fuse INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2046 of 2395

SPD670

9. Take out drive pinion together with rear bearing inner cone,

drive pinion bearing spacer and pinion bearing adjusting

washer.

10. Remove front oil seal and pinion front bearing inner cone.

PD349

11. Remove pinion bearing outer races with a brass drift.

SPD209

12. Remove pinion rear bearing inner cone and drive pinion height

adjusting washer.

Tool number: ST30031000 (J22912-01)

SPD207A

DIFFERENTIAL CASENBPD0018S031. Remove side bearing inner cones.

To prevent damage to bearing, engage puller jaws in grooves.

Tool number:

A ST33051001 (J22888-20)

B ST33061000 (J8107-2)

SPD022

Be careful not to confuse the right and left hand parts.

Keep bearing and bearing race for each side together.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Disassembly (Cont'd)

PD-21

Page 2071 of 2395

SPD563

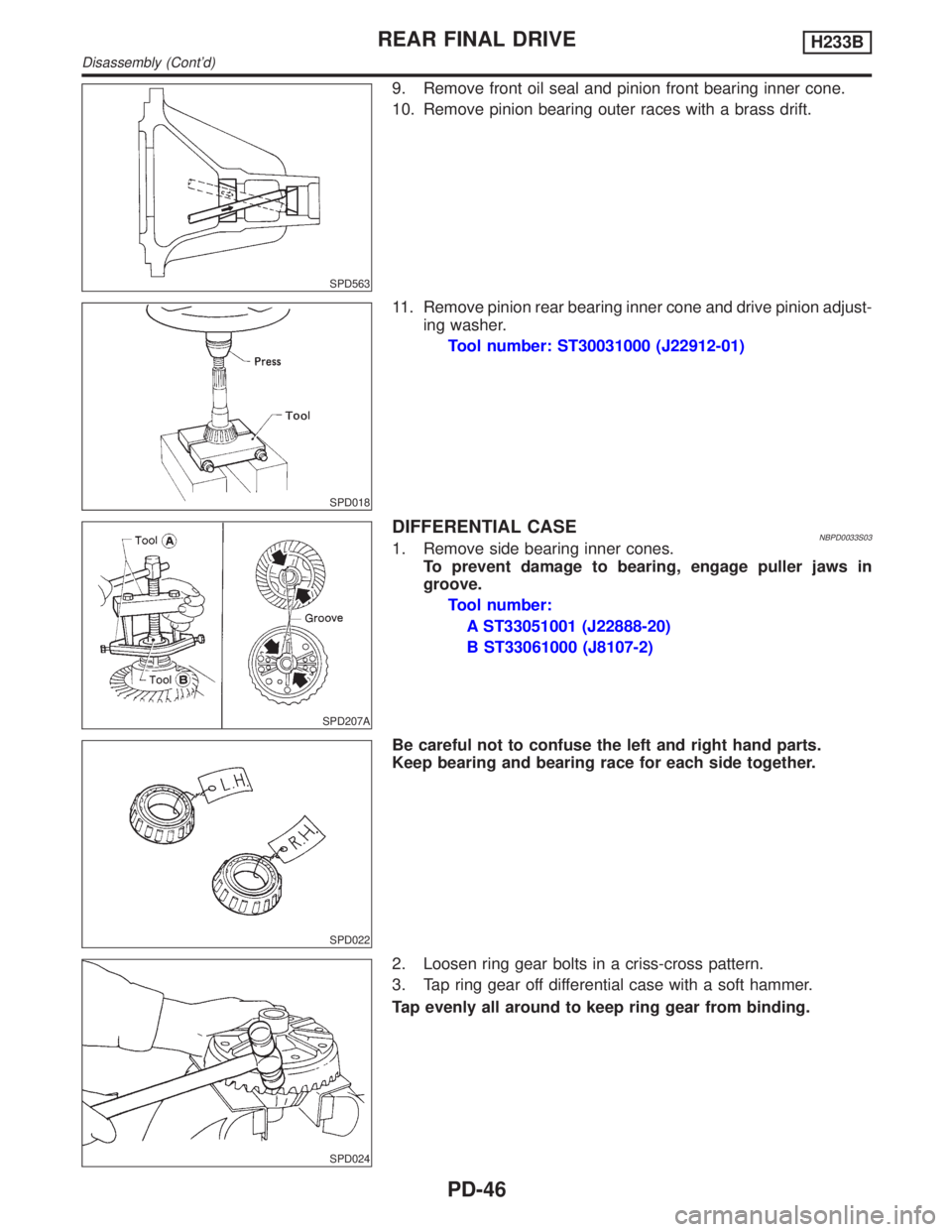

9. Remove front oil seal and pinion front bearing inner cone.

10. Remove pinion bearing outer races with a brass drift.

SPD018

11. Remove pinion rear bearing inner cone and drive pinion adjust-

ing washer.

Tool number: ST30031000 (J22912-01)

SPD207A

DIFFERENTIAL CASENBPD0033S031. Remove side bearing inner cones.

To prevent damage to bearing, engage puller jaws in

groove.

Tool number:

A ST33051001 (J22888-20)

B ST33061000 (J8107-2)

SPD022

Be careful not to confuse the left and right hand parts.

Keep bearing and bearing race for each side together.

SPD024

2. Loosen ring gear bolts in a criss-cross pattern.

3. Tap ring gear off differential case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

REAR FINAL DRIVEH233B

Disassembly (Cont'd)

PD-46

Page 2121 of 2395

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

=NBRS0041A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malfunction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

INFORMATION FROM CUSTOMERNBRS0041S01WHAT ..... Vehicle model

WHEN ..... Date, Frequencies

WHERE ..... Road conditions

HOW ..... Operating conditions, Symptoms

PRELIMINARY CHECKNBRS0041S02Check that the following parts are in good order.

IBattery [Refer to SC-4, ÂȘBATTERYÂș.]

IFuse [Refer to EL-16, ÂȘFuseÂș, ÂȘPOWER SUPPLY ROUTINGÂș.]

ISystem component-to-harness connections

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

How to Perform Trouble Diagnoses for Quick and Accurate Repair

RS-32

Page 2127 of 2395

SRS800

SRS Operation CheckNBRS0044DIAGNOSTIC PROCEDURE 1NBRS0044S01Checking Air Bag Operation by Using ÂȘAIR BAGÂș

Warning Lamp Ă User Mode

NBRS0044S01011. After turning ignition switch from ÂȘOFFÂș to ÂȘONÂș, ÂȘAIR BAGÂș

warning lamp operates.

2. Compare ÂȘAIR BAGÂș warning lamp operation to the chart

below.

ÂȘAIR BAGÂș warning lamp operation Ă User mode Ă SRS condition Reference item

MRS095A

No malfunction is

detected. No further action

is necessary.

Ă

MRS096A

The system is malfunction-

ing and needs to be

repaired as indicated.Go to DIAGNOSTIC PRO-

CEDURE 2 or 6 (RS-39 or

RS-48).

MRS097A

Air bag is deployed.

Seat belt pre-tensioner is

deployed.Go to COLLISION DIAG-

NOSIS (RS-56).

Air bag fuse, diagnosis

sensor unit or harness is

malfunctioning and needs

to be repaired.Go to DIAGNOSTIC PRO-

CEDURE 9 (RS-59).

MRS098A

One of the following has

occurred and needs to be

repaired.

IMeter fuse is blown.

IÂȘAIR BAGÂș warning

lamp circuit has open or

short.

IDiagnosis sensor unit is

malfunctioning.Go to DIAGNOSTIC PRO-

CEDURE 10 (RS-58).

NOTE:

If ÂȘAIR BAGÂș warning lamp operates differently from the

operations shown above, refer to ÂȘAIR BAGÂș warning lamp

operation Ă Diagnosis mode Ă, DIAGNOSTIC PROCEDURE 6

(step 4), RS-48.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS Operation Check

RS-38

Page 2144 of 2395

ÂȘAIR BAGÂș warning lamp operation Ă User mode Ă SRS condition Reference item

MRS095A

No malfunction is

detected.

No further action is neces-

sary.Ă

MRS096A

The system is malfunction-

ing and needs to be

repaired as indicated.Go to DIAGNOSTIC PRO-

CEDURE 6 (RS-48).

MRS097A

Air bag is deployed.

Seat belt pre-tensioner is

deployed.Go to COLLISION DIAG-

NOSIS (RS-59).

Air bag fuse, diagnosis

sensor unit or harness is

malfunctioning and needs

to be repaired.Go to DIAGNOSTIC PRO-

CEDURE 9 RS-56).

MRS098A

One of the following has

occurred and needs to be

repaired.

IMeter fuse is blown.

IÂȘAIR BAGÂș warning

lamp circuit has open or

short.

IDiagnosis sensor unit is

malfunctioning.Go to DIAGNOSTIC PRO-

CEDURE 10 (RS-58).

DIAGNOSTIC PROCEDURE 8 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 6)

NBRS0046S03Inspecting SRS malfunctioning record

1 CONSIDER POSSIBILITY OF NOT ERASING SELF-DIAGNOSTIC RESULT AFTER REPAIRING

Is it the first time for maintenance of SRS?

YesorNo

Ye s©Go to DIAGNOSTIC PROCEDURE 5 (RS-44). (Further inspection cannot be performed

without CONSULT-II.)

No©Diagnosis results (previously stored in the memory) might not be erased after repair. Go

to DIAGNOSTIC PROCEDURE 7, step 5 (RS-53).

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont'd)

RS-55

Page 2145 of 2395

Trouble Diagnoses: ÂȘAIR BAGÂș Warning Lamp

Does Not Turn Off

=NBRS0047DIAGNOSTIC PROCEDURE 9NBRS0047S01

1 SEE THE DEPLOYMENT OF AIR BAG MODULE

Is air bag module deployed?

YesorNo

Ye s©Refer to COLLISION DIAGNOSIS (RS-59).

No©GO TO 2.

2 CHECK AIR BAG FUSE

Is SRS ÂȘAir BagÂș fuse OK?

SRS577

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 CHECK AIR BAG FUSE AGAIN

Replace ÂȘAIR BAGÂș fuse and turn ignition switch ON.

Is ÂȘAIR BAGÂș fuse blown again?

Ye s©Repair main harness and/or replace air bag harness.

No©INSPECTION END

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses: ÂȘAIR BAGÂș Warning Lamp Does Not Turn Off

RS-56

Page 2147 of 2395

Trouble Diagnoses: ÂȘAIR BAGÂș Warning Lamp

Does Not Turn On

=NBRS0048DIAGNOSTIC PROCEDURE 10NBRS0048S01

1 CHECK ÂȘMETERÂș FUSE

Is meter fuse OK?

SRS852

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 CHECK ÂȘMETERÂș FUSE AGAIN

Replace meter fuse and turn ignition switch ON.

Is meter fuse blown again?

Ye s©Repair main harness.

No©INSPECTION END

3 CHECK ÂȘAIR BAGÂș WARNING LAMP LED

Is ÂȘAIR BAGÂș warning lamp LED OK?

OK or NG

OK©GO TO 4.

NG©Replace ÂȘAIR BAGÂș warning lamp LED.

4 CHECK HARNESS CONNECTION BETWEEN DIAGNOSIS SENSOR UNIT AND ÂȘAIR BAGÂș WARNING

LAMP

Disconnect diagnosis sensor unit connector and turn ignition switch ÂȘONÂș.

IDoes ÂȘAIR BAGÂș warning lamp turn on?

YesorNo

Ye s©Replace diagnosis sensor unit.

No©Check the ground circuit of ÂȘAIR BAGÂș warning lamp.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses: ÂȘAIR BAGÂș Warning Lamp Does Not Turn On

RS-58

Page 2161 of 2395

System DescriptionNBSC0004Power is supplied at all times

Ito ignition switch terminal 1

Ithrough 40A fusible link (lettere, located in the fuse and fusible link box).

With the ignition switch in the ON or START position, power is supplied through 10A fuse [No. 18, located in

the fuse block (J/B)].

Ito park/neutral position relay terminal 1.

Also, with the ignition switch in the START position, power is supplied

Ifrom ignition switch terminal 5

Ito park/neutral position relay terminal 6.

With the selector lever in the P or N position, ground is supplied

Ito park/neutral position relay terminal 2 through the park/neutral position switch.

Then park/neutral position relay is energized and power is supplied

Ifrom park/neutral position relay terminal 7

Ito terminal 2 of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

STARTING SYSTEM

System Description

SC-10

Page 2166 of 2395

DIAGNOSTIC PROCEDURE 1NBSC0019S03Check ÂȘBÂș Terminal CircuitNBSC0019S0301

1 CHECK POWER SUPPLY FOR STARTER MOTOR ÂȘBÂș TERMINAL

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition OFF.

4. Check that the starter motor terminal 1 connection is clean and tight.

5. Check voltage between starter motor terminal 1 and ground using a digital circuit tester.

SEL412X

OK or NG

OK©GO TO 2.

NG©Check harness between the battery and the starter motor for open circuit.

2 CHECK BATTERY CABLE CONNECTION QUALITY (VOLTAGE DROP TEST)

1. Check voltage between starter motor terminal 1 and battery positive terminal using a digital circuit tester.

SEL413X

OK or NG

OK©GO TO 3.

NG©Check harness between the battery and the starter motor for poor continuity.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-15

Page 2168 of 2395

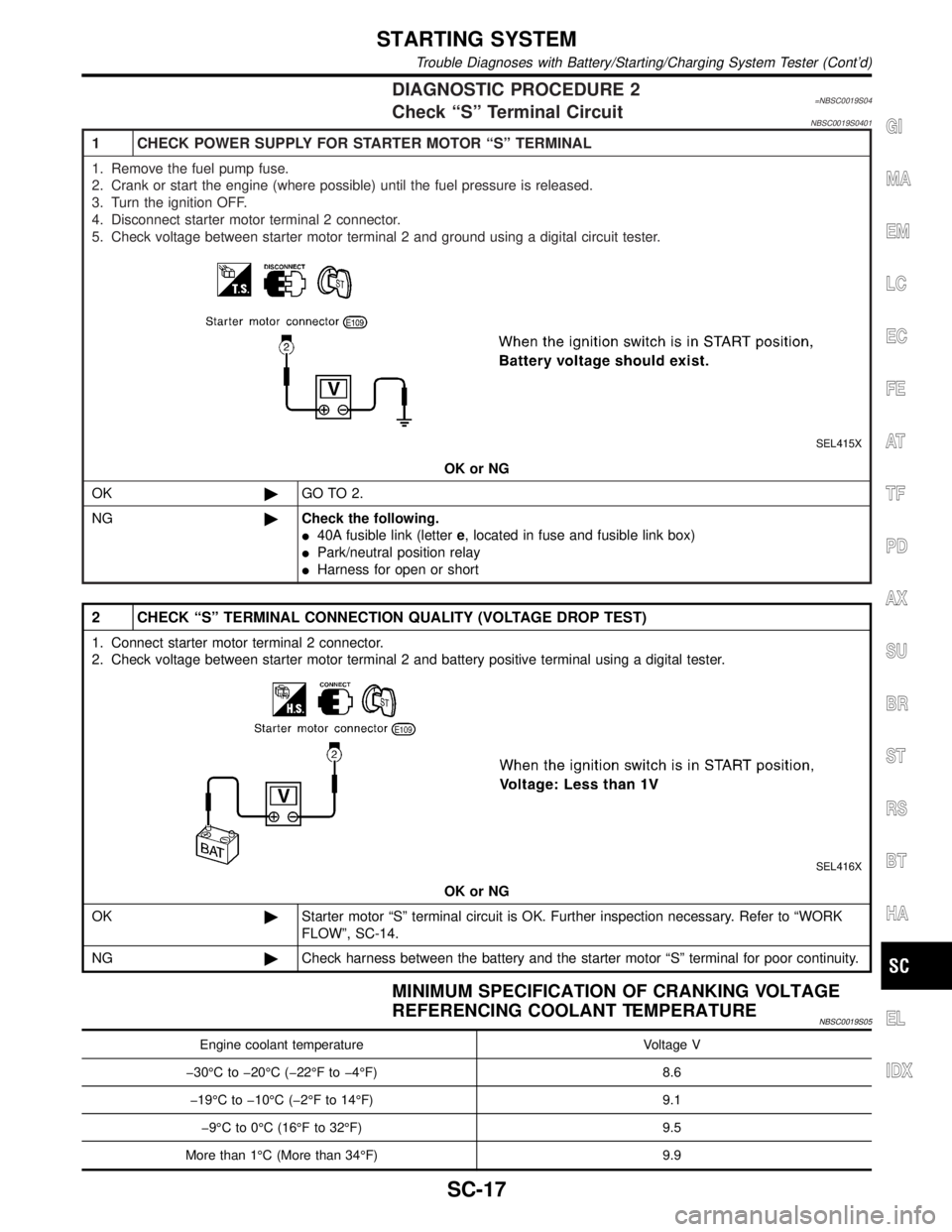

DIAGNOSTIC PROCEDURE 2=NBSC0019S04Check ÂȘSÂș Terminal CircuitNBSC0019S0401

1 CHECK POWER SUPPLY FOR STARTER MOTOR ÂȘSÂș TERMINAL

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition OFF.

4. Disconnect starter motor terminal 2 connector.

5. Check voltage between starter motor terminal 2 and ground using a digital circuit tester.

SEL415X

OK or NG

OK©GO TO 2.

NG©Check the following.

I40A fusible link (lettere, located in fuse and fusible link box)

IPark/neutral position relay

IHarness for open or short

2 CHECK ÂȘSÂș TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

1. Connect starter motor terminal 2 connector.

2. Check voltage between starter motor terminal 2 and battery positive terminal using a digital tester.

SEL416X

OK or NG

OK©Starter motor ÂȘSÂș terminal circuit is OK. Further inspection necessary. Refer to ÂȘWORK

FLOWÂș, SC-14.

NG©Check harness between the battery and the starter motor ÂȘSÂș terminal for poor continuity.

MINIMUM SPECIFICATION OF CRANKING VOLTAGE

REFERENCING COOLANT TEMPERATURE

NBSC0019S05

Engine coolant temperature Voltage V

ĂŸ30ĂC to ĂŸ20ĂC (ĂŸ22ĂF to ĂŸ4ĂF) 8.6

ĂŸ19ĂC to ĂŸ10ĂC (ĂŸ2ĂF to 14ĂF) 9.1

ĂŸ9ĂC to 0ĂC (16ĂF to 32ĂF) 9.5

More than 1ĂC (More than 34ĂF) 9.9

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-17