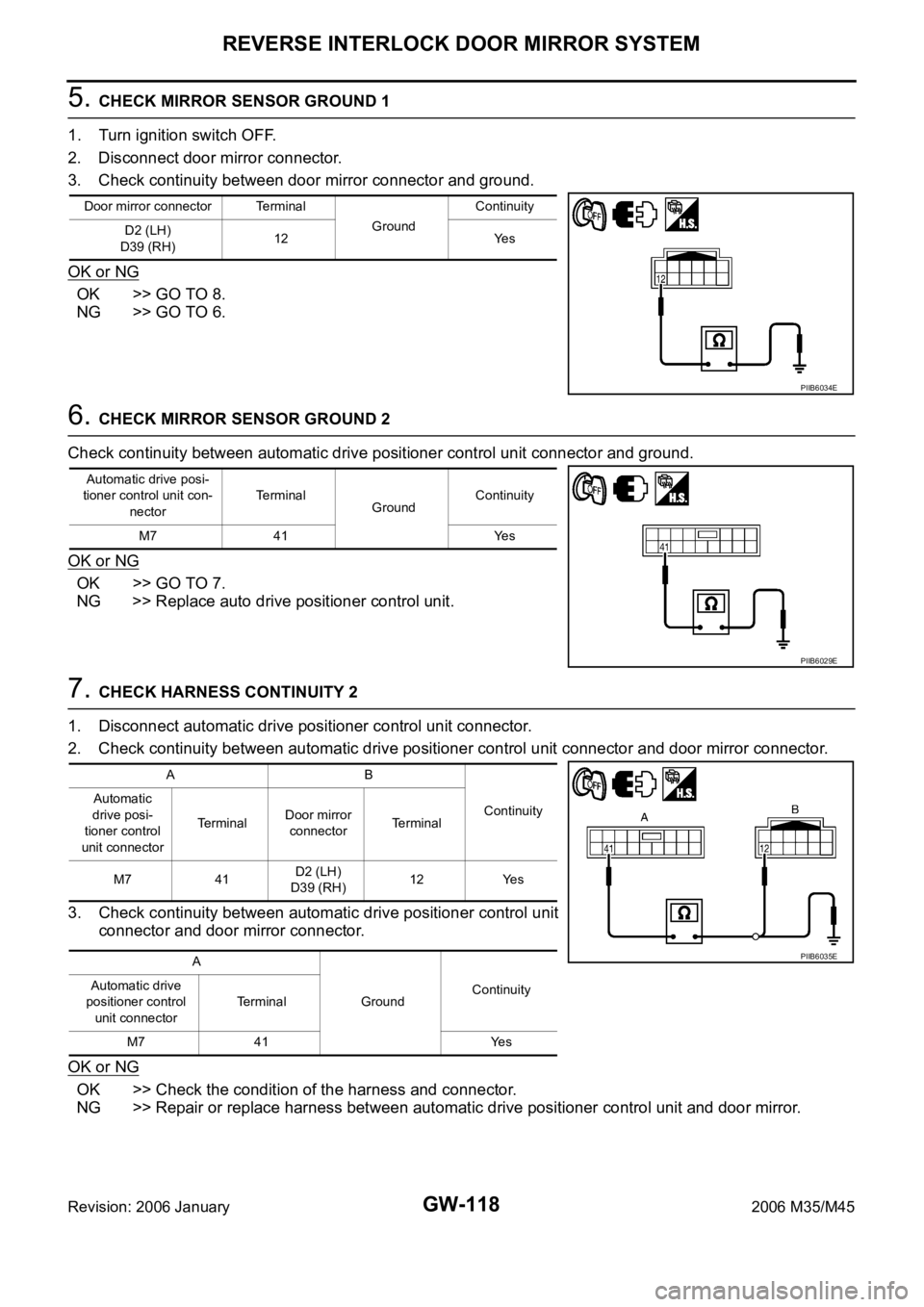

5. CHECK MIRROR SENSOR GROUND 1

1. Turn ignition switch OFF.

2. Disconnect door mirror connector.

3. Check continuity between door mirror connector and ground.

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

6. CHECK MIRROR SENSOR GROUND 2

Check continuity between automatic drive positioner control unit connector and ground.

OK or NG

OK >> GO TO 7.

NG >> Replace auto drive positioner control unit.

7. CHECK HARNESS CONTINUITY 2

1. Disconnect automatic drive positioner control unit connector.

2. Check continuity between automatic drive positioner control unit connector and door mirror connector.

3. Check continuity between automatic drive positioner control unit

connector and door mirror connector.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror.

Door mirror connector Terminal

GroundContinuity

D2 (LH)

D39 (RH)12 Yes

PIIB6034E

Automatic drive posi-

tioner control unit con-

nectorTerminal

GroundContinuity

M7 41 Yes

PIIB6029E

AB

Continuity Automatic

drive posi-

tioner control

unit connectorTerminalDoor mirror

connectorTerminal

M7 41D2 (LH)

D39 (RH)12 Yes

A

GroundContinuity Automatic drive

positioner control

unit connectorTerminal

M7 41 Yes

PIIB6035E

Page 3638 of 5621

REVERSE INTERLOCK DOOR MIRROR SYSTEM

GW-119

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

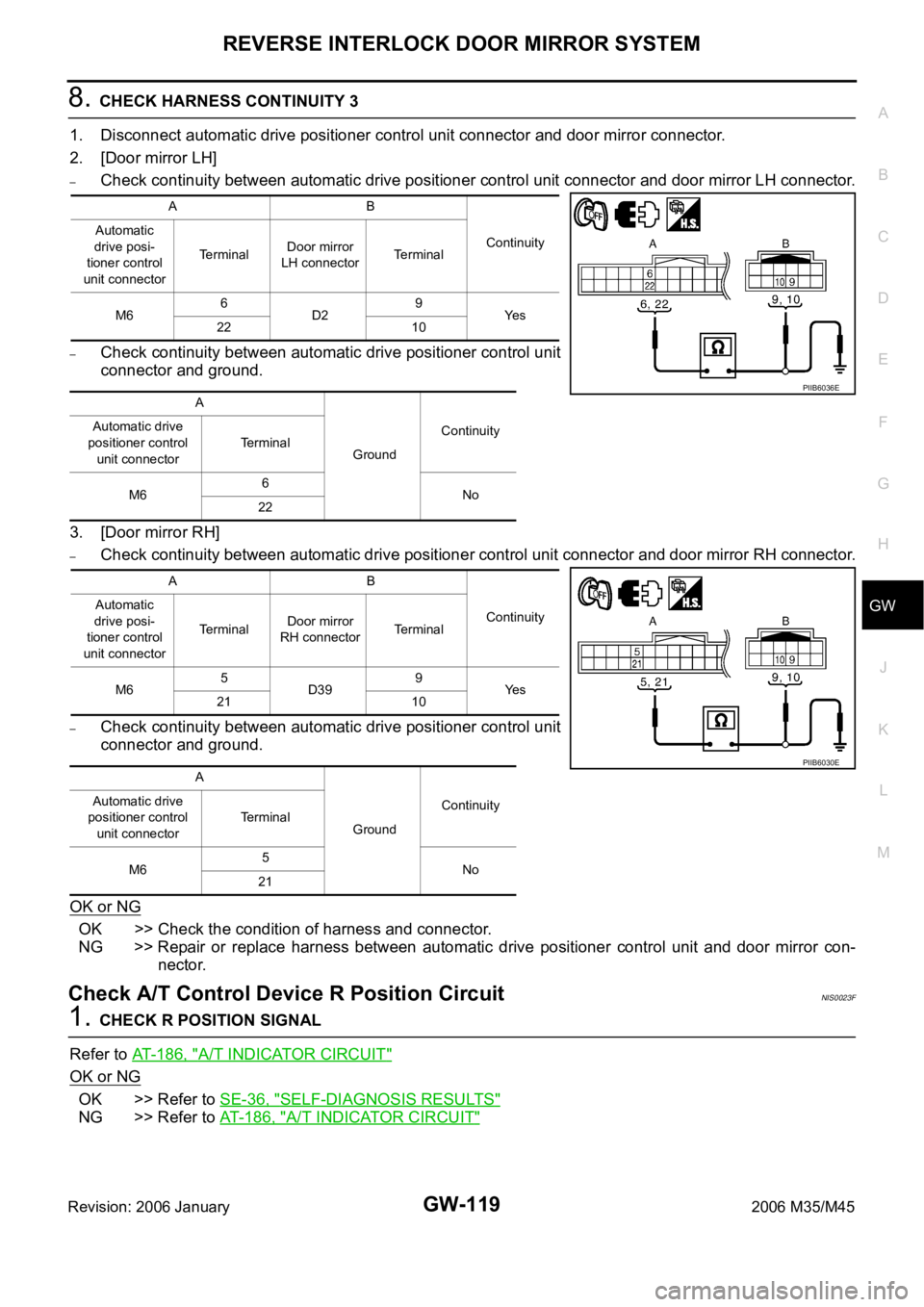

8. CHECK HARNESS CONTINUITY 3

1. Disconnect automatic drive positioner control unit connector and door mirror connector.

2. [Door mirror LH]

–Check continuity between automatic drive positioner control unit connector and door mirror LH connector.

–Check continuity between automatic drive positioner control unit

connector and ground.

3. [Door mirror RH]

–Check continuity between automatic drive positioner control unit connector and door mirror RH connector.

–Check continuity between automatic drive positioner control unit

connector and ground.

OK or NG

OK >> Check the condition of harness and connector.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror con-

nector.

Check A/T Control Device R Position CircuitNIS0023F

1. CHECK R POSITION SIGNAL

Refer to AT-186, "

A/T INDICATOR CIRCUIT"

OK or NG

OK >> Refer to SE-36, "SELF-DIAGNOSIS RESULTS"

NG >> Refer to AT-186, "A/T INDICATOR CIRCUIT"

AB

Continuity Automatic

drive posi-

tioner control

unit connectorTerminalDoor mirror

LH connectorTerminal

M66

D29

Ye s

22 10

A

GroundContinuity Automatic drive

positioner control

unit connectorTerminal

M66

No

22

AB

Continuity Automatic

drive posi-

tioner control

unit connectorTerminalDoor mirror

RH connectorTerminal

M65

D399

Ye s

21 10

A

GroundContinuity Automatic drive

positioner control

unit connectorTerminal

M65

No

21

PIIB6036E

PIIB6030E

Page 3645 of 5621

IDX-4

ALPHABETICAL INDEX

Electronic ignition (EI) system ............. EC-33, EC-743

Engine control module (ECM) .......... EC-496, EC-1215

Engine control system diagram ........... EC-30, EC-740

Engine coolant temperature sensor (ECTS) ... EC-226,

EC-238

, EC-948, EC-961

Engine coolant(VK45DE) .................................. CO-40

Engine coolant(VQ35DE) ................................. CO-11

Engine oil filter replacement ............................. MA-26

Engine oil filter replacement(VQ35DE) ............. MA-19

Engine oil precautions .......................................... GI-8

Engine oil replacement(VQ35DE) ..................... MA-18

Engine oil(VK45DE) ........................................... LU-26

Engine oil(VQ35DE) ............................................ LU-7

Engine removal(VK45DE) ............................... EM-244

Engine removal(VQ35DE) .............................. EM-113

Engine room cover ............................................ EM-14

Engine room cover(VK45DE) ......................... EM-173

ETC1 - Wiring diagram .................... EC-614, EC-1345

ETC2 - Wiring diagram .................... EC-609, EC-1340

ETC3 - Wiring diagram .................... EC-620, EC-1352

EVAP canister ...................................... EC-42, EC-752

EVAP canister purge volume control solenoid valve ....

EC-412

, EC-420, EC-1132, EC-1140

EVAP canister vent control valve ...... EC-427, EC-434,

EC-1147

, EC-1154

EVAP control system (small leak) diagnosis .. EC-403,

EC-466

, EC-1124, EC-1185

EVAP control system pressure sensor ........... EC-440,

EC-443

, EC-450, EC-1160, EC-1163, EC-1170

EVAP control system purge flow monitoring diagnosis

EC-398

, EC-1119

EVAP vapor lines inspection ................. MA-21, MA-28

Evaporative emission (EVAP) system . EC-39, EC-749

Evaporator ..................................................... ATC-168

Exhaust manifold(VK45DE) ............................ EM-183

Exhaust system ................................................... EX-3

Exhaust system inspection ..................... EX-3, MA-29

Expansion valve ............................................. ATC-169

F

F/FOG - Wiring diagram ................................... LT-197

F/PUMP - Wiring diagram ................ EC-686, EC-1428

Final drive pre-inspection .................. FFD-16, RFD-19

Final drive removal and installation .. FFD-13, RFD-16

Floor trim ............................................................. EI-50

Flow charts ......................................................... GI-28

Fluid temperature sensor (A/T) ........................ AT-135

Fluorescent leak detector .............................. ATC-170

FPCM - Wiring diagram ................... EC-527, EC-1253

Freeze frame data ............................... EC-59, EC-770

Front brake solenoid valve ................. AT-151, AT-153

Front bumper ...................................................... EI-11

Front combination lamp removal and installation LT-76

Front door ............................. BL-190, BL-196, GW-63

Front passenger air bag .................................. SRS-42

Front seat belt .................................................... SB-30

Front seat belt pre-tensioner ..... SB-2, SRS-3, SRS-47

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-136

FTTS - Wiring diagram .... EC-345, EC-350, EC-1068,

EC-1073

Fuel cut control (at no load high engine speed) EC-34,

EC-744

Fuel filter replacement ......................................... FL-4

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) ......... EC-321, EC-332,

EC-1044

, EC-1055

Fuel injection system (Bank 2) ......... EC-321, EC-332,

EC-1044

, EC-1055

Fuel injector ................................................... EC-1420

Fuel injector and fuel tube(VK45DE) .............. EM-193

Fuel injector and fuel tube(VQ35DE) ................ EM-45

Fuel level sensor EC-475, EC-477, EC-479, EC-1194,

EC-1196

, EC-1198

Fuel line inspection .................................. FL-3, MA-25

Fuel line inspection(VQ35DE) .......................... MA-18

Fuel precautions ................................................... GI-6

Fuel pressure check ........................... EC-98, EC-809

Fuel pressure release ......................... EC-98, EC-809

Fuel pump ....................................... EC-685, EC-1427

Fuel pump and gauge .......................................... FL-4

Fuel pump control module .............. EC-525, EC-1251

Fuel pump dropping resistor ........... EC-525, EC-1251

Fuel system ......................................................... FL-3

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor .......... EC-343, EC-349,

EC-1066

, EC-1072

Fuel tank vacuum relief valve ............. EC-42, EC-752

FUELB1 - Wiring diagram EC-323, EC-334, EC-1046,

EC-1057

FUELB2 - Wiring diagram EC-325, EC-336, EC-1048,

EC-1059

Fuse .................................................................. PG-17

Fuse and fusible link box ................................ PG-112

Fusible link ........................................................ PG-17

G

Gauges ................................................................. DI-5

Generator ........................................................... SC-23

Generator - See Alternator ................................ SC-23

Glass ........................ GW-11, GW-61, GW-63, GW-67

Grille - See Exterior ............................................ EI-16

Ground distribution ........................................... PG-46

H

H/LAMP - Wiring diagram ....................... LT-13

, LT-48

Harness connector .......................................... PG-102

Harness layout .................................................. PG-63

Hazard warning lamp ....................................... LT-211

Headlamp removal and installation .................... LT-76

Headlining - See Roof trim .................................. EI-52

Heated oxygen sensor 2 (bank 1) .... EC-286, EC-297,

EC-310

, EC-1009, EC-1020, EC-1033

Heated oxygen sensor 2 (bank 2) .... EC-286, EC-297,

Page 3678 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN](/img/42/57023/w960_57023-3677.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN A MALFUNCTION IS DETECTED BY CAN COMMUNICATION SYSTEM

CAN communication line is open. (CAN H, CAN L, or both)

CAN communication line is shorted. (Ground, between CAN lines, or other harnesses)

The areas related to CAN communication of unit is malfunctioning.

WHEN A MALFUNCTION IS DETECTED EXCEPT CAN COMMUNICATION SYSTEM

Removal and installation of parts: When the units that perform CAN communication or the sensors related

to CAN communication are removed and installed, malfunction may be detected (or DTC other than CAN

communication may be detected).

Fuse blown out (removed): CAN communication of the unit may be stopped at such time.

Low voltage: If the voltage decreases because of battery discharge when IGN is ON, malfunction may be

detected by self-diagnosis according to the units.

Page 3751 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-82

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

2. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect following connectors.

–ECM connector

–Harness connector M72

–BCM connector

� INFINITI M35 2006 Factory Service Manual LAN-82

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

2. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect following connectors.

–ECM connector

–Harness connector M72

–BCM connector

�](/img/42/57023/w960_57023-3750.png)

LAN-82

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

2. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect following connectors.

–ECM connector

–Harness connector M72

–BCM connector

–Harness connector M61

2. Check continuity between ECM harness connector terminals.

OK or NG

OK >> GO TO 3.

NG >> Check the following harnesses. If any harness is dam-

aged, repair the harness.

Harness between ECM and harness connector M72

Harness between ECM and BCM

Harness between ECM and harness connector M61

3. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector terminals and

ground.

OK or NG

OK >> GO TO 4.

NG >> Check the following harnesses. If any harness is dam-

aged, repair the harness.

Harness between ECM and harness connector M72

Harness between ECM and BCM

Harness between ECM and harness connector M61

4. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect A/T assembly connector.

2. Check continuity between A/T assembly harness connector ter-

minals.

OK or NG

OK >> GO TO 5.

NG >> Repair harness between A/T assembly and harness

connector F102.

ECM connector Terminal Continuity

M71 94 86 No

PKIA9860E

ECM connector Terminal

GroundContinuity

M7194 No

86 No

PKIA9867E

A/T assembly

connectorTerminal Continuity

F42 3 8 No

SKIA6866E

Page 3752 of 5621

![INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-83

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

5. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between A/T assembly harness connector termi-

INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-83

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

5. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between A/T assembly harness connector termi-](/img/42/57023/w960_57023-3751.png)

CAN SYSTEM (TYPE 1)

LAN-83

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

5. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between A/T assembly harness connector termi-

nals and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness between A/T assembly and harness

connector F102.

6. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect following connectors.

–Low tire pressure warning control unit connector

–Steering angle sensor connector

–Intelligent Key unit connector

–Unified meter and A/C amp. connector

–Harness connector M53

–Harness connector M13

2. Check continuity between data link connector terminals.

OK or NG

OK >> GO TO 7.

NG >> Check the following harnesses. If any harness is dam-

aged, repair the harness.

Harness between data link connector and harness

connector M62

Harness between data link connector and low tire pressure warning control unit

Harness between data link connector and steering angle sensor

Harness between data link connector and Intelligent Key unit

Harness between data link connector and unified meter and A/C amp.

Harness between data link connector and harness connector M53

Harness between data link connector and harness connector M13

A/T assembly

connectorTerminal

GroundContinuity

F423No

8No

SKIA6875E

Data link

connectorTerminal Continuity

M60 6 14 No

PKIA9865E

Page 3753 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-84

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

7. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector terminals and ground.

OK or NG

OK >> GO TO 8.

NG >> INFINITI M35 2006 Factory Service Manual LAN-84

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

7. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector terminals and ground.

OK or NG

OK >> GO TO 8.

NG >>](/img/42/57023/w960_57023-3752.png)

LAN-84

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

7. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector terminals and ground.

OK or NG

OK >> GO TO 8.

NG >> Check the following harnesses. If any harness is dam-

aged, repair the harness.

Harness between data link connector and harness

connector M62

Harness between data link connector and low tire pressure warning control unit

Harness between data link connector and steering angle sensor

Harness between data link connector and Intelligent Key unit

Harness between data link connector and unified meter and A/C amp.

Harness between data link connector and harness connector M53

Harness between data link connector and harness connector M13

8. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect AV control unit connector.

2. Check continuity between AV control unit harness connector ter-

minals.

OK or NG

OK >> GO TO 9.

NG >> Repair harness between AV control unit and harness

connector M216.

9. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between AV control unit harness connector termi-

nals and ground.

OK or NG

OK >> GO TO 10.

NG >> Repair harness between AV control unit and harness

connector M216.

Data link

connectorTerminal

GroundContinuity

M606No

14 No

PKIA9872E

AV control unit

connectorTerminal Continuity

M210 71 72 No

PKIC0288E

AV control unit

connectorTerminal

GroundContinuity

M21071 No

72 No

PKIC0291E

Page 3754 of 5621

![INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-85

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

10. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect harness connector B15 and harness connector B3.

2. Chec INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-85

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

10. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect harness connector B15 and harness connector B3.

2. Chec](/img/42/57023/w960_57023-3753.png)

CAN SYSTEM (TYPE 1)

LAN-85

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

10. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect harness connector B15 and harness connector B3.

2. Check continuity between harness connector terminals.

OK or NG

OK >> GO TO 11.

NG >> Check the following harnesses. If any harness is dam-

aged, repair the harness.

Harness between harness connector B15 and har-

ness connector B2

Harness between harness connector B15 and har-

ness connector B3

11 . CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between harness connector terminals and ground.

OK or NG

OK >> GO TO 12.

NG >> Check the following harnesses. If any harness is dam-

aged, repair the harness.

Harness between harness connector B15 and har-

ness connector B2

Harness between harness connector B15 and harness connector B3

12. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect driver seat control unit connector.

2. Check continuity between driver seat control unit harness con-

nector terminals.

OK or NG

OK >> GO TO 13.

NG >> Repair harness between driver seat control unit and har-

ness connector B202.

Harness connector Terminal Continuity

B15 3 19 No

PKIC0292E

Harness connector Terminal

GroundContinuity

B153No

19 No

PKIC0293E

Driver seat

control unit

connectorTerminal Continuity

B204 3 19 No

PKIA6842E

Page 3755 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-86

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

13. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between driver seat control unit harness connector

terminals and ground.

OK or INFINITI M35 2006 Factory Service Manual LAN-86

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

13. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between driver seat control unit harness connector

terminals and ground.

OK or](/img/42/57023/w960_57023-3754.png)

LAN-86

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

13. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between driver seat control unit harness connector

terminals and ground.

OK or NG

OK >> GO TO 14.

NG >> Repair harness between driver seat control unit and har-

ness connector B202.

14. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connector and IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector termi-

nals.

OK or NG

OK >> GO TO 15.

NG >> Check the following harnesses. If any harness is dam-

aged, repair the harness.

Harness between IPDM E/R and harness connector

E105

Harness between IPDM E/R and ABS actuator and electric unit (control unit)

15. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between IPDM E/R harness connector terminals

and ground.

OK or NG

OK >> GO TO 16.

NG >> Check the following harnesses. If any harness is dam-

aged, repair the harness.

Harness between IPDM E/R and harness connector E105

Harness between IPDM E/R and ABS actuator and electric unit (control unit)

Driver seat

control unit

connectorTerminal

GroundContinuity

B2043No

19 No

SKIA5025E

IPDM E/R

connectorTerminal Continuity

E9 49 50 No

PKIC0290E

IPDM E/R

connectorTerminal

GroundContinuity

E949 No

50 No

PKIC0294E

Page 3757 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-88

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

IPDM E/R Ignition Relay Circuit InspectionNKS003YH

Check the following. If no malfunction is found, replace the IPDM E/R.

IPDM E/R p INFINITI M35 2006 Factory Service Manual LAN-88

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

IPDM E/R Ignition Relay Circuit InspectionNKS003YH

Check the following. If no malfunction is found, replace the IPDM E/R.

IPDM E/R p](/img/42/57023/w960_57023-3756.png)

LAN-88

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

IPDM E/R Ignition Relay Circuit InspectionNKS003YH

Check the following. If no malfunction is found, replace the IPDM E/R.

IPDM E/R power supply circuit. Refer to PG-30, "Check IPDM E/R Power Supply and Ground Circuit" .

Ignition power supply circuit. Refer to PG-12, "IGNITION POWER SUPPLY — IGNITION SW. IN “ON”

AND/OR “START”" .