Battery terminal INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1840 of 2395

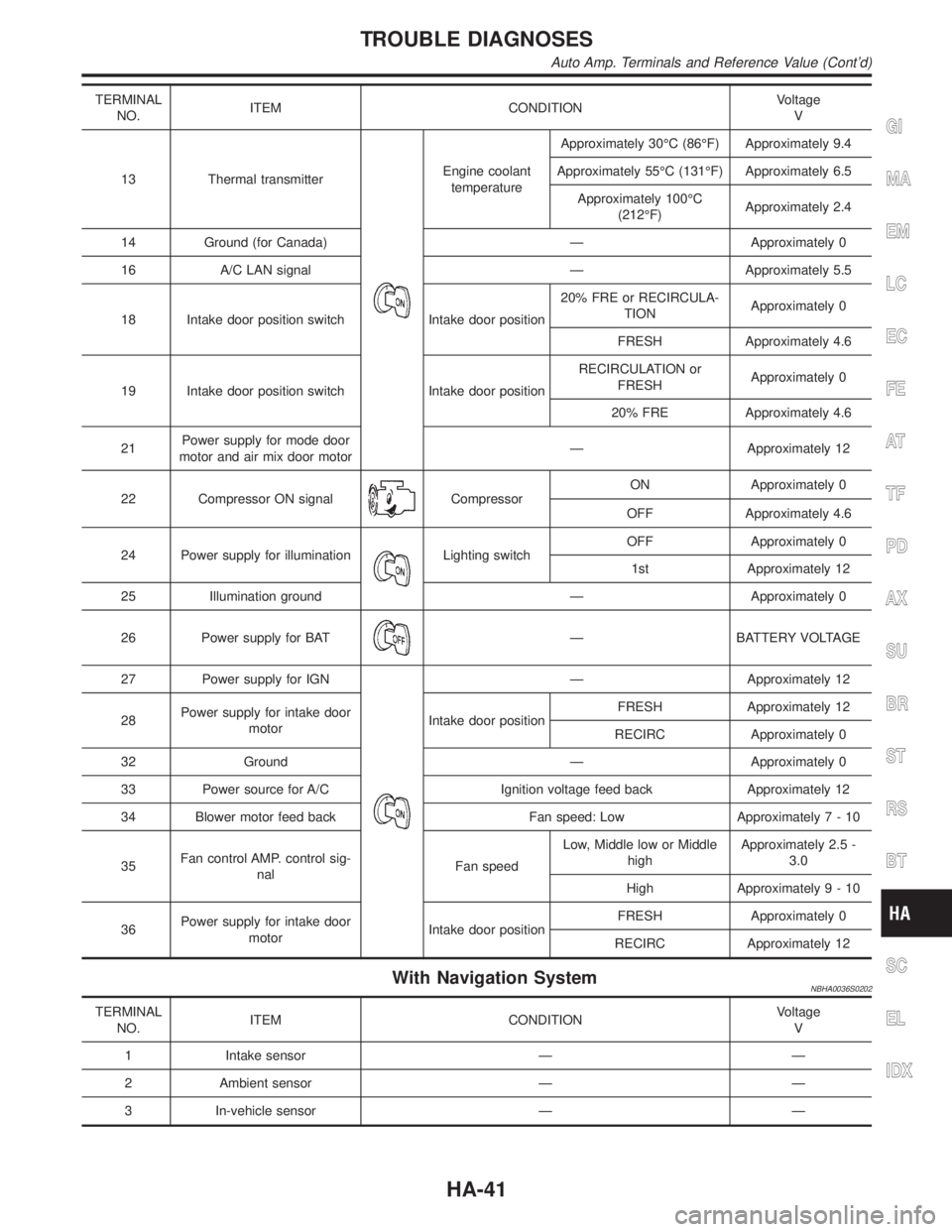

TERMINAL

NO.ITEM CONDITIONVoltage

V

13 Thermal transmitter

Engine coolant

temperatureApproximately 30ÉC (86ÉF) Approximately 9.4

Approximately 55ÉC (131ÉF) Approximately 6.5

Approximately 100ÉC

(212ÉF)Approximately 2.4

14 Ground (for Canada) Ð Approximately 0

16 A/C LAN signal Ð Approximately 5.5

18 Intake door position switch Intake door position20% FRE or RECIRCULA-

TIONApproximately 0

FRESH Approximately 4.6

19 Intake door position switch Intake door positionRECIRCULATION or

FRESHApproximately 0

20% FRE Approximately 4.6

21Power supply for mode door

motor and air mix door motorÐ Approximately 12

22 Compressor ON signal

CompressorON Approximately 0

OFF Approximately 4.6

24 Power supply for illumination

Lighting switchOFF Approximately 0

1st Approximately 12

25 Illumination ground Ð Approximately 0

26 Power supply for BAT

Ð BATTERY VOLTAGE

27 Power supply for IGN

Ð Approximately 12

28Power supply for intake door

motorIntake door positionFRESH Approximately 12

RECIRC Approximately 0

32 Ground Ð Approximately 0

33 Power source for A/C Ignition voltage feed back Approximately 12

34 Blower motor feed back Fan speed: Low Approximately7-10

35Fan control AMP. control sig-

nalFan speedLow, Middle low or Middle

highApproximately 2.5 -

3.0

High Approximately9-10

36Power supply for intake door

motorIntake door positionFRESH Approximately 0

RECIRC Approximately 12

With Navigation SystemNBHA0036S0202

TERMINAL

NO.ITEM CONDITIONVoltage

V

1 Intake sensor Ð Ð

2 Ambient sensor Ð Ð

3 In-vehicle sensor Ð Ð

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Auto Amp. Terminals and Reference Value (Cont'd)

HA-41

Page 1841 of 2395

TERMINAL

NO.ITEM CONDITIONVoltage

V

6 Intake door position switch

Intake door positionRECIRCULATION Approximately 4.6

FRESH or 20% FRESH Approximately 0

7Multiplex communication sig-

nal

(AMP,NAVI)ÐÐ

8Multiplex communication sig-

nal

(NAVI,AMP)ÐÐ

9 Sensor ground

Ð Approximately 0

10 Sunload sensor Ð Ð

11 Thermal transmitter

Engine coolant

temperatureApproximately 30ÉC (86ÉF) Approximately 9.4

Approximately 55ÉC (131ÉF) Approximately 6.5

Approximately 100ÉC

(212ÉF)Approximately 2.4

Approximately 110ÉC

(230ÉF)Approximately 1.9

14 A/C LAN signal Ð Approximately 5.5

17 ECM signalCompressor: ON Approximately 0

Compressor: OFF Approximately 4.6

18 Intake door position switch Intake door positionFRESH Approximately 4.6

RECIRCULATION or 20%

FRESHApproximately 0

19 Intake door position switch Intake door position20% FRESH Approximately 4.6

RECIRCULATION or

FRESHApproximately 0

20Multiplex communication sig-

nal (CLK)ÐÐ

21 Power supply for door motor

Ð Approximately 12

22 Compressor ON signalCompressor: ON Approximately 0

Compressor: OFF Approximately 4.6

24 Power supply for BAT Ð BATTERY VOLTAGE

TROUBLE DIAGNOSES

Auto Amp. Terminals and Reference Value (Cont'd)

HA-42

Page 2112 of 2395

IWhen deploying the air bag module and seat belt pre-

tensioner, stand at least 5 m (16 ft) away from the deployment

component.

IWhen deploying air bag module and seat belt pre-tensioner, a

fairly loud noise is made, followed by smoke being released.

The smoke is not poisonous, however, be careful not to inhale

smoke since it irritates the throat and can cause choking.

IAlways activate one air bag module at a time.

IDue to heat, leave air bag module unattended for more than

30 minutes after deployment. Also leave seat belt pre-ten-

sioner unattended for move than 10 minutes after deployment.

IBe sure to wear gloves when handling a deployed air bag

module and seat belt pre-tensioner.

INever apply water to the deployed air bag module and seat

belt pre-tensioner.

IWash your hands clean after finishing work.

IPlace the vehicle outdoors with an open space of at least 6 m

(20 ft) on all sides when deploying air bag module and seat belt

pre-tensioner while mounted in vehicle.

IUse a voltmeter to make sure the vehicle battery is fully

charged.

IDo not dispose of the air bag module and seat belt pre-ten-

sioner un-deployed.

SRS019

CHECKING DEPLOYMENT TOOLNBRS0018S01Connecting to BatteryNBRS0018S0101CAUTION:

The battery must show voltage of 9.6V or more.

Remove the battery from the vehicle and place it on dry wood

blocks approximately 5 m (16 ft) away from the vehicle.

IWait 3 minutes after the vehicle battery is disconnected before

proceeding.

IConnect red clip of deployment tool to battery positive termi-

nal and black clip to negative terminal.

Make sure the polarity is correct. The right side lamp in the

tool, marked ªdeployment tool powerº, should glow with a

green light. If the right side lamp glows red, reverse the con-

nections to the battery.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-tensioner (Cont'd)

RS-23

Page 2114 of 2395

SRS020-B

5. Connect red clip of deployment tool to battery positive termi-

nal and black clip to negative terminal.

6. The lamp on the right side of the tool, marked ªdeployment tool

powerº, should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked ªair bag connector voltageº, will illuminate and

the air bag module will deploy.

CAUTION:

When deploying the air bag module, stand at least 5 m (16 ft)

away from the air bag module.

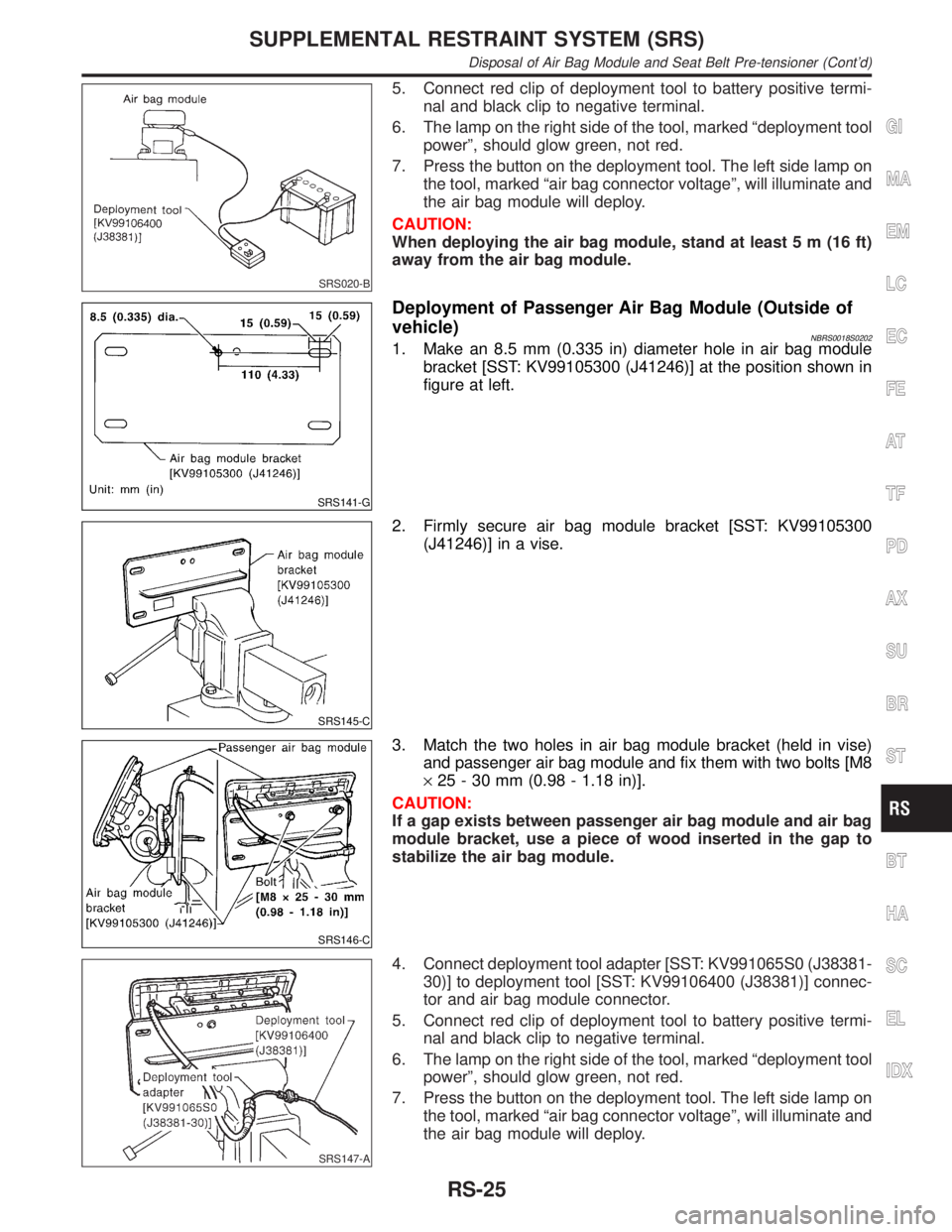

SRS141-G

Deployment of Passenger Air Bag Module (Outside of

vehicle)

NBRS0018S02021. Make an 8.5 mm (0.335 in) diameter hole in air bag module

bracket [SST: KV99105300 (J41246)] at the position shown in

figure at left.

SRS145-C

2. Firmly secure air bag module bracket [SST: KV99105300

(J41246)] in a vise.

SRS146-C

3. Match the two holes in air bag module bracket (held in vise)

and passenger air bag module and fix them with two bolts [M8

´25 - 30 mm (0.98 - 1.18 in)].

CAUTION:

If a gap exists between passenger air bag module and air bag

module bracket, use a piece of wood inserted in the gap to

stabilize the air bag module.

SRS147-A

4. Connect deployment tool adapter [SST: KV991065S0 (J38381-

30)] to deployment tool [SST: KV99106400 (J38381)] connec-

tor and air bag module connector.

5. Connect red clip of deployment tool to battery positive termi-

nal and black clip to negative terminal.

6. The lamp on the right side of the tool, marked ªdeployment tool

powerº, should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked ªair bag connector voltageº, will illuminate and

the air bag module will deploy.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-tensioner (Cont'd)

RS-25

Page 2115 of 2395

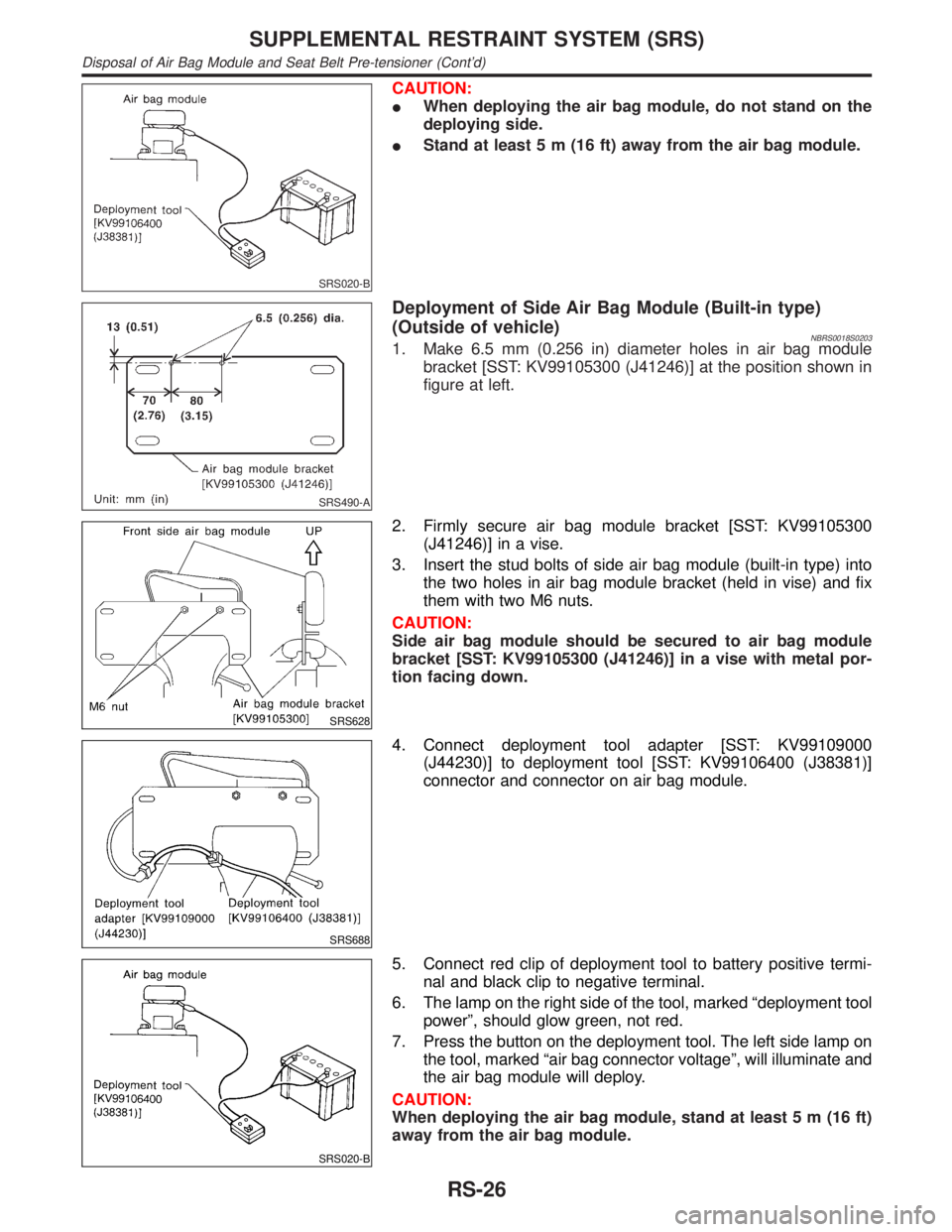

SRS020-B

CAUTION:

IWhen deploying the air bag module, do not stand on the

deploying side.

IStand at least 5 m (16 ft) away from the air bag module.

SRS490-A

Deployment of Side Air Bag Module (Built-in type)

(Outside of vehicle)

NBRS0018S02031. Make 6.5 mm (0.256 in) diameter holes in air bag module

bracket [SST: KV99105300 (J41246)] at the position shown in

figure at left.

SRS628

2. Firmly secure air bag module bracket [SST: KV99105300

(J41246)] in a vise.

3. Insert the stud bolts of side air bag module (built-in type) into

the two holes in air bag module bracket (held in vise) and fix

them with two M6 nuts.

CAUTION:

Side air bag module should be secured to air bag module

bracket [SST: KV99105300 (J41246)] in a vise with metal por-

tion facing down.

SRS688

4. Connect deployment tool adapter [SST: KV99109000

(J44230)] to deployment tool [SST: KV99106400 (J38381)]

connector and connector on air bag module.

SRS020-B

5. Connect red clip of deployment tool to battery positive termi-

nal and black clip to negative terminal.

6. The lamp on the right side of the tool, marked ªdeployment tool

powerº, should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked ªair bag connector voltageº, will illuminate and

the air bag module will deploy.

CAUTION:

When deploying the air bag module, stand at least 5 m (16 ft)

away from the air bag module.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-tensioner (Cont'd)

RS-26

Page 2116 of 2395

SRS662

DEPLOYMENT PROCEDURES FOR SEAT BELT PRE-

TENSIONER (OUTSIDE OF VEHICLE)

NBRS0018S051. Firmly grip pre-tensioner in a vise and cut the webbing off.

SRS663

2. Connect deployment tool adapter [SST: KV99108200 (J38381-

50)] to deployment tool [SST: KV99106400 (J38381)] connec-

tor and seat belt pre-tensioner connector.

SRS242

3. Connect red clip of deployment tool to battery positive termi-

nal and black clip to negative terminal.

4. The lamp on the right side of the tool, marked ªdeployment tool

powerº, should glow green, not red.

5. Press the button on the deployment tool. The left side lamp on

the tool, marked ªseat belt pre-tensioner connector voltageº,

will illuminate and the seat belt pre-tensioner will deploy.

CAUTION:

When deploying the seat belt pre-tensioner, stand at least 5 m

(16 ft) away from the seat belt pre-tensioner.

DEPLOYMENT OF AIR BAG MODULE AND SEAT BELT

PRE-TENSIONER WHILE MOUNTED IN VEHICLE

NBRS0018S03When disposing of a vehicle, deploy air bag module and seat belt

pre-tensioners while they are mounted in vehicle.

CAUTION:

When deploying air bag module or seat belt pre-tensioner,

ensure vehicle is empty.

1. Disconnect both the vehicle battery cables and wait 3 minutes.

2. Disconnect air bag module and seat belt pre-tensioner connec-

tor.

3. Connect deployment tool [SST: KV99106400 (J38381)] to air

bag module or seat belt pre-tensioner.

For front passenger air bag module, attach deployment tool

adapter [SST: KV991065S0 (J38381-30)] to the tool connector.

For side air bag module (built-in type), attach deployment tool

adapter [SST: KV99109000 (J44230)]. For seat belt pre-

tensioner, attach deployment tool adapter [SST: KV99108200

(J38381-50)] to the tool connector.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-tensioner (Cont'd)

RS-27

Page 2117 of 2395

SRS006-C

4. Connect red clip of deployment tool to battery positive termi-

nal and black clip to negative terminal.

5. The lamp on the right side of the tool, marked ªdeployment tool

powerº, should glow green, not red.

6. Press the button on the deployment tool. The left side lamp on

the tool, marked ªair bag connector voltageº, will illuminate and

the air bag module will deploy.

SBF276H

DISPOSING OF AIR BAG MODULE AND SEAT BELT

PRE-TENSIONER

NBRS0018S04Deployed air bag module and seat belt pre-tensioner are very hot.

Before disposing of air bag module, and seat belt pre-tensioner

wait at least 30 minutes, and 10 minutes, respectively. Seal them

in a plastic bag before disposal.

CAUTION:

INever apply water to a deployed air bag module and seat

belt pre-tensioner.

IBe sure to wear gloves when handling a deployed air bag

module and seat belt pre-tensioner.

INo poisonous gas is produced upon air bag module

deployment. However, be careful not to inhale gas since it

irritates throat and can cause choking.

IDo not attempt to disassemble air bag module and seat

belt pre-tensioner.

IAir bag module and seat belt pre-tensioner cannot be

reused.

IWash your hands clean after finishing work.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-tensioner (Cont'd)

RS-28

Page 2155 of 2395

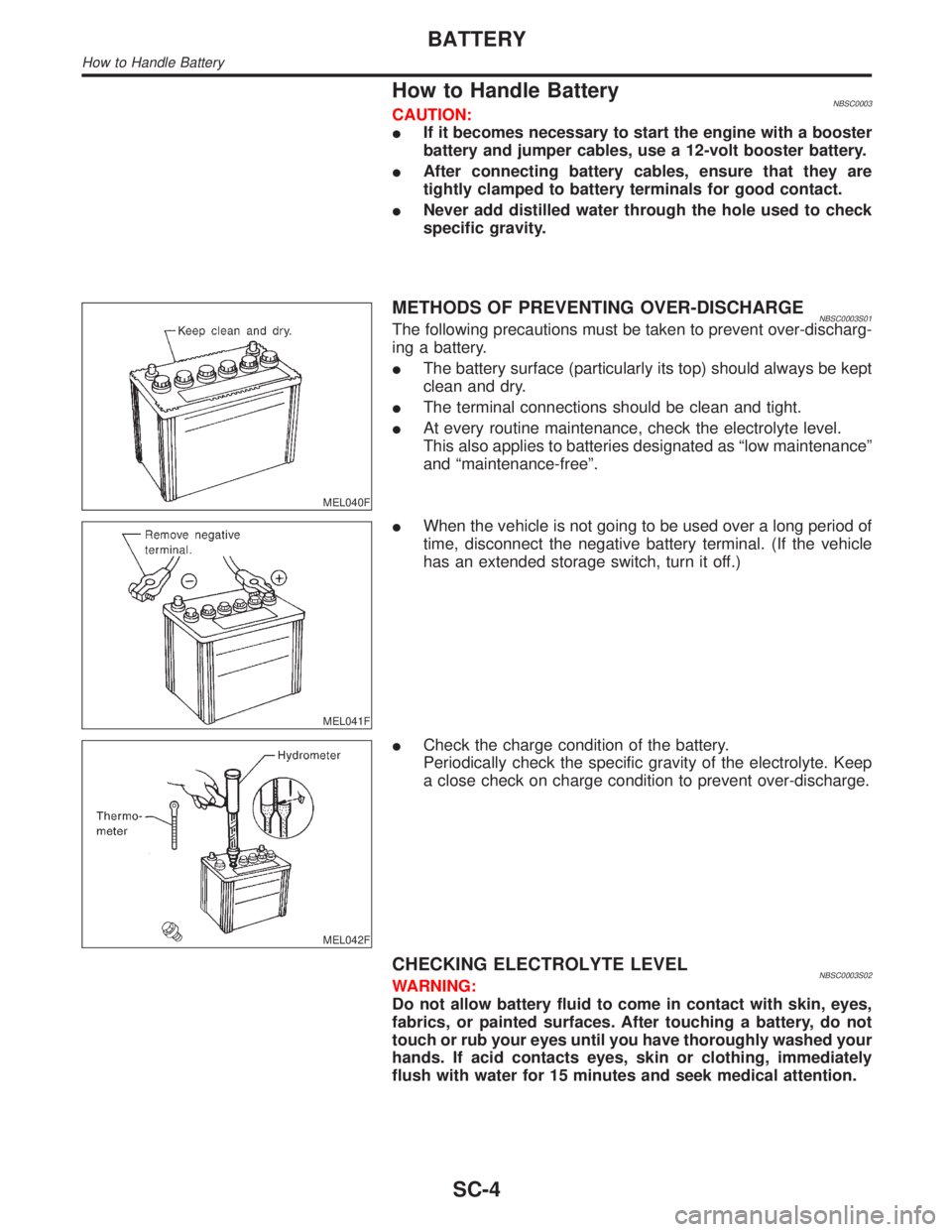

How to Handle BatteryNBSC0003CAUTION:

IIf it becomes necessary to start the engine with a booster

battery and jumper cables, use a 12-volt booster battery.

IAfter connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

INever add distilled water through the hole used to check

specific gravity.

MEL040F

METHODS OF PREVENTING OVER-DISCHARGENBSC0003S01The following precautions must be taken to prevent over-discharg-

ing a battery.

IThe battery surface (particularly its top) should always be kept

clean and dry.

IThe terminal connections should be clean and tight.

IAt every routine maintenance, check the electrolyte level.

This also applies to batteries designated as ªlow maintenanceº

and ªmaintenance-freeº.

MEL041F

IWhen the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal. (If the vehicle

has an extended storage switch, turn it off.)

MEL042F

ICheck the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVELNBSC0003S02WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub your eyes until you have thoroughly washed your

hands. If acid contacts eyes, skin or clothing, immediately

flush with water for 15 minutes and seek medical attention.

BATTERY

How to Handle Battery

SC-4

Page 2158 of 2395

Trouble Diagnoses with

Battery/Starting/Charging System Tester

NBSC0018CAUTION:

When working with batteries, always wear appropriate eye

protection.

NOTE:

ITo ensure a complete and thorough diagnosis, the battery,

starter and alternator test segments must be done as a set

from start to finish.

IIf battery surface charge is detected while testing, the tester

will prompt you to turn on the headlights to remove the surface

charge.

IIf necessary, the tester will prompt you to determine if the bat-

tery temperature is above or below 0ÉC (32ÉF). Choose the

appropriate selection by pressing the up or down arrow button,

then press ªENTERº to make the selection.

SEL404X

1. Turn off all loads on the vehicle electrical system. Clean or

repair as necessary.

2. Visually inspect the battery, battery terminals and cable ends

with ignition switch in ªOFFº position.

NOTE:

The contact surface between the battery terminals, cable ends and

tester leads must be clean for a valid test. A poor connection will

prevent testing and a ªCHECK CONNECTIONº message will

appear during the test procedures. If this occurs, clean the battery

post and terminals, reconnect them and restart the test.

3. Connect the red tester lead clamp to the positive battery

terminal, and the black to the negative terminal.

SEL405X

4. The tester will turn on automatically. Using the arrow keys,

select ªIN VEHICLEº on the tester and then press the ªENTERº

key.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

BATTERY

Trouble Diagnoses with Battery/Starting/Charging System Tester

SC-7

Page 2161 of 2395

System DescriptionNBSC0004Power is supplied at all times

Ito ignition switch terminal 1

Ithrough 40A fusible link (lettere, located in the fuse and fusible link box).

With the ignition switch in the ON or START position, power is supplied through 10A fuse [No. 18, located in

the fuse block (J/B)].

Ito park/neutral position relay terminal 1.

Also, with the ignition switch in the START position, power is supplied

Ifrom ignition switch terminal 5

Ito park/neutral position relay terminal 6.

With the selector lever in the P or N position, ground is supplied

Ito park/neutral position relay terminal 2 through the park/neutral position switch.

Then park/neutral position relay is energized and power is supplied

Ifrom park/neutral position relay terminal 7

Ito terminal 2 of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

STARTING SYSTEM

System Description

SC-10