fuse INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2170 of 2395

System DescriptionNBSC0009The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal S through:

I120A fusible link (lettera, located in the fuse and fusible link box), and

I7.5A fuse (No. 65, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal S detecting the input voltage. The charging circuit is protected by

the 120A fusible link.

Terminal E of the alternator supplies ground through body ground E101.

With the ignition switch in the ON or START position, power is supplied

Ithrough 10A fuse [No. 8, located in the fuse block (J/B)]

Ito combination meter terminal 12 for the charge warning lamp.

Ground is supplied to terminal 43 of the combination meter through terminal L of the alternator. With power

and ground supplied, the charge warning lamp will illuminate. When the alternator is providing sufficient volt-

age with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

System Description

SC-19

Page 2176 of 2395

DIAGNOSTIC PROCEDURE 1NBSC0020S03Check ÂȘLÂș Terminal CircuitNBSC0020S0301

1 CHECK ÂȘLÂș TERMINAL CONNECTION

Check to see if ÂȘLÂș terminal is clean and tight.

OK or NG

OK©GO TO 2.

NG©Repair ÂȘLÂș terminal connection. Confirm repair by performing complete Battery/Starting/

Charging system test.

2 CHECK ÂȘLÂș TERMINAL CIRCUIT

1. Disconnect E106 connector from alternator.

2. Apply ground to E106 connector terminal 1 with the ignition switch in the ON position.

SEL424X

OK or NG

OK©Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG©Check the following.

I10A fuse [No. 8, located in fuse block (J/B)]

ICHARGE lamp

IHarness for open or short between combination meter and fuse

IHarness for open or short between combination meter and alternator

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-25

Page 2177 of 2395

DIAGNOSTIC PROCEDURE 2=NBSC0020S04Check ÂȘBÂș Terminal CircuitNBSC0020S0401

1 CHECK ÂȘBÂș TERMINAL CONNECTION

Check to see if ÂȘBÂș terminal is clean and tight.

OK or NG

OK©GO TO 2. Confirm repair by performing complete Battery/Starting/Charging system test.

NG©Repair ÂȘBÂș terminal connection.

2 CHECK ALTERNATOR ÂȘBÂș TERMINAL CIRCUIT

Check voltage between alternator terminal B and ground using a digital circuit tester.

SEL425X

OK or NG

OK©GO TO 3.

NG©Check the following.

I120A fusible link (lettera, located in fuse and fusible link box)

IHarness for open or short between alternator and fusible link

3 CHECK ÂȘBÂș TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between alternator terminal B and battery positive terminal using a digital tester.

SEL426X

OK or NG

OK©Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG©Check harness between the battery and the alternator for poor continuity.

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-26

Page 2178 of 2395

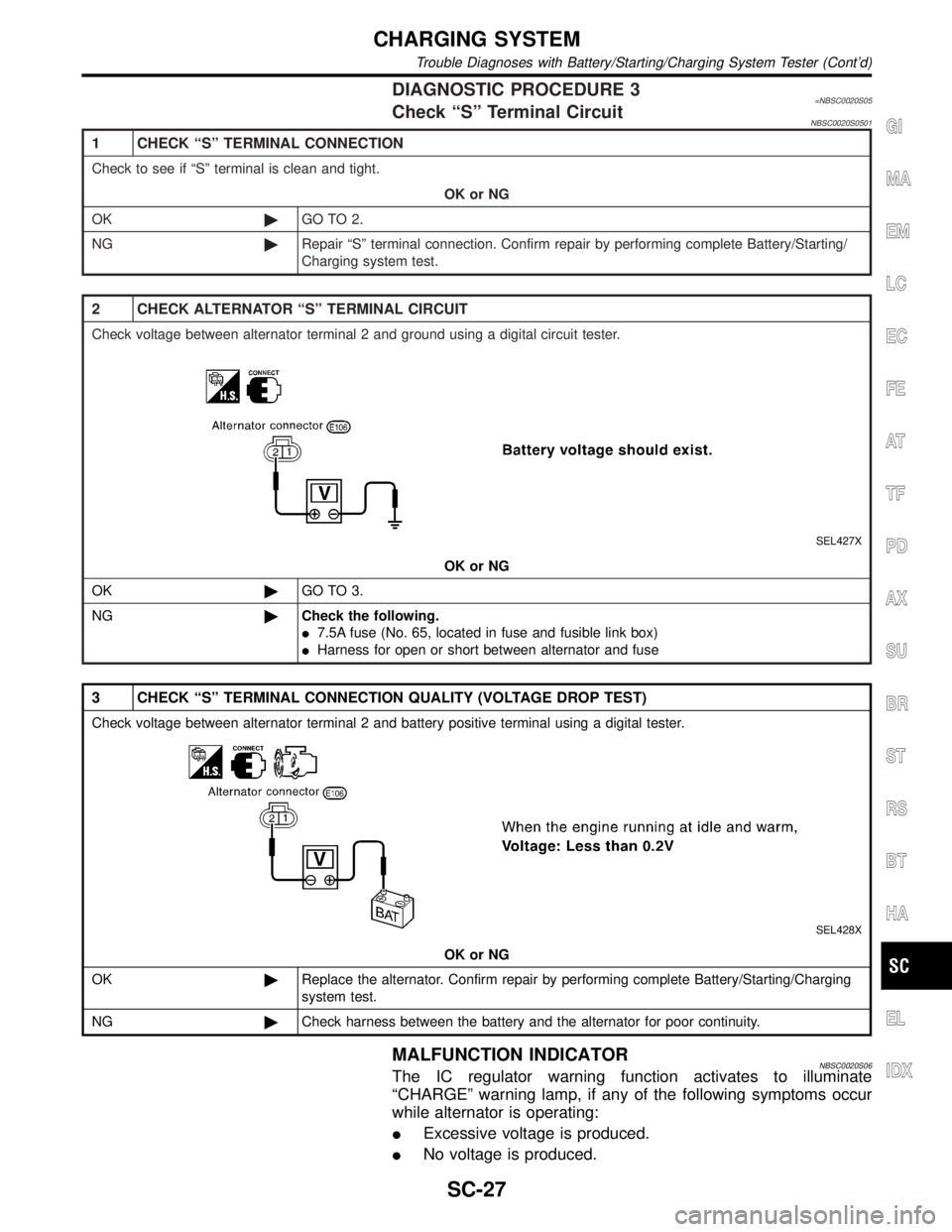

DIAGNOSTIC PROCEDURE 3=NBSC0020S05Check ÂȘSÂș Terminal CircuitNBSC0020S0501

1 CHECK ÂȘSÂș TERMINAL CONNECTION

Check to see if ÂȘSÂș terminal is clean and tight.

OK or NG

OK©GO TO 2.

NG©Repair ÂȘSÂș terminal connection. Confirm repair by performing complete Battery/Starting/

Charging system test.

2 CHECK ALTERNATOR ÂȘSÂș TERMINAL CIRCUIT

Check voltage between alternator terminal 2 and ground using a digital circuit tester.

SEL427X

OK or NG

OK©GO TO 3.

NG©Check the following.

I7.5A fuse (No. 65, located in fuse and fusible link box)

IHarness for open or short between alternator and fuse

3 CHECK ÂȘSÂș TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between alternator terminal 2 and battery positive terminal using a digital tester.

SEL428X

OK or NG

OK©Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG©Check harness between the battery and the alternator for poor continuity.

MALFUNCTION INDICATORNBSC0020S06The IC regulator warning function activates to illuminate

ÂȘCHARGEÂș warning lamp, if any of the following symptoms occur

while alternator is operating:

IExcessive voltage is produced.

INo voltage is produced.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-27

Page 2303 of 2395

3 CHECK 4WD SHIFT SWITCH POWER SOURCE

1. Disconnect 4WD shift switch harness connector.

2. Turn ignition switch to ÂȘONÂș position.

3. Check voltage between 4WD shift switch harness connector terminal 1 and body ground.

Voltage: Battery voltage

SMT852D

OK or NG

OK©GO TO 4.

NG©Check the following.

INo. 18 fuse (10A)

IContinuity between ignition switch and 4WD shift switch

2-4WD SHIFT SOLENOID VALVE AND 4WD SHIFT SWITCH

Diagnostic Procedure (Cont'd)

TF-68

Page 2306 of 2395

4 CHECK TRANSFER MOTOR RELAY POWER SOURCE

1. Disconnect transfer motor relay harness connector.

2. Turn ignition switch to ÂȘONÂș position.

3. Check voltage between transfer motor relay harness connector terminals 1, 3 and body ground.

Voltage: Battery voltage

SMT854DA

OK or NG

OK©GO TO 5.

NG©Check the following.

INo. 55 fuse (20A)

INo. 18 fuse (10A)

IHarness continuity between fuse and transfer motor relay

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TRANSFER MOTOR AND TRANSFER MOTOR RELAY

Diagnostic Procedure (Cont'd)

TF-71

Page 2323 of 2395

Diagnostic ProcedureNBTF0028

1 CHECK TRANSFER CONTROL UNIT POWER SOURCE

1. Turn ignition switch to ÂȘOFFÂș position and perform self-diagnosis again.

Refer to ÂȘTrouble Diagnosis without CONSULT-IIÂș, TF-27 and ÂȘTrouble Diagnosis with CONSULT-IIÂș, TF-30.

2. Turn ignition switch to ÂȘOFFÂș position.

3. Disconnect transfer control unit harness connector.

4. Check voltage between transfer control unit harness connector terminal 47 and body ground.

Voltage: Battery voltage

SMT794D

OK or NG

OK©GO TO 2.

NG©Check the following.

INo. 24 fuse (7.5A)

IHarness continuity between fuse and transfer control unit

2 PERFORM SELF-DIAGNOSIS AGAIN

After driving for a while, perform self-diagnosis again.

Refer to ÂȘTrouble Diagnosis without CONSULT-IIÂș, TF-27 and ÂȘTrouble Diagnosis with CONSULT-IIÂș, TF-30.

OK or NG

OK©INSPECTION END

NG©1. Perform transfer control unit input/output signal inspection. Refer to ÂȘTRANSFER

CONTROL UNIT INSPECTION TABLEÂș, ÂȘTROUBLE DIAGNOSIS Ă GENERAL

DESCRIPTIONÂș, TF-55.

2. If NG, recheck transfer control unit pin terminals for damage or loose connection with

harness connector.

DATA ERASE/DISPLAY

Diagnostic Procedure

TF-88

Page 2324 of 2395

Diagnostic ProcedureNBTF0064

1 SHIFT ACTUATOR

Refer to ÂȘActuator & Actuator Position SwitchÂș, ÂȘCOMPONENT INSPECTIONÂș, TF-115.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 CHECK POWER SOURCE

SMT825DA

1. Disconnect transfer control device terminal.

2. Turn ignition switch to ÂȘONÂș. (Do not start engine.)

3. Check voltage between transfer control device harness connector 3 (or 4) and body ground while 4WD shift switch is

set from 4H to 4LO (or from 4LO to 4H).

Voltage: Battery voltage

OK or NG

OK©Repair or replace actuator.

NG©1. Recheck the following.

IContinuity between ignition switch and transfer HI & LOW relays

IIgnition switch and No. 3 fuse (20A)

IContinuity between transfer shift HI & LOW relays and transfer control device

2. If NG, repair or replace damaged part.

3 CHECK INPUT SIGNAL

WITH CONSULT-II©GO TO 4.

WITHOUT CONSULT-II©GO TO 5.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SHIFT ACTUATOR

Diagnostic Procedure

TF-89

Page 2329 of 2395

Diagnostic ProcedureNBTF0066

1 SHIFT ACTUATOR CIRCUIT

Refer to ÂȘTransfer Shift Relay (High & Low)Âș, ÂȘCOMPONENT INSPECTIONÂș and ÂȘActuator & Actuator Position SwitchÂș,

ÂȘCOMPONENT INSPECTIONÂș, TF-114, 115.

OK or NG

OK©GO TO 2.

NG©Repair or replace transfer shift relay and actuator and actuator position switch.

2 CHECK POWER SOURCE OF TRANSFER SHIFT (HI & LOW) RELAY

SMT825DA

1. Disconnect transfer control device terminal.

2. Turn ignition switch to ÂȘONÂș (Do not start engine).

3. Check voltage between transfer shift HI and LOW relay terminal 5 and body ground.

Voltage: Battery voltage

SMT831D

OK or NG

OK©GO TO 3.

NG©Check the following.

IContinuity between ignition switch and transfer shift HI & LOW relays

ICheck ground circuit between transfer shift HI & LOW relays and body ground.

IIgnition switch and No. 3 fuse (20A)

SHIFT ACTUATOR CIRCUIT

Diagnostic Procedure

TF-94

Page 2333 of 2395

Symptom 1. 4WD Shift Indicator Lamp Does

Not Turn ON

NBTF0029SYMPTOM: Although ignition switch is turned ÂȘONÂș, all the

4WD shift indicator lamps do not turn ON for 1 second.

1 CHECK TRANSFER CONTROL UNIT POWER SOURCE

SMT958D

SMT860D

1. Turn ignition switch to ÂȘOFFÂș position and disconnect transfer control unit harness connector.

2. Turn ignition switch to ÂȘONÂș position. (Do not start engine.)

3. Check voltage between transfer control unit harness connector terminals 16, 22 and body ground.

Voltage: Battery voltage

SMT796D

OK or NG

OK©GO TO 2.

NG©Check the following.

IContinuity between ignition switch and transfer control unit

IIgnition switch and No. 18 fuse (10A)

TROUBLE DIAGNOSES FOR SYMPTOMS

Symptom 1. 4WD Shift Indicator Lamp Does Not Turn ON

TF-98