wipers INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 39 of 5621

![INFINITI M35 2006 Factory Service Manual ACS-30

[ICC]

TROUBLE DIAGNOSIS - GENERAL DESCRIPTION

Revision: 2006 January2006 M35/M45

Display Item List

Laser Beam Adjust

For details, refer to ACS-13, "LASER BEAM AIMING ADJUSTMENT" .

SELF- INFINITI M35 2006 Factory Service Manual ACS-30

[ICC]

TROUBLE DIAGNOSIS - GENERAL DESCRIPTION

Revision: 2006 January2006 M35/M45

Display Item List

Laser Beam Adjust

For details, refer to ACS-13, "LASER BEAM AIMING ADJUSTMENT" .

SELF-](/img/42/57023/w960_57023-38.png)

ACS-30

[ICC]

TROUBLE DIAGNOSIS - GENERAL DESCRIPTION

Revision: 2006 January2006 M35/M45

Display Item List

Laser Beam Adjust

For details, refer to ACS-13, "LASER BEAM AIMING ADJUSTMENT" .

SELF-DIAGNOSTIC RESULTS

For details, refer to ACS-39, "Diagnostic Trouble Code (DTC) Chart" .

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch any of “MAIN SIGNALS” and “SELECTION FROM

MENU” on selection screen.

3. Touch “START”.

4. Display the data monitor.

5. Touch “COPY” to print data if necessary.

Monitored Item

: Applicable Cause of cancellation Description

OPERATING WIPER Windshield wipers were operated at HI or LO speed operation.

OPERATING ABS ABS function was operated.

OPERATING TCS TCS function was operated.

OPERATING VDC VDC function was operated.

OPE SW VOLT CIRC Outside the standard control switch input voltage was detected.

ECM CIRCUIT ECM did not permit ICC operation.

LASER SUN BEAM Intense light such as sunlight entered ICC sensor integrated unit light sensing part.

LASER TEMP Temperature around ICC sensor integrated unit became low.

OP SW DOUBLE TOUCH ICC steering switches were pressed at the same time.

WHL SPD ELEC NOISE Wheel speed sensor signal caught electromagnetic noise.

VDC/TCS OFF SW VDC OFF switch was pressed.

WHEEL SPD UNMATCH Wheel speed became different from A/T vehicle speed.

TIRE SLIP Wheel slipped.

IGN LOW VOLT Power supply voltage became low.

SNOW MODE SW Snow mode switch was pressed.

VHCL SPD DOWN Vehicle speed becomes 20 MPH (32 km/h for CANADA models) and under.

VHCL SPD UNMATCH Vehicle speed becomes unusual.

NO RECORD —

PKIB8365E

Monitored Item [unit]MAIN

SIGNALSSELEC-

TION FROM

MENUDescription

VHCL SPEED SE

[km/h] or [mph]

Indicates vehicle speed calculated from ICC sensor integrated unit through

CAN communication [ABS actuator and electric unit (control unit) transmits

vehicle speed signal (wheel speed) through CAN communication].

SET VHCL SPD

[km/h] or [mph]

Indicates set vehicle speed memorized in ICC sensor integrated unit.

THRTL OPENING

[%]

Indicates throttle position read from ICC sensor integrated unit through CAN

communication (ECM transmits accelerator pedal position signal through

CAN communication).

Page 4782 of 5621

GENERAL MAINTENANCE

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

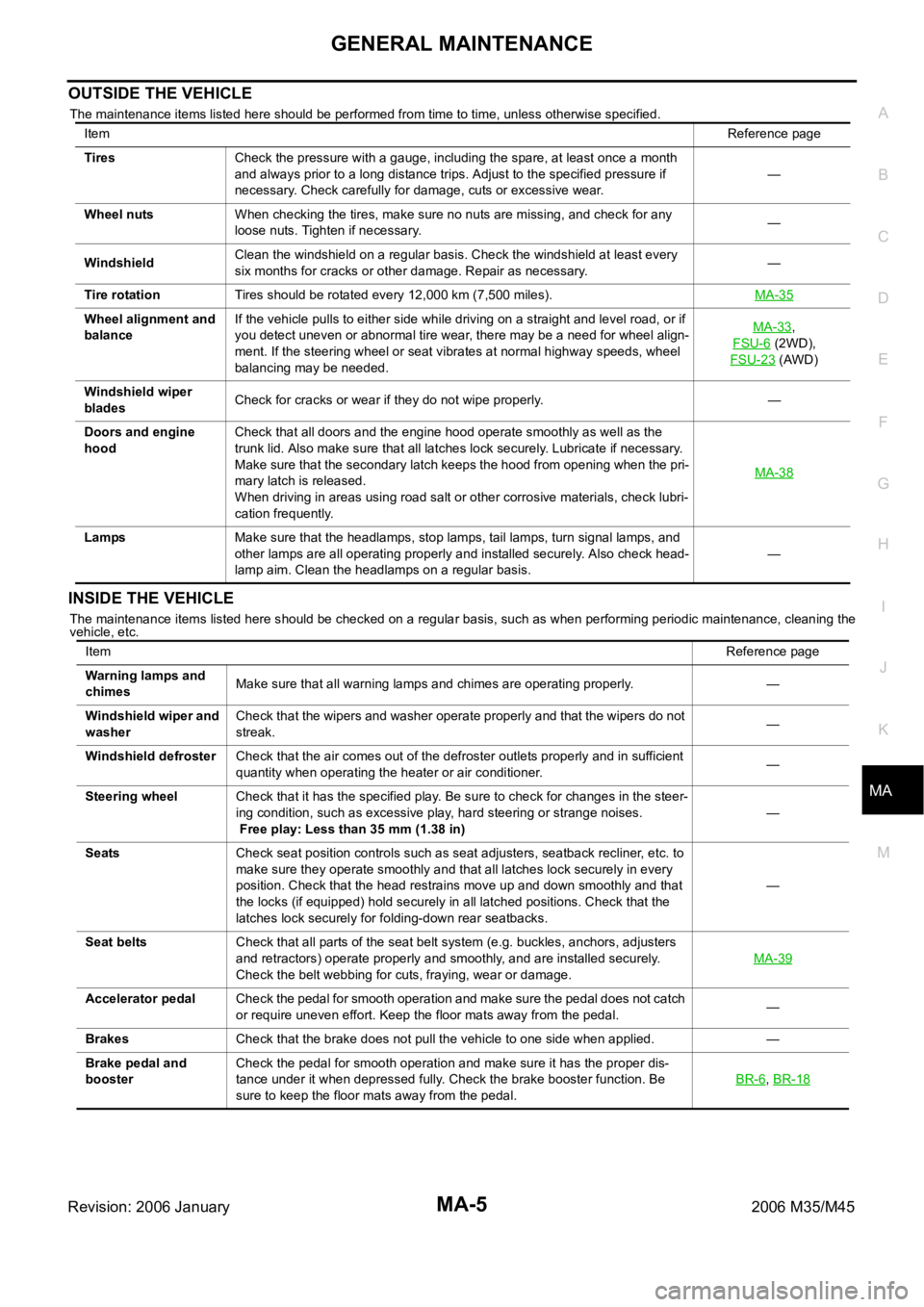

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.ItemReference page

TiresCheck the pressure with a gauge, including the spare, at least once a month

and always prior to a long distance trips. Adjust to the specified pressure if

necessary. Check carefully for damage, cuts or excessive wear.—

Wheel nutsWhen checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.—

WindshieldClean the windshield on a regular basis. Check the windshield at least every

six months for cracks or other damage. Repair as necessary.—

Tire rotationTires should be rotated every 12,000 km (7,500 miles).MA-35

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel

balancing may be needed.MA-33,

FSU-6

(2WD),

FSU-23

(AWD)

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly. —

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the

trunk lid. Also make sure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the pri-

mary latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently.MA-38

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

ItemReference page

Warning lamps and

chimesMake sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.—

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner.—

Steering wheelCheck that it has the specified play. Be sure to check for changes in the steer-

ing condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for folding-down rear seatbacks.—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.MA-39

Accelerator pedalCheck the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal.—

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

boosterCheck the pedal for smooth operation and make sure it has the proper dis-

tance under it when depressed fully. Check the brake booster function. Be

sure to keep the floor mats away from the pedal.BR-6

, BR-18

Page 4845 of 5621

PG-18

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Revision: 2006 January2006 M35/M45

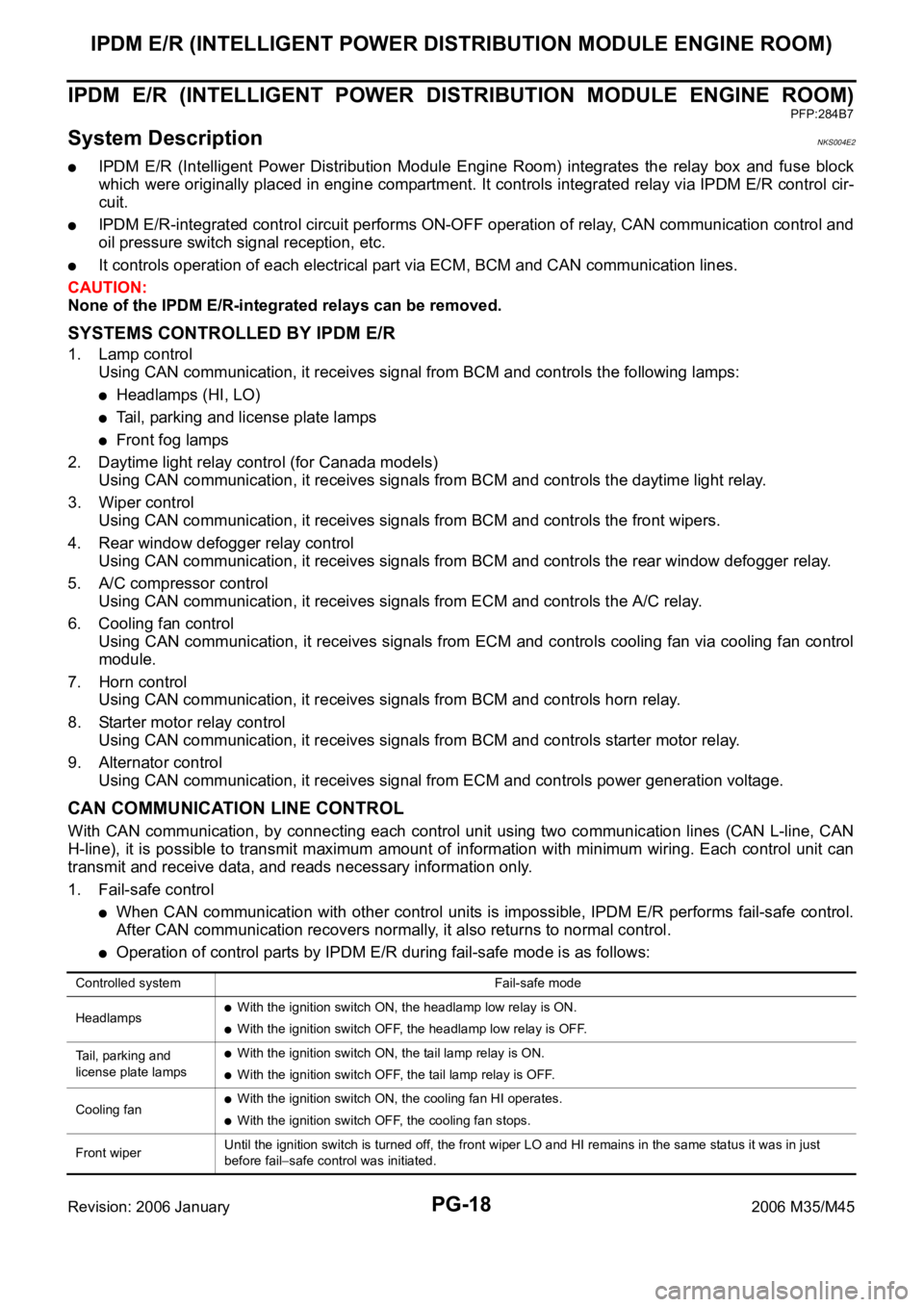

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PFP:284B7

System DescriptionNKS004E2

IPDM E/R (Intelligent Power Distribution Module Engine Room) integrates the relay box and fuse block

which were originally placed in engine compartment. It controls integrated relay via IPDM E/R control cir-

cuit.

IPDM E/R-integrated control circuit performs ON-OFF operation of relay, CAN communication control and

oil pressure switch signal reception, etc.

It controls operation of each electrical part via ECM, BCM and CAN communication lines.

CAUTION:

None of the IPDM E/R-integrated relays can be removed.

SYSTEMS CONTROLLED BY IPDM E/R

1. Lamp control

Using CAN communication, it receives signal from BCM and controls the following lamps:

Headlamps (HI, LO)

Tail, parking and license plate lamps

Front fog lamps

2. Daytime light relay control (for Canada models)

Using CAN communication, it receives signals from BCM and controls the daytime light relay.

3. Wiper control

Using CAN communication, it receives signals from BCM and controls the front wipers.

4. Rear window defogger relay control

Using CAN communication, it receives signals from BCM and controls the rear window defogger relay.

5. A/C compressor control

Using CAN communication, it receives signals from ECM and controls the A/C relay.

6. Cooling fan control

Using CAN communication, it receives signals from ECM and controls cooling fan via cooling fan control

module.

7. Horn control

Using CAN communication, it receives signals from BCM and controls horn relay.

8. Starter motor relay control

Using CAN communication, it receives signals from BCM and controls starter motor relay.

9. Alternator control

Using CAN communication, it receives signal from ECM and controls power generation voltage.

CAN COMMUNICATION LINE CONTROL

With CAN communication, by connecting each control unit using two communication lines (CAN L-line, CAN

H-line), it is possible to transmit maximum amount of information with minimum wiring. Each control unit can

transmit and receive data, and reads necessary information only.

1. Fail-safe control

When CAN communication with other control units is impossible, IPDM E/R performs fail-safe control.

After CAN communication recovers normally, it also returns to normal control.

Operation of control parts by IPDM E/R during fail-safe mode is as follows:

Controlled system Fail-safe mode

Headlamps

With the ignition switch ON, the headlamp low relay is ON.

With the ignition switch OFF, the headlamp low relay is OFF.

Tail, parking and

license plate lamps

With the ignition switch ON, the tail lamp relay is ON.

With the ignition switch OFF, the tail lamp relay is OFF.

Cooling fan

With the ignition switch ON, the cooling fan HI operates.

With the ignition switch OFF, the cooling fan stops.

Front wiperUntil the ignition switch is turned off, the front wiper LO and HI remains in the same status it was in just

before fail

safe control was initiated.

Page 4853 of 5621

PG-26

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Revision: 2006 January2006 M35/M45

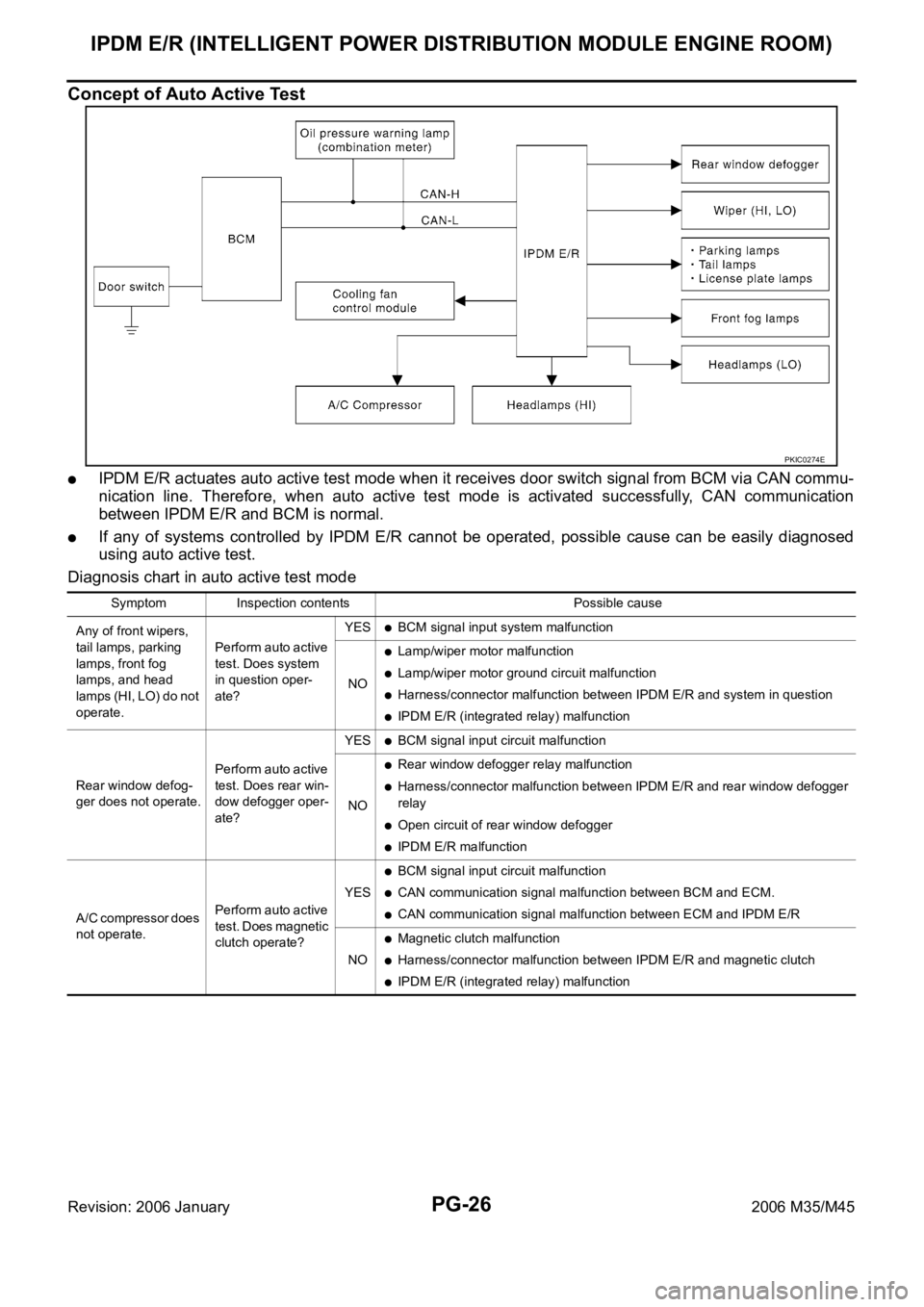

Concept of Auto Active Test

IPDM E/R actuates auto active test mode when it receives door switch signal from BCM via CAN commu-

nication line. Therefore, when auto active test mode is activated successfully, CAN communication

between IPDM E/R and BCM is normal.

If any of systems controlled by IPDM E/R cannot be operated, possible cause can be easily diagnosed

using auto active test.

Diagnosis chart in auto active test mode

PKIC0274E

Symptom Inspection contents Possible cause

Any of front wipers,

tail lamps, parking

lamps, front fog

lamps, and head

lamps (HI, LO) do not

operate.Perform auto active

test. Does system

in question oper-

ate?YES

BCM signal input system malfunction

NO

Lamp/wiper motor malfunction

Lamp/wiper motor ground circuit malfunction

Harness/connector malfunction between IPDM E/R and system in question

IPDM E/R (integrated relay) malfunction

Rear window defog-

ger does not operate.Perform auto active

test. Does rear win-

dow defogger oper-

ate?YES

BCM signal input circuit malfunction

NO

Rear window defogger relay malfunction

Harness/connector malfunction between IPDM E/R and rear window defogger

relay

Open circuit of rear window defogger

IPDM E/R malfunction

A/C compressor does

not operate.Perform auto active

test. Does magnetic

clutch operate?YES

BCM signal input circuit malfunction

CAN communication signal malfunction between BCM and ECM.

CAN communication signal malfunction between ECM and IPDM E/R

NO

Magnetic clutch malfunction

Harness/connector malfunction between IPDM E/R and magnetic clutch

IPDM E/R (integrated relay) malfunction

Page 5165 of 5621

SC-28

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

Trouble Diagnoses with Battery/Starting/Charging System Tester (Charging)NKS003NP

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and alternator test segments must be done

as a set from start to finish.

Before starting, perform the preliminary inspection. Refer to SC-32, "

PRELIMINARY INSPECTION" .

1. Stop the operation of the power generation voltage variable control in either of the following procedures.

After selecting “ENGINE” of “SELECT SYSTEM” using CONSULT-II, set the DUTY value of “ALTERNA-

TOR DUTY” to 0% by selecting “ALTERNATOR DUTY” of “ACTIVE TEST”. Continue “ACTIVE TEST”

until the end of inspection. (When the DUTY value is 0 or 100%, the normal power generation is per-

formed according to the characteristic of the IC regulator of the alternator.)

Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC

(P1550 - P1554) of the engine might remain. After finishing the inspection, connect the battery current

sensor connector and erase the self-diagnostic results history of the engine using CONSULT-II.]

2. Turn off all loads on the vehicle electrical system.

3. Perform battery and starting system test with Battery/Starting/

Charging system tester.

4. Press “ENTER” to begin the charging system test.

5. Start engine.

6. Press “ENTER” until “LOADS OFF REV ENGINE 5 SEC” is dis-

played.

7. Raise and hold the engine speed at 1,500 to 2,000 rpm for about

5 seconds, then return the engine to idle.

Once the increase in engine rpm is detected, press “ENTER” to

continue.

NOTE:

If after 30 seconds an increase in engine idle speed is not

detected, “RPM NOT DETECTED” will display.

Some engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect

this without any other action being taken. If this occurs, con-

tinue on with the testing process. The final results will not be affected.

8. The tester now checks the engine at idle and performs the

DIODE/RIPPLE check.

9. When complete, the tester will prompt you to turn on the follow-

ing electrical loads.

Heater fan set to highest speed. Do not run the A/C or wind-

shield defroster.

Headlamp high beam

Rear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads.

SEL417X

SEL418X

SEL419X

Page 5574 of 5621

FRONT WIPER AND WASHER SYSTEM

WW-7

C

D

E

F

G

H

I

J

L

MA

B

WW

Revision: 2006 January2006 M35/M45

AUTO STOP OPERATION

With wiper switch turned OFF, wiper motor will continue to operate until wiper arms reach windshield base.

When wiper arms are not located at base of windshield with wiper switch OFF, ground is provided

from IPDM E/R terminal 23

to front wiper motor terminal 3, in order to continue wiper motor operation at low speed.

When wiper arms reach base of windshield, front wiper motor terminals 4 and 5 are connected

to IPDM E/R terminal 32

through front wiper motor terminals 4 and 5.

Then the IPDM E/R sends auto stop operation signal to BCM with CAN communication line.

When BCM receives auto stop operation signal, BCM sends wiper stop signal to IPDM E/R with CAN commu-

nication line.

IPDM E/R stops wiper motor. Wiper motor will then stop wiper arms at the STOP position.

WAS H ER O P E R ATI O N

When wiper switch is in front wiper washer position with ignition switch ON, BCM detects front wiper washer

signal by BCM wiper switch reading function (refer to BCS-3, "

COMBINATION SWITCH READING FUNC-

TION" ). Combination switch ground is supplied

to front washer motor terminal 2

through combination switch terminal 14

to combination switch terminal 12

through grounds M16 and M70.

And power is supplied

through combination switch terminal 13

to front washer motor terminal 1.

With power and ground supplied, front washer motor is operated.

When BCM detects that front washer motor has operated for 0.4 seconds or longer, BCM operates front wiper

motor for low speed.

When BCM detects washer switch is OFF, low speed operation cycles approximately 2 times and stops.

MIST OPERATION

When the wiper switch is turned to the MIST position, wiper low speed operation cycles once and then stops.

For additional information about wiper operation under this condition, refer to WW-5, "

LOW SPEED WIPER

OPERATION" .

If the switch is held in the MIST position, low speed operation continues.

FAIL-SAFE FUNCTION

If an abnormality occurs in CAN communications, IPDM E/R holds the condition just before fail-safe status is

initiated until ignition switch is turned OFF. (If wipers were operating in LO just before the initiation of fail-safe

status, they continue to operate in LOW until ignition switch is turned OFF.)

Page 5575 of 5621

WW-8

FRONT WIPER AND WASHER SYSTEM

Revision: 2006 January2006 M35/M45

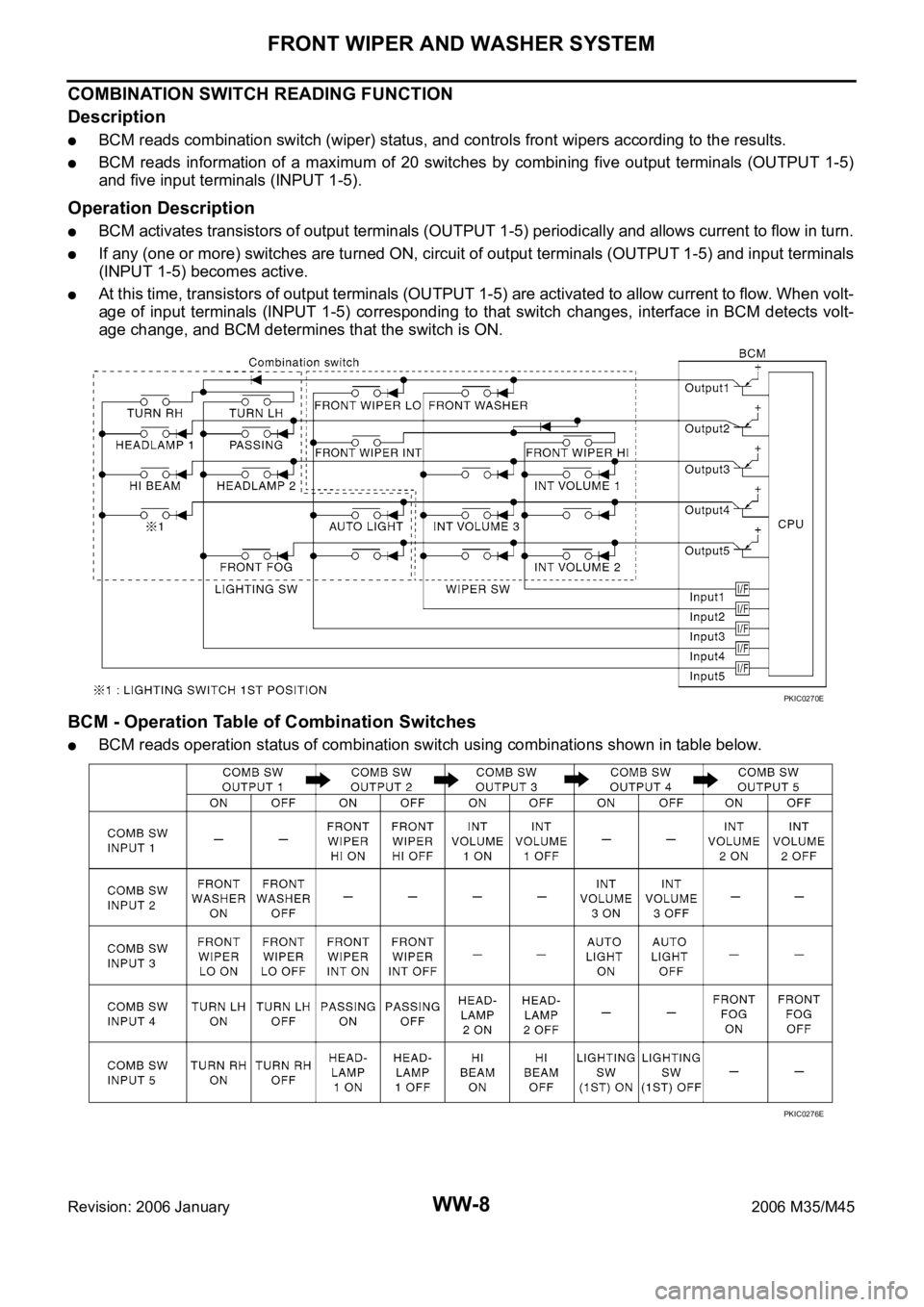

COMBINATION SWITCH READING FUNCTION

Description

BCM reads combination switch (wiper) status, and controls front wipers according to the results.

BCM reads information of a maximum of 20 switches by combining five output terminals (OUTPUT 1-5)

and five input terminals (INPUT 1-5).

Operation Description

BCM activates transistors of output terminals (OUTPUT 1-5) periodically and allows current to flow in turn.

If any (one or more) switches are turned ON, circuit of output terminals (OUTPUT 1-5) and input terminals

(INPUT 1-5) becomes active.

At this time, transistors of output terminals (OUTPUT 1-5) are activated to allow current to flow. When volt-

age of input terminals (INPUT 1-5) corresponding to that switch changes, interface in BCM detects volt-

age change, and BCM determines that the switch is ON.

BCM - Operation Table of Combination Switches

BCM reads operation status of combination switch using combinations shown in table below.

PKIC0270E

PKIC0276E

Page 5595 of 5621

WW-28

FRONT WIPER AND WASHER SYSTEM

Revision: 2006 January2006 M35/M45

Front Wiper Does Not OperateNKS003WN

CAUTION:

During IPDM E/R fail-safe control, front wipers may not operate. Refer to PG-18, "CAN COMMUNI-

CATION LINE CONTROL" in “PG IPDM E/R” to make sure that it is not in fail-safe status.

1. ACTIVE TEST

With CONSULT-II

1. Select “IPDM E/R” by CONSULT-II, and select “ACTIVE TEST”

on “SELECT DIAG MODE” screen.

2. Select “FRONT WIPER” on “SELECT TEST ITEM” screen.

3. Touch “LO” or “HI” screen.

Without CONSULT-II

Start up auto active test. Refer to PG-24, "

Auto Active Test" .

Does front wiper operate normally?

YES >> GO TO 2.

NO >> GO TO 4.

2. CHECK CIRCUIT BETWEEN COMBINATION SWITCH AND BCM

With CONSULT-II

1. Select “BCM” on CONSULT-II, and select “WIPER” on “SELECT

TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

Make sure that “FR WIPER INT”, “FR WIPER LOW”, and “FR

WIPER HI” turn ON-OFF according to wiper switch operation.

Without CONSULT-II

Refer to LT- 2 4 0 , "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 3.

NG >> Check combination switch (wiper switch). Refer to LT-

240, "Combination Switch Inspection" .

3. CHECK CIRCUIT BETWEEN IPDM E/R AND BCM

Select “BCM” on CONSULT-II, and perform self-diagnosis for

“BCM”.

Displayed self

-diagnosis results

NO DTC>>Replace BCM. Refer to BCS-17, "Removal and Installa-

tion of BCM" .

CAN COMM CIRCUIT>>Check CAN communication line of BCM.

Refer to BCS-15, "

CAN Communication Inspection

Using CONSULT-II (Self-Diagnosis)" .

SKIA3486E

PKIB0110E

PKIA7627E

Page 5598 of 5621

FRONT WIPER AND WASHER SYSTEM

WW-31

C

D

E

F

G

H

I

J

L

MA

B

WW

Revision: 2006 January2006 M35/M45

7. CHECK IPDM E/R

With CONSULT-II

1. Connect IPDM E/R connector and front wiper motor connector.

2. Install front wiper reverse relay.

3. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “FRONT WIPER” on “SELECT TEST ITEM” screen.

5. Touch “LO” or “HI” screen.

6. Check voltage between IPDM E/R harness connector and

ground while front wiper (HI, LO) is operating.

Without CONSULT-II

1. Connect IPDM E/R connector and front wiper motor connector.

2. Install front wiper reverse relay.

3. Start up auto active test. Refer to PG-24, "

Auto Active Test" .

4. Check voltage between IPDM E/R harness connector and ground while front wiper (HI, LO) is operating.

OK or NG

OK >> Replace front wiper motor. Refer to WW-43, "Disassembly and Assembly of Front Wiper Drive

Assembly" .

NG >> Replace IPDM E/R. Refer to PG-31, "

Removal and Installation of IPDM E/R" .

Front Wiper Does Not Return to Stop Position (After Front Wiper Operate for 10

Seconds, They Stop for 20 Seconds, and After Repeating the Operations Five

Times, They Become Inoperative)

NKS003WO

CAUTION:

When auto stop signal has not varied for 10 seconds or longer while IPDM E/R is operating front

wipers, IPDM E/R considers that front wipers are locked, and stops wiper output. That causes this

symptom.

This status can be checked by “DATA MONITOR” of “IPDM E/R” on which “WIPER PROTECTION”

item shows “BLOCK”.

Terminal

Condition Voltage (+)

(-)

IPDM E/R

connectorTerminal

E719

GroundStopped

Battery voltage

HI operation

23Stopped Approx. 0V

LO operation Battery voltage

Terminal

Condition Voltage (+)

(-)

IPDM E/R

connectorTerminal

E719

GroundStopped

Battery voltage

HI operation

23Stopped Approx. 0V

LO operation Battery voltage

SKIB4663E

Page 5600 of 5621

FRONT WIPER AND WASHER SYSTEM

WW-33

C

D

E

F

G

H

I

J

L

MA

B

WW

Revision: 2006 January2006 M35/M45

Front Wiper Does Not Return to Stop Position When Front Wiper Motor Oper-

ates at Low Speed (After Front Wiper Operate for 10 Seconds, They Stop for 20

Seconds, and After Repeating the Operations Five Times, They Become Inoper-

ative)

NKS003WP

CAUTION:

When auto stop signal has not varied for 10 seconds or longer while IPDM E/R is operating front

wipers, IPDM E/R considers that front wipers are locked, and stops wiper output. That causes this

symptom.

This status can be checked by “DATA MONITOR” of “IPDM E/R” on which “WIPER PROTECTION”

item shows “BLOCK”.

1. CHECK FRONT WIPER STOP SIGNAL

With CONSULT-II

Select “IPDM E/R” on CONSULT-II. With “DATA MONITOR”, make

sure that “WIP AUTO STOP” turns “ACT P” - “STOP P” linked with

wiper LO operation.

Without CONSULT-II

GO TO 2.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-31, "Removal and

Installation of IPDM E/R" .

NG >> GO TO 2.

2. CHECK IPDM E/R

Check voltage between IPDM E/R harness connector and ground

while front wiper motor is stopped and while front wiper LO is operat-

ing.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-31, "Removal and Installation of IPDM E/R" .

NG >> GO TO 3.

3. CHECK CIRCUIT BETWEEN FRONT WIPER MOTOR AND GROUND

1. Turn ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Check continuity between front wiper motor harness connector

E27 terminal 6 and ground.

OK or NG

OK >> Replace front wiper motor. Refer to WW-43, "Disassem-

bly and Assembly of Front Wiper Drive Assembly" .

NG >> Repair harness or connector.

PKIA7614E

Terminal

Condition Voltage (+)

(-)

IPDM E/R

connectorTe r m i n a l

E7 32 GroundWiper stopped Battery voltage

Wiper operating Approx. 0V

SKIB4665E

6 – Ground : Continuity should exist.

SKIB4667E