spare wheel INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 369 of 2395

SBR686C

Precautions

PRECAUTIONSNBAX0001IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

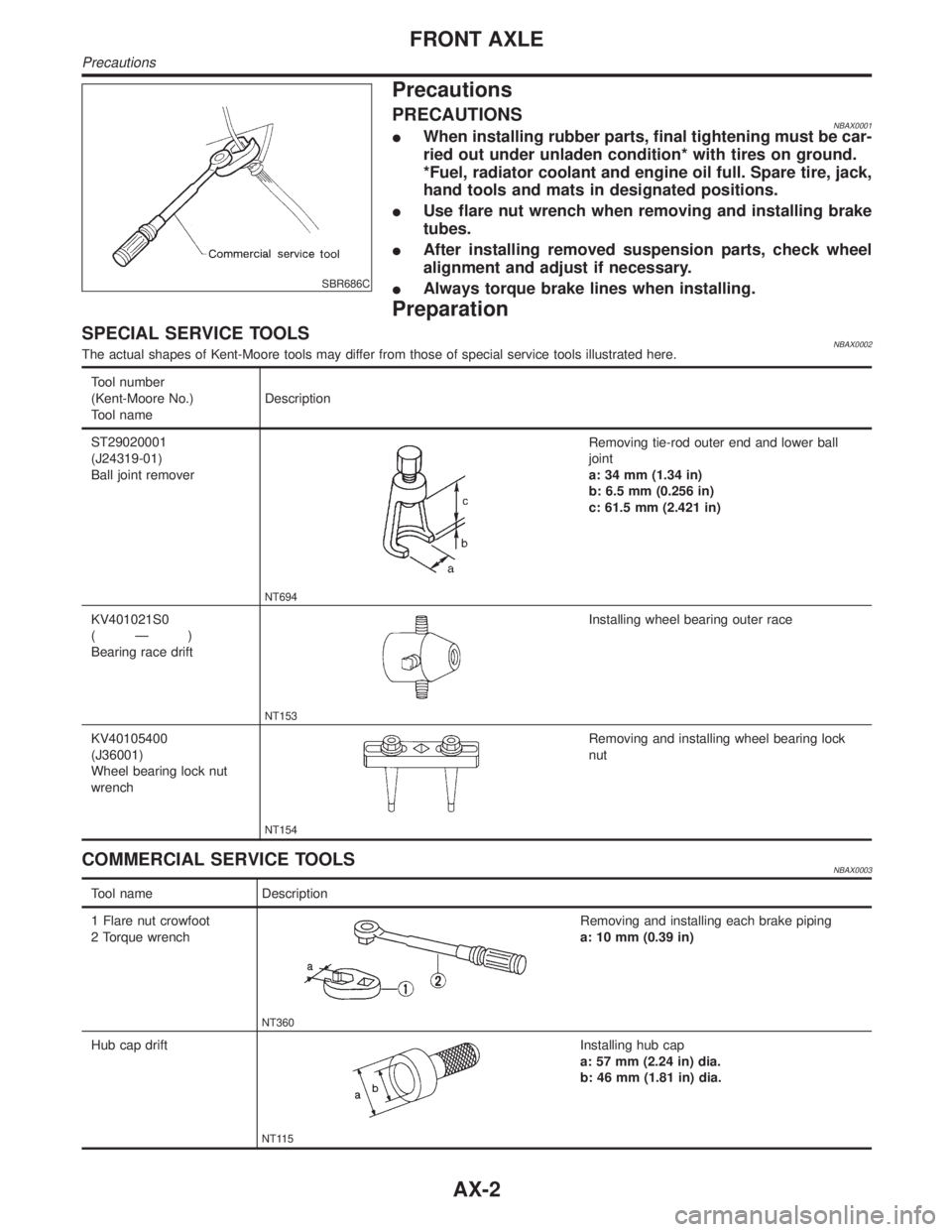

SPECIAL SERVICE TOOLSNBAX0002The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST29020001

(J24319-01)

Ball joint remover

NT694

Removing tie-rod outer end and lower ball

joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV401021S0

(Ð)

Bearing race drift

NT153

Installing wheel bearing outer race

KV40105400

(J36001)

Wheel bearing lock nut

wrench

NT154

Removing and installing wheel bearing lock

nut

COMMERCIAL SERVICE TOOLSNBAX0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Hub cap drift

NT115

Installing hub cap

a: 57 mm (2.24 in) dia.

b: 46 mm (1.81 in) dia.

FRONT AXLE

Precautions

AX-2

Page 384 of 2395

SBR686C

Precautions

PRECAUTIONSNBAX0023IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

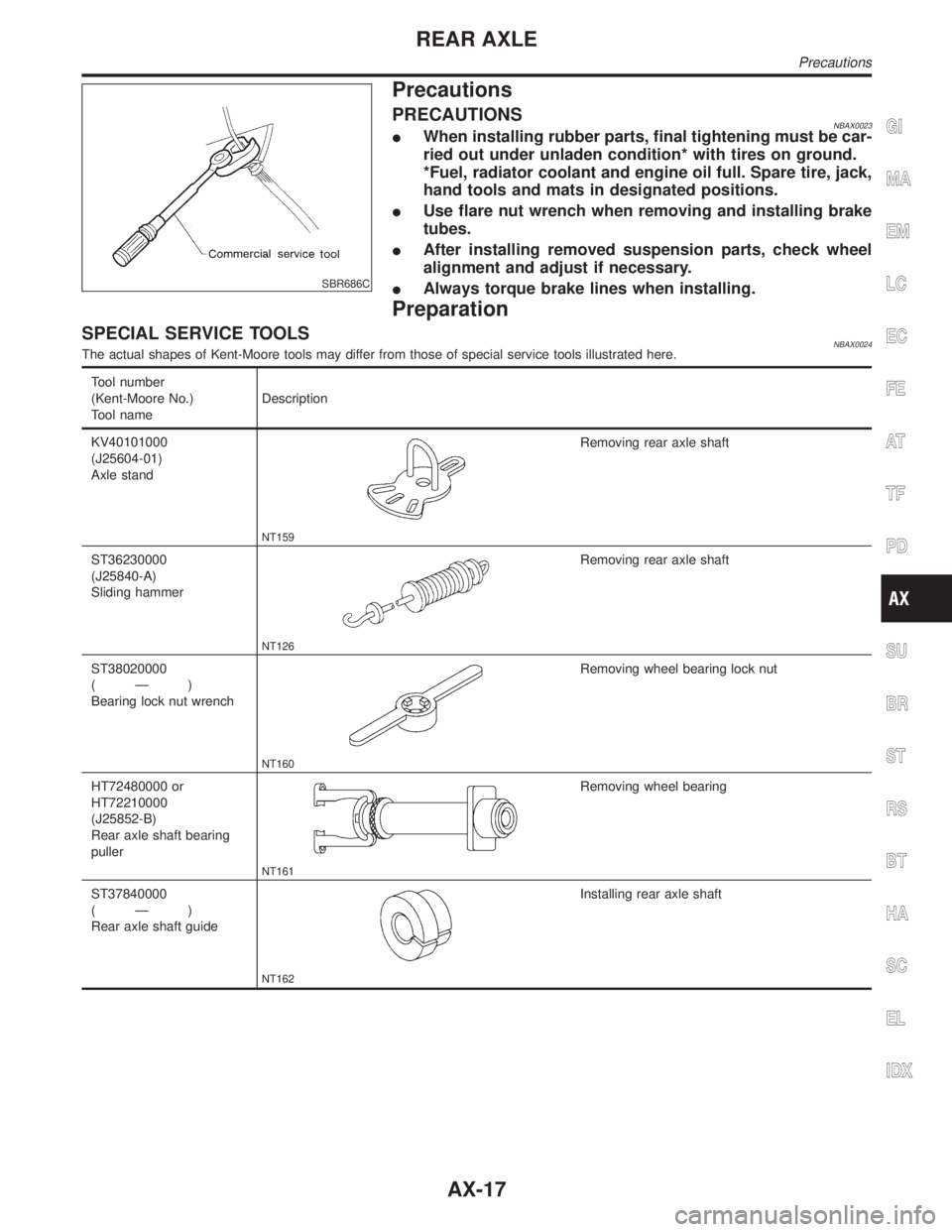

SPECIAL SERVICE TOOLSNBAX0024The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV40101000

(J25604-01)

Axle stand

NT159

Removing rear axle shaft

ST36230000

(J25840-A)

Sliding hammer

NT126

Removing rear axle shaft

ST38020000

(Ð)

Bearing lock nut wrench

NT160

Removing wheel bearing lock nut

HT72480000 or

HT72210000

(J25852-B)

Rear axle shaft bearing

puller

NT161

Removing wheel bearing

ST37840000

(Ð)

Rear axle shaft guide

NT162

Installing rear axle shaft

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR AXLE

Precautions

AX-17

Page 1745 of 2395

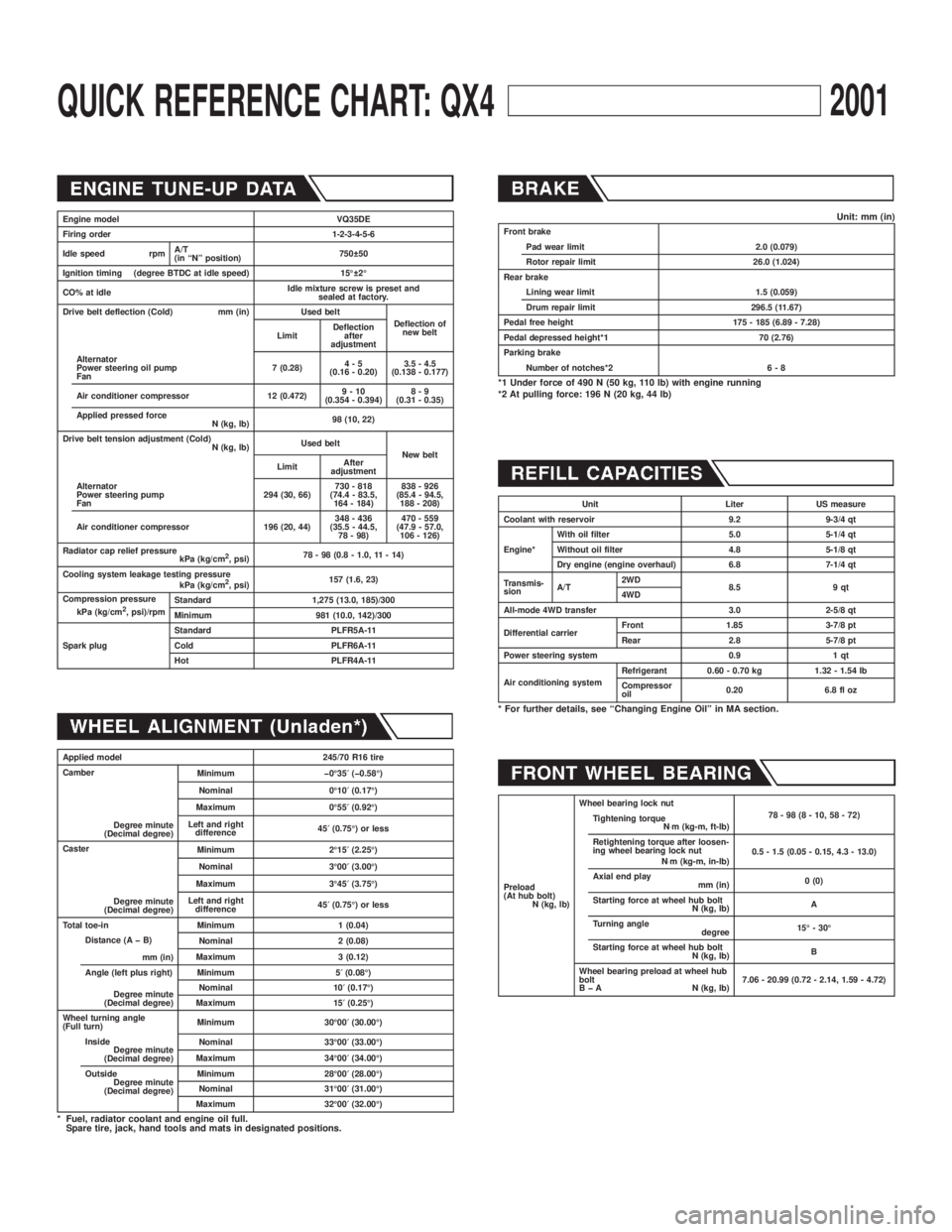

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 1789 of 2395

Wheels & TiresNBGI0007S04

Grade Road wheel/offset mm (in) Tire Spare tire size

LE17 x 8JJ Aluminum/20 (0.79)

16 x 7JJ Aluminum/20 (0.79)*P245/65R17 105S

P245/70R16 106S*P245/65R17 105S

* Option for 2WD model

IDENTIFICATION INFORMATION

Wheels & Tires

GI-44

Page 1966 of 2395

Propeller shaft greasing .................................MA-23

Propeller shaft inspection ..............................MA-23

Propeller shaft on vehicle service ....................PD-6

Propeller shaft vibration ...................................PD-6

PST/SW - Wiring diagram ............................EC-635

R

Rack retainer adjustment ..................................ST-8

Radiator ....................................................LC-19, 21

Radio - See Audio.........................................EL-160

Rear air spoiler ...............................................BT-35

Rear axle ........................................................AX-17

Rear bumper ...................................................BT-15

Rear case (Transfer) .....................................TF-123

Rear combination lamp removal and

installation ...................................................BT-35

Rear cover packing replacement diff. ............PD-16

Rear door ........................................................BT-20

Rear drum brake ............................................BR-26

Rear heated oxygen sensor

(HO2S) .............................EC-247, 257, 267, 277

Rear heated oxygen sensor (HO2S)

heater ........................................................EC-286

Rear seat ........................................................BT-44

Rear seat belt ...................................................RS-5

Rear side window ...........................................BT-55

Rear suspension ............................................SU-15

Rear washer..................................................EL-141

Rear window defogger ..................................EL-151

Rear wiper.....................................................EL-141

REF - Wiring diagram ..................................EC-510

Refregerant pressure sensor ........................HA-111

Refrigerant connection precaution ...................HA-4

Refrigerant discharging evacuating

charging ....................................................HA-144

Refrigerant general precaution.........................HA-3

Refrigerant lines ...........................................HA-154

Refrigerant pressure sensor.........................EC-639

Refrigeration cycle..........................................HA-14

REMOTE - Wiring diagram ...........................EL-168

Removal and installation (A/T) ......................AT-277

Removal and installation (Transfer) ..............TF-119

Reverse clutch...............................................AT-314

Revolution sensor (A/T).................................AT-115

Ring gear diff. inspection .........................PD-23, 47

RO2H-L - Wiring diagram.............................EC-290

RO2H-R - Wiring diagram ............................EC-289

Road wheel size ..............................................GI-44

Roof trim .........................................................BT-32

Room lamp - See Interior lamp ......................EL-88

RRO2LH - Wiring diagram...EC-251, 261, 271, 281

RRO2RH - Wiring diagram ..EC-250, 260, 270, 280

S

SAE J1930 terminology list .............................GI-51

Screw jack .......................................................GI-45Seal - See Exterior .........................................BT-35

SEAT - Wiring diagram .................................EL-181

Seat belt inspection .............................MA-28, RS-7

Seat belt pre-tensioner .....................................RS-3

Seat belt pre-tensioner disposal ....................RS-22

Seat belt, front ..................................................RS-4

Seat belt, rear...................................................RS-5

Seat, front .......................................................BT-41

Seat, rear ........................................................BT-44

Self-diagnosis (Transfer) .................................TF-27

SHIFT - Wiring diagram ................................AT-266

Shift lock system ...........................................AT-265

Shift schedule ................................................AT-356

Shift solenoid valve A (A/T) ..AT-125, 137, 147, 171

Shift solenoid valve B (A/T) ..AT-125, 131, 147, 175

Shock absorber (rear) ....................................SU-18

Side air bag ....................................................RS-21

Side bearing preload (front final drive

4WD) ...........................................................PD-24

Side trim ..........................................................BT-28

Side window - See Rear side window ............BT-55

Smart entrance control unit ..........................EL-319

SMJ (super multiple junction) .......................Foldout

Spare tire size .................................................GI-44

Spark plug replacement .................................MA-19

Speedometer...................................................EL-94

Spiral cable.....................................................RS-17

Spot lamp ........................................................EL-88

Spring (Wheelarch) height ...............................SU-5

SROOF - Wiring diagram .............................EL-174

SRS - See Supplemental Restraint

System ........................................................RS-10

SRS - Wiring diagram ....................................RS-35

S/SIG - Wiring diagram ................................EC-622

Stabilizer bar (front)........................................SU-10

Stabilizer bar (rear) ........................................SU-20

Stall test (A/T) .................................................AT-59

Standardized relay ............................................EL-7

START - Wiring diagram.................................SC-11

Start signal ...................................................EC-621

Starter .............................................................SC-18

Starting system...............................................SC-10

Steering gear, linkage and transfer

gear inspection ...........................................MA-26

Steering linkage ..............................................ST-17

Steering switch................................................EL-30

Steering transfer gear .....................................ST-15

Steering wheel and column.............................ST-11

Steering wheel play ..........................................ST-7

Steering wheel turning force .............................ST-9

Stop lamp ........................................................EL-67

STOP/L - Wiring diagram................................EL-67

Strut (front) .......................................................SU-8

Sub-oil pump (Transfer) ................................TF-131

Sun gear (Transfer).......................................TF-134

Sun roof, electric ...........................................EL-173

Sunload sensor ............................................HA-135

Sunroof............................................................BT-45

Supplemental Restraint System .....................RS-10

Supplemental restraint system - Wiring

diagram .......................................................RS-35

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

ALPHABETICAL INDEX

IDX-7

Page 1999 of 2395

NBMA0003

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or they can have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

ItemReference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.Ð

Wheel nutsWhen checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.Ð

Tire rotationTires should be rotated every 12,000 km (7,500 miles). MA-24

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or

if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed.MA-24, SU-6, ªFront

Wheel Alignmentº

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the

trunk lid and back hatch. Also make sure that all latches lock securely. Lubri-

cate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check

lubrication frequently.MA-27

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

ItemReference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.Ð

Warning lamps and

buzzers/chimesMake sure that all warning lamps and buzzers/chimes are operating properly. Ð

Windshield wiper

and washerCheck that the wipers and washer operate properly and that the wipers do

not streak.Ð

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning.Ð

Steering wheelCheck that it has the specified play. Be sure to check for changes in the

steering condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for folding-down rear seatbacks.Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.MA-28, RS-7, ªSeat Belt

Inspectionº

BrakesCheck that the brake does not pull the vehicle to one side when applied. Ð

GENERAL MAINTENANCE

MA-4

Page 2217 of 2395

SBR686C

Precautions

PRECAUTIONSNBSU0001IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNBSU0002The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST29020001

(J24319-01)

Ball joint remover

NT694

Removing tie-rod outer end and lower ball joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

COMMERCIAL SERVICE TOOLSNBSU0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Spring compressor

NT717

Removing and installing coil spring

FRONT SUSPENSION

Precautions

SU-2

Page 2220 of 2395

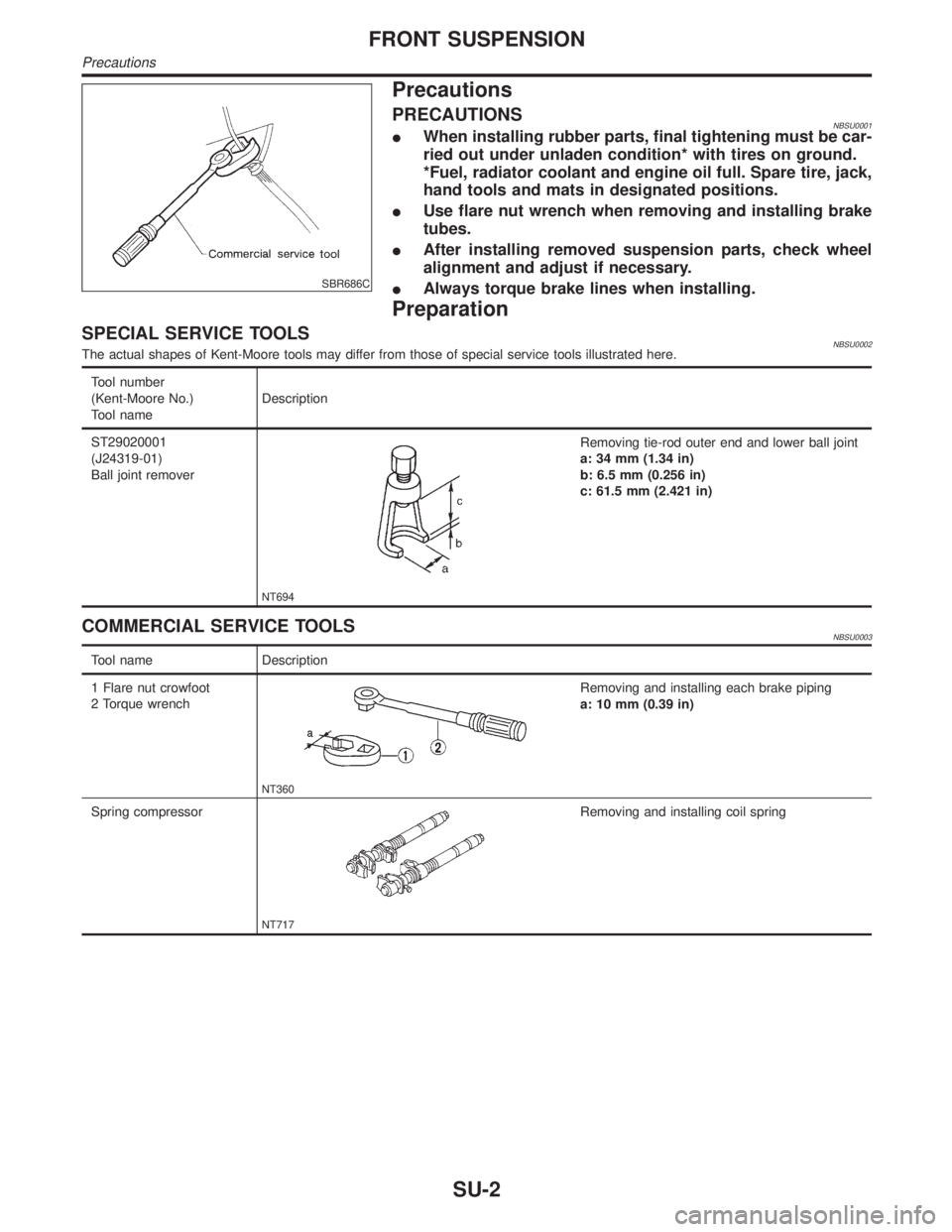

SMA525A

On-vehicle Service

FRONT SUSPENSION PARTSNBSU0005Check front axle and front suspension parts for excessive play,

cracks, wear and other damage.

1. Shake each front wheel to check for excessive play.

2. Retighten all axle and suspensions nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to ªComponentsº, SU-8.

SFA392B

3. Check strut (shock absorber) for oil leakage and other dam-

age.

4. Check suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

If ball joint dust cover is cracked or damaged, replace ball joint

assembly.

5. Check suspension ball joint end play.

a. Jack up front of vehicle and set the stands.

b. Clamp dial indicator onto transverse link and place indicator tip

on lower edge of brake caliper.

c. Make sure front wheels are straight and brake pedal is

depressed.

SFA745B

d. Place a pry bar between transverse link and knuckle.

e. While raising and releasing pry bar, observe maximum dial

indicator value.

Vertical end play:

0mm(0in)

If ball joint vertical end play exists, remove lower ball joint

assembly and recheck the ball joint. Refer to ªTranverse Link

and Lower Ball Jointº, SU-11.

SFA746B

6. Check spring height from top of wheelarch to ground using the

following procedure.

a. Park vehicle on a level surface with vehicle unladen*.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

b. Check tires for proper inflation and wear (tread wear indicator

must not be showing).

c. Bounce vehicle up and down several times and measure

dimensions Hf and Hr. Refer to SDS, SU-14.

Spring height is not adjustable. If out of specification, check for

worn springs and suspension parts.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

On-vehicle Service

SU-5

Page 2221 of 2395

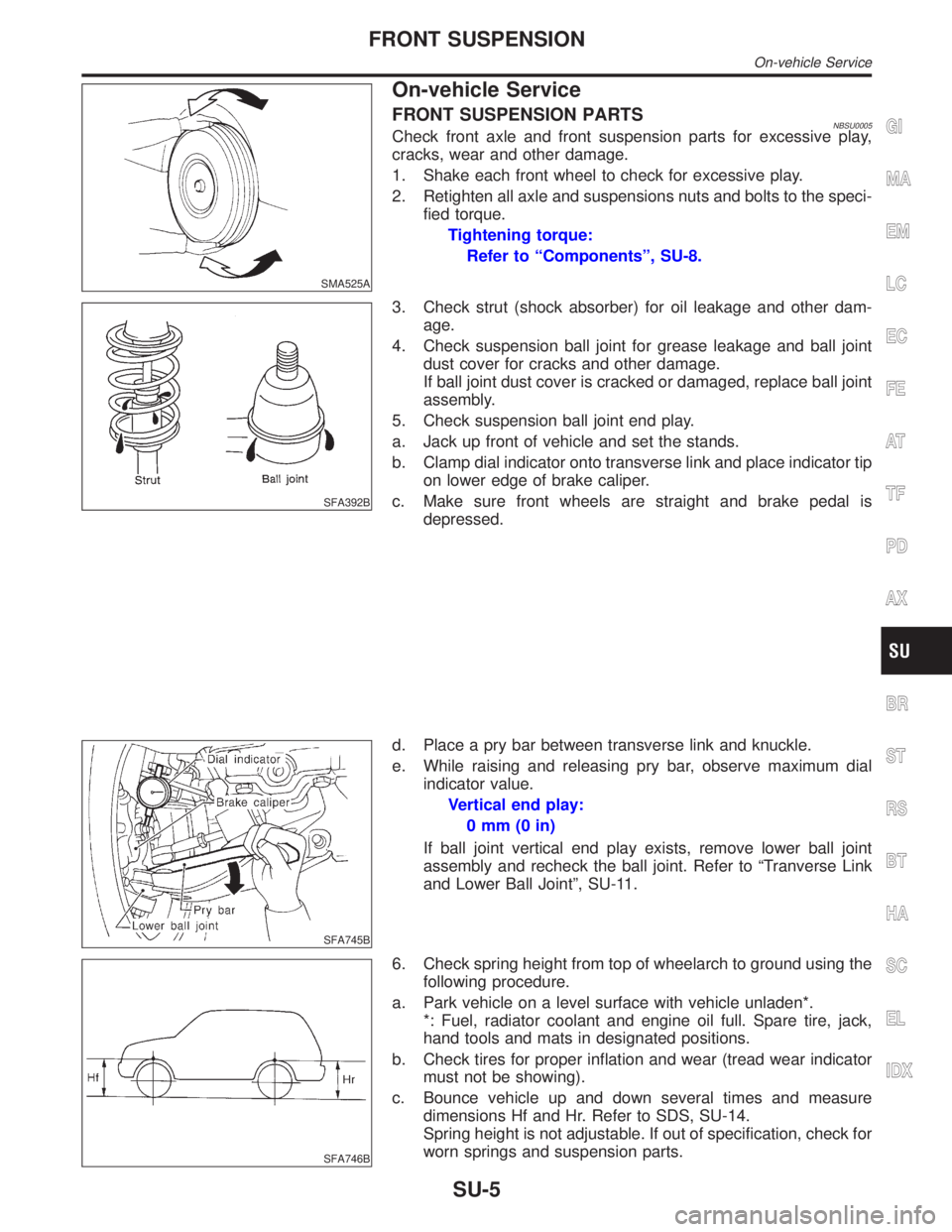

SFA975B

FRONT WHEEL ALIGNMENTNBSU0006Before checking front wheel alignment, be sure to make a prelimi-

nary inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand

tools and mats in designated positions.

Preliminary InspectionNBSU0006S011. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage.

If deformed, remove wheel and check wheel runout.

NOTE:

Measure both the inner and outer sides for the radial runout and

lateral runout, and confirm the figures are within the standards.

Wheel runout (Dial indicator value):

Refer to SDS.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly.

7. Check vehicle posture (Unladen).

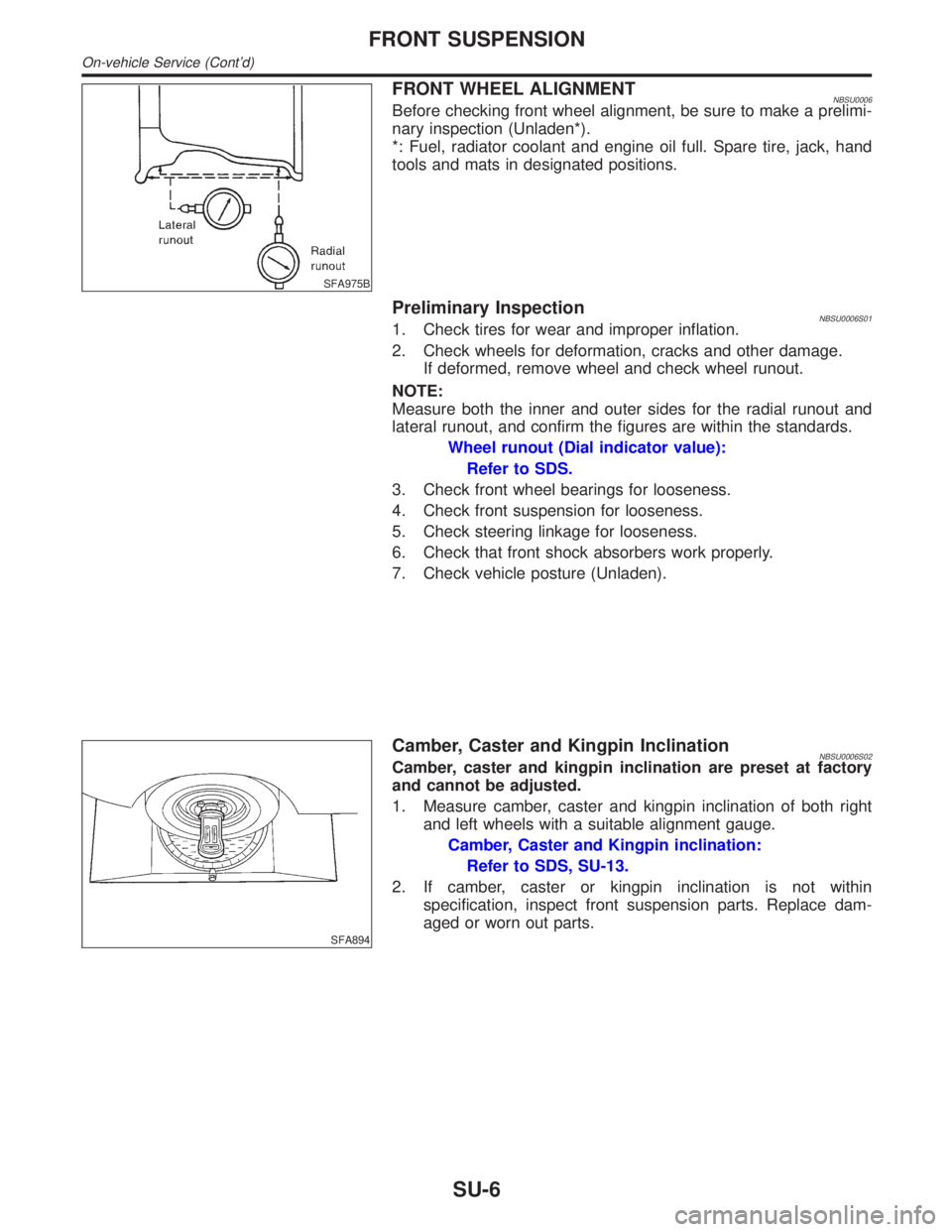

SFA894

Camber, Caster and Kingpin InclinationNBSU0006S02Camber, caster and kingpin inclination are preset at factory

and cannot be adjusted.

1. Measure camber, caster and kingpin inclination of both right

and left wheels with a suitable alignment gauge.

Camber, Caster and Kingpin inclination:

Refer to SDS, SU-13.

2. If camber, caster or kingpin inclination is not within

specification, inspect front suspension parts. Replace dam-

aged or worn out parts.

FRONT SUSPENSION

On-vehicle Service (Cont'd)

SU-6

Page 2228 of 2395

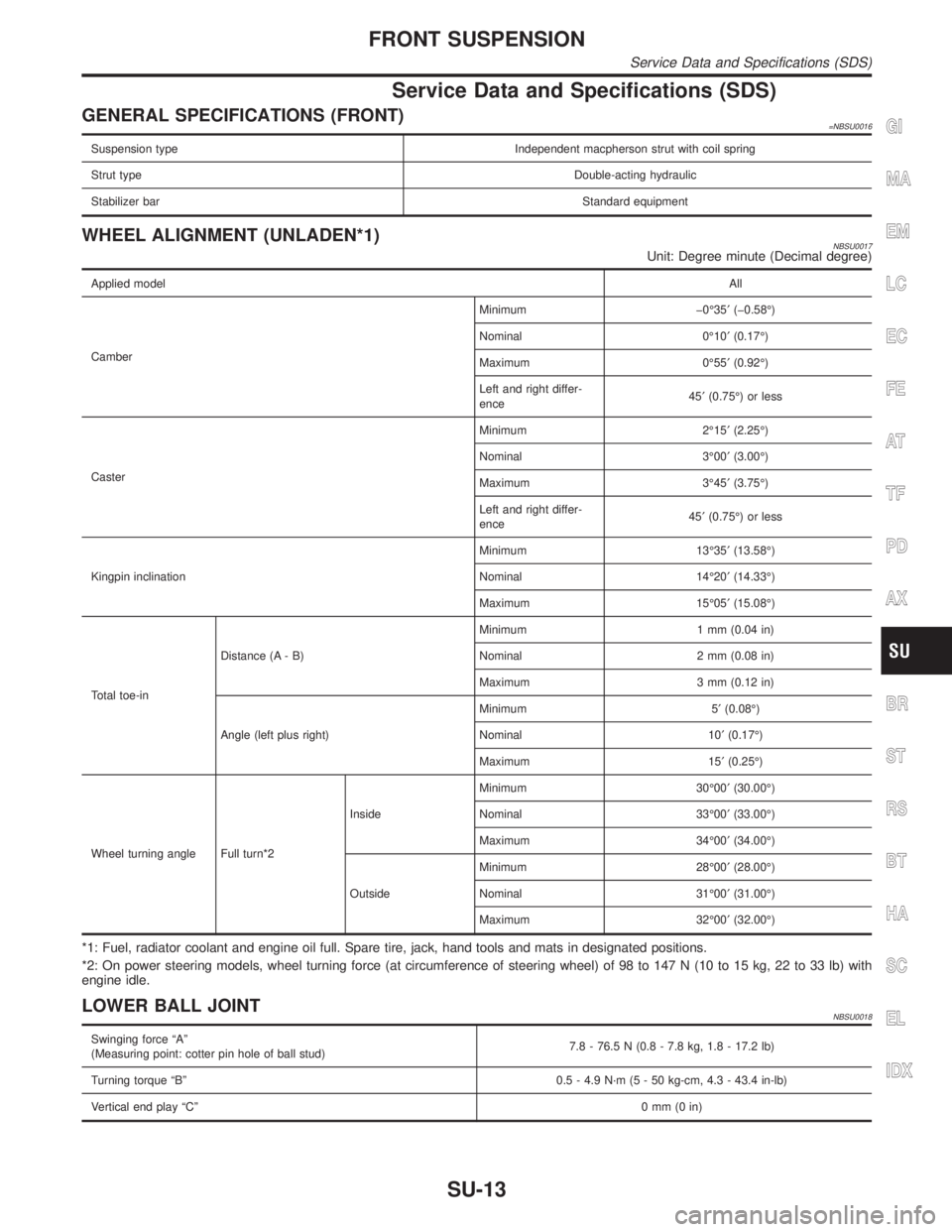

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS (FRONT)=NBSU0016

Suspension type Independent macpherson strut with coil spring

Strut typeDouble-acting hydraulic

Stabilizer barStandard equipment

WHEEL ALIGNMENT (UNLADEN*1)NBSU0017Unit: Degree minute (Decimal degree)

Applied modelAll

CamberMinimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right differ-

ence45¢(0.75É) or less

CasterMinimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right differ-

ence45¢(0.75É) or less

Kingpin inclinationMinimum 13É35¢(13.58É)

Nominal 14É20¢(14.33É)

Maximum 15É05¢(15.08É)

Total toe-inDistance (A - B)Minimum 1 mm (0.04 in)

Nominal 2 mm (0.08 in)

Maximum 3 mm (0.12 in)

Angle (left plus right)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle Full turn*2InsideMinimum 30É00¢(30.00É)

Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

OutsideMinimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: On power steering models, wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with

engine idle.

LOWER BALL JOINTNBSU0018

Swinging force ªAº

(Measuring point: cotter pin hole of ball stud)7.8 - 76.5 N (0.8 - 7.8 kg, 1.8 - 17.2 lb)

Turning torque ªBº 0.5 - 4.9 N´m (5 - 50 kg-cm, 4.3 - 43.4 in-lb)

Vertical end play ªCº0mm(0in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

Service Data and Specifications (SDS)

SU-13