steering INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2205 of 2395

SST609C

14. Ensure that the rack is centered. Install rear cover cap so that

its protrusion is positioned as shown in figure.

Be careful not to damage worm ring and oil seal.

15. Install retainer, spring and adjusting screw temporarily.

SST135C

16. Install new lock plate.

IAttach lock plate 2 to side rod inner socket 1.

IApply locking sealant to inner socket threads 3.

Screw inner socket into rack 4 and tighten to specified torque.

IClinch two places of lock plate at rack's groove.

CAUTION:

To prevent scratching the boot, remove burrs from lock plate.

SST655C

17. Tighten outer socket lock nut.

Tie-rod length ªLº:

Refer to SDS, ST-33.

18. Measure rack stroke.

Rack stroke ªSº:

Refer to SDS, ST-33.

SST967A

19. Before installing boot, coat the contact surfaces between boot

and tie-rod with grease.

SST619C

AdjustmentNBST0031Adjust pinion rotating torque as follows:

1. Set rack to the neutral position without fluid in the gear.

2. Coat the adjusting screw with locking sealant and screw it in.

3. Lightly tighten lock nut.

4. Tighten adjusting screw to a torque of 4.9 to 5.9 N´m (50 to 60

kg-cm, 43 to 52 in-lb).

5. Loosen adjusting screw, then retighten it to 0.2 N´m (2 kg-cm,

1.7 in-lb).

POWER STEERING GEAR AND LINKAGE

Assembly (Cont'd)

ST-24

Page 2206 of 2395

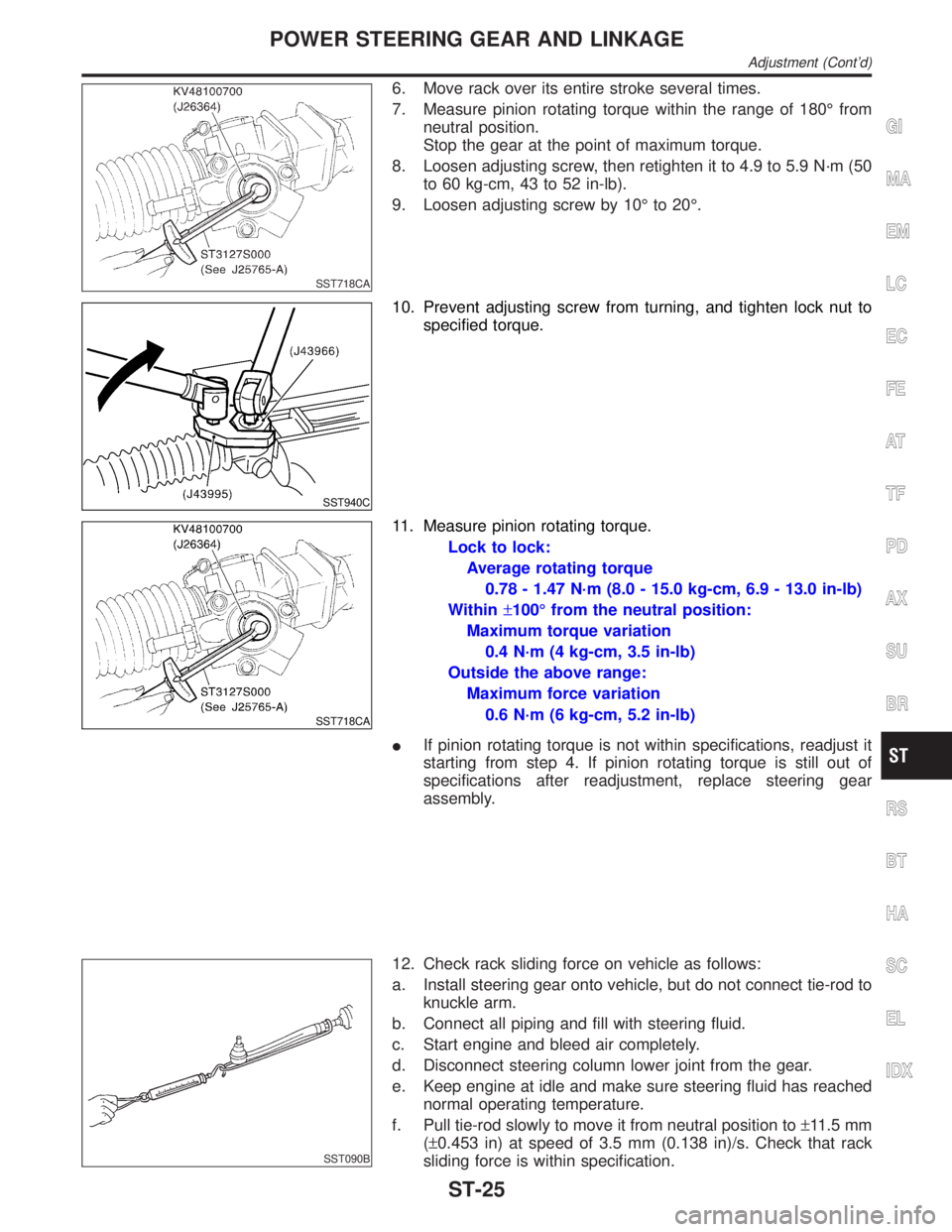

SST718CA

6. Move rack over its entire stroke several times.

7. Measure pinion rotating torque within the range of 180É from

neutral position.

Stop the gear at the point of maximum torque.

8. Loosen adjusting screw, then retighten it to 4.9 to 5.9 N´m (50

to 60 kg-cm, 43 to 52 in-lb).

9. Loosen adjusting screw by 10É to 20É.

SST940C

10. Prevent adjusting screw from turning, and tighten lock nut to

specified torque.

SST718CA

11. Measure pinion rotating torque.

Lock to lock:

Average rotating torque

0.78 - 1.47 N´m (8.0 - 15.0 kg-cm, 6.9 - 13.0 in-lb)

Within±100É from the neutral position:

Maximum torque variation

0.4 N´m (4 kg-cm, 3.5 in-lb)

Outside the above range:

Maximum force variation

0.6 N´m (6 kg-cm, 5.2 in-lb)

IIf pinion rotating torque is not within specifications, readjust it

starting from step 4. If pinion rotating torque is still out of

specifications after readjustment, replace steering gear

assembly.

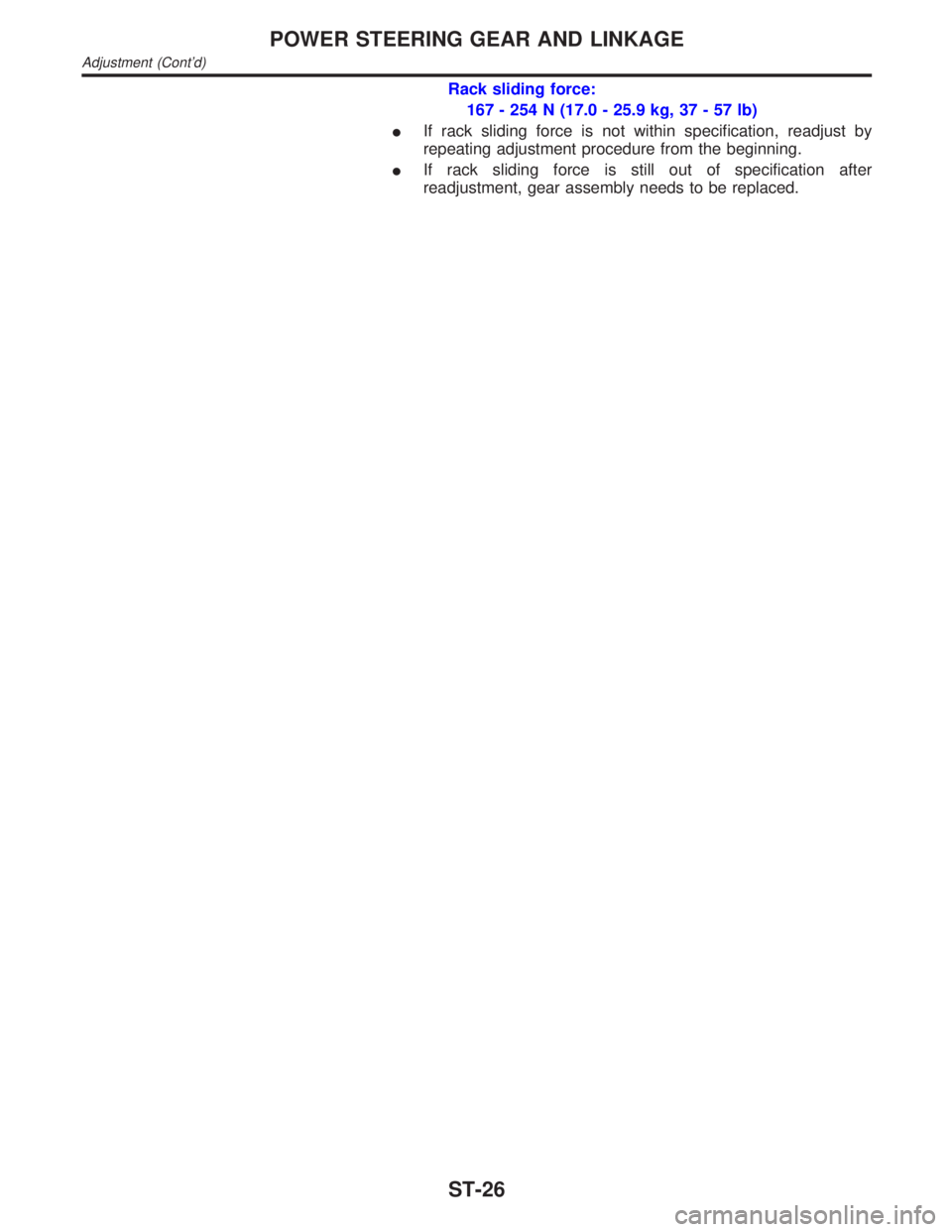

SST090B

12. Check rack sliding force on vehicle as follows:

a. Install steering gear onto vehicle, but do not connect tie-rod to

knuckle arm.

b. Connect all piping and fill with steering fluid.

c. Start engine and bleed air completely.

d. Disconnect steering column lower joint from the gear.

e. Keep engine at idle and make sure steering fluid has reached

normal operating temperature.

f. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Adjustment (Cont'd)

ST-25

Page 2207 of 2395

Rack sliding force:

167 - 254 N (17.0 - 25.9 kg, 37 - 57 lb)

IIf rack sliding force is not within specification, readjust by

repeating adjustment procedure from the beginning.

IIf rack sliding force is still out of specification after

readjustment, gear assembly needs to be replaced.

POWER STEERING GEAR AND LINKAGE

Adjustment (Cont'd)

ST-26

Page 2208 of 2395

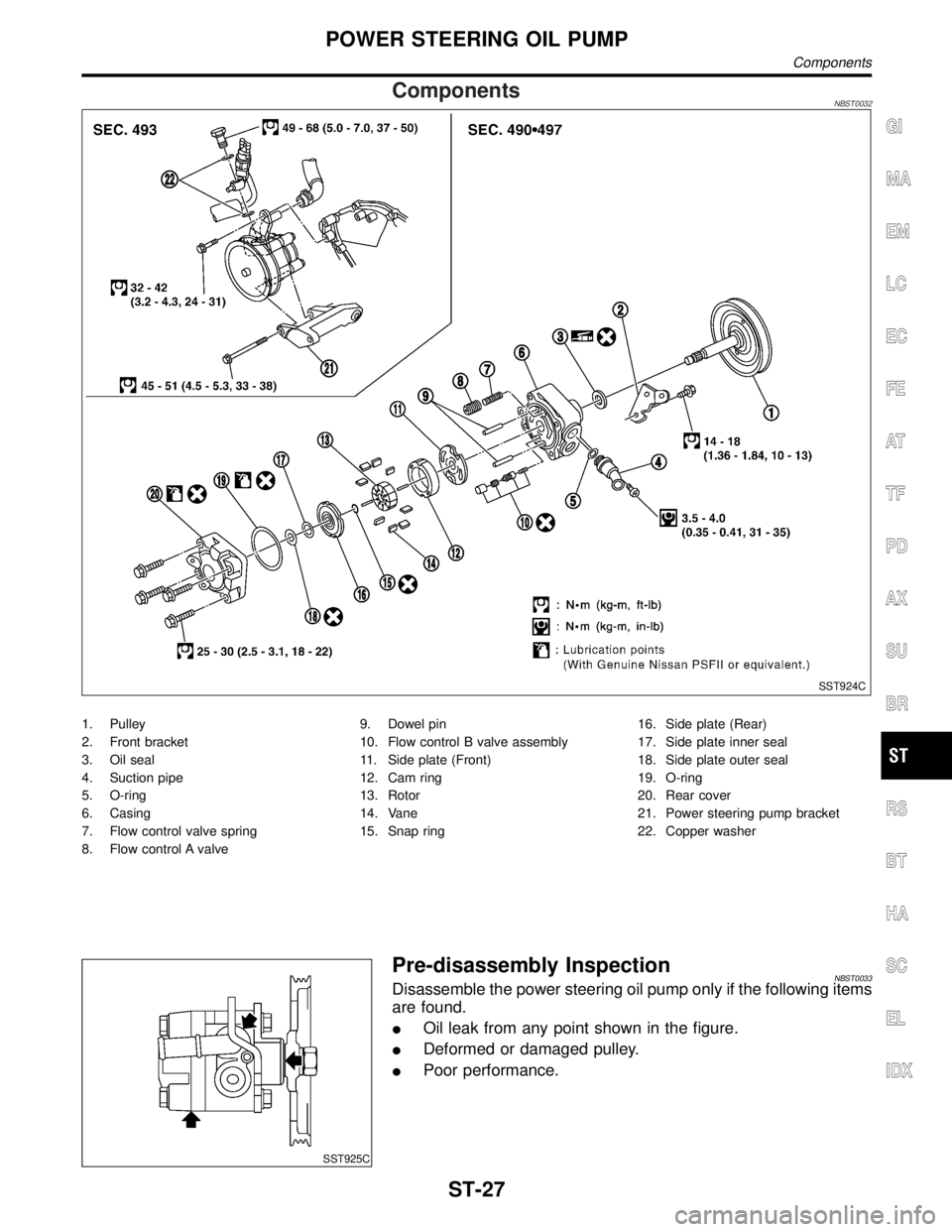

ComponentsNBST0032

SST924C

1. Pulley

2. Front bracket

3. Oil seal

4. Suction pipe

5. O-ring

6. Casing

7. Flow control valve spring

8. Flow control A valve9. Dowel pin

10. Flow control B valve assembly

11. Side plate (Front)

12. Cam ring

13. Rotor

14. Vane

15. Snap ring16. Side plate (Rear)

17. Side plate inner seal

18. Side plate outer seal

19. O-ring

20. Rear cover

21. Power steering pump bracket

22. Copper washer

SST925C

Pre-disassembly InspectionNBST0033Disassemble the power steering oil pump only if the following items

are found.

IOil leak from any point shown in the figure.

IDeformed or damaged pulley.

IPoor performance.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PUMP

Components

ST-27

Page 2209 of 2395

DisassemblyNBST0034CAUTION:

IParts which can be disassembled are strictly limited.

Never disassemble parts other than those specified.

IDisassemble in as clean a place as possible.

IClean your hands before disassembly.

IDo not use rags; use nylon cloths or paper towels.

IFollow the procedures and cautions in the Service

Manual.

IWhen disassembling and reassembling, do not let foreign

matter enter or contact the parts.

1. Fix power steering pump to vise.

CAUTION:

When fixing the pump to vise, use an aluminum plate or such

to avoid damaging the fitting plane of the steering pump.

2. Remove the front bracket mounting bolt, and remove the front

bracket from the casing.

3. Remove the rear cover mounting bolt, and remove the rear

cover from the casing.

4. Remove the O-ring from the casing.

SST926C

5. Remove side plate (rear side) from cam ring, then remove side

plate inner/outer seals from side plate (rear side).

6. Remove rotor snap ring using snap ring pliers, and remove

pulley from casing.

CAUTION:

Do not damage pulley shaft when removing rotor snap ring.

SST928C

7. Remove the followings from casing.

ICam ring

IRotor

IVane

ISide plate (front side)

IFlow control A valve

IFlow control valve spring

IFlow control B valve assembly

CAUTION:

Be careful not to drop flow control valve.

8. Remove inlet connector mounting bolt, and remove inlet con-

nector from casing.

9. Remove inlet connector seal from inlet connector.

10. Remove drive shaft seal from casing with a screwdriver.

CAUTION:

Do not damage casing surface with the screwdriver.

POWER STEERING OIL PUMP

Disassembly

ST-28

Page 2210 of 2395

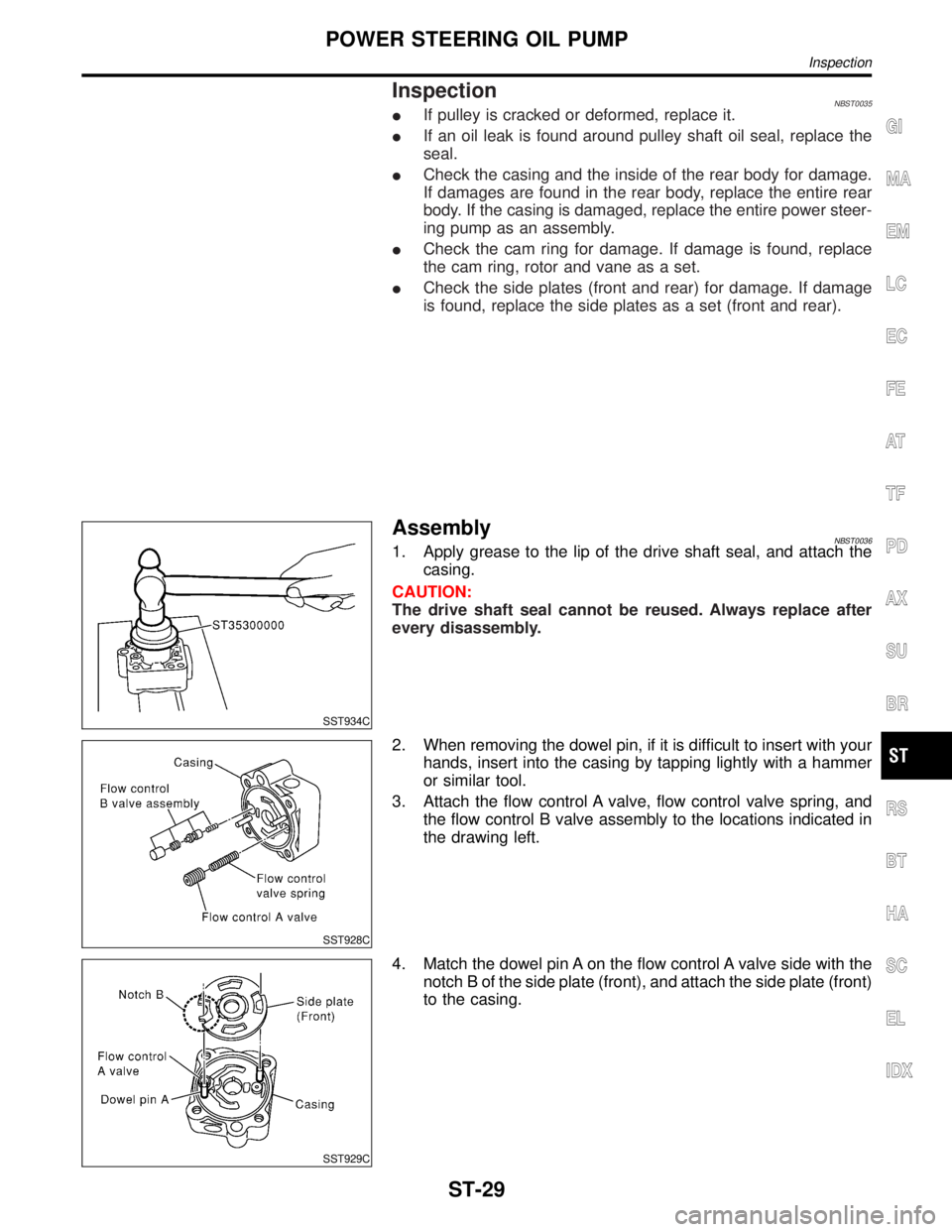

InspectionNBST0035IIf pulley is cracked or deformed, replace it.

IIf an oil leak is found around pulley shaft oil seal, replace the

seal.

ICheck the casing and the inside of the rear body for damage.

If damages are found in the rear body, replace the entire rear

body. If the casing is damaged, replace the entire power steer-

ing pump as an assembly.

ICheck the cam ring for damage. If damage is found, replace

the cam ring, rotor and vane as a set.

ICheck the side plates (front and rear) for damage. If damage

is found, replace the side plates as a set (front and rear).

SST934C

AssemblyNBST00361. Apply grease to the lip of the drive shaft seal, and attach the

casing.

CAUTION:

The drive shaft seal cannot be reused. Always replace after

every disassembly.

SST928C

2. When removing the dowel pin, if it is difficult to insert with your

hands, insert into the casing by tapping lightly with a hammer

or similar tool.

3. Attach the flow control A valve, flow control valve spring, and

the flow control B valve assembly to the locations indicated in

the drawing left.

SST929C

4. Match the dowel pin A on the flow control A valve side with the

notch B of the side plate (front), and attach the side plate (front)

to the casing.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PUMP

Inspection

ST-29

Page 2211 of 2395

SST930C

5. Face the cam ring side with fewer pores towards the casing,

and attach the cam ring on top of the side plate (front).

6. Attach the pulley to the casing.

CAUTION:

Attach with care so as not to damage the drive shaft seal.

SST289A

7. Face the side of the rotor with the punch mark towards the

casing, and attach the rotor to the pulley shaft.

SST843A

8. Attach the vane to the rotor so that the vane's arc touches the

cam ring.

SST931C

9. Use a hammer or suitable tool to insert the rotor snap ring into

the pulley shaft channel.

CAUTION:

IThe rotor snap ring cannot be reused. Always replace after

every disassembly.

IInsert with care so as not to damage the rotor or the pul-

ley shaft.

IIf the rotor is damaged, replace the power steering as an

assembly.

SST932C

10. Match the dowel pin A on the flow control A valve side with the

notch B of the side plate (rear), and attach the side plate (rear)

to the cam ring.

11. Apply Genuine Nissan PSF II or equivalent to O-ring and

attach to the casing.

CAUTION:

The O-ring cannot be reused. Always replace after every dis-

assembly.

POWER STEERING OIL PUMP

Assembly (Cont'd)

ST-30

Page 2212 of 2395

SST933C

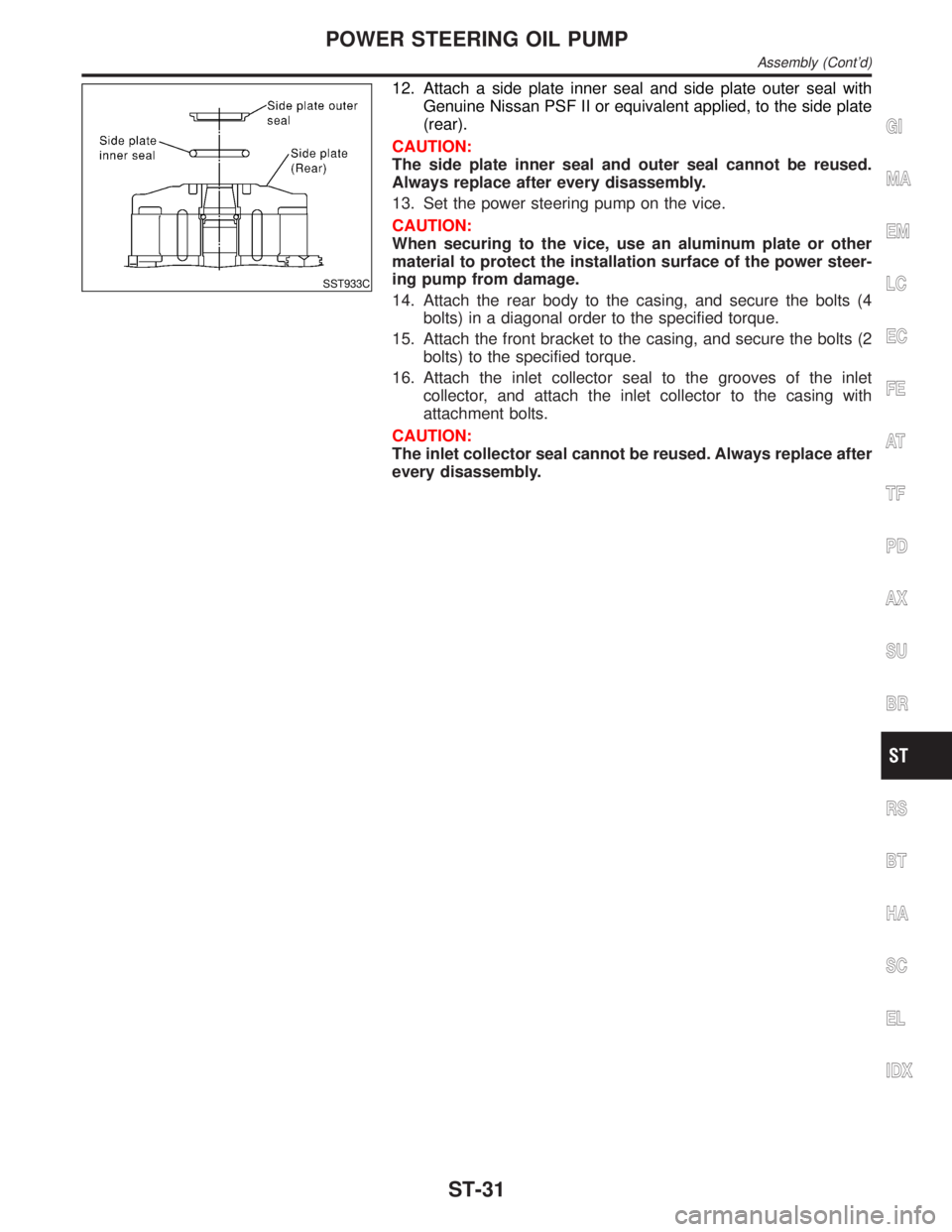

12. Attach a side plate inner seal and side plate outer seal with

Genuine Nissan PSF II or equivalent applied, to the side plate

(rear).

CAUTION:

The side plate inner seal and outer seal cannot be reused.

Always replace after every disassembly.

13. Set the power steering pump on the vice.

CAUTION:

When securing to the vice, use an aluminum plate or other

material to protect the installation surface of the power steer-

ing pump from damage.

14. Attach the rear body to the casing, and secure the bolts (4

bolts) in a diagonal order to the specified torque.

15. Attach the front bracket to the casing, and secure the bolts (2

bolts) to the specified torque.

16. Attach the inlet collector seal to the grooves of the inlet

collector, and attach the inlet collector to the casing with

attachment bolts.

CAUTION:

The inlet collector seal cannot be reused. Always replace after

every disassembly.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PUMP

Assembly (Cont'd)

ST-31

Page 2213 of 2395

General SpecificationsNBST0037

Applied modelAll

Steering modelPower steering

Steering gear typePR32K

Steering overall gear ratio 17.2

Turns of steering wheel

(Lock to lock)3.09

Steering column type Collapsible, tilt

Steering WheelNBST0038Unit: mm (in)

Steering wheel axial play0 (0)

Steering wheel play35 (1.38) or less

Movement of gear housing±2(±0.08) or less

Steering ColumnNBST0039Unit: mm (in)

Steering column length ªL1º 716.7 - 718.7 (28.22 - 28.30)

Steering column lower shaft length ªL

2º 178 - 180 (7.01 - 7.09)

Steering column upper joint length ªL

3º 430.7 - 432.7 (16.96 - 17.04)

SST739C

Steering Transfer GearNBST0041

Rotating torque0.25 - 0.69 N´m (2.5 - 7.0 kg-cm, 2.2 - 6.1 in-lb)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

ST-32

Page 2214 of 2395

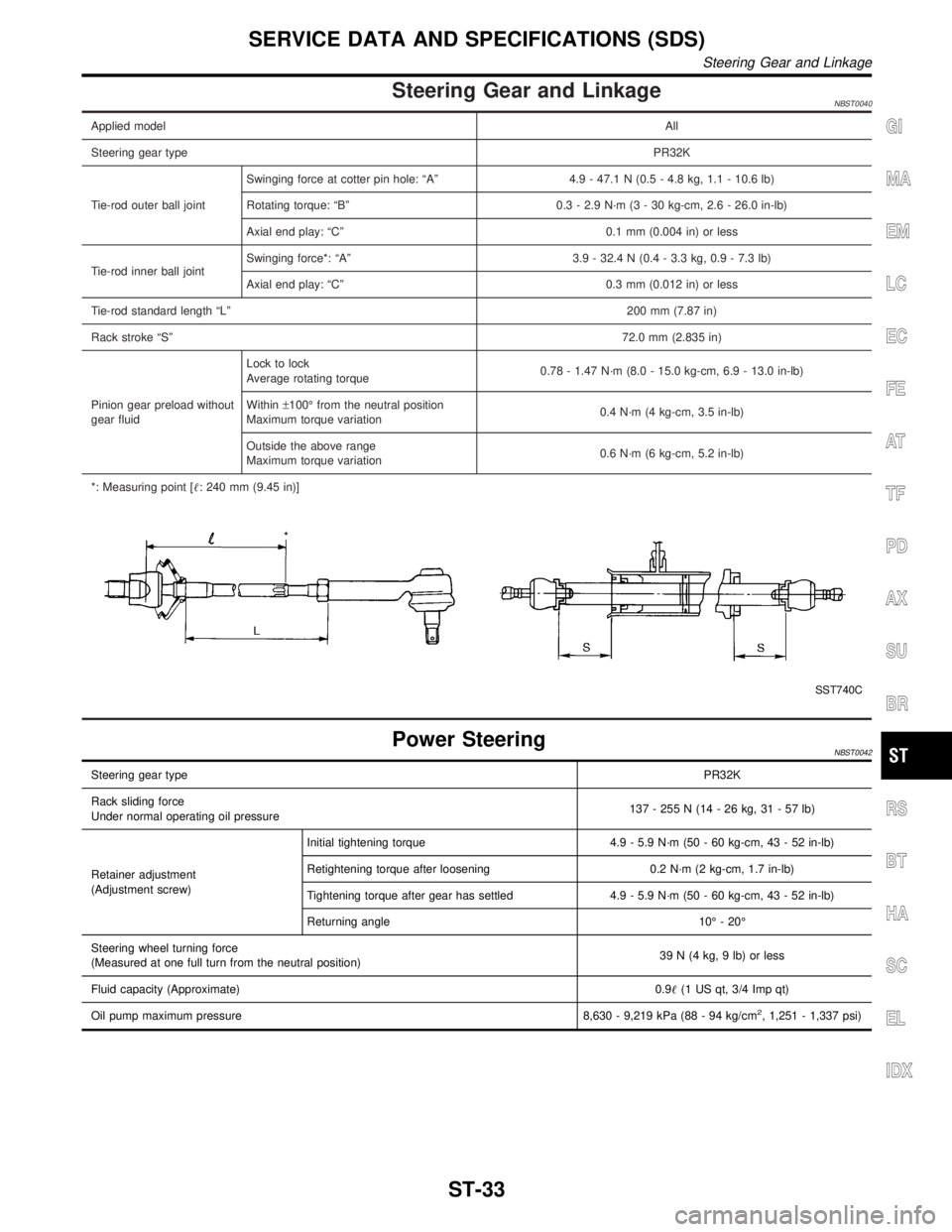

Steering Gear and LinkageNBST0040

Applied modelAll

Steering gear typePR32K

Tie-rod outer ball jointSwinging force at cotter pin hole: ªAº 4.9 - 47.1 N (0.5 - 4.8 kg, 1.1 - 10.6 lb)

Rotating torque: ªBº 0.3 - 2.9 N´m (3 - 30 kg-cm, 2.6 - 26.0 in-lb)

Axial end play: ªCº 0.1 mm (0.004 in) or less

Tie-rod inner ball jointSwinging force*: ªAº 3.9 - 32.4 N (0.4 - 3.3 kg, 0.9 - 7.3 lb)

Axial end play: ªCº 0.3 mm (0.012 in) or less

Tie-rod standard length ªLº200 mm (7.87 in)

Rack stroke ªSº72.0 mm (2.835 in)

Pinion gear preload without

gear fluidLock to lock

Average rotating torque0.78 - 1.47 N´m (8.0 - 15.0 kg-cm, 6.9 - 13.0 in-lb)

Within±100É from the neutral position

Maximum torque variation0.4 N´m (4 kg-cm, 3.5 in-lb)

Outside the above range

Maximum torque variation0.6 N´m (6 kg-cm, 5.2 in-lb)

*: Measuring point [: 240 mm (9.45 in)]

SST740C

Power SteeringNBST0042

Steering gear typePR32K

Rack sliding force

Under normal operating oil pressure137 - 255 N (14 - 26 kg, 31 - 57 lb)

Retainer adjustment

(Adjustment screw)Initial tightening torque 4.9 - 5.9 N´m (50 - 60 kg-cm, 43 - 52 in-lb)

Retightening torque after loosening 0.2 N´m (2 kg-cm, 1.7 in-lb)

Tightening torque after gear has settled 4.9 - 5.9 N´m (50 - 60 kg-cm, 43 - 52 in-lb)

Returning angle 10É - 20É

Steering wheel turning force

(Measured at one full turn from the neutral position)39 N (4 kg, 9 lb) or less

Fluid capacity (Approximate)0.9(1 US qt, 3/4 Imp qt)

Oil pump maximum pressure 8,630 - 9,219 kPa (88 - 94 kg/cm

2, 1,251 - 1,337 psi)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Steering Gear and Linkage

ST-33