ESP INFINITI Q50 HYBRID 2015 First responder´s Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2015, Model line: Q50 HYBRID, Model: INFINITI Q50 HYBRID 2015Pages: 43, PDF Size: 5.82 MB

Page 1 of 43

2015 Q50 HYBRIDFirst Responder’s Guide

Page 2 of 43

Foreword

This manual describes first response operations and related warnings and cautions for this vehicle.

This vehicle is equipped with a high voltage battery pack.Failure to follow recommended practices

during emergency responses will cause death or serious personal injury.

Please read this manual in advance in order to understand the features of this vehicle and to help you deal

with incidents involving this vehicle. Follow the procedures in order to help assure a successful first

response operation.

This manual is periodically updated. If you are not viewing this manual on the Infiniti web site, we urge you to

go to

www.infinitiusa.comorwww.infiniti-techinfo.comto make sure you have the most recent version of this

manual.

INFINITI EMERGENCY CONTACT INFORMATION

• Infiniti Consumer Affairs: 1-800-662-6200 (US) or 1-800-361-4792 (Canada)

• Hours of operation are 8am - 5pm (Monday-Friday) Eastern, Central and Pacific time zones

IMPORTANT INFORMATION ABOUT THIS MANUAL

You may see various symbols in this manual. They have the following meanings:

DANGER

This symbol is used to inform you of an operation which will result in death or serious

personal injury if instructions are not followed.

Example: Touching high voltage components without using the appropriate protective

equipment will result in electrocution. PPE must always be worn when touching or

working on high voltage components.

This symbol is used to inform you of an operation which may cause death or serious

personal injury if instructions are not followed.

This symbol is used to inform you of an operation which may cause personal injury or

component damage if instructions are not followed.

Please note that there may be differences between this manual and the vehicle specification due to

specification changes. FRG–2

Page 3 of 43

Table of Contents

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . FRG–2

INFINITI EMERGENCY CONTACT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–2

IMPORTANT INFORMATION ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–2

1. ABOUT THE INFINITI Q50 HYBRID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–5

1-1 Q50 HYBRID IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–6

1-1.1 EXTERIOR AND ENGINE COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–6

1-1.2 INTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–7

1-2 VEHICLE IDENTIFICATION NUMBER (VIN) LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–8

1-3 WARNING AND INDICATOR LAMP INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–9

2. BASIC HIGH VOLTAGE SYSTEM AND 12-VOLT SYSTEM INFORMATION . . . . . . . . . . . . . . . FRG–10 2-1 BATTERY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–10

2-1.1 12-VOLT BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–10

2-1.2 HIGH VOLTAGE BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–10

2-2 HIGH VOLTAGE-RELATED AND 12-VOLT-RELATED COMPONENT LOCATIONS AND DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–11

2-3 HIGH VOLTAGE BATTERY PACK SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–12

2-4 HIGH VOLTAGE SAFETY MEASURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–13 2-4.1 WARNING LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–13

2-5 HIGH VOLTAGE SAFETY SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–14

2-6 HIGH VOLTAGE CIRCUIT SHUT-OFF SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–15

2-7 PREVENTING ELECTRICAL SHOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–15

2-8 EMERGENCY MEDICAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–15

3. EMERGENCY RESPONSE STEPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–16

3-1 PREPARATION ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–17

3-1.1

PERSONAL PROTECTIVE EQUIPMENT (PPE) PROTECTIVE WEAR CONTROL. . . FRG–17

3-1.2 DAILY INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–18

3-1.3 INSULATED TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–18

3-2 VEHICLE IMMOBILIZATION AND STABILIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–18

3-3 HOW TO HANDLE A DAMAGED VEHICLE AT AN ACCIDENT SCENE . . . . . . . . . . . . . FRG–19 3-3.1 HIGH VOLTAGE SYSTEM SHUT-DOWN PROCEDURE . . . . . . . . . . . . . . . . . . . . FRG–20

3-3.2 WATER SUBMERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–30

3-3.3 VEHICLE FIRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FRG–31

FRG–3

Page 13 of 43

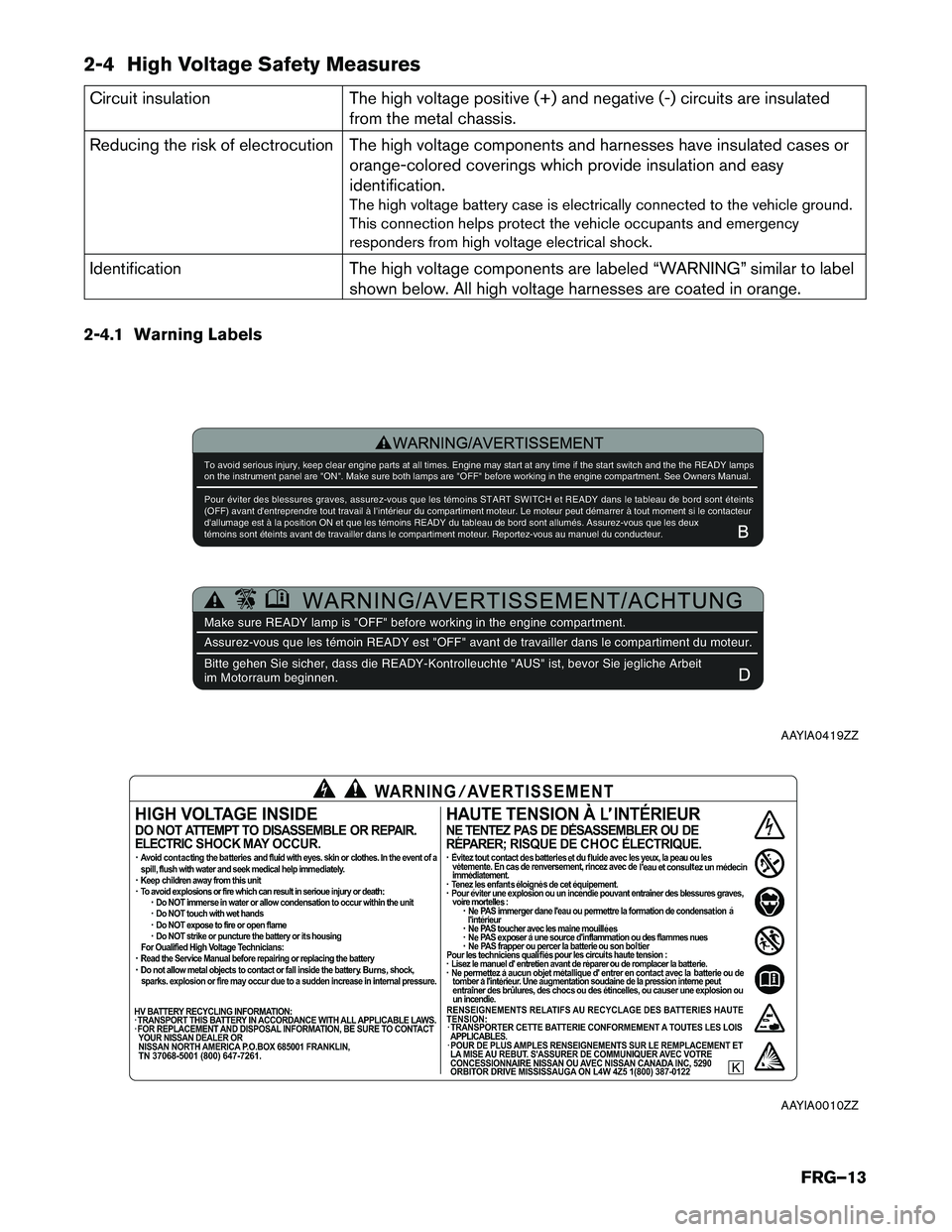

2-4 High Voltage Safety Measures

Circuit insulation The high voltage positive (+) and negative (-) circuits are insulatedfrom the metal chassis.

Reducing the risk of electrocution The high voltage components and harnesses have insulated cases or orange-colored coverings which provide insulation and easy identification.

The high voltage battery case is electrically connected to the vehicle ground.

This connection helps protect the vehicle occupants and emergency

responders from high voltage electrical shock.

Identification The high voltage components are labeled “WARNING” similar to label shown below. All high voltage harnesses are coated in orange.

2-4.1 Warning Labels

WARNING/AVERTISSEMENT

To avoid serious injury, keep clear engine parts at all times. Engine may start at any time if the start switch and the the READY lamps

on the instrument panel are "ON". Make sure both lamps are "OFF" before working in the engine compartment. See Owners Manual.

Pour éviter des blessures graves, assurez-vous que les témoins START SWITCH et READY dans le tableau d e bord sont éteints

(OFF) avant d'entreprendre tout travail à I'intérieur du compartiment moteur. Le moteur peut démarrer à tout moment si le contacteur

d'allumage est à la position ON et que les témoins READY du tableau de bord sont allumés. Assurez-vous que les deux

témoins sont éteints avant de travailler dans le compartiment moteur. Reportez-vous au manuel du conducteur.

B

W A R N I N G / A V E R T I S S E M E N T / A C H T U N G

Make sure READY lamp is "OFF" before working in the engine compartment.

Assurez-vous que les témoin READY est "OFF" avant d e travailler dans le compartiment du moteur.

Bitte gehen Sie sicher, dass die READY-Kontrolleuch te "AUS" ist, bevor Sie jegliche Arbeit

im Motorraum beginnen. D

AAYIA0419ZZ

AAYIA0010ZZ

FRG–13

Page 14 of 43

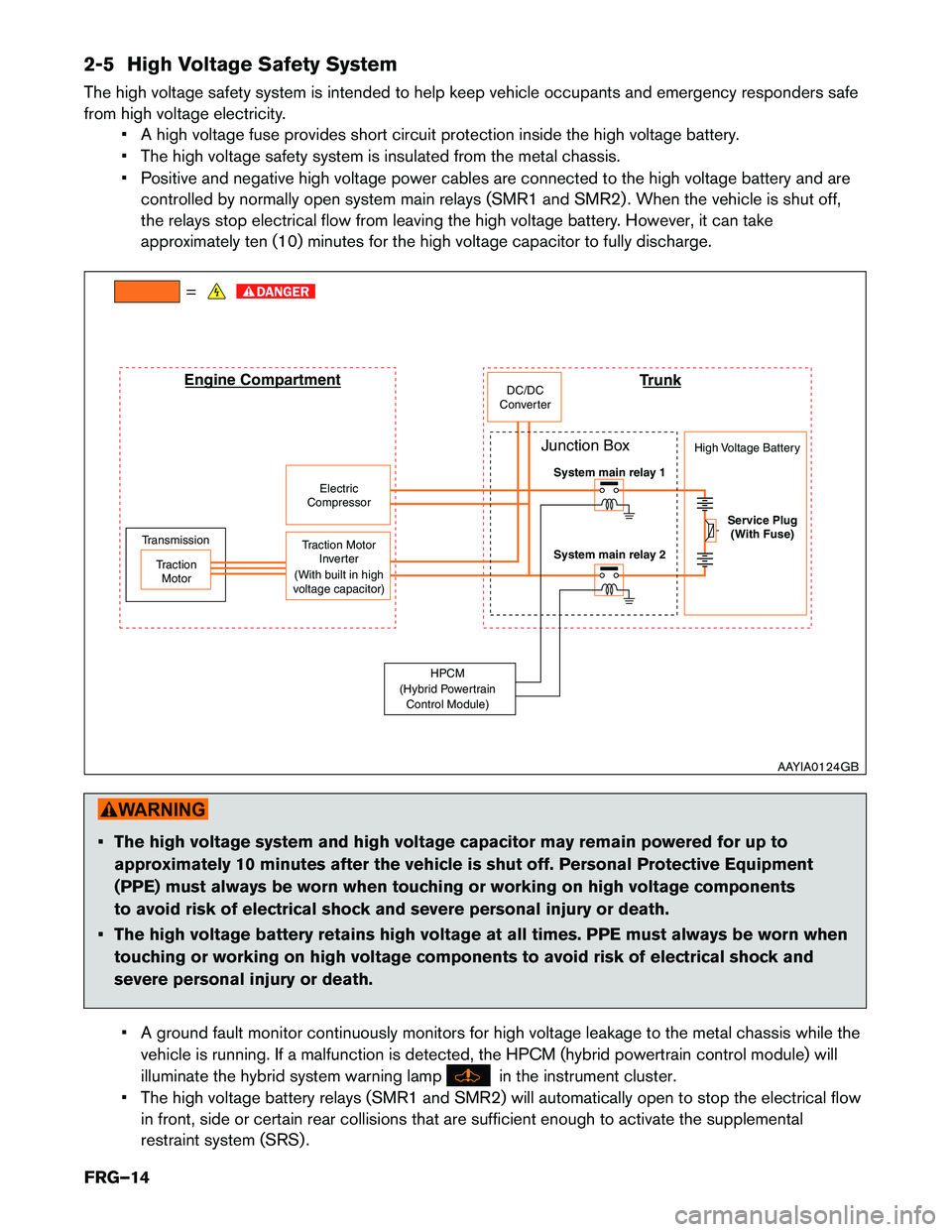

2-5 High Voltage Safety System

The high voltage safety system is intended to help keep vehicle occupants and emergency responders safe

from high voltage electricity.• A high voltage fuse provides short circuit protection inside the high voltage battery.

• The high voltage safety system is insulated from the metal chassis.

• Positive and negative high voltage power cables are connected to the high voltage battery and arecontrolled by normally open system main relays (SMR1 and SMR2) . When the vehicle is shut off,

the relays stop electrical flow from leaving the high voltage battery. However, it can take

approximately ten (10) minutes for the high voltage capacitor to fully discharge.

• The high voltage system and high voltage capacitor may remain powered for up to

approximately 10 minutes after the vehicle is shut off. Personal Protective Equipment

(PPE) must always be worn when touching or working on high voltage components

to avoid risk of electrical shock and severe personal injury or death.

• The high voltage battery retains high voltage at all times. PPE must always be worn when touching or working on high voltage components to avoid risk of electrical shock and

severe personal injury or death.

• A ground fault monitor continuously monitors for high voltage leakage to the metal chassis while the vehicle is running. If a malfunction is detected, the HPCM (hybrid powertrain control module) will

illuminate the hybrid system warning lamp

in the instrument cluster.

• The high voltage battery relays (SMR1 and SMR2) will automatically open to stop the electrical flow in front, side or certain rear collisions that are sufficient enough to activate the supplemental

restraint system (SRS) .

Trunk

Junction Box High Voltage Battery

System main relay 1

Service Plug (With Fuse)

System main relay 2

Transmission

Traction Motor Traction Motor

Inverter

(With built in high

voltage capacitor) Electric

Compressor DC/DC

Converter

Engine Compartment

HPCM

(Hybrid Powertrain Control Module)

AAYIA0124GB

FRG–14

Page 16 of 43

3. Emergency Response Steps

DANGER

•Failure to properly shut down the high voltage electrical system before the

Emergency Response Procedures are performed will result in serious injury or death

from electrical shock. To prevent serious injury or death, NEVER touch high voltage

harnesses or components without always wearing appropriate Personal Protective

Equipment (PPE) . PPE must always be worn when touching or working on high

voltage components.

•

If it is necessary to touch any of the high voltage harnesses or components you

must always wear appropriate PPE to avoid electrical shock. PPE must always beworn

when touching or working on high voltage components. Shut downthe high voltage

system by following the steps outlined in

3-3.1 High Voltage System Shut-Down

Procedure (FRG–20)

Wait approximately ten (10) minutes for complete discharge of

the high voltage capacitor after the high voltage system has been shut down.

• NEVER assume the Q50 HYBRID is shut OFF simply because it is quiet.

• If the READY

indicator is ON thehigh voltage system is active.

• If possible, besure to check the READY

indicator on the instrument cluster and

verify that theREADY

indicatoris OFF and the high voltage system is stopped.

FRG–16

Page 18 of 43

3-1.2 Daily Inspection

This inspection is performed before and after use. The responder who will be using the items should

perform the inspection and check for deterioration and damage.• Insulated rubber gloves should be inspected for scratches, holes and tears. (Visual check and airleakage test)

• Insulated safety boots should be inspected for holes, damage, nails, metal pieces, wear or other problems on the soles. (Visual check)

• Insulated rubber sheet should be inspected for tears. (Visual check)

3-1.3 Insulated Tools

When performing work at locations where high voltage is applied (such as terminals) , use insulated tools

meeting 1,000V/300A specifications.

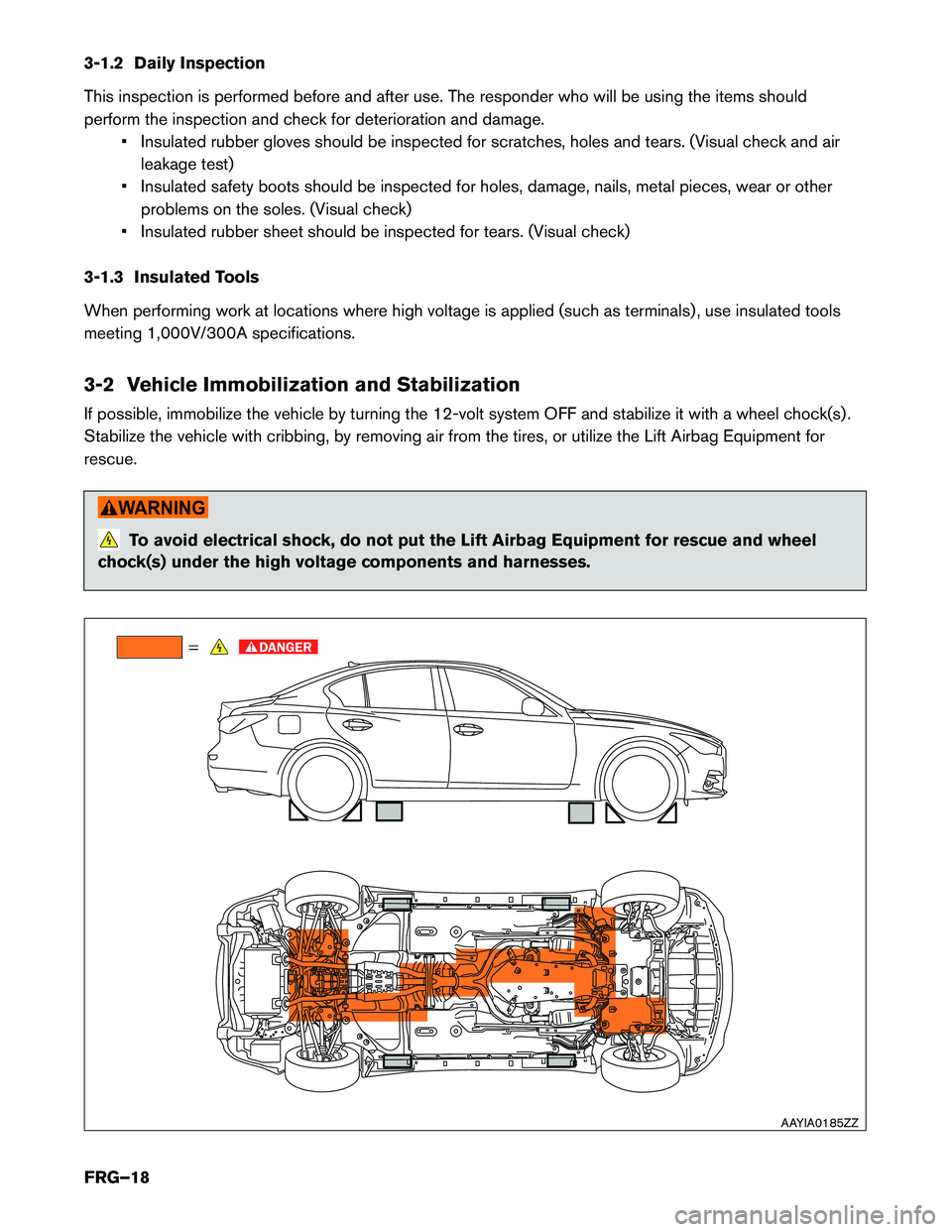

3-2 Vehicle Immobilization and Stabilization

If possible, immobilize the vehicle by turning the 12-volt system OFF and stabilize it with a wheel chock(s) .

Stabilize the vehicle with cribbing, by removing air from the tires, or utilize the Lift Airbag Equipment forrescue.

To avoid electrical shock, do not put the Lift Airbag Equipment for rescue and wheel

chock(s) under the high voltage components and harnesses.

AAYIA0185ZZ

FRG–18

Page 19 of 43

3-3 How to Handle a Damaged Vehicle at an Accident Scene

NOTE:

If any air bags have deployed in the following 3 situations, the high-voltage (HV) system has

been designed to automatically shut off at the time of deployment.

The Infiniti Q50 HYBRID high-voltage system incorporates capacitors which are energized whenever the

high-voltage system is on. If the high-voltage system is shut down (either through one of the built-in

automatic mechanisms or manually through one of the procedures explained in this FRG) , the capacitors

will begin to gradually discharge.Complete discharge requires approximately 10 minutes after

high-voltage system shut down. It is within this period of time that responders must be most cautious.

When arriving to an incident involving an Infiniti Q50 HYBRID, the vehicle should be approached with

caution and inspected for the level of damage. In addition to overall vehicle condition (location and

severity of body damage, air bag deployment, etc.) , the high-voltage system should be assessed

specifically. The locations of the high-voltage component parts are illustrated in this FRG. Refer to

2-2 High Voltage-Related and 12-Volt-Related Component Locations and Descriptions (FRG–11).

Appropriate personal protective equipment (PPE) must always be worn when approaching a vehicle of

unknown condition, as described in this FRG.

Situation 1) High voltage system intact, occupants can be accessed without extrication tools

The HV system can be shut down by following the procedure in this guide, while wearing appropriate PPE.

After HV system shut down, occupant assistance can begin immediately, and no wait period is necessary.

Situation 2) High voltage system intact, occupants cannot be accessed without extrication tools

The HV system can be shut down by following the procedure in this guide, while wearing appropriate PPE.

After HV system shut down, absolute care must be taken never to cut through or damage any HV system

wiring, battery or components within approximately ten (10) minutes of HV system shut down ,

but occupant assistance operations using extrication equipment can begin immediately. The locations of the

HV components are illustrated in this guide.

Situation 3) High-voltage (HV) system damaged

If there is any evidence that the HV system has been compromised (such as arcing/sparking, orange wiring

harnesses cut or damaged, HV component casings damaged, etc.) , the responder may still be at risk of

high voltage exposure. The vehicle must be approached with extreme caution prior to initiating any system

shut down procedures or rendering assistance to occupants. Appropriate PPE must always be worn as

described in this guide, and the approximate ten (10) minute wait time must be observed after

HV system shut down in order to ensure the system is de-energized.

In rare situations where vehicle damage is very severe, HV system shut down procedures as described in

this guide may not work. In these instances extreme caution and appropriate risk management must be

followed to prevent shock or electrocution to the responder or occupant.

FRG–19

Page 20 of 43

3-3.1 High Voltage System Shut-Down Procedure

Any of the following procedures can shut down the high voltage system. The first response operation should

only begin after shutting down the high voltage system. If the vehicle is heavily damaged, for example the

high voltage battery is deformed, broken or cracked, appropriate PPE must always be used and the high

voltage battery and high voltage components must not be touched. PPE must always be worn when

touching or working on high voltage components.

DANGER

•Failure to properly shut down the high voltage system before the Emergency

Response Procedures are performed will result in serious injury or death from electrical

shock. To prevent serious injury or death, NEVER touch high voltage harnesses or

components without always wearing appropriate Personal Protective Equipment (PPE) .

PPE must always be worn when touching or working on high voltage components.

•When contact with high voltage components or high voltage harnesses is

unavoidable, or when there is risk of such contact, you must always wear appropriate

PPE. PPE must always be worn when touching or working on high voltage components.

•The vehicle contains parts that contain powerful magnets. If a person who is wearing

a pacemaker or other medical device is close to these parts, the medical device may be

affected by the magnets. Such persons must not perform work on the vehicle.

• Be sure to verify that the READY

indicator is off (if possible) , and the high voltage

system is stopped.

• After the high voltage system is shut down, please wait approximately ten (10) minutes for complete discharge of the high voltage capacitor. While waiting, do not operate any

vehicle functions.

NOTE:

The high voltage full discharge takes approximately ten (10) minutes.

• After shutting down the high voltage system and removing the 12-volt battery negative (-) terminal, wait at least three (3) minutes to discharge the air bag capacitor. Even though

the 12-volt battery negative (-) is disconnected, the Supplemental Restraint System (SRS)

air bag maintains voltage at least three (3) minutes. During this time, there is a possibility

of sudden SRS air bag inflation due to harness short circuit or damage and it may cause

serious injuries.

• The 12V system will remain active even after the 12-volt battery negative (-) terminal is removed while the high voltage system is active.This is because the charging system

will not shut down and power will be supplied to the 12V system and high voltage systemcontinuously.

Before disconnecting the 12-volt battery terminal, if necessary, lower the windows, adjust the steering

column, adjust the seats, unlock the doors, open the trunk, etc. as required. Once the 12-volt battery is

disconnected, power controls will not operate. FRG–20

Page 23 of 43

6. Open the 12-volt battery service access cover.

7. Disconnect negative (-) battery cable and cover it withinsulated tape.

8. Wait approximately ten (10) minutes for complete discharge of the high voltage capacitor

after the battery cable has been disconnected.

9. Perform the first response action.

AAYIA0195ZZ

AAYIA0196ZZ

FRG–23